The history of the development of a well security system: through thorns to intelligent sensors

Today I want to tell you about our experience in the development of cable manhole protection systems, which are operated by telecom operators. For the past 9 years we have been dealing with this complex topic. How many technical solutions have been tested, how many “copies broken” during this time, and here are some of the reasons:

Today I want to tell you about our experience in the development of cable manhole protection systems, which are operated by telecom operators. For the past 9 years we have been dealing with this complex topic. How many technical solutions have been tested, how many “copies broken” during this time, and here are some of the reasons:Firstly, the aggressive environment of the well (temperature drops, flooding) is destructive for any electronics;

Secondly , installation in a well is not convenient - it requires different stages of sealing and well-designed recommendations from the manufacturer.

Add to this low profitability (the technical solution must be inexpensive, because there are at least hundreds of wells within each branch) and the need to be responsible for the result, which under such conditions is hardly predictable - here’s a set of reasons why only a few manufacturers do this work the world.

')

We are "brought" in this topic by the "wind of history." So historically, with the topic of control of linear cable structures , of which the protection of wells is a part, began our hardware-software complex "Sensor-Technotronics". Therefore, we were involved in this issue, and now our interest is determined to a greater degree by responsibility to numerous users and professional pride, than the level of profitability of the product.

For reference: why is it necessary to protect the cable wells?

For those who are far from this topic, I want to clarify that cable sewer wells are part of linear cable structures operated by a telecoms operator since Soviet times. Through cable wells access to the trunk cable, which is a desirable prey for homeless people and other intruders. In addition, the iron cap itself is of interest to scrap metal seekers. And finally, the last danger from which setting wells on an alarm eliminates is the unauthorized laying of cable by competing operators who do not have their own infrastructure (cable ducts).

The first pancake - lumpy

The first solution that existed on the market at the beginning of the two thousandths and was made by us is the control of wells on the basis of the USRI96 controller. During operation, it turned out that it does not fully satisfy either the criteria of reliability (devices placed in wells, often failed due to humidity and flooding), nor the criteria for ease of installation. The fact is that there were only 16 wells on one pair of wires (there were six entrances for such pairs on one device), so additional wires had to be laid and when the route had an extensive topology, and when there were more than 16 wells on one route, in most cases this is the case.

2007 - Matrix way to control wells

In 2007, in spite of the previous experience, we developed a unique technology - the matrix method of well control. The matrix method did not require the installation of active electronics in the wells, and therefore was the most reliable - there was simply nothing to break. As a communication line in this system, the cable of the Chamber of Commerce and Industry (or another) was used, which connected the well opening sensor to the MAKS LKS controller located on the PBX. In the matrix method, the address identifier of the opened well was not active electronics, but a certain pair of wires connected in a special way. I will not describe the essence of technology here - it is not the easiest to understand and requires a separate conversation, but those who want to understand can follow the link . I can only say that with the obvious advantages of popularity in Russia, the method has not won. Among the reasons customers called complexity to understand and significant cable consumption. But in Kazakhstan, the matrix method gained recognition - Kazakhtelecom controls its wells in this way and continues to equip routes.

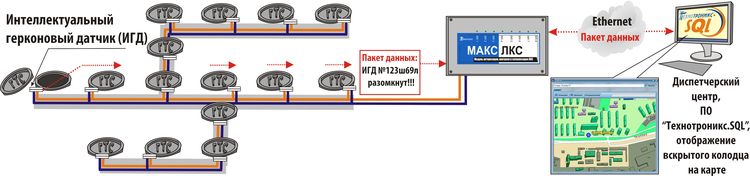

2009-2011 - development of Intelligent Reed Sensors (IGD)

So, once the solution satisfying all was not found, we continued the search. And in 2009, a new element base appeared in the world (a microprocessor with the necessary characteristics), which made it possible to develop an Intelligent Reed Sensor (IGD) . DIG are magnetic contact detectors with a built-in electronic board that constantly transmit data about their condition to the MAKS LKS or MiniMAX controller , which is usually placed on the PBX. DI are distinguished by speed (fixation time of the autopsy - 0.1 sec., Data delivery time to the Dispatch Center - 1 sec.), Resistance to interference, lightning noise, internal short circuits. In addition, the failure of one or more DGD sensors does not affect the operation of the others. But the most important advantage of the system based on IHD was ease of installation. The technology allows targeted control of one pair of wires at least 64 wells and therefore is ideal for any routes, even with a complex branched topology.

