We collect the pocket laser

In this post I will describe how I collected a purple laser pointer from the rubbish that I found at hand. For this I needed: a violet laser diode, a collimator for converging the light beam, driver details, a laser housing, a power source, a good soldering iron, straight arms, and a desire to create.

Interested and willing to dig into electronics - please under the cat.

')

I caught the arm of a dead Blu-ray cutter. It was a pity to throw it away, but what could be done out of it - I did not know. Six months later, I came across a video in which such a self-made “toy” was shown. Here and bluray useful!

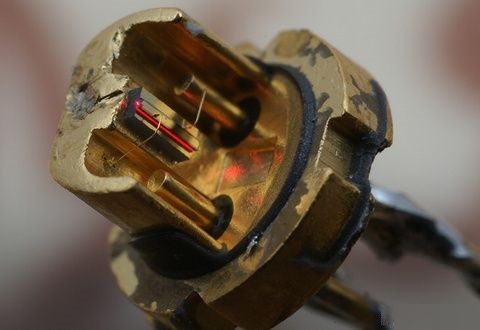

The drive read / write system uses a laser diode. In most cases, it looks like this:

Or like this.

3-3.05 volts are needed to power the red diode, and from 10-15 to 1500-2500 milliamperes, depending on its power.

But the diode "purple" requires as much as 4.5-4.9 volts, so it will not work to power the lithium battery through a resistor. Have to make a driver.

Since I had a positive experience with the ZXSC400 chip, I chose it without hesitation. This chip is a driver for high-power LEDs. Datashit . With a strapping in the form of a transistor, a diode and inductance, I didn’t play a big deal - all from datasheet.

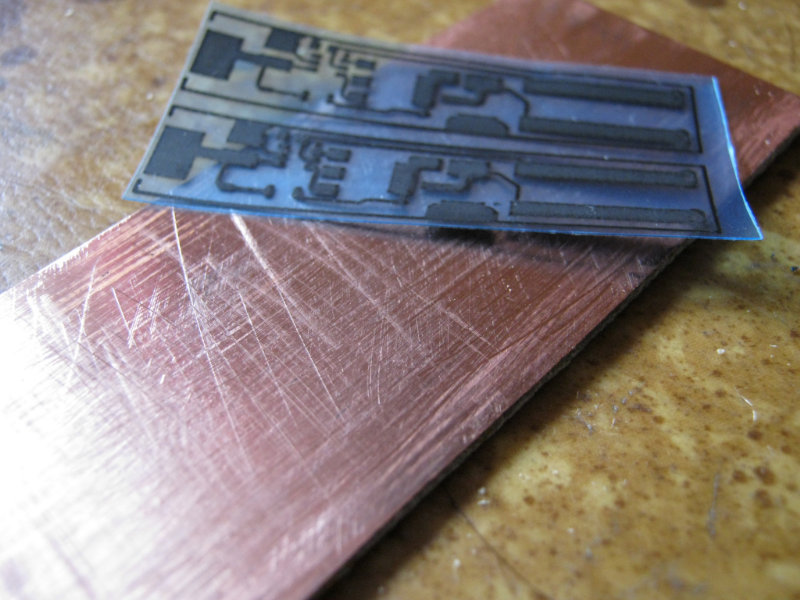

I made a printed circuit board for the laser driver, which was known to many radio amateurs by LUT-ohm (laser-iron technology). This requires a laser printer. The scheme is drawn in the SprintLayout5 program and printed on film for the further transfer of the figure to textolite. The film can be used almost any, just not stuck in the printer and it was printed on high quality. It is suitable film from plastic folders, envelopes.

If there is no film, do not get upset! We lend a glossy magazine to a girlfriend or wife, cut out the most uninteresting page and adjust it to A4 size. Then we print.

