LED workplace lighting

I read for a long time, I couldn’t decide what to write, what would be useful and interesting for others.

And now, having once read the article Home CNC milling cutter of the user vbifkol , I decided - this is it!

A year ago, when I was still a beginner and a greedy newbie, I decided that I could take something cheaper and trample me. I bought one machine, produced in small batches by one person. As a beginner machine, the machine was an acceptable choice. But as they say, the miser pays twice. Being a sociable person, he told friends to advertisers about a machine tool and immediately received the first trial order. And then it began, it is not so, it is not so - there is no speed, the accuracy is not the same, the working field is ridiculous (33 by 43 centimeters). Having rushed a little more than a year, it was decided to sell the machine and take the machine of industrial assembly. If you are interested in what happened in the end,

Since I am a humanist (a physicist by training), I began an active search by studying specialized forums. The links to these forums are not intentionally indicated, if it is interesting, then I will publish the links. Studying the forums - it came to an understanding of what I need - and what parameters need to be voiced by sellers.

')

So, the choice was limited to the following:

1. the control of the CNC should be carried out by the DSP processor;

2. The working field must be at least 90 to 60 cm, and the height of the workpiece at least 100mm;

3. the spindle must be water-cooled, at least 1.5kW;

4. the presence of the sensor tool for setting the height along the Z axis.

Almost 2 weeks spent on correspondence with 3 sellers, in the process of conversation reducing the number of sellers and specifying all sorts of subtleties, including such as shipping, packing machine, availability of a guarantee and so on. Due to the peculiarities of the rented premises and the lack of regularly transporting almost 200 kg, it was decided to take a desktop version of the machine (the desktop one is conditional, since the table was welded, the so-called bed).

Having paid almost 200 thousand rubles through a bank transfer, he began nervously to expect a letter from the seller to receive the money. 3 days later I received the message "the machine was sent to the transport company, wait for the call." When receiving time was spent 4 friends, the jeep of one of the friends was shot down - at the wrong time the pickup door was open.

A week later, after reading the article about home cnc router, it was decided to finally do something useful for the house. Being an active PC user, I was constantly concerned about the issue of workplace lighting. A table lamp, equipped with an energy-saving lamp, gave too little light, and the lamp burned out with frightening regularity. Changing a lamp at the price of 90 rubles 2-3 times a month turned out to be a very sad process.

So, the implementation of the topic was a matter of decision.

I thought for a long time how to solve the issue of organizing the background lighting behind the monitor. There was an option - to glue the LED tape on the back panel of the LCD monitor, but then this option was discarded:

1. the tape heats up quite noticeably, and I decided that for the monitor such heating would not be good;

2. The power supply for the LED strip will still hang on the table uncontrollably;

3. there is a high-tech unit;

4. P1-P2 in combination will look very impartial, and P3 did not give a reason to do so at all.

As a material, it was decided to choose 10mm plywood. Plywood is quite convenient material for processing on the CNC router, the price is very budget. A plywood sheet was bought at the nearest hardware store for 450 rubles (1.5m x 1.5m)

Electronics was purchased:

1. 1 meter of LED tape (I don’t remember the name, it was just the brightest tape in the store) - 260 rubles;