Fig. 1. Scheme of the security system based on intelligent reed sensors (IGD)

Thus, both with electronic filling and with mounting technology everything was wonderful, one question remained - reliable sealing of electronics. Since the sensor was originally made on the basis of a known tamper-proof type IO102-20 type opening sensor, we placed the installation and encapsulation of our electronic boards at the manufacturer of these sensors. The second stage of sealing, of course, had to be performed by the user during installation - it was necessary to seal the junction between the sensor and cable wires. We were very pleased with the development, however, at the first flood, the sensors began to fail. As it turned out on the basis of the travel of our specialists, some of the sensors or the junction of the sensor wire with the track could not stand for many days in the water in the flooded well. Particularly problematic were the tracks, mounted without proper adherence to the installation rules developed for this system. Trails mounted by all the rules, in general, worked properly.

Photo 1. Intelligent reed sensor IGD in the old building. year 2009.

However, to blame on mounting flaws is not a solution. Our developers understood that it is necessary to radically revise the design of the sensor itself and the wire in terms of sealing and to make it so as to minimize the impact of the factor "quality of installation" on the performance of the system.

We also understood that a reliable solution for sealing needs to be found in a completely different area - not from manufacturers of sensors, who simply don’t have to have developments on this topic. First of all, we thought about the manufacturers of products for the oil and gas industry or the defense industry. And we were lucky! We found a partner whose own developments in sealing were suitable for solving our problems as well as possible. A small remark: we don’t want to disclose the name of our partner’s organization in order to make it difficult for competitors to copy our technical solutions.

Our then future partner enthusiastically responded to the proposal to resolve the issue of sealing our "well" sensor and the cable connected to it. And the work began to boil: numerous approvals, business trips, tests, further strengthening of the structure, again tests and revisions. And finally, we have an IGD sealed in such a way that no “paranoid” could find fault, because it was sealed by the “paranoids” themselves, who constantly ask questions from the category “but if force majeure and ....” happen. Below are the results of our joint efforts.

Monolithic polyurethane "cocoon"

Photo 2, fig. 2. Modern intelligent reed sensor IGD

The case of the device and the sensor cable connected to the highway is a single unit made of polyurethane. Polyurethane is a synthetic polymeric material, which is called “material with unlimited possibilities” because it:

- First, it is completely sealed and commonly used for waterproofing.

- Secondly , the operating temperatures of polyurethane products lie in the range from minus 70 to 100 ° , while the elasticity practically does not change.

- Thirdly , polyurethane has high dielectric properties, which is very important for the insulation of electronics.

- Fourthly , polyurethane has a high mechanical strength, because it is not for nothing that parts and units of machines that are subjected to high dynamic loads are made of it, and there is nothing to say about the production of polyurethane soles and naboek.

Sensor cable has 4 degrees of protection

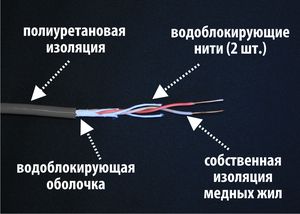

Fig. 3. Layers of cable insulation

The polyurethane cable used in the sensor is the development of our Partner, the first use of which is operation under conditions of constant immersion in water (it was used in cable systems for underwater installation). Therefore, it is unnecessary to talk about the durability and tightness of this cable - this is obvious. Initially, this cable had 2 degrees of protection against moisture penetration, but at our request a third and fourth one was added.