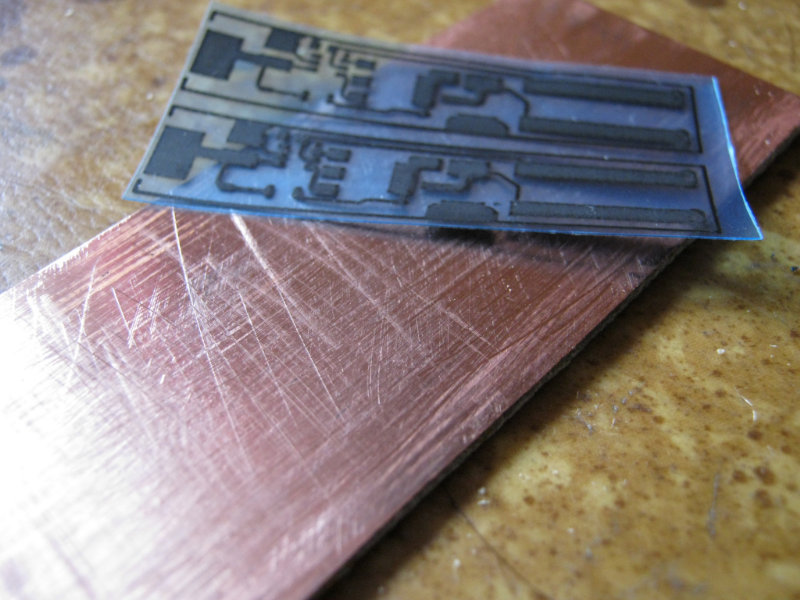

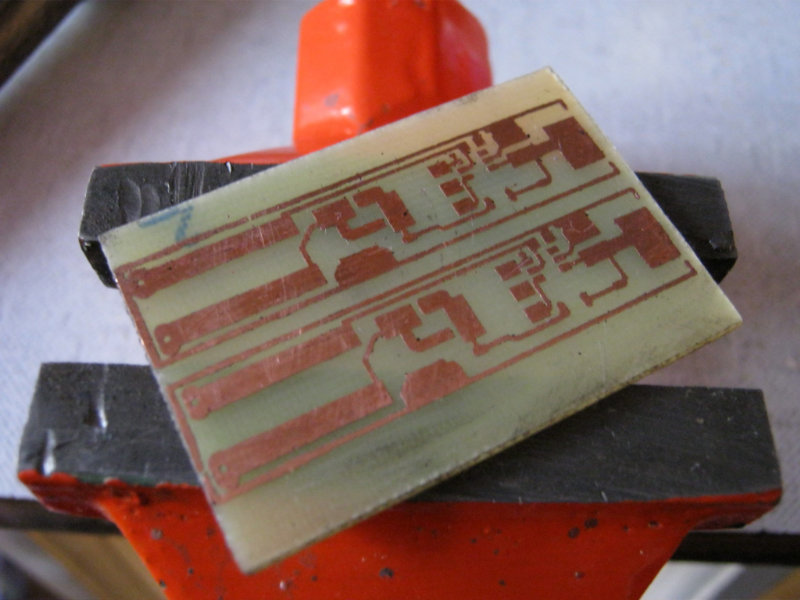

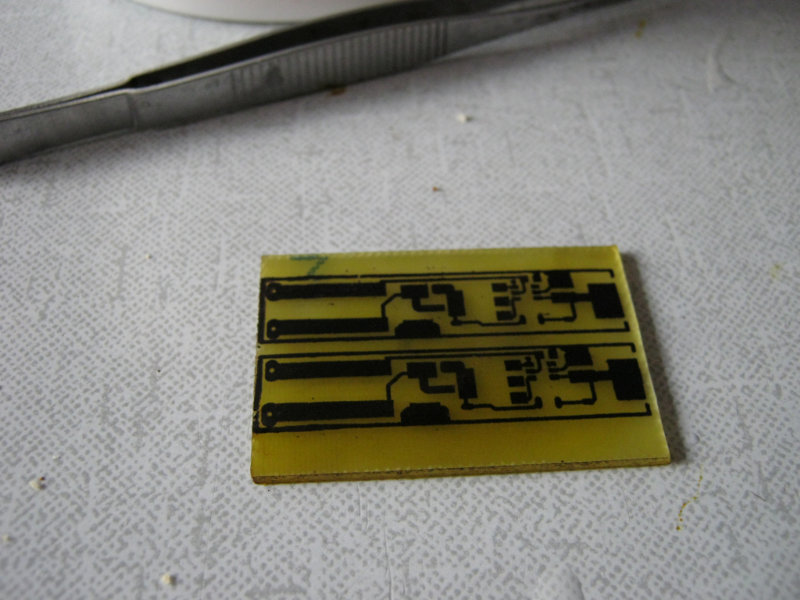

In the photo below you can see the film with the applied toner in the form of a wiring diagram, and a piece of PCB prepared for transferring toner. The next step is to prepare the PCB. It is best to take a piece, two times larger than our scheme, to make it easier to press to the surface during the next step. The copper surface must be sanded and degreased.

Now you need to transfer the "drawing". We find an iron in the closet, turn it on. While it is warming up, put a piece of paper with a scheme for textolite.

As soon as the iron heats up, you need to gently iron the film through the paper.

In this video, the process is very clearly shown.

When it “sticks” to the PCB, you can turn off the iron and proceed to the next step.

