As I bought, I finished and set up a Chinese 3D printer Wanhao Duplicator 4

After the recent heartbreaking story of buying a 3D printer and passing through customs, I want to tell you about my equally dramatic story of buying and finishing a Chinese printer Wanhao Duplicator 4.

After the recent heartbreaking story of buying a 3D printer and passing through customs, I want to tell you about my equally dramatic story of buying and finishing a Chinese printer Wanhao Duplicator 4.Since I need a printer more likely to satisfy interest, but not work, I did not give a toad to give ~ 3k $ for Makerbot Replicator 2 (+ he does not know how to print ABS). There were DIY KIT options (like PrintrBot Junior KIT, but there is a lot of free time and there are questions about the mechanical strength of the structure), numerous options with Kickstarter are not expensive, but slowly, the well-known Ultimaker 1/2 is good, but like Replicator it is expensive, especially when assembled (significantly higher than the duty-free limit).

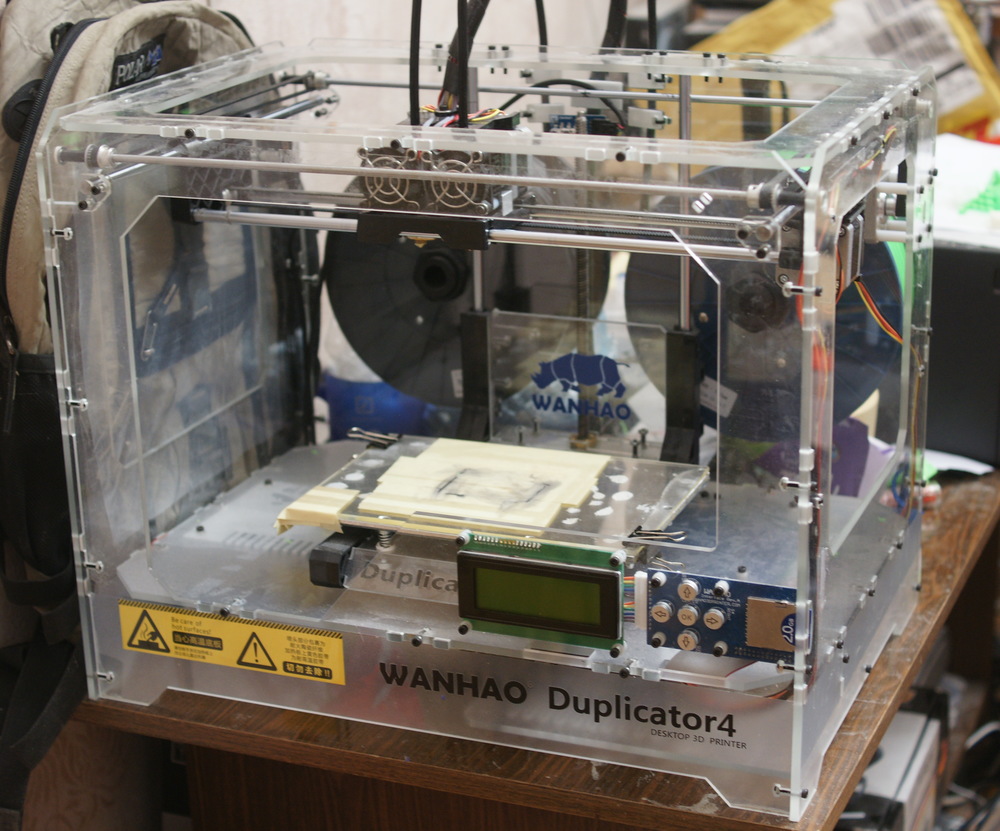

Finally, looking for aliexpress - I found an interesting model - Wanhao Duplicator 4: two extruders (you can do both two-color printing, and immediately print 2 small identical parts), at first glance the design is similar to Replicator 2, there is an option from plexiglass (there is no plywood - from moisture can skew), hot table for printing ABS, 2 plastic coils to choose from in the kit, there are reviews on the Internet. The price of the question is $ 1142 for the collected including delivery. I also ordered 3 hanks of ABS plastic from another seller for $ 29 (with delivery), including "green glowing in the dark" (about the results at the end).

')

But of course, if everything had ended so simply “chose-bought-received-printed” - this article would hardly have come into being.

