Automation of online store warehouse processes: Audiomania experience - Part 1

One of the main pain points of most online stores is a warehouse. To maintain it is quite a costly business, but even if you have a warehouse, it is extremely difficult to organize its work properly. We in Audiomania ourselves are faced with many difficulties of warehouse logistics and have developed a number of approaches that allow us to effectively solve the most common warehouse problems.

Problems

First you need to break the general problem called “warehouse logistics” into smaller ones. The first thing we faced was that the warehouse staff often had too much responsibility: they had to make decisions related to how and where to put the goods, how to group it, what and where to store. Accordingly, when one of them was absent, serious difficulties began - in fact, many of these decisions were taken by employees individually. We in Audiomania sell audio products, among which there are not only large acoustic systems, but also rather small radio components that it was simply impossible to find if, for example, an employee who took them to the warehouse suddenly fell ill.

')

From this problem, the second flowed out smoothly - in fact, the search for goods in the warehouse. Very often, an online store faces the following situation: there is an exact understanding that the product is in stock, but nobody knows exactly where exactly it is (often simply because there is no person in the warehouse who accepted this product). Often, such confusion and personal responsibility of storekeepers lead to re-grading (a situation where a customer receives a wrong or not exactly the product that was originally ordered): for example, once a batch of headphones came to our warehouse, marked with the abbreviation BL. As a rule, black goods are marked in this way, but this time by “BL” the manufacturer had in mind “blue” - “blue”. As a result, many customers received headphones of a different color, and since we did not have a system for informing storekeepers, each of them had to first make a mistake in order to learn from their own experience what was behind this marking.

Tasks

At some point (by the summer of 2012) such fatigue had accumulated from all this confusion, that it was decided by strong-willed effort to tackle the reorganization of the warehouse. The main engine of progress in this case was the rapid growth of the company - we developed at such a rate that it became impossible to solve the problem by an extensive increase in the staff of storekeepers. Among the main objectives of this process were the following:

- Elimination of regrading;

- Increase productivity;

- Providing easy and fast scalability;

- Accelerating the training of new employees;

- Creating a flexible system of control of goods in stock.

Decision

Software and equipment storekeeper

As part of the optimization of the warehouse, we wrote software that allows us to automate the work of storage facilities and simplify the tasks of storekeepers (given that all software development and support is carried out within the company, we have no problems with data exchange and work with them). The software continues to be improved, but the main works on its writing took three months (including preparation). During preparation, we traveled to the logistics centers of partner companies, studied their experience. After that, a team of several people, including the technical director, the head of the development department, and the warehouse manager, developed the technical assignment that our full-time programmer received (he was directly involved in writing the code).

There were two reasons why we created our solution and did not use the existing ones:

- The need to use and maintain software written for obsolete platforms ( most warehouse terminals use software written for the Windows Mobile platform). For example, the top storage terminals from Motorola still work under Microsoft Windows CE 5.0 Professional Version.

- High cost of equipment. We reasonably wanted to reduce the cost of our warehouse terminals compared to ready-made solutions: an ordinary terminal costs from several dozen to one hundred thousand rubles (on average, a warehouse terminal costs about 35,000 rubles, large logistics complexes use terminals costing about 50,000 rubles). At the same time (see clause 1), for the money, devices are offered on the market with the same slow and obsolete operating system.

Even the main advantage of the industrial terminal - resistance to shocks and falls - was not serious for us however: according to our calculations, even if we split one “custom” terminal a week, the costs (on the scale of several years of working with “national »Terminals) will be lower than with the purchase of specialized solutions.

Even the main advantage of the industrial terminal - resistance to shocks and falls - was not serious for us however: according to our calculations, even if we split one “custom” terminal a week, the costs (on the scale of several years of working with “national »Terminals) will be lower than with the purchase of specialized solutions.However, the “prefab” version of the warehouse terminal was also fraught with “pitfalls”. In the photo (on the left) you see the original version of the equipment of our warehouse worker - the one that was abandoned for a number of reasons. Initially, we used small five-inch tablets with portable wire scanners connected to them.

It would seem that it is convenient to carry a tablet on the wrist that tells you which product you should pick up from which shelf, conveniently and fairly modernly - our employees, for example, immediately remembered the characters from the movie “In Time”, which also had important wrists attached to their wrists. information.

And yet, the ergonomics of such a decision was not up to par. Since on an industrial scale to transmit information directly to the hand, bypassing additional devices, have not yet learned, the tablet needed to be fixed to the wrist with a special case. These covers were made to order in a workshop for sewing leather goods and cost 1000 rubles apiece - which led to a rise in the cost of a set of equipment. In addition, in cases where an employee, for example, had to get something out of the boxes, the tablet on his wrist only interfered.

Card from the movie “Time”: after receiving new tablets, our employees immediately remembered something similar

A lot of problems were brought to us by the wired connection of the tablet and the scanner: time after time, the contacts of an unreliable mini-USB connection failed. They had to be replaced (the tablets visited the service center more than once - they changed either the connector or the entire tablet). As a result, inconvenient and unreliable tablets and wired scanners had to be abandoned - we replaced them with more compact Highscreen Boost smartphones (4.3 ”, Android OS, 4160 mAh), which supplemented the Bluetooth scanner (made by Chinese OEM).

The advantage of this option is that, firstly, this relatively inexpensive phone is discharged extremely slowly, and secondly, it can be easily put in your pocket - so it does not interfere when working with a product, and the scanner connected via Bluetooth does not require extra wires , works well and also does not hinder employee movement (scanners, among other things, come complete with a case that allows you to attach them to the phone, so if necessary, these two devices can work as a unit). Let's say right away: we had the idea to transfer employees to iPads, we refused from it due to the fact that not every wireless (and no wired) scanner can connect to them.