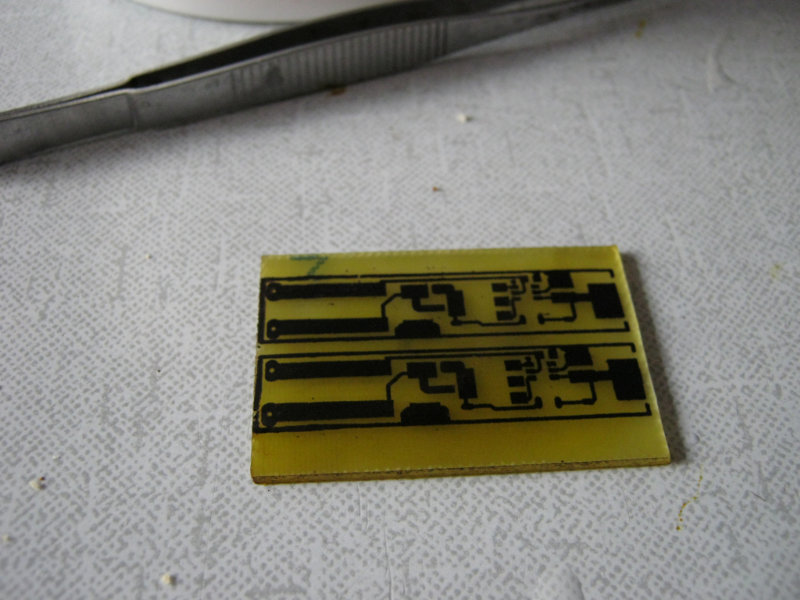

After the transfer of toner using a conventional iron, this case looks like this:

If some tracks were not transferred, or were not transferred very well, they can be corrected with a CD marker and a sharp needle. It is advisable to use a magnifying glass, the tracks are rather small, only 0.4 mm. The board is ready for pickling.

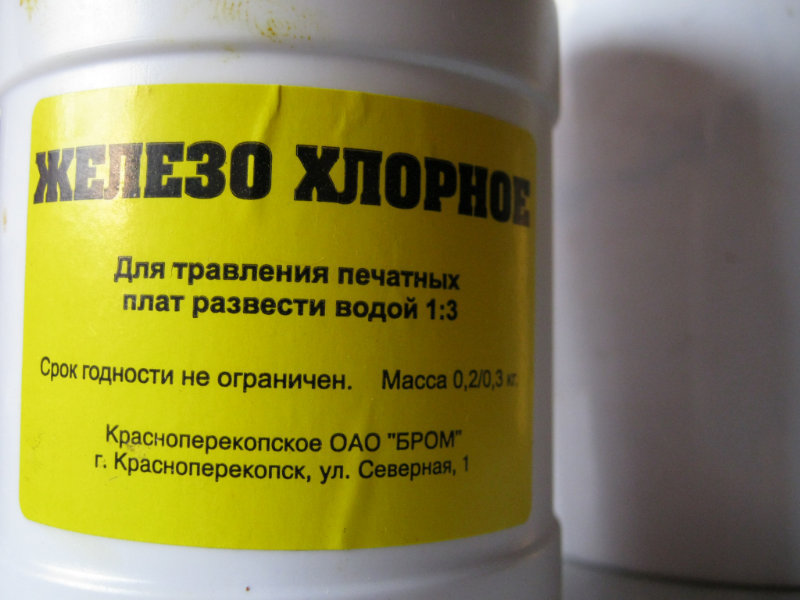

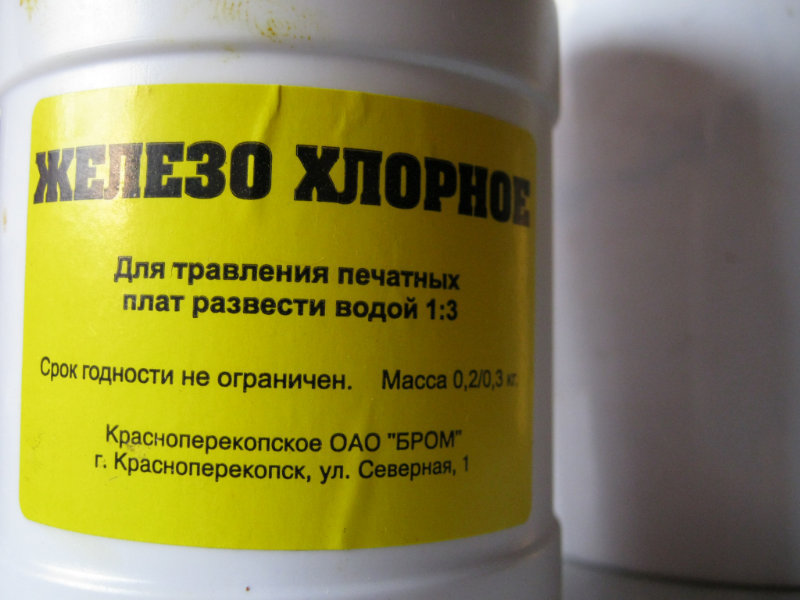

We will poison with ferric chloride. 150 rubles for a jar, enough for a long time.