So, firstly , each copper conductor inside a polyurethane cable IGD has its own insulation (there are two wires in the cable - for power supply and for transferring information to the dispatch center (DC), it is also used to control the IGD from DC to reset the sensor).

Secondly , there is another insulation layer on top - polyurethane, about which I have already described above the unique physicomechanical characteristics.

The third and fourth degree of protection , performed at our request, are, firstly, 2 specialized water blocking threads inside the cable and intertwined with wires for greater reliability and, secondly, a water blocking sheath which wraps the wires with the sturdy stocking . The main task of water-blocking materials - filaments and shells - to absorb moisture, if suddenly the polyurethane insulation is somehow broken in some way incomprehensible to us. In this case, hydrophobic materials absorb moisture, turning into a gel, and prevent further penetration of water, becoming a layer of insulation in a damaged place.

Thus, all components of the IHD - the case and the cable - are sealed with the same material, which is the main advantage of the sealing technology. The homogeneity of the materials provides excellent adhesion, that is, the sensor sheath and the connecting cable are very well bonded to each other. By the way, the sealing is so good that it withstands the pressure of a water column up to 200 m high, that is, 20 atmospheres. This was established by crimping the sensor in a pressure vessel.

The last question remained - the technology of sealing the junction of the sensor wires and the route. And we thought it through thoroughly.

Photo 3. The appearance of the sealed connection of the sensor with the cable type PRPPM

First , the sensor wire has a diameter of 0.78 mm. Most of our customers are oriented when installing this system on a low-pair route-forming material, namely the PRPPM cable, the most common diameter of which is 0.9, sometimes found 0.7. Thus, the wires to be connected are approximately the same in diameter and can easily be joined with any clip (the clip used to connect the wires has a certain tolerance on the variation of the diameters of the wires joined together and we completely fit this tolerance).

Secondly , our specialists have selected the most optimal splicing technology of wires available, providing high tightness and minimum labor costs - cold sealing by the 3M technology known among installers.

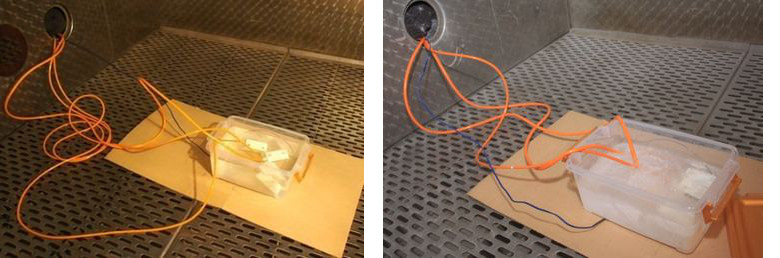

Operational tests in the laboratory of JSC "Morion"

As soon as we received the first experimental batch of IGD, which suited us in all respects, we organized operational tests of sensors based on the Perm factory Morion. Morion is one of the leading communications equipment factories whose testing laboratories are accredited in accordance with the certificate of the Gosstandart of Russia for testing, including third-party products, which we used.

So, in January 2011, the IGD sensors successfully passed the “exam” at the Reliability Testing and Certification Bureau (BINiS) of Morion. The purpose of the test, of course, was to check the tightness of the DI in harsh operating conditions, as well as determining the range of operating temperatures.

In the presence of developers from Tehnotroniks and expert testers from Morion, the IGD sensors were checked for several hours: they were completely submerged and placed in a thermocamera, changing the temperature in it and constantly checking the IHD performance. DIG were first connected to the MAKS LKS controller , and then to MiniMAX . Software "Tehnotroniks.SOL" displayed data from the sensors through the controllers.

Photos 4, 5. Tests of the IHD in a thermal chamber with full immersion in water. Sensor in water, sensor frozen.

Photo 6. Testing the operation of the DI located in the thermal chamber at different temperatures. Sensors are connected to the MiniMAX controller.