This is the new equipment for warehouse workers.

The subtleties of this stage were precisely in the selection of an uninterruptedly working “tablet / smartphone-scanner” combination, which we eventually found: in the case of choosing the right kit, for the phone, processing the data received from the Bluetooth scanner will not be a problem he recognizes them as information entered from the keyboard (therefore, no additional drivers should be installed, and even more so, there is no need to write). During operation, the devices are not confused and not lost - at night, employees leave them to be charged in individual cells provided for sharing the phone and scanner together. Device kits are not tied to a specific employee — at the beginning of a working day, an employee can take any kit, scan his badge (thus logging in to the system) and start work.

Our warehouse software works through the smartphone's browser - this is where all the prompts and instructions from the system about which item to pick up appear (then the employee remains to find and scan it, the system will not allow the wrong item to pick up). Thanks to this, the solution turned out to be quite flexible: if for one reason or another it turns out that the current hardware of the storekeepers is not convenient enough, it will not be difficult to switch to a different type of device.

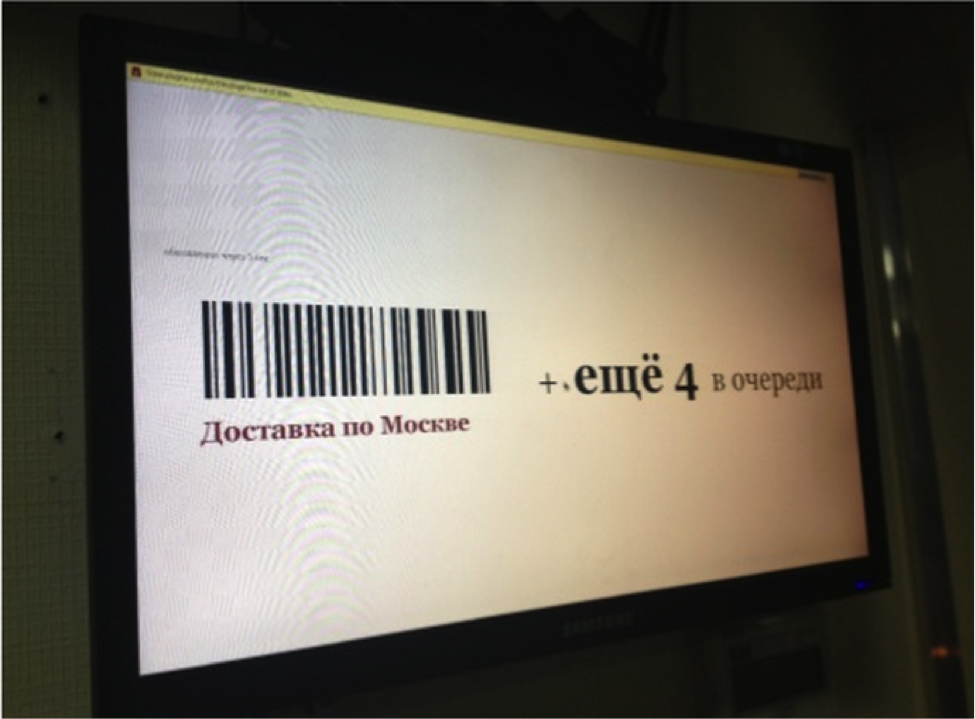

Accepting applications for the assembly, we also automated. To obtain tasks at the first stage of the warehouse reorganization process, employees used a warehouse monitor — a screen from which information could be read by the scanner on which goods should be collected.

The first stage of reorganization: a monitor showing the bar code of the highest priority at the moment assembly

For all its manufacturability, we decided to simplify this approach: since the warehouse has a single queue for order assembly, there is no need to dynamically change the barcode with information about the new assembly. Now we use a single barcode for everyone (printed on paper) - scanning it means that the storekeeper simply confirms that he is ready to process the next order in the queue, the details of which are already sent directly to the employee’s smartphone. This decision was dictated not only by the desire to simplify the process: it turned out that the wireless scanners we purchased do not read the information from the monitor screen. And although the monitor is no longer used for this task, we continue to successfully use it in stock: it now displays statistical data on the status and characteristics of orders in the queue.

The system generates and prioritizes assemblies automatically, changing their order if necessary. Wherein:

- Retail customers are always in priority (this rule is relevant for those premises in which retail space is adjacent to storage space - in our case, this is the central store on Elektrozavodskaya metro station, where all innovations were tested. Now, proven approaches are used in a large warehouse in 1000 sq.m.

- When forming sets of goods for delivery in Moscow, we adapt to the situation. At the same time, we collect orders only for the day ahead (not more), as less urgent orders receive lower priority.

- Regional shipments to various companies, as a rule, are tied to a specific time, because employees of transport companies arrive at the warehouse at a pre-selected hour (in this case, the assembly priority is higher, the closer the designated X hour is, and after it expires, the priority of this type of assembly decreases).

- Despite the fact that all decisions on the priority of assemblies are made by the system, the warehouse manager can adjust its actions if, for example, couriers or representatives of the transport company are late by the appointed date.

[ About how the “physical” organization of warehouse logic and the entire system as a whole looks like from the user's point of view, we will discuss the findings and results of the reorganization in Part 2 ]

Source: https://habr.com/ru/post/211420/

All Articles