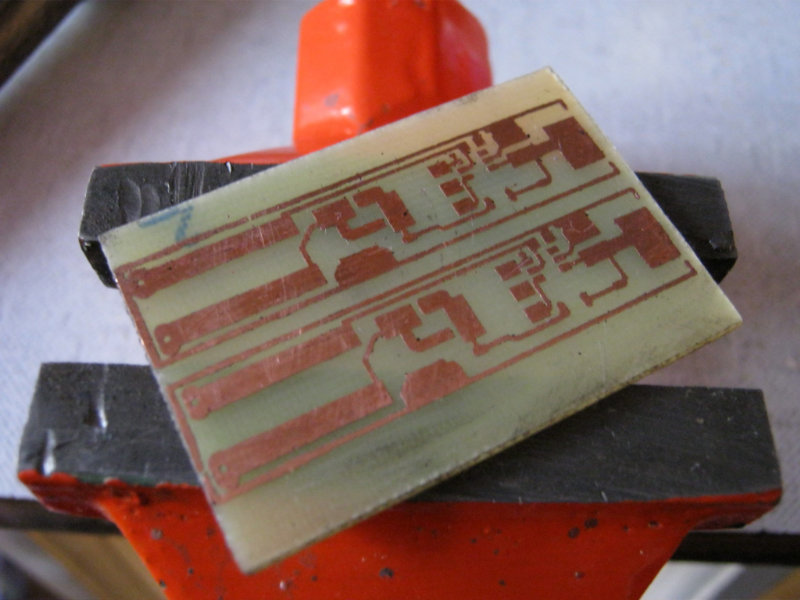

We dilute the solution, we throw our stock there, “stir” the board and wait for the result.

Do not forget to control the process. Carefully pull out the board with tweezers (it is also better to buy it, this will save ourselves from excess mat and “snot” solder on the future board when soldering).

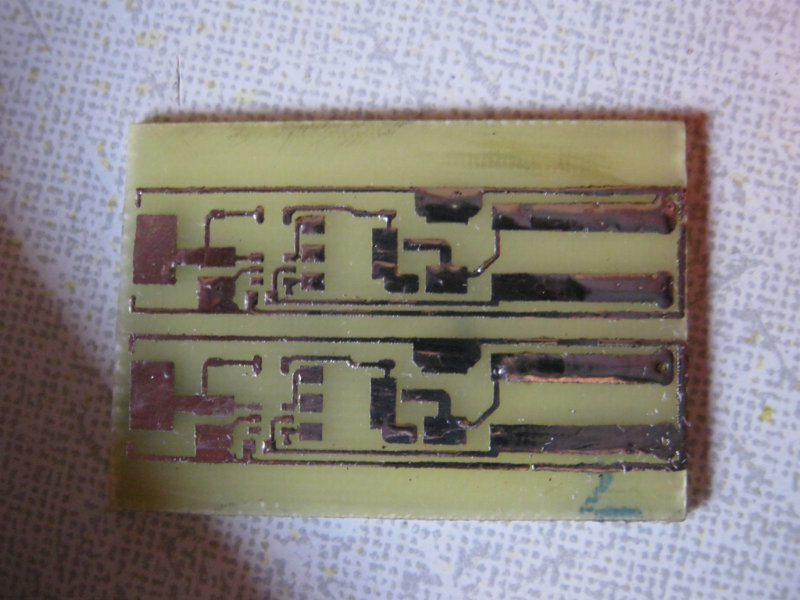

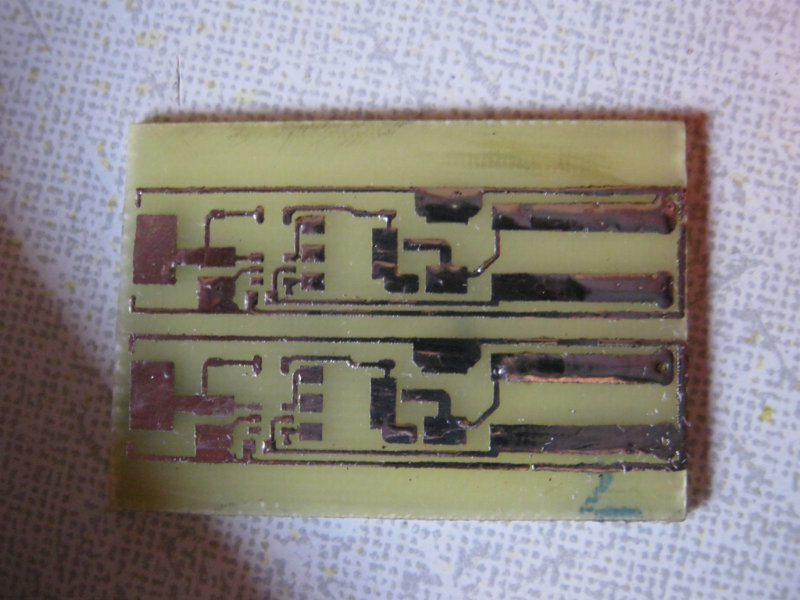

Well, the board is worn out!

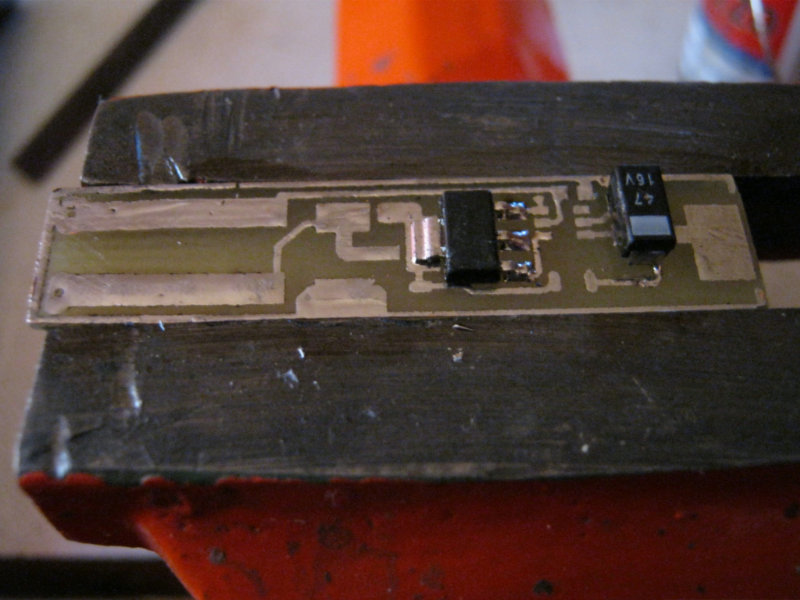

Carefully cleaned with fine sandpaper, apply flux, tinned. That is what happens after serving.

Solder contact pads can be applied a little more than anywhere else, so that it is more convenient to solder parts, and without additional solder deposition.

It remains to cut a little further outlined contours, and grind the extra files. I made the driver in two copies - just in case. Textolite is convenient to cut with scissors for metal.

We will collect the driver according to this scheme. Note: R1 is 18 million , not mega-ohm !

When soldering it is best to use a soldering iron with a thin sting, for convenience, you can use a magnifying glass, because the details are quite small. This soldering uses LTI-120 flux.