Delivery

The printer reached me in 32 days, delivered by Ruston - with re-sending by Russian Post after crossing the border. They have not traditionally been detained at customs (it looks like they just accidentally select about 1% of the parcels, in the entire history of purchases they had to go to them 2 times). If delayed - at a cost ($ 1142 with delivery) and weight (17kg) while falls within duty-free borders. Of course, we could find fault with the fact that this is “not for personal use” - but this is already a matter of luck / not luck.On the day of receipt, the post office was closed (an employee got sick), the remaining manager found my phone number on the box, personally called the cell phone and told me to come and pick up my package. He came, I opened the mail - and personally gave the parcel. Rays of good to the department of OPS-308 (index - 123308). There are, however, and the bright side of the Russian Post.

The inclusion and the beginning of the drama

They brought, unpacked - at first glance, the build quality is excellent. Plexiglas thick, durable construction and does not play. Software - standard: ReplicatorG + Skeinforge / slic3r, iron too: MightyBoard.

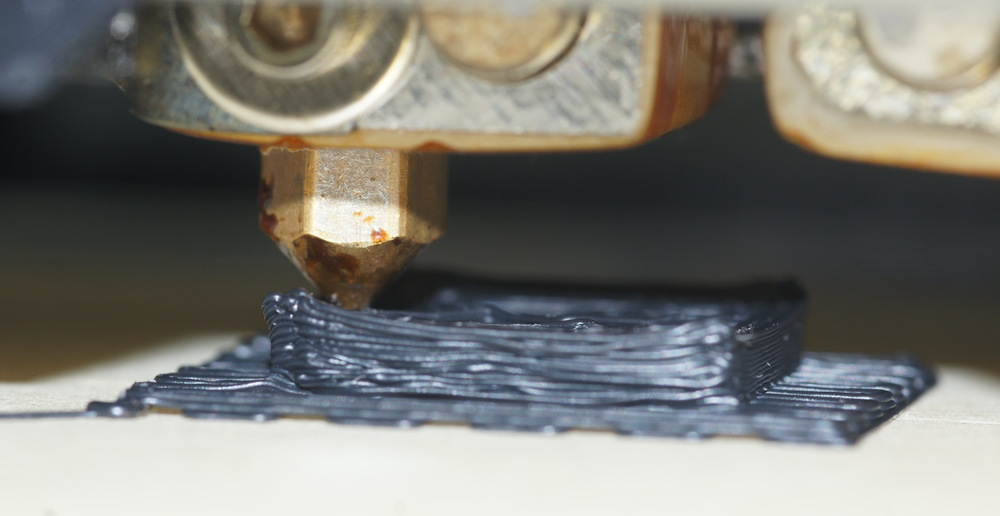

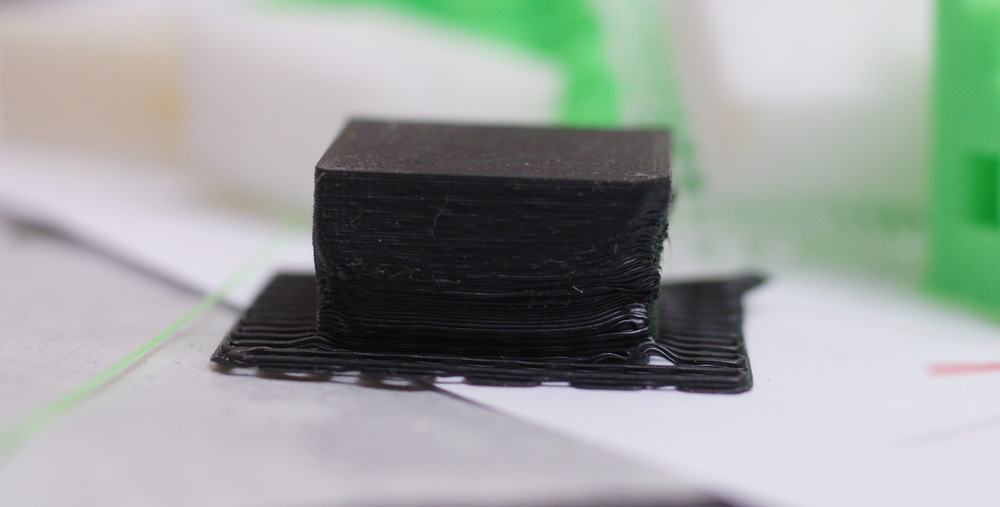

We start to print a test "cube" from the memory card ... 20 minutes of printing all keep their eyes on the printer (as was the case when the washing machine was first turned on). However, the result is monstrous:

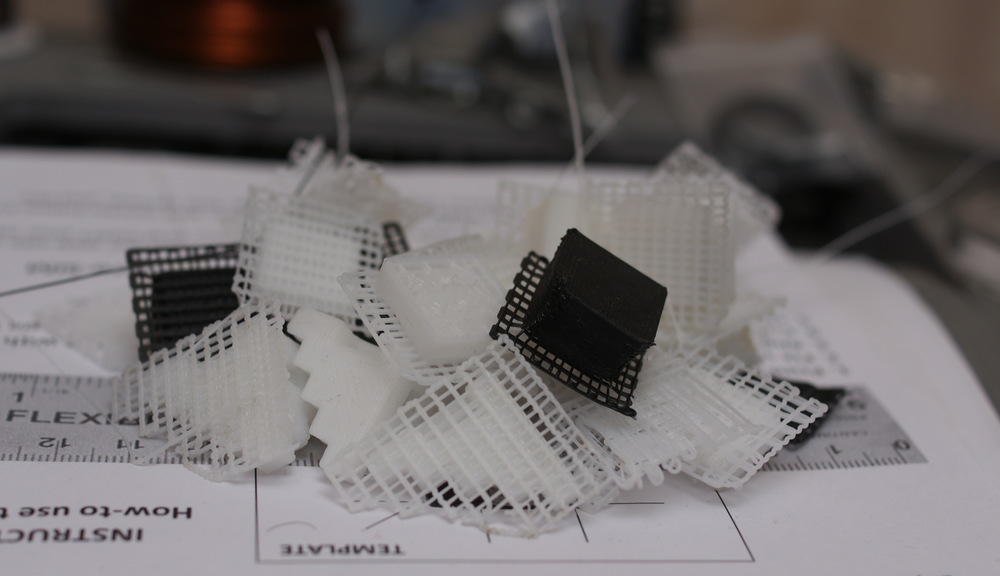

The corners are curves, and the cube is not a cube at all. Why the height is half the width? Day 2, I figured it out, fired on the mechanics / step on the Z axis - but it turned out to be all trite: it should be so - the model is so drawn. However, no dancing with tambourines made the printer print the corners normally ... After ~ 50 attempts with different settings, it became clear that I was at a dead end.

