Part 3. Meet - laser called Amaris. Moving and first awakening of VisuMax

Other parts

Part 1. Unboxing VisuMax - femto laser for vision correction

Part 2. How many megabits / s can be passed through the optic nerve and what is the resolution of the retina? Some theory

Part 4.1 We return the sight. From points to the excimer laser

Part 4.2 We return the sight. From points to the excimer laser

In this article we will meet with another laser for vision correction - Amaris 500E from the company Schwind. And together we will take part in a very important event for our clinic - the first launch of the VisuMax femto laser.

Vendor lock-in and exceptions

Each equipment manufacturer is always trying to fill the whole complex with its line. This is understandable and has several advantages both in terms of comprehensive service and in terms of equipment compatibility. But sometimes a more optimal solution is a combination of products from several manufacturers. That is why we made the difficult decision to take the best from two large companies producing equipment for vision correction - Zeiss and Schwind. This event was preceded by a whole range of studies in the field of compatibility of protocols, methods, dimensions, and much more. As far as I know, we are the first in the world who managed to combine together the VisuMax femto laser and the Amaris 500E excimer laser in one operating room.

Moving

After VisuMax took its rightful place in the new operating room, it was time to move Amaris to the 5th floor. The operating room smells like a disinfectant solution, the walls shine clean. Everything is ready for the rest of the equipment.

VisuMax awaits launch

As usual at the last moment it turns out that the cable infrastructure is not quite ready to start and you need to make some more changes. However, these problems were quickly resolved and we went directly to the move. If it seems to you that for the full operation of the laser does not require a special number of communication channels, then you are mistaken. In order for the laser to produce a vision correction in a matter of seconds, we need the well-coordinated work of many specialists who work as a single efficient mechanism. And the operation itself is only the tip of the iceberg, behind which lies the labor of dozens of people.

Some photos of familiar workflow

Transportation of extremely accurate medical equipment has its own nuances, which are somewhat similar to high-precision machines. You can not tilt more than a few degrees, you can not expose vibrations, falls, etc. Many sensors that monitor the state of the device are extremely gentle and no one wants to get involved with service problems. Therefore, the transfer was thoughtful and cautious, to which the considerable weight of the laser — about 300 kg — was especially worthwhile.

Photos of the lifting installation

')

After some time, both the "hero of the occasion" took their permanent place in the future operating room.

Final installation of Amaris on site. In the working position, the laser frame is rotated 90 degrees so that the surgical table with the patient at the turn will be at the desired point.

VisuMax predecessor - Ziemer Femto LDV

Femto LDV is a very reliable and accurate Femto laser that was used previously. It is not inferior to VisuMax in the quality of work, but it has a little less opportunity in terms of the range of surgical procedures. For example, it does not have the ability to work with ReLEx technology — simultaneous vision surgery using only a femtosecond laser. Unlike VisuMax, it is more compact and can be transferred to another place of work. At first, he will be in the operating room with his “successor” as a backup option.

Other infrastructure

Thousands of trifles are important for the full launch of the operating room, each of which needs to be given a lot of attention. Medicine, especially ophthalmosurgery, does not forgive careless attitude to details. Every nuance is important to achieve a good result.

Firstly, it is the provision of uninterrupted power supply for installations in any situation. Responsibility we have no less than the data center. Only because of the specifics of our work, we do not need to have diesel generators, since the operation itself rarely takes more than half an hour, and the operation of the laser usually lasts no more than 15-20 seconds. Therefore, the task of back-up power supply is assigned to completely traditional lead-acid batteries. VisuMax has an integrated version, and an external one is used for Amaris.

Secondly, climate control is very important. Here is a huge mass of nuances. Traditionally, the air flow in the operating room is planned so that the pressure inside the operating room is always higher than outside. This is an additional barrier to dust, small microbial particles and other undesirable things. A separation into a “clean” and “dirty” zone is also planned. Any movement of objects, people, tools and air should be carried out from the “clean” to the “dirty” zone. The room should be ideally stable temperature (20-21 degrees) and optimum humidity. This is a necessary condition for working with such a delicate thing as the cornea of the eye. One of the links in this infrastructure is an air dryer.

Installation

Completion of work

All installations took their place and the operating room was once again fully treated with disinfectant solution to achieve maximum sterility.