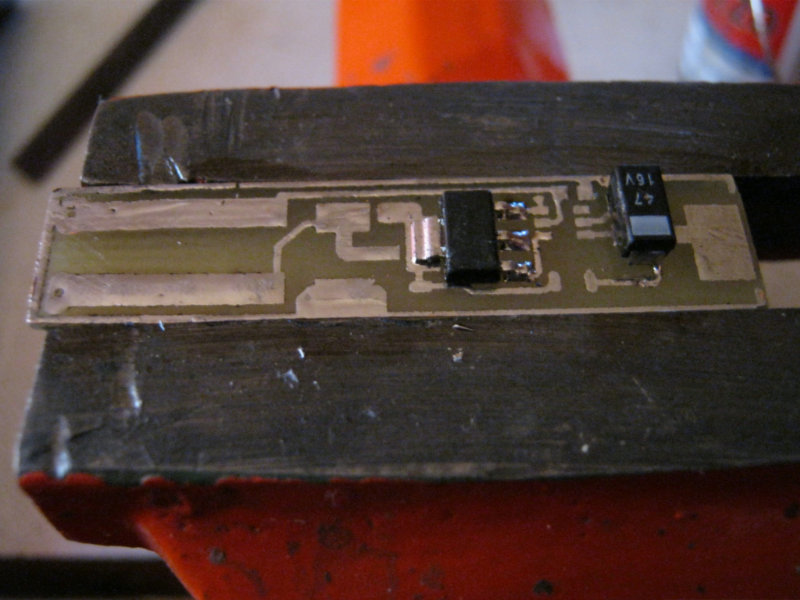

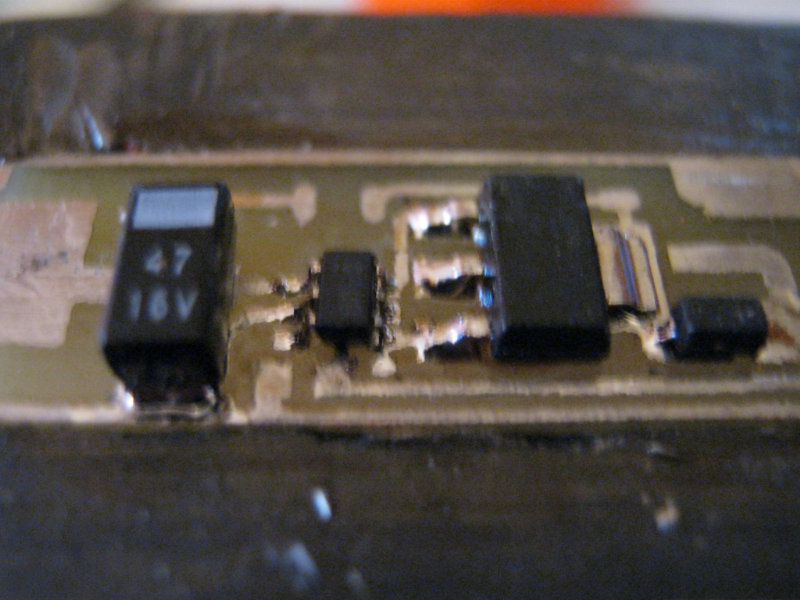

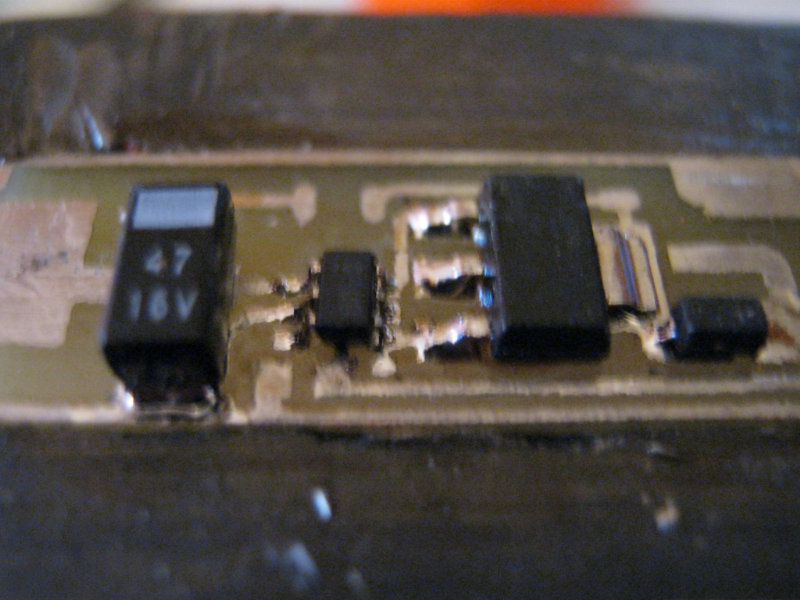

So, the board is almost soldered.

The wire is soldered to the resistor by 0.028 Ohm, since we can hardly find such a resistor. You can solder in parallel 3-4 SMD-jumpers (look like resistors, but with the inscription 0), they are about 0.1 ohm real resistance.

But there were none, so I used ordinary copper wire of similar resistance. I definitely didn’t measure it - just the calculations of some kind of online calculator.

