Using a 3D printer, a material is created that is lighter than water and has the strength of steel

The Karlsruhe Institute of Technology has created a new composite material, the density of which is less than the density of water, and the compressive strength reaches 274 megapascals, which is comparable to magnesium and aluminum alloys and some steel grades. The strength of the new material exceeds the strength of any artificial and natural materials that are lighter than water.

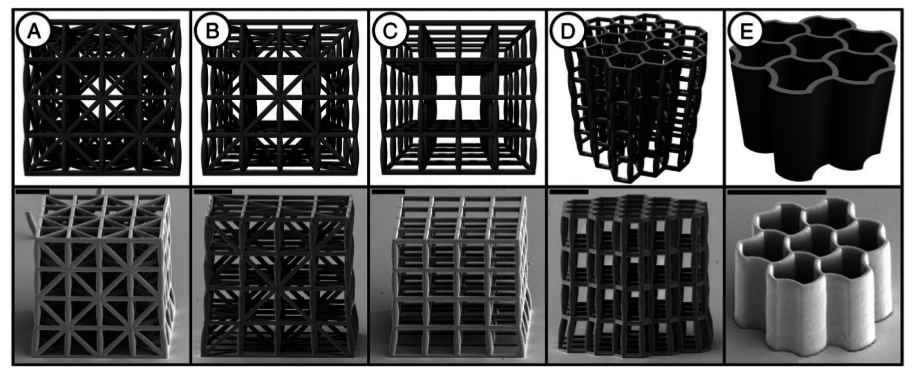

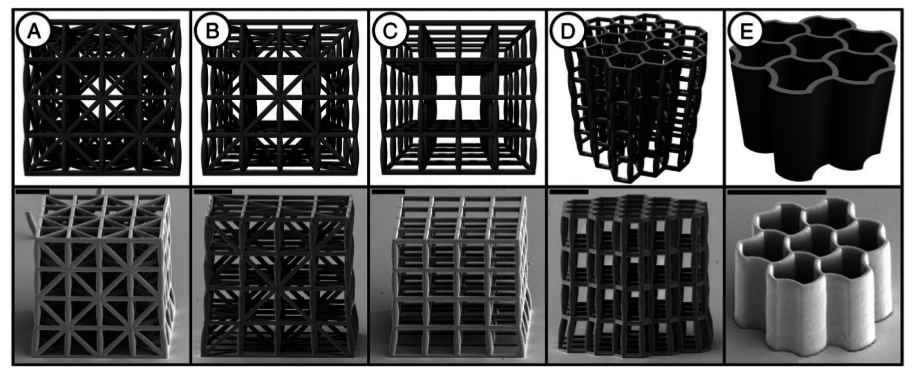

The material has a cellular structure. It is based on a microscopic grid printed on a 3D printer. Printing in microscales is carried out using two-photon lithography technology. The printer focuses the laser beam in the thickness of the polymer resin, which instantly freezes at the point of focus. The resolution of such microprinter can reach 100 nanometers. The printed polymer grid itself is not very durable. The whole secret of the new material is that after printing the grid is covered with a thin layer of aluminum oxide (corundum) - one of the most durable materials, only slightly inferior to diamond. Although the density of corundum is four times higher than the density of water, it takes from 1% to 10% of the volume of the resulting structure (depending on the layer thickness).

Scientists have conducted experiments with different types of polymer lattices and different thickness of the layer of aluminum oxide. The greatest strength was demonstrated by the structure in the form of hexagonal honeycombs. When the thickness of the corundum coating of 50 nanometers, the compressive strength was 273.6 megapascals at a density of 863 mg / cm 3 . You can visually compare the strength and density of a new material compared to others in this diagram:

')

An article describing the technology and experimental data is freely available on pnas.org.

The material has a cellular structure. It is based on a microscopic grid printed on a 3D printer. Printing in microscales is carried out using two-photon lithography technology. The printer focuses the laser beam in the thickness of the polymer resin, which instantly freezes at the point of focus. The resolution of such microprinter can reach 100 nanometers. The printed polymer grid itself is not very durable. The whole secret of the new material is that after printing the grid is covered with a thin layer of aluminum oxide (corundum) - one of the most durable materials, only slightly inferior to diamond. Although the density of corundum is four times higher than the density of water, it takes from 1% to 10% of the volume of the resulting structure (depending on the layer thickness).

Scientists have conducted experiments with different types of polymer lattices and different thickness of the layer of aluminum oxide. The greatest strength was demonstrated by the structure in the form of hexagonal honeycombs. When the thickness of the corundum coating of 50 nanometers, the compressive strength was 273.6 megapascals at a density of 863 mg / cm 3 . You can visually compare the strength and density of a new material compared to others in this diagram:

')

An article describing the technology and experimental data is freely available on pnas.org.

Source: https://habr.com/ru/post/211416/

All Articles