Engineers perform final calibration before launch.

Final rehearsal

Before such a crucial event as the treatment of the first patients need to do a lot of work. In many ways, these are weeks of education and training in Germany for doctors and engineers. Dmitry, an engineer specializing in the maintenance of ophthalmic lasers - in particular VisuMax, flew in specially to ensure a smooth start-up.

At Dmitry's request, I will not publish photos of the laser service menus, but I can share some details. Firstly inside Windows.

Here you need to tell a little about the licensing system. The whole range of surgical capabilities is initially limited to purchased licenses. The clinic acquires, for example, 200 standard operations on femto technology. Each activation of a one-time set and the launch of a laser reduce this counter. Keys are purchased separately. After a certain number of operations, the service engineer arrives and collects statistics that are necessary to ensure a strict quality standard. Many of these rules seem unfair, but you need to understand that this is not about producing titanium discs on the machine, but about the vision of living people. Ophthalmic surgery companies highly value their reputation and closely monitor the smallest deviations in the operation of their products. It is this system that allows minimizing potential risks and ensuring maximum quality of vision for patients.

Disposable treatment-pack - sterile consumables with marking and serial number.

Doctors discuss with the engineers the latest nuances

The latest test launches are held on special models, most similar to the human eye. Unfortunately, for several reasons, I cannot publish more detailed photos of the test targets themselves.

We learn more about VisuMax

We will look at the technology of the operations themselves and their variations in the following articles, and now we will try to tell a little more about the VisuMax femto-second laser. It will be a question only of one of possible options - classical Femto-LASIK. The task of the femto laser to remove a thin flap from the cornea - flap. The shape of this flap is calculated in advance and has a complex three-dimensional configuration.

Schematic representation of the future of the flap on the planning screen of the operation

In order to accomplish this difficult task, the laser acts as follows: a precisely focused pulse in the ultraviolet range evaporates a very small area of the cornea at a given depth. Expanding gases form a bubble with a size of about 1-2 microns. The energy transmitted to the cornea per pulse is approximately 130-170 nJ. The next microbubble is formed at a distance of 3-4 microns, depending on the settings. The trajectory of movement has a spiral structure. The pitch between the turns of the helix is usually 3 µm.

You can directly observe the process of flap formation in the video below:

For the patient, it is absolutely painless and looks like a temporary veil in front of the eyes. The operating time of the laser is only 15-25 seconds.