Dispute with the manufacturer and repair

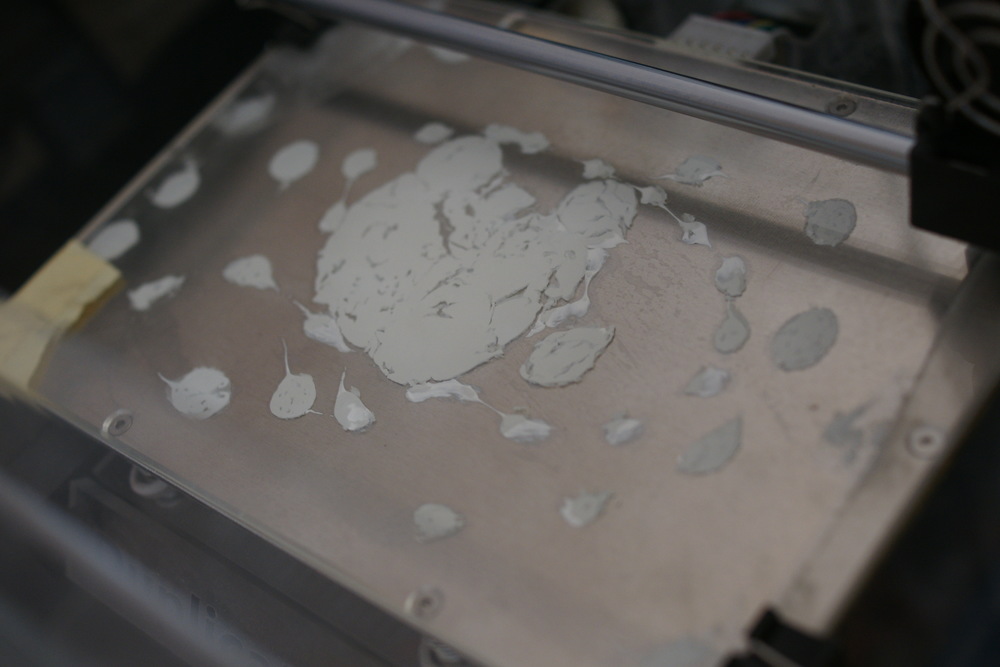

Opened the dispute on aliexpress. The manufacturer could not help me in any way to solve both print quality problems and detected mechanical problems: somewhat bent shafts transmitting the rotation of the Y-axis and the curved table: the center is about 1mm below the edges - this does not allow the print height of the first layer to be set normally. There was glass in the kit, but it touched the table only with edges - and accordingly there was a very large temperature difference in different places of the table.

I suggested to the manufacturer to send me a replacement for the bent parts, but after 2 weeks of altercations, calls from China in monstrous English (they suggested closing the dispute and promised to "solve all the problems") - the seller finally made a partial refand of $ 200. I ordered new 5mm shafts on ebay - they came a month later, but turned out to be just as bent (about 3-4mm). With the help of a flat table, a marker, a flashlight, and such and such a mother (extra effort - and the shafts were bent in the opposite direction worse than they were), in half an hour they managed to level the original shafts and assemble them back.

The temperature of the glass leveled with thermal paste KPT-8. Kapton film from the aluminum table tore off - all the same with the glass from it is no use. Glass holds the table "clothespins" for documents.

It turned out that 5mm steel shafts bend so easily that even after leveling the timing belts bend them with tension. It was necessary to reduce the tension force of the belts - this largely reduced the issue of further bending of the shafts at the cost of potentially greater backlash.

However, after all these fixes mechanics - the result of printing did not differ at all whatsoever. There are software settings.

Customize Skeinforge to print ABS

All that is written here is printing ABS plastic. I chose it because It provides greater strength, durability and can be treated with acetone. But in general, it seems much easier to achieve good quality with PLA plastic. Regarding horror stories about the smell of ABS when printing - I did not mention this problem (at least with my plastic), there is no particular smell, but of course you shouldn’t forget about airing .When I first looked at the skeinforge settings - hair stood on end. There are several hundreds of parameters that can be twisted - straight hands are falling. But it turned out that there are not so many parameters that can help. About a month of attempts left to realize that the problem of printing is at too high a temperature (both the table and the extruder). Because of this, the plastic remains soft, and it bends so hard. In the end, the first results, similar to the truth, were achieved in the following way:

- Leveling the table is the most important part. The first layer should be directly smeared with a thin layer on the table.

- With a heated table - it makes sense to learn to print without a raft (the mesh at the bottom of the model) - this makes the bottom surface smoother and saves a bit of plastic.

- To improve the sticking of the model - you can use paper tape (cheap and cheerful, it sticks well - the manufacturer immediately put the roll). You can grease the tape / glass dissolved in acetone ABS. Small models can be printed directly on the glass - the bottom surface is mirror-smooth. Also, the stripping of the adhesive tape with a metal brush has some effect - so that the surface is slightly uneven. But the "stripping" of the glass with diamond paste and GOI for some reason did not give a significant effect, perhaps the scratches were too small.

- The temperature of the table - 70-90 degrees. The lower the better, until the model twists. The smaller the model, the lower the table temperature can be used. For example, for small models, I set 80 degrees for the first layer, and for a print height of more than 0.5mm - 30 degrees (= turning off the heat, this is done on the Chamber tab). For large models, the table has to be kept heated at all times, the twisting force is much greater.

- The temperature of the extruder (tab Temperature) - the minimum at which it can normally squeeze the plastic. In my case, it is about 195-200 degrees. The first layer can be printed slightly hotter to improve adhesion. The temperature probably needs to be selected for each printer separately - thermal sensors may produce slightly different numbers.