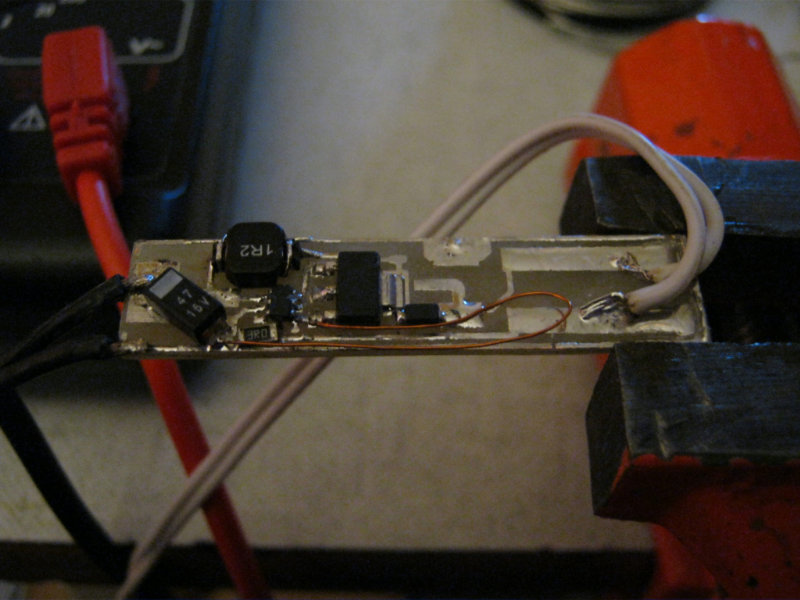

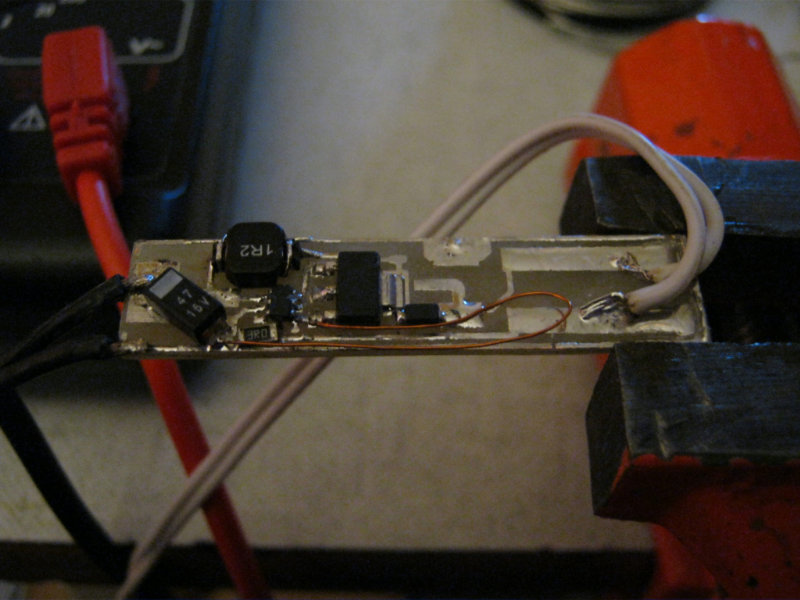

We are testing.

The voltage is set at only 4.5 volts, so the light is not very bright.

Of course, the board looks dirty before washing the flux. Rinse can be simple alcohol.

Now it is worth writing about the collimator. The fact is that the laser diode itself does not shine with a thin beam. If you turn it on without optics, it will shine like a normal LED with a divergence of 50-70 degrees. In order to create a beam, we need optics and the collimator itself.

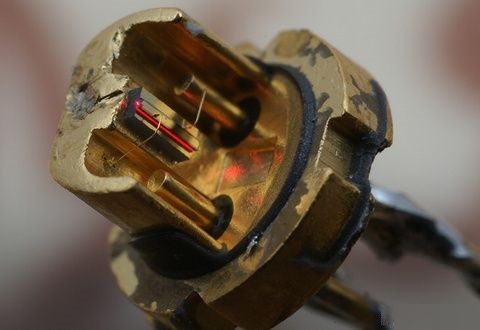

Collimator ordered from China . It also contains a weak red diode, but I did not need it. The old diode can be knocked out with an ordinary M6 bolt.

Spin the collimator, unscrew the lens and the back part, unsolder the driver from the diode. The remaining mount is clamped in a vice. You can knock out the diode by hitting it.

Diode knocked out.

Now you need to press the new purple diode.

But the diode can not be pressed on its feet, and it is inconvenient to press it in another way.

What to do?

The back of the collimator is perfect for this.

Insert the new diode legs into the hole in the back of the cylinder, and clamp in a vice.

Slowly tighten the vise until the diode is fully pressed into the collimator.

So, the driver and collimator are collected.

Now we fix the collimator to the “head” of our laser, and solder the diode to the driver outputs using wires, or directly to the driver board.

As a corps, I decided to use a simple flashlight from a hardware store for a hundred rubles.

It looks like this:

All glands for laser and collimator.

On the clothespin for ease of mounting pinned magnet.

It remains only to insert the laser device into the case and twist.

Sprint layout 5, PCB layout files in the archive .

PS This pocket laser is a rather dangerous "toy." Lasers of class I-II for humans and eyes are not particularly dangerous, except that the diode accidentally gets into the eye if the assembly fails. But classes III-IV can damage or deprive of sight at all. Need to use glasses . Directing the beam towards people, and especially in the face - it is impossible .

Chinese red pointer shines with a power of 0.5-1 mW. This laser has a power of 150-200 milliwatts. Imagine that 150-200 pointers were sent to you at the same time!

Interested and willing to dig into electronics - please under the cat.

')

I caught the arm of a dead Blu-ray cutter. It was a pity to throw it away, but what could be done out of it - I did not know. Six months later, I came across a video in which such a self-made “toy” was shown. Here and bluray useful!

The drive read / write system uses a laser diode. In most cases, it looks like this:

Or like this.

3-3.05 volts are needed to power the red diode, and from 10-15 to 1500-2500 milliamperes, depending on its power.

But the diode "purple" requires as much as 4.5-4.9 volts, so it will not work to power the lithium battery through a resistor. Have to make a driver.

Since I had a positive experience with the ZXSC400 chip, I chose it without hesitation. This chip is a driver for high-power LEDs. Datashit . With a strapping in the form of a transistor, a diode and inductance, I didn’t play a big deal - all from datasheet.