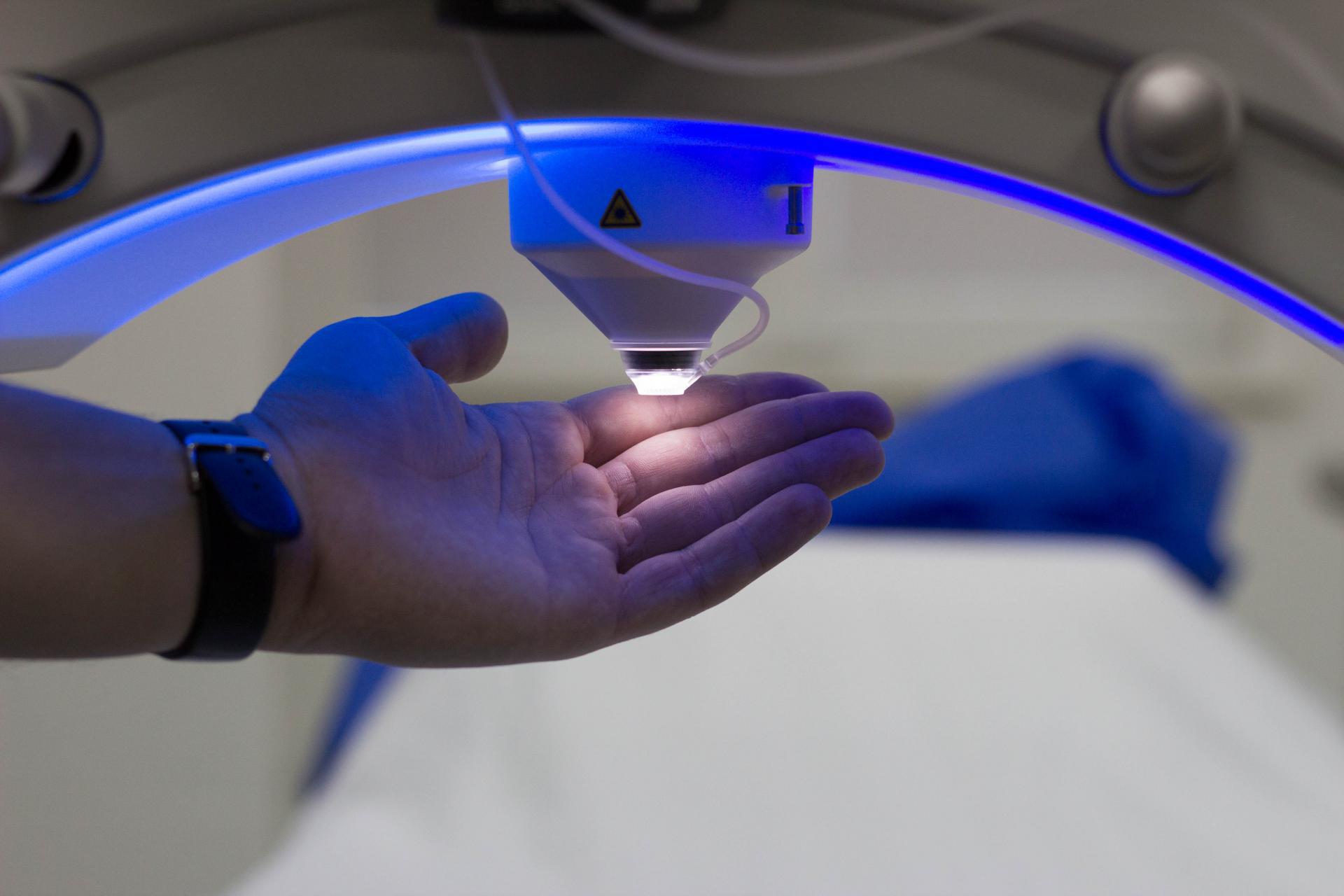

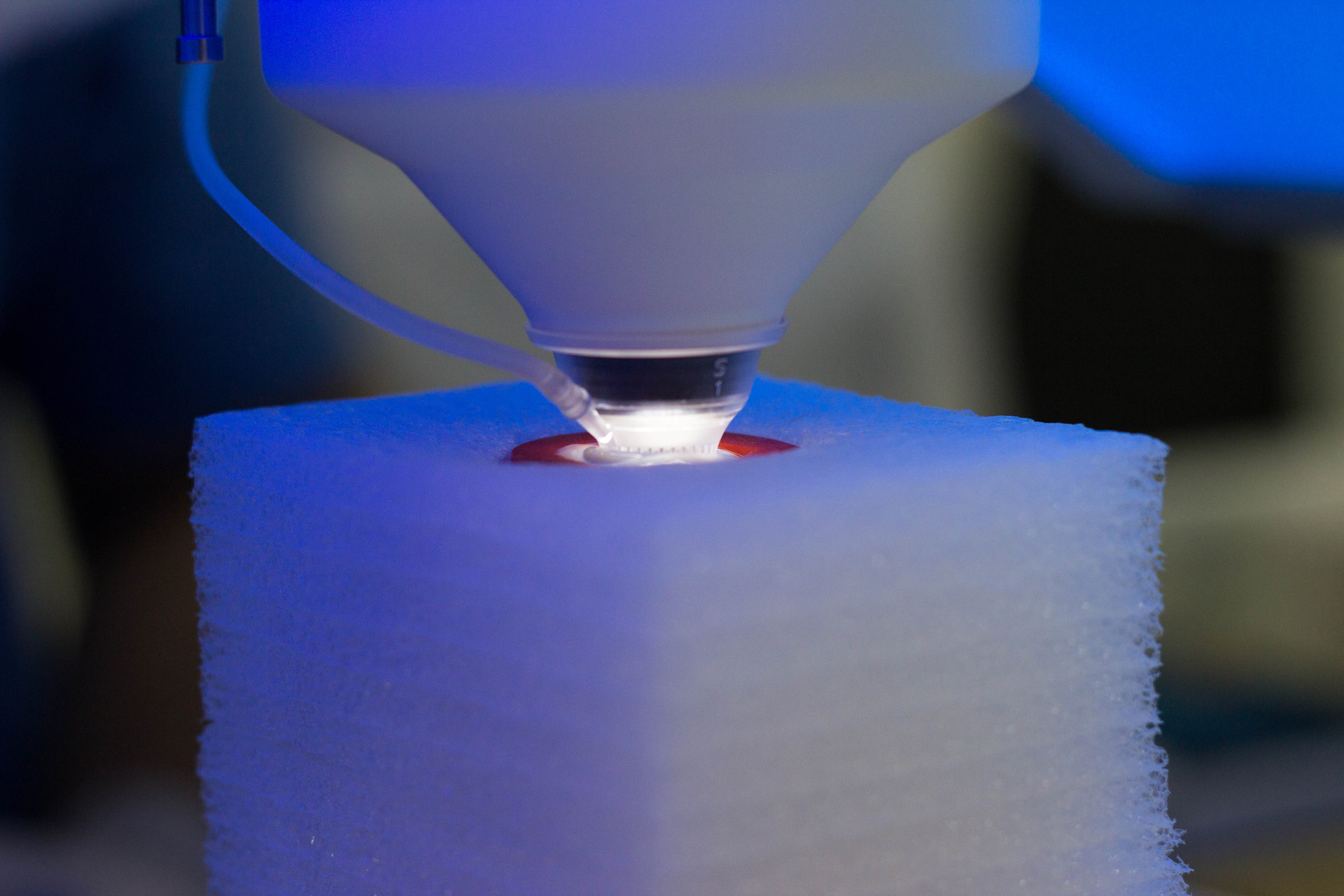

In order to ensure accurate guidance during the formation of the flap, special consumables are used, which have already been mentioned earlier. Their essence is to create a zone of reduced pressure in the area of contact with the cornea, which ensures reliable fixation during operation.

One end of the tube is fixed to the vacuum aspirator, the other to the working part of the laser

After the flap is formed on both eyes, the surgical table turns and control is transferred to the second “hero of the occasion” - the Amaris excimer laser.

Amaris and its tasks

Amaris 500E is one of the newest devices for laser vision correction. His task is to evaporate the strictly specified amount of corneal tissue after the surgeon raises the flap with a special tool. After the operation, the flap is flattened back and does not require any special fixation.

Features of this laser:

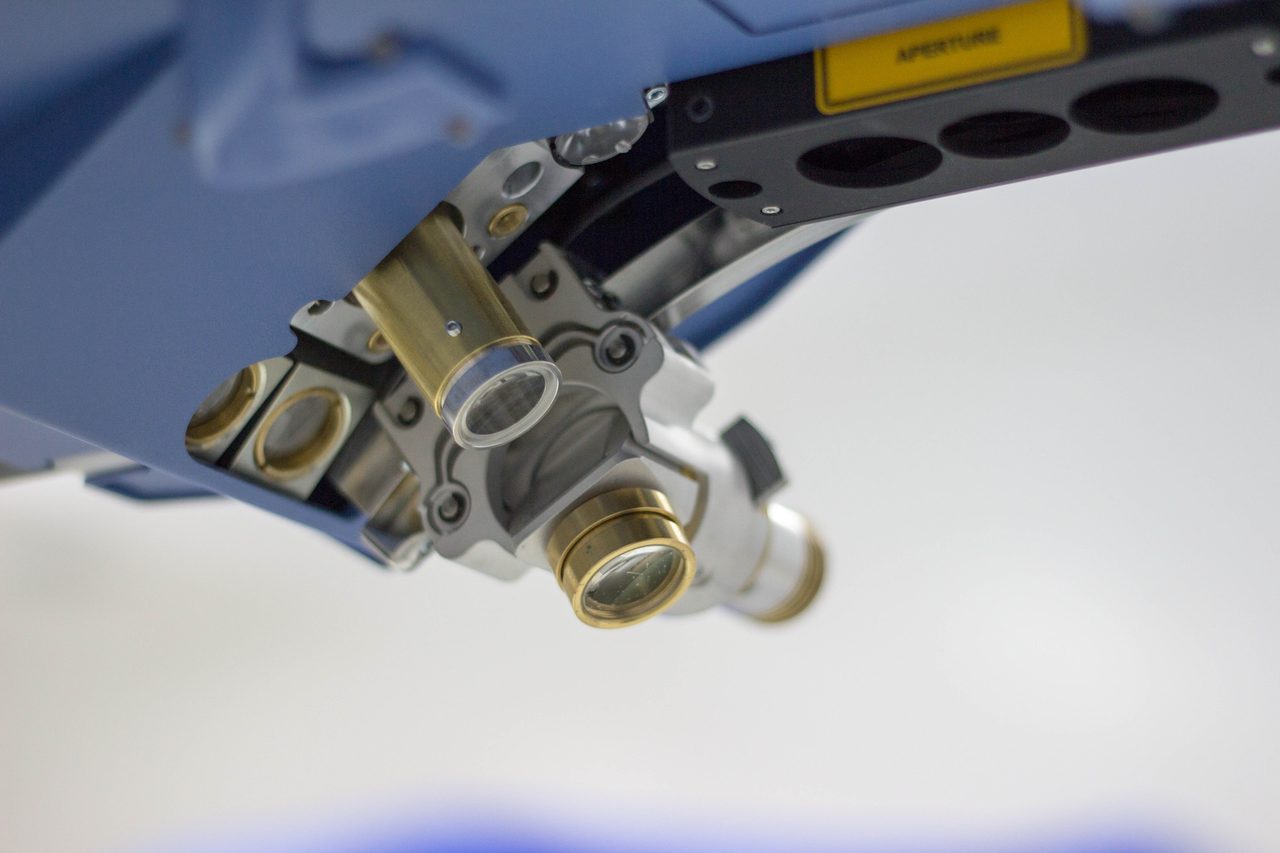

Eye tracking in multiple dimensions.

Accuracy in Amaris 500E provides a unique built-in tracking system. It tracks eye movements 1050 times per second in five dimensions and compensates for the slightest change. Thus, a laser pulse always hits exactly the calculated spot. This greatly increases the accuracy and, therefore, the safety of the correction.

Minimum procedure time

The Amaris 500E is faster than other laser systems. For example, it is 5 times faster than the NIDEK excimer laser (Japan). Amaris 500E corrects myopia by 1 diopter in 2 seconds. That is, it is possible to remove the myopia of one eye in -8 diopters in just 16 seconds.

Very small beam diameter

This feature allows you to perform evaporation with high resolution, achieving the highest quality and accurate surface of the cornea. As a result, patients often see better than with glasses or contact lenses before surgery.

Constant measurements of the temperature and thickness of the cornea

The on-line pachymetry system built into the laser throughout the entire procedure provides the surgeon with information on the cornea thickness. The doctor sees all the changes on the screen. Corneal thickness is determined before, during and after surgery. This maximizes the safety of the procedure, as it allows the surgeon to constantly see how much tissue has already been “removed” and how thick the untreated cornea is. In addition, the laser is equipped with a unique temperature control system, which does not allow tissues to overheat. The result is a minimal thermal effect on the cornea, which shortens the recovery time and ensures quick recovery.

Such a neat mini-jack made in Switzerland. Used to set the height of the calibration target.

More photos near

Slit lamp, visualizing the transverse structure of eye tissue

Laser in the process of calibration. Checks the composition of the gas mixture and a number of other parameters.

Slit lamp, visualizing the transverse structure of eye tissue

Laser in the process of calibration. Checks the composition of the gas mixture and a number of other parameters.

The final. First happy patient

For ethical reasons, I will confine myself to a small number of photographs of the operation itself, but, looking ahead, I can say that the result was excellent. The ideal correction is strictly according to the prescribed treatment program.

The patient is awaiting surgery.

Our ophthalmic surgeon, Boyko A.A., talks with the patient, giving recommendations and explanations before the operation

Engineers monitor VisuMax performance

Amaris interface. The planned map of the evaporation of the cornea

After VisuMax, Amaris takes over. The screen shows the process of tissue evaporation to correct myopia.

Group photo for memory

The whole team, which provided the whole process from the beginning to the end, from the first run to the first patient, who left the operating room without glasses. For some, this may seem like a fairly mundane event, but for us it is a small victory, an important step forward. This is what will allow us to better fulfill the difficult mission entrusted to us - to return sight to people. Thanks to everyone who helped in this difficult work.

Source: https://habr.com/ru/post/211272/

All Articles