After the tests, experts of Morion OJSC concluded that:

- The recommended temperature range of IHD operation is (-40 ... + 50) ° . This is quite sufficient for the use of sensors in the outdoor conditions of the Russian climate, in particular for the protection of wells KKS.

- tests for tightness, which took place with the sensors completely immersed in water for several hours in the temperature range (-40 ... + 50) ° , were crowned with success. Datum fully retained its performance. Moreover, the insulation resistance of the IHD, measured by experts, was more than 30,000 Mom, which is 30 times more than the normal resistance of the “native” cable operator in the CCI, which lies in the wells of the CCM.

All stages and results of tests are officially recorded in the act and test report.

Certificates, Patents for IGD

After operational tests, already being confident that the new design of the sensor, it is also a way of sealing, is really a good solution, we started the process of certification of sensors. And in March 2011, Tehnotroniks received a certificate in the GOST R system for IGD sensors as a guarantee of their quality.

After operational tests, already being confident that the new design of the sensor, it is also a way of sealing, is really a good solution, we started the process of certification of sensors. And in March 2011, Tehnotroniks received a certificate in the GOST R system for IGD sensors as a guarantee of their quality.In addition, there are as many as three patents on IGD. As you already understand, the development lasted two years (2009-2011), and we have consistently patented our achievements: first, the system itself, then the hermetic sensor design, and, finally, the method of protection against short-circuit IGD sensors.

|  |  |

Operating results

Now, 3 years after we found a solution that suits everyone, a large base of implemented projects has been accumulated and there are official reviews about the successful operation of the system. Who cares, please read .

2012 - Intelligent PHOTO sensor or "ray of light in the dark kingdom"

Photo 7. Intelligent photo sensor (IFD)

However, having achieved success, we continued our research, which culminated in the development of the Intelligent Photo-Sensor - abbreviated IFD. What is the essence of the sensor?

Any primary transducer is more effective than the environmental conditions that it (the transducer) responds to more dramatically. So, it is the illumination in the “closed hatch / open hatch” conditions that changes most significantly . As it is easy to understand, with the hatch closed inside the well, total darkness reigns around the clock. Taking advantage of this fact, we oriented ourselves to a sensor sensitive to the faintest light, without fear of its false operating results in the “closed” state. When the manhole cover is opened, even at night, the sensor receives ambient ambient lighting, which is always available in urban environments. And the sensor due to its high sensitivity is triggered. This is the first. And secondly, those who opened the well, will try to either steal the cable or lay an unauthorized route. It is impossible to do both without the use of flashlights and other lighting fixtures.

Also, IFD does not leave any opportunities for sabotage such as "took, quickly covered the sensor with a cap - that's all." The sensor detects and remembers even short-term dissections. And, of course, will transmit disturbing information to the monitoring center.

Its differences from the usual IHD - is a translucent body with the effect of dispersion of the received luminous flux. Well, of course, the absence of the second half - the usual magnet. And here lies its main advantage. They are REALLY much easier to install and operate. After all, the problems of mounting the magnet, its fitting to the reed-off part, breaking off during shocks and throws, etc., disappear. Our users have already appreciated these benefits.

You can find more photos of the mounted IFD on our website. Who wants to get acquainted with the telecom reviews about the operation of the system based on IFD, I ask here

2012-2013 IFD-R, IGD-R - intelligent sensors that disable the short-circuited part of the route.

Almost in parallel with the development of Intelligent Photo-Sensors, we began work on the modification of the IGD, which, in addition to its main function of controlling the dissection, would provide additional opportunities - disabling the short-circuited portion of the route.

The route may be short-circuited for two reasons: 1) the closure of the well control sensor itself, or 2) a leak-tight sensor joint with the track.

In the case of using a dcd, the first option is unlikely. This is due to the circuitry of the IGD sensor: it is designed in such a way that the risk of a short circuit inside the sensor itself is minimized. And this fact is officially confirmed by the RF Patent No. 116671. Therefore, the most likely cause is a leak in the interface between the sensor and the track during installation.

Of course, the elimination of a short circuit is a solvable problem. But finding a problem when a parallel connection scheme is sometimes extremely difficult. After all, most of the time, a leak in the tightness of the track does not occur immediately after installation, and it is not easy to find out in which well it was shorted. And the wells are located at fairly long distances, often in remote places.

Prior to the development of the IGD-R sensors, the way out of this situation, which we saw, was a rather complicated method of searching for a damaged area — the half division method. The essence of the method is that, in the event of damage, first one of the connections of the cable is disassembled near its middle, then its part distant from the MAKS LKS module or MiniMAX is disconnected and it is examined whether the voltage in the cable has increased. If the voltage has increased, the damage is in the far part, if not increased - in the part nearest to the module. Then the procedure is repeated for the part of the loop in which the damage was found, and so on ...

The disadvantages of the method are obvious. First, it is necessary to break a large number of intact, “innocent” compounds. Well, and secondly, the method is quite time consuming and requires considerable expenses in man-hours and, accordingly, "in finance". In general, such a non-optimal way of identifying the place of failure clearly required the creation of an alternative option. And we have developed IGD-R sensors.

IGD-R, in addition to protection of wells, performs the function of an insulating set , that is, it disconnects (forcibly opens) the section of the route following this IGD-R in the event of a short circuit of this section. Disconnection occurs by opening the corresponding electronic keys inside the sensor, hence the prefix "P" in the name of this device.

After the route is opened, the Customer needs to check for leak tightness only that part of the route that is between this IGD-R and the next one. Thus, IGD-R becomes for the Customer a tool for segmentation of the route and, in the event of damage to the route and the occurrence of a short circuit, will indicate a problem location or area. Examples of placing IGD-R on different types of tracks, IGD-R connection diagram and many other details can be found in a separate article dedicated to this device .

Soon after the development of IGD-R, we, of course, made a similar modification for IFD. Thus, our latest device was developed for this direction - the IFD-R sensor.

Summarizing ...

Now we offer the Customer a choice of 4 types of sensors, which, by the way, are absolutely compatible with each other and can be used in any combination:

- The intelligent reed sensor IGD is a “reed magnet” sensor, which has all the advantages listed above.

- Intelligent reed sensor IGD-R is a modification of the sensor IGD that allows you to specify the part of the route on which a short circuit occurred.

- Intelligent Photo-Sensor IFD - a unique sensor that works on a photo-principle. IFD responds instantly to light that falls into the well when it is opened, even at night.

- Intelligent Photo-Sensor IFD-R is a modification of the IFD sensor, which allows you to specify the part of the route where a short circuit occurred.

All of them work with the MAKS LKS or MiniMAX controllers placed on the PBX.

In summary, once again I want to list the advantages of smart sensors :

- Speed: IGD and IGD-R fix the opening of the well in 0.1 sec., IFD, IFD-R - for 0.3 sec., Data delivery time to the control center using IHD and IGD-R - 1 sec., IFD - 5 sec.

- Resistance to interference, lightning and internal short-circuits.

- Targeting: accurate identification of each well in case of opening.

- Operation even with a break: the break of one or more sensors IHD or IFD does not affect the operation of other sensors.

- Guaranteed information delivery: even with simultaneous operation of several sensors, a signal from each of them will come to the control center.

- Operating temperature range: from -40 ° C to + 50 ° C, which corresponds to the conditions of operation of wells KKS ..

- Full tightness:

- The electronic board of the sensor is hermetically sealed in a monolithic polyurethane case;

- Reliable tight connection of the sensor case and cable;

- A copper pair of wires has 4 levels of protection against ingress of moisture: polyurethane insulation, water blocking threads, a water blocking sheath, and own insulation of copper wires.

The cost of sensors IGD, IFD - 1534 p. VAT included.

Source: https://habr.com/ru/post/210184/

All Articles