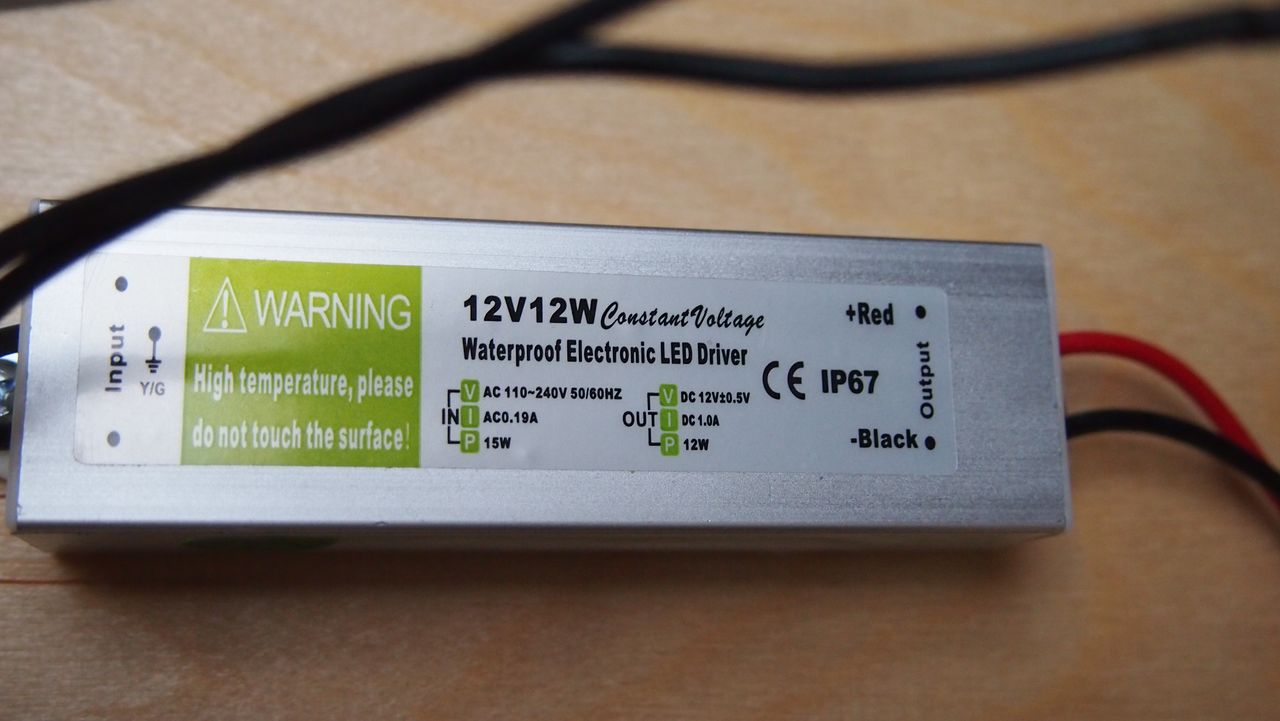

2. power supply 12 watts - 320 rubles;

3. plug for connecting to the network - 25 rubles;

4. meter of wire to connect the power supply to the mains 220V - 12 rubles.

Total: 617 rubles.

Having spent a lot of time, following the principle of 7 times, 1 cut off, the necessary dimensions were chosen (looking ahead, I say, I still missed).

The whole process of cutting parts for the stand took about 15 minutes. Slightly less than 30% of the time was spent on fixing plywood on the desktop.

So, I prepared, opened the tube of glue "Moment" and the process went:

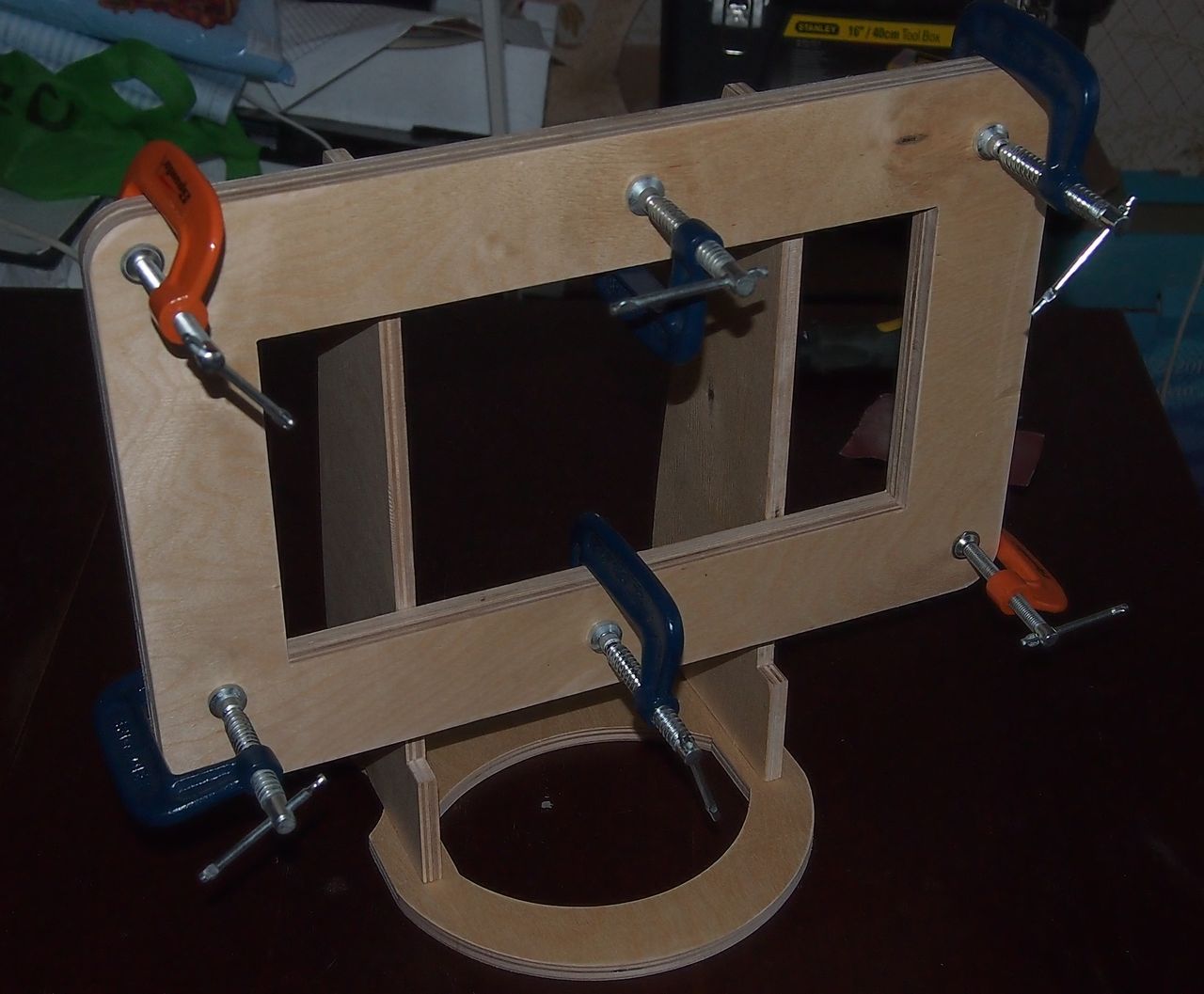

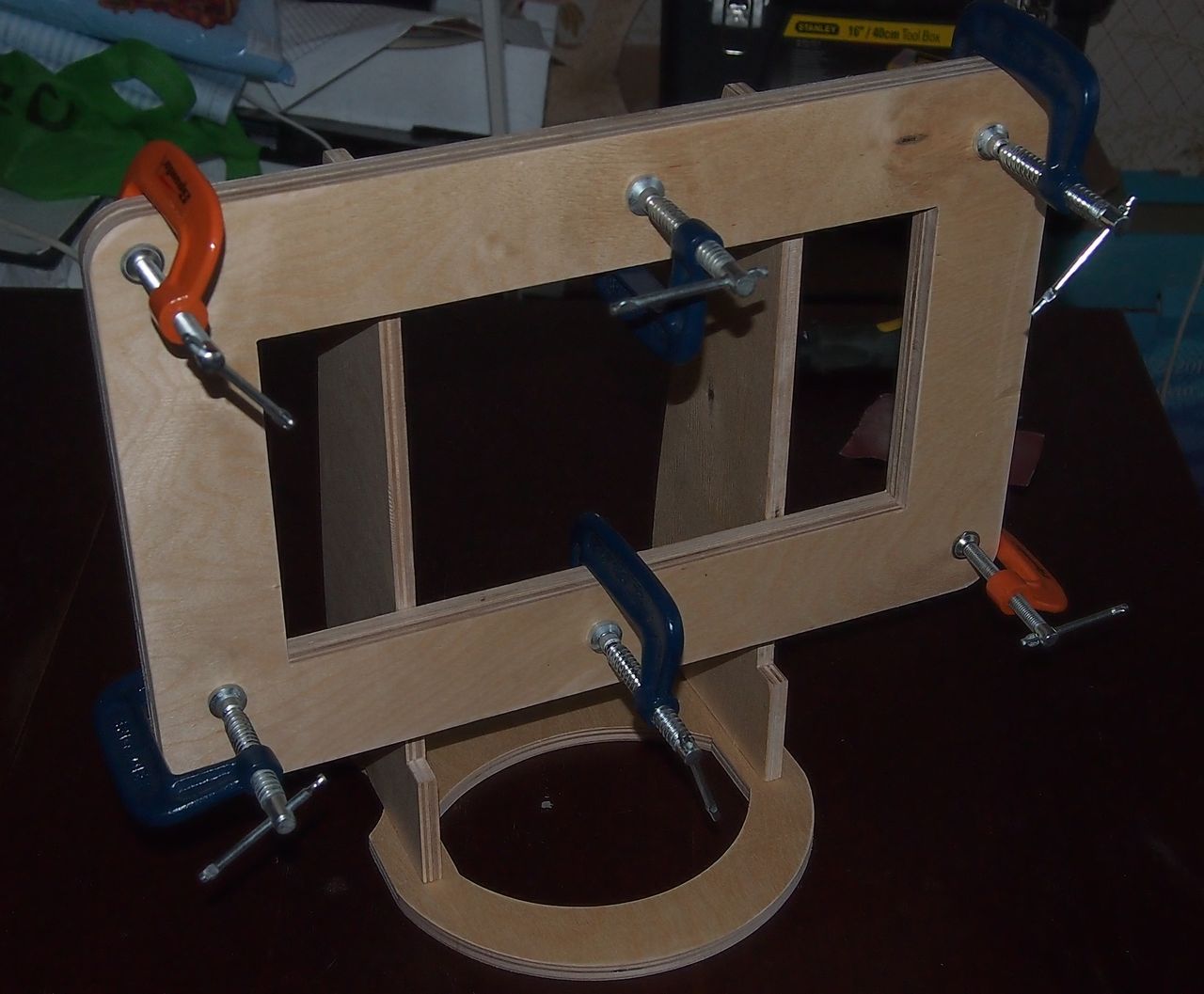

After waiting an hour with deprive took off the clamp, and here it is, stand:

back view

she's in full face

Making sure that the glue grabbed and the halves of the supporting structure do not diverge, it was decided to glue the LED tape:

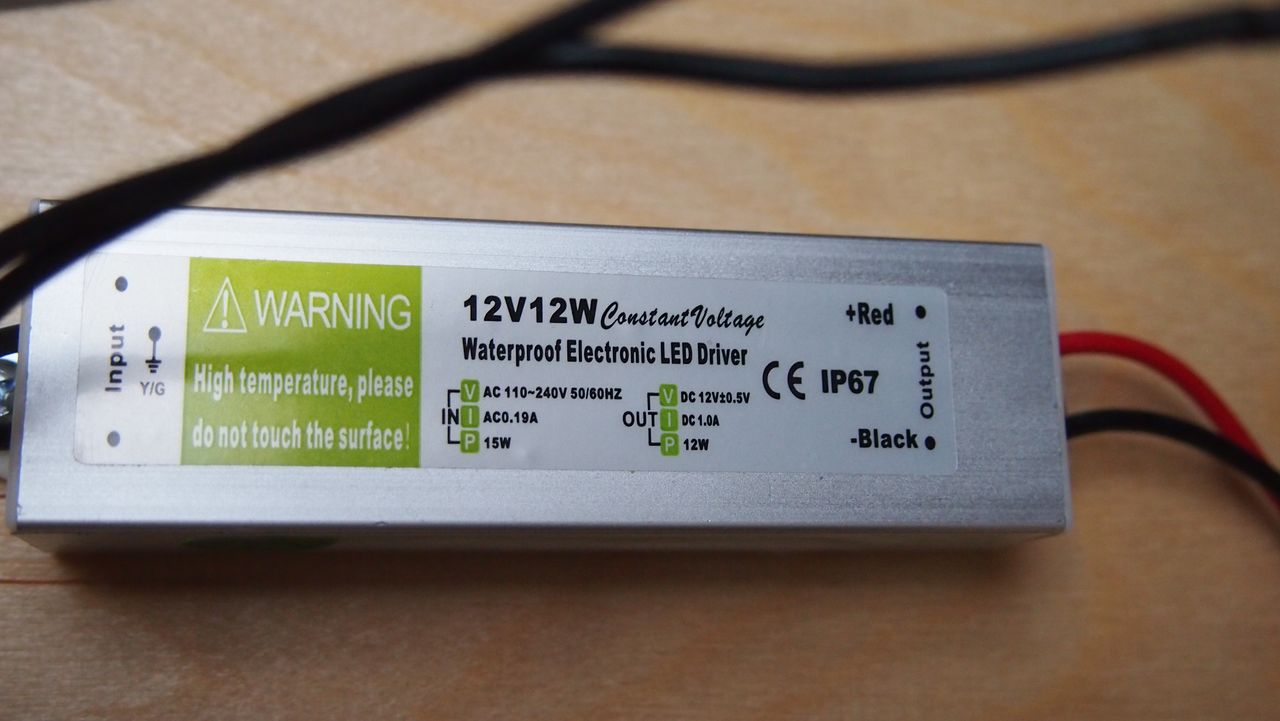

on one of the side racks was mounted power supply:

Having completed the installation of LED strip, power supply and sockets, conducted a trial run of the structure:

(The camera made its decision, and the trick "floated away." The use of the wire was due to the fact that the complete 2-sided adhesive tape had very low adhesion to plywood, and when heated, the free end of the LED strip began to sag)

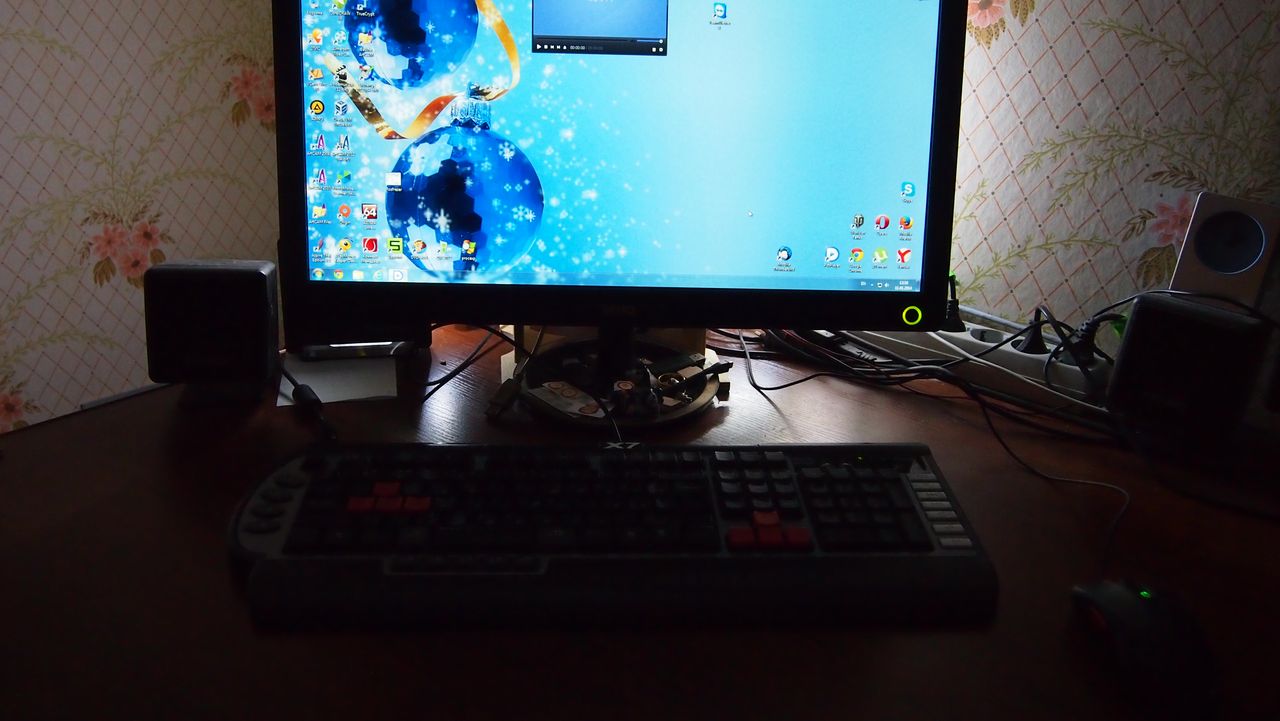

Making sure that everything is normal, it was decided to install this design for permanent residence for the monitor:

The result is a day off, about 700 rubles of money and this is what happened at the exit:

It was:

1. my workplace without lighting:

2. My workplace, with a desk lamp:

3. My workplace with a desk lamp and a chandelier (controlled through a dimmer, so the background lighting is so dim):

It became:

