Photo report of the construction process of the data center "DataPro Tver". Part I

The construction of the DataPro Tver Data Center is a good example of proper project management. The work on the creation of the data center was carried out in accordance with a clearly controlled schedule and was completed as soon as possible: in May 2013 the builders arrived at the site, and in mid-November the data center was put into operation.

Located within the city, the building where it was decided to place the DataPro Tver data center was originally occupied by an industrial enterprise. Subsequently, a business center is located here.

The area adjacent to the back of the building at the initial stage of construction was a free site, which they decided to use to house a transformer substation and diesel generator sets. The windows on the first floor are not brick.

')

On the second floor it was planned to accommodate office and warehouse premises, as well as a fire extinguishing system and two cross-country rooms for the placement of telecommunication racks.

The central heating batteries in the rooms where it was supposed to install the air conditioning system were dismantled.

Window openings are prepared for laying them brick.

Beacons in the form of metal guide pipes were installed on the prepared floor surface, which were subsequently filled with cement mortar.

The premises of the second floor are located above the four engine rooms to accommodate racks with client equipment.

Therefore, special attention in the premises of the second floor is paid to waterproofing.

The windows of the first floor, where the tight areas of the server rooms are located, are bricked up.

To increase the load capacity of the floors of the second floor in the zone where the gas extinguishing system module is located (using heavy gas cylinders), a reinforcing metal frame structure was installed.

The fortification of the first and second floors has been completed. Completed screed.

Fully made waterproofing of the second floor of a special waterproofing coating. It is also worth noting that the capacity of the entire heating system of the building is only 1 m³ of water, and all the risers and pipes are brought into rooms where there is no electrical equipment.

The foundation on which the fire extinguishing station is installed is lined with bricks. A route has been prepared for laying pipelines through which gas will be supplied to the premises.

The second floor is shed with water: waterproofing quality is being tested.

The installation of wall sandwich panels.

On the second floor, the installation of a framework made of a metal profile for the installation of drywall has been completed:

On July 17, the installation of metal support frames for the installation of external air conditioner units began on the roof of the main building. Outdoor units (compressors and fans) are mounted at some distance from the roof surface: they are mounted on brackets with mechanical protection in the form of gratings and fixed with anchor bolts to eliminate the effects of vibration.

Due to the fact that the data center is located in the historical center of Tver, on the territory of a business center with administrative premises, it was necessary to take measures to suppress noise: use more fans with a lower rotational speed.

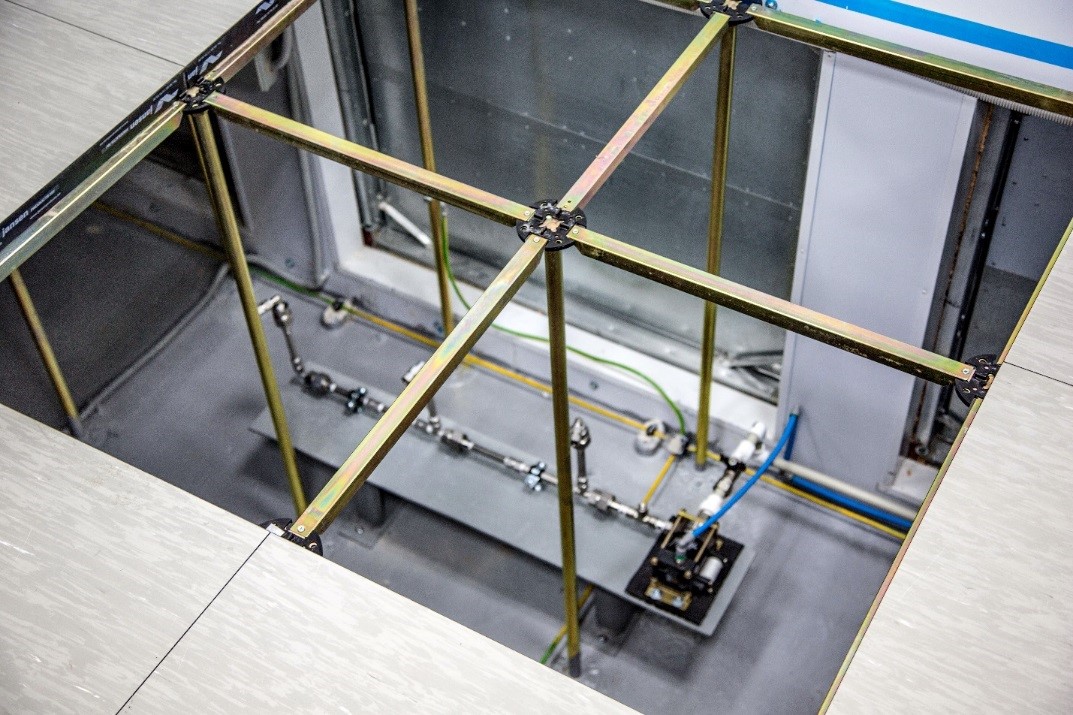

To accommodate them, a special room has been created - a ventilation chamber located between the rooms of the machine rooms. In the ventilation chamber, pre-assembled supporting metal structures are strong enough to withstand the internal blocks of air conditioners and suppress vibration. At the same time, the required height of the raised floor (1.2 M) is ensured to ensure efficient heat and air exchange.

Above the air conditioners there are special hatches with automatic valves through which hot air is drawn from the car rooms.

When installing the cooling system, requirements regarding the length of the path between the blocks up to 30 meters and the height difference up to 15 meters are taken into account.

Air conditioners are included under the scheme N + 1. Cold air in the gates is supplied from under the raised floor, from bottom to top, for this purpose, special hatches with automatic shutters are also provided in the lower part. In server rooms, the air temperature is maintained at 18–27 ° C and humidity is 40–60%.

The process of forming the premises of the first and second floors continues. There is an installation of wall panels.

The adjacent territory has laid the foundation for the installation of a step-down transformer substation.

Gas cylinders are installed on the second floor in the area of the fire extinguishing station and a fire alarm system is installed.

A room has been prepared to house the UPS system and battery racks.

An external ground loop is being installed around the building.

The floor in the room shield reinforced reinforcement.

Located within the city, the building where it was decided to place the DataPro Tver data center was originally occupied by an industrial enterprise. Subsequently, a business center is located here.

The area adjacent to the back of the building at the initial stage of construction was a free site, which they decided to use to house a transformer substation and diesel generator sets. The windows on the first floor are not brick.

')

May 23, 2013

Before the reconstruction of the building, an engineering survey of building structures was carried out to determine the bearing capacity of floor slabs and columns. On the ground floor, it was planned to place four gas stations, rooms for the main switchboard (MSB), air conditioners, UPS with battery packs, that is, to install heavy equipment.On the second floor it was planned to accommodate office and warehouse premises, as well as a fire extinguishing system and two cross-country rooms for the placement of telecommunication racks.

The central heating batteries in the rooms where it was supposed to install the air conditioning system were dismantled.

Window openings are prepared for laying them brick.

May 26, 2013

The survey showed that the floor slabs of the first and second floors of the data center building need to be strengthened. First of all, the reinforcement of the first floor slab was reinforced with a metal grid of strained reinforcement, which would eliminate the risk of failure of the slab under pressure from heavy engineering equipment. Then the structure with reinforcing mesh was poured with a solution of reinforced concrete.

June 6, 2013

The overlaps of the second floor do not require a large load capacity, since office and warehouse premises will be located here. Therefore, the usual floor screed was performed.

Beacons in the form of metal guide pipes were installed on the prepared floor surface, which were subsequently filled with cement mortar.

The premises of the second floor are located above the four engine rooms to accommodate racks with client equipment.

Therefore, special attention in the premises of the second floor is paid to waterproofing.

The windows of the first floor, where the tight areas of the server rooms are located, are bricked up.

July 1, 2013

On the second floor it is planned to place a fire extinguishing station.To increase the load capacity of the floors of the second floor in the zone where the gas extinguishing system module is located (using heavy gas cylinders), a reinforcing metal frame structure was installed.

The fortification of the first and second floors has been completed. Completed screed.

Fully made waterproofing of the second floor of a special waterproofing coating. It is also worth noting that the capacity of the entire heating system of the building is only 1 m³ of water, and all the risers and pipes are brought into rooms where there is no electrical equipment.

The foundation on which the fire extinguishing station is installed is lined with bricks. A route has been prepared for laying pipelines through which gas will be supplied to the premises.

August 14, 2013

On the ground floor, the installation of metal structures has been started, on which wall sandwich panels will be mounted, as a result of which four containment rooms of machine rooms, rooms, MSB, air-conditioning systems and UPS with battery shelves will be organized.

The second floor is shed with water: waterproofing quality is being tested.

July 25 - August 7, 2013

On the ground floor, the installation of a metal frame for the creation of containment zones and corridors is completed.

The installation of wall sandwich panels.

On the second floor, the installation of a framework made of a metal profile for the installation of drywall has been completed:

Roof

According to the plan, it was decided to use the roof of the building to house the outdoor modules of the air conditioning system. The required slope of the roof created with the help of ties made of expanded clay gravel.

On July 17, the installation of metal support frames for the installation of external air conditioner units began on the roof of the main building. Outdoor units (compressors and fans) are mounted at some distance from the roof surface: they are mounted on brackets with mechanical protection in the form of gratings and fixed with anchor bolts to eliminate the effects of vibration.

Due to the fact that the data center is located in the historical center of Tver, on the territory of a business center with administrative premises, it was necessary to take measures to suppress noise: use more fans with a lower rotational speed.

August 9, 2013

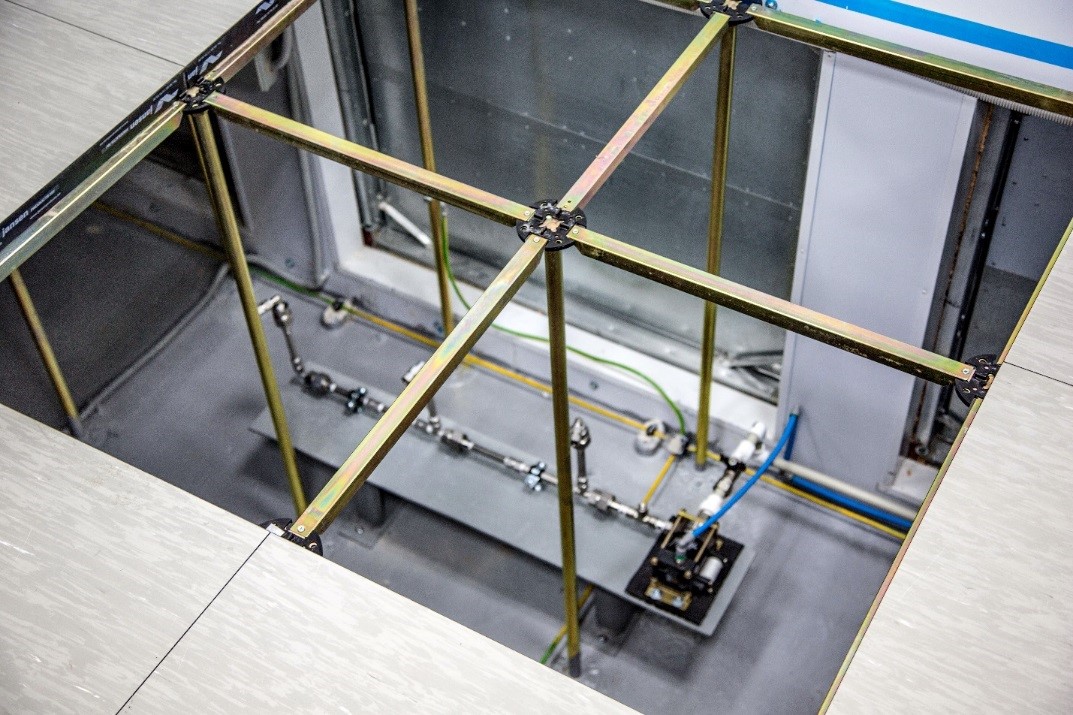

Data center equipment has been delivered to the data center. These are precision air conditioners Uniflair produced by Schneider Electric using freon lines.To accommodate them, a special room has been created - a ventilation chamber located between the rooms of the machine rooms. In the ventilation chamber, pre-assembled supporting metal structures are strong enough to withstand the internal blocks of air conditioners and suppress vibration. At the same time, the required height of the raised floor (1.2 M) is ensured to ensure efficient heat and air exchange.

Above the air conditioners there are special hatches with automatic valves through which hot air is drawn from the car rooms.

When installing the cooling system, requirements regarding the length of the path between the blocks up to 30 meters and the height difference up to 15 meters are taken into account.

Air conditioners are included under the scheme N + 1. Cold air in the gates is supplied from under the raised floor, from bottom to top, for this purpose, special hatches with automatic shutters are also provided in the lower part. In server rooms, the air temperature is maintained at 18–27 ° C and humidity is 40–60%.

August 13 - August 23, 2013

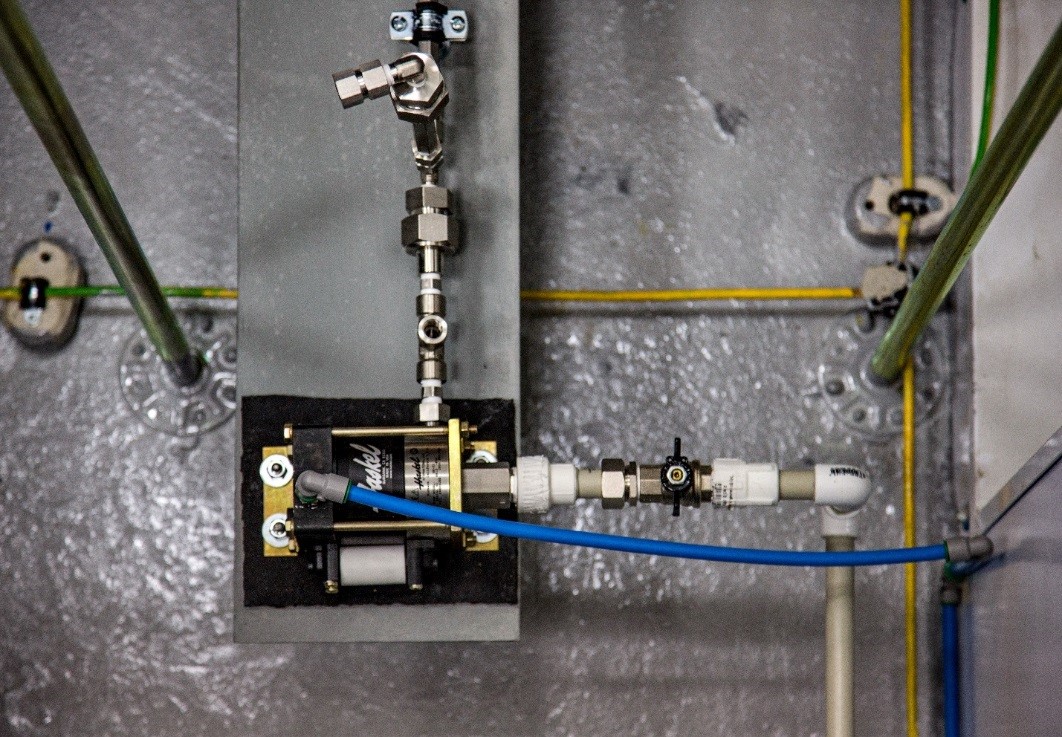

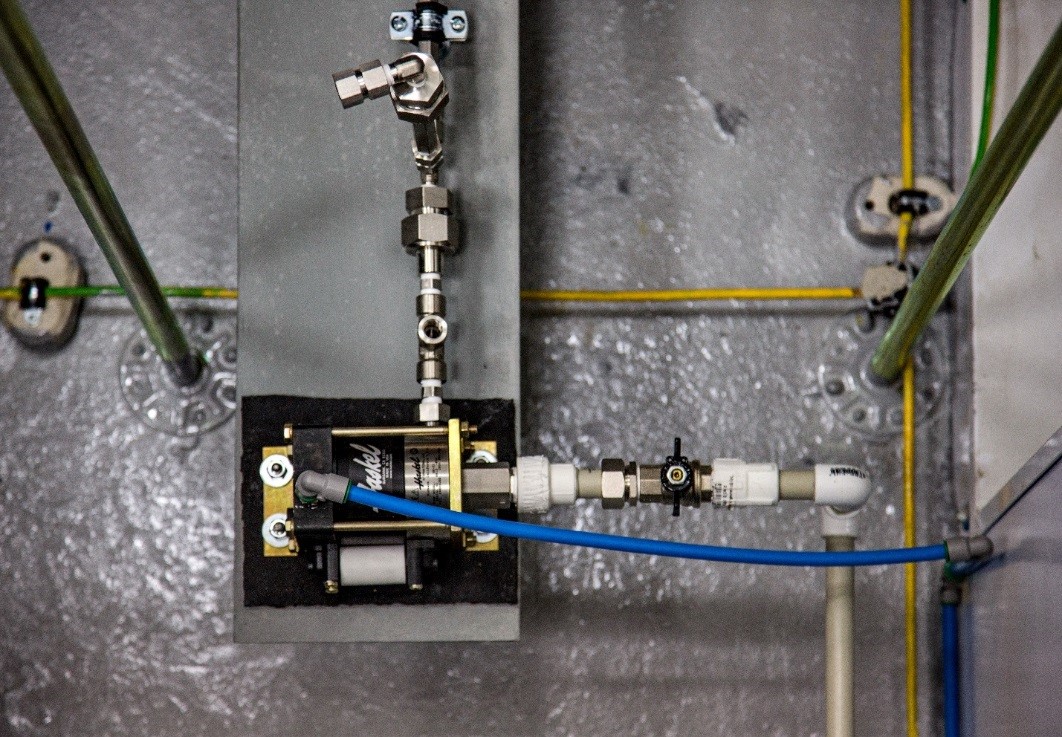

Before getting into the car rooms, the air from the air conditioners passes through the adiabatic humidification system: the prepared water under pressure is sprayed in the air flow through the nozzles, moistened and fed to the gym. Water consumption when using this method is small, but the energy savings are significant.

The process of forming the premises of the first and second floors continues. There is an installation of wall panels.

September 11, 2013

The premises of the first floor of the data center are practically prepared for the installation of equipment. On the second floor, the installation of the profile metal frame was completed.

The adjacent territory has laid the foundation for the installation of a step-down transformer substation.

September 14-27, 2013

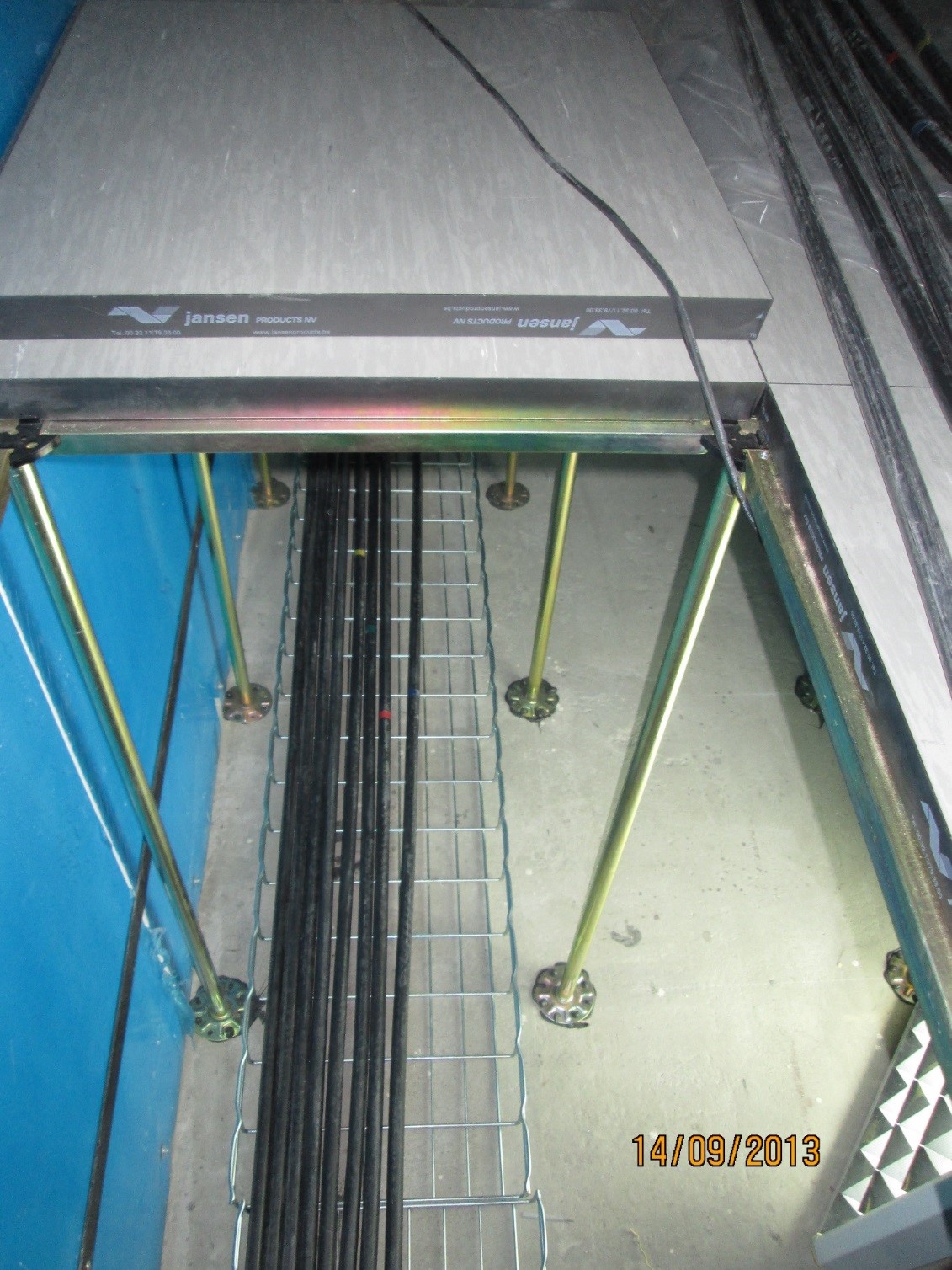

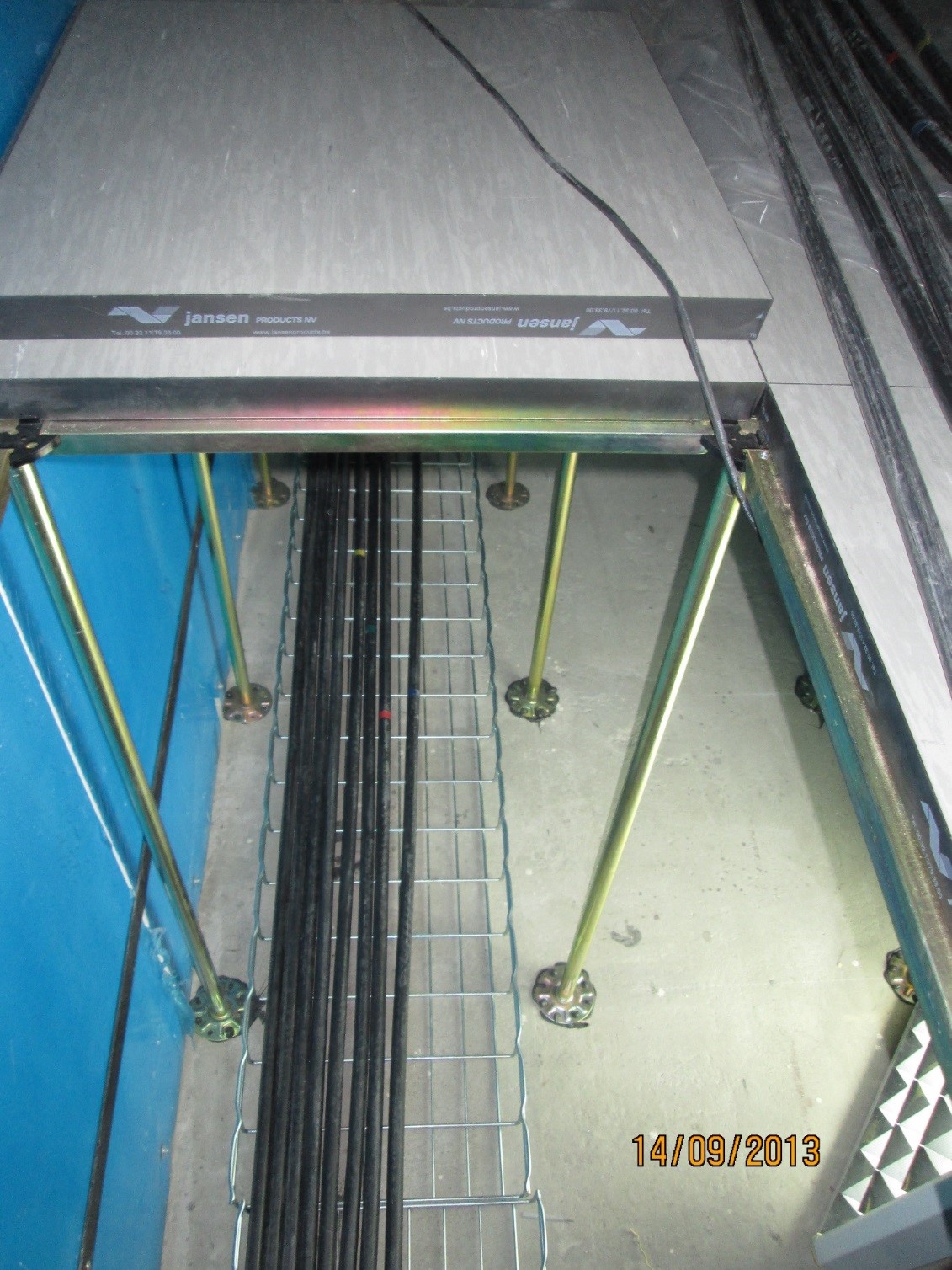

By September 14, cable ducts were installed in the underfloor space. Mounted raised floor in the process rooms.

Gas cylinders are installed on the second floor in the area of the fire extinguishing station and a fire alarm system is installed.

A room has been prepared to house the UPS system and battery racks.

An external ground loop is being installed around the building.

The floor in the room shield reinforced reinforcement.

Source: https://habr.com/ru/post/210578/

All Articles