I made a printed circuit board for the laser driver, which was known to many radio amateurs by LUT-ohm (laser-iron technology). This requires a laser printer. The scheme is drawn in the SprintLayout5 program and printed on film for the further transfer of the figure to textolite. The film can be used almost any, just not stuck in the printer and it was printed on high quality. It is suitable film from plastic folders, envelopes.

If there is no film, do not get upset! We lend a glossy magazine to a girlfriend or wife, cut out the most uninteresting page and adjust it to A4 size. Then we print.

In the photo below you can see the film with the applied toner in the form of a wiring diagram, and a piece of PCB prepared for transferring toner. The next step is to prepare the PCB. It is best to take a piece, two times larger than our scheme, to make it easier to press to the surface during the next step. The copper surface must be sanded and degreased.

Now you need to transfer the "drawing". We find an iron in the closet, turn it on. While it is warming up, put a piece of paper with a scheme for textolite.

As soon as the iron heats up, you need to gently iron the film through the paper.

In this video, the process is very clearly shown.

When it “sticks” to the PCB, you can turn off the iron and proceed to the next step.

After the transfer of toner using a conventional iron, this case looks like this:

If some tracks were not transferred, or were not transferred very well, they can be corrected with a CD marker and a sharp needle. It is advisable to use a magnifying glass, the tracks are rather small, only 0.4 mm. The board is ready for pickling.

We will poison with ferric chloride. 150 rubles for a jar, enough for a long time.

We dilute the solution, we throw our stock there, “stir” the board and wait for the result.

Do not forget to control the process. Carefully pull out the board with tweezers (it is also better to buy it, this will save ourselves from excess mat and “snot” solder on the future board when soldering).

Well, the board is worn out!

Carefully cleaned with fine sandpaper, apply flux, tinned. That is what happens after serving.

Solder contact pads can be applied a little more than anywhere else, so that it is more convenient to solder parts, and without additional solder deposition.

It remains to cut a little further outlined contours, and grind the extra files. I made the driver in two copies - just in case. Textolite is convenient to cut with scissors for metal.

We will collect the driver according to this scheme. Note: R1 is 18 million , not mega-ohm !

When soldering it is best to use a soldering iron with a thin sting, for convenience, you can use a magnifying glass, because the details are quite small. This soldering uses LTI-120 flux.

So, the board is almost soldered.

The wire is soldered to the resistor by 0.028 Ohm, since we can hardly find such a resistor. You can solder in parallel 3-4 SMD-jumpers (look like resistors, but with the inscription 0), they are about 0.1 ohm real resistance.

But there were none, so I used ordinary copper wire of similar resistance. I definitely didn’t measure it - just the calculations of some kind of online calculator.

We are testing.

The voltage is set at only 4.5 volts, so the light is not very bright.

Of course, the board looks dirty before washing the flux. Rinse can be simple alcohol.

Now it is worth writing about the collimator. The fact is that the laser diode itself does not shine with a thin beam. If you turn it on without optics, it will shine like a normal LED with a divergence of 50-70 degrees. In order to create a beam, we need optics and the collimator itself.

Collimator ordered from China . It also contains a weak red diode, but I did not need it. The old diode can be knocked out with an ordinary M6 bolt.

Spin the collimator, unscrew the lens and the back part, unsolder the driver from the diode. The remaining mount is clamped in a vice. You can knock out the diode by hitting it.

Diode knocked out.

Now you need to press the new purple diode.

But the diode can not be pressed on its feet, and it is inconvenient to press it in another way.

What to do?

The back of the collimator is perfect for this.

Insert the new diode legs into the hole in the back of the cylinder, and clamp in a vice.

Slowly tighten the vise until the diode is fully pressed into the collimator.

So, the driver and collimator are collected.

Now we fix the collimator to the “head” of our laser, and solder the diode to the driver outputs using wires, or directly to the driver board.

As a corps, I decided to use a simple flashlight from a hardware store for a hundred rubles.

It looks like this:

All glands for laser and collimator.

On the clothespin for ease of mounting pinned magnet.

It remains only to insert the laser device into the case and twist.

Sprint layout 5, PCB layout files in the archive .

PS This pocket laser is a rather dangerous "toy." Lasers of class I-II for humans and eyes are not particularly dangerous, except that the diode accidentally gets into the eye if the assembly fails. But classes III-IV can damage or deprive of sight at all. Need to use glasses . Directing the beam towards people, and especially in the face - it is impossible .

Chinese red pointer shines with a power of 0.5-1 mW. This laser has a power of 150-200 milliwatts. Imagine that 150-200 pointers were sent to you at the same time!

Source: https://habr.com/ru/post/215353/

All Articles