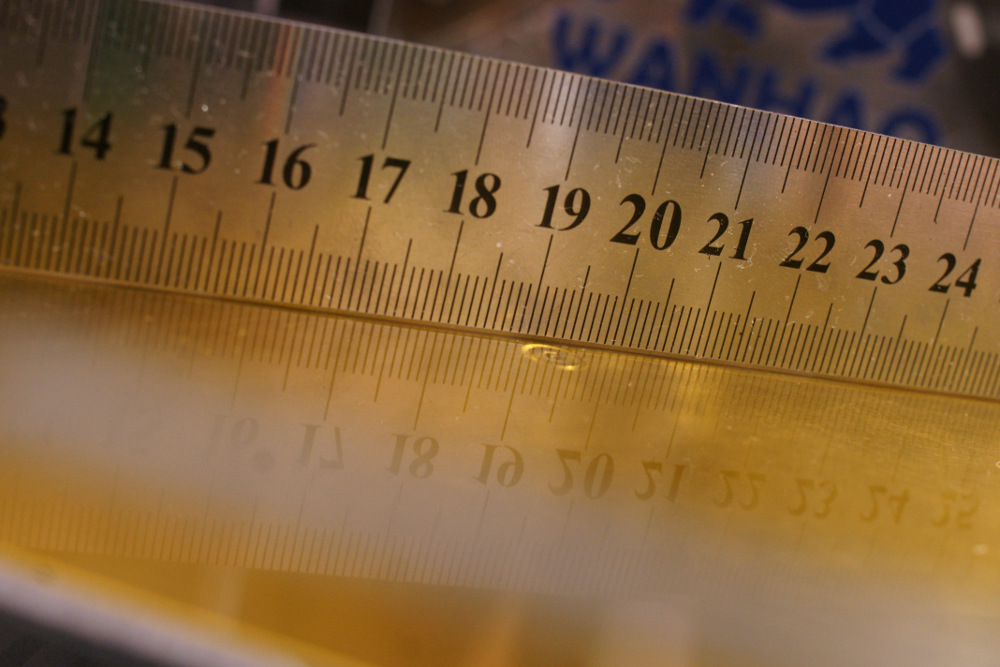

- Plastic different parties - may have a different diameter. With the printer, you must have a caliper and measure each roll in 5 places and take the average. In some batches - 1.75mm, in others - 1.82mm. This difference in diameter may be significant. The actual plastic thickness must be set when generating the g-code in the skeinforge window.

- To improve adhesion - on the Skirt insert it is possible to turn on the bezel print on the first layer. Gap over perimeter width = 0.8.

- If the layers have gaps between the perimeter and the entrails, it is necessary to try to increase Fill-> Infill perimeter overlap by no more than 0.45, if not enough, then further increase Stretch-> Path Stretch Over Perimeter Width (you can go to ~ 1)

- On the Bottom tab - by changing Altitude you can fine-tune the height of the first layer to achieve the desired degree of smearing and adhesion of the first layer

- There is a problem with printing small parts. The printer prints them too fast - and they do not have time to cool. The simplest solution is to limit the minimum printing time of the layer, to 10-15 seconds on the Cool-> Minimum Layer Time tab. Cool Type = Orbit (standard setting simply reduces print speed - and continues to carry a hot extruder on the printed). It is because of this function that I could not switch to a more modern and faster Slic3r - there is no possibility of slowing down the printing of “Orbit”.

- Print speed (Speed tab) - while I was typing at a speed of 30mm / s and movement at a speed of 45mm / s. Then I think you can increase the infill print speed up to 50-60mm / s with the Accelerate = ON function enabled in the printer settings (this limits physical accelerations).

After a couple of hundred attempts, finally something will start. This is a very convenient model for checking the quality of 5mm Calibration Cube Steps :

On offset it was necessary to print the owl familiar to many . Skeinforge poured on the g-code for about 8 minutes, for reliability printed from the SD card. Result: the owl is of course not perfect yet, but the light at the end of the tunnel is already visible. An owl took 50g of plastic, which is about 45 rubles. 6 hours of hard labor printer for 1.5 minutes of video. It's nice to see how the car itself does something real:

And if you turn off the light ...

However, plastic, glowing in the dark, did not meet expectations - it’s too dim and not long glowing (in reality, everything is worse than in the photo - the exposure is long). So I do not recommend buying such plastic from the Chinese.

Summary

If you have too much free time, the 3D printer will easily solve this problem.

From the point of view of hardware and software - I am glad that the Chinese have not made a single bicycle - everything is standard. Chinese Wanhao Duplicator 4 - in my opinion it’s more or less worth its money (and it doesn’t have two extruder competitors in this price range), but the manufacturer could put more effort into setting up Skeinforge profiles by default.

Source: https://habr.com/ru/post/215581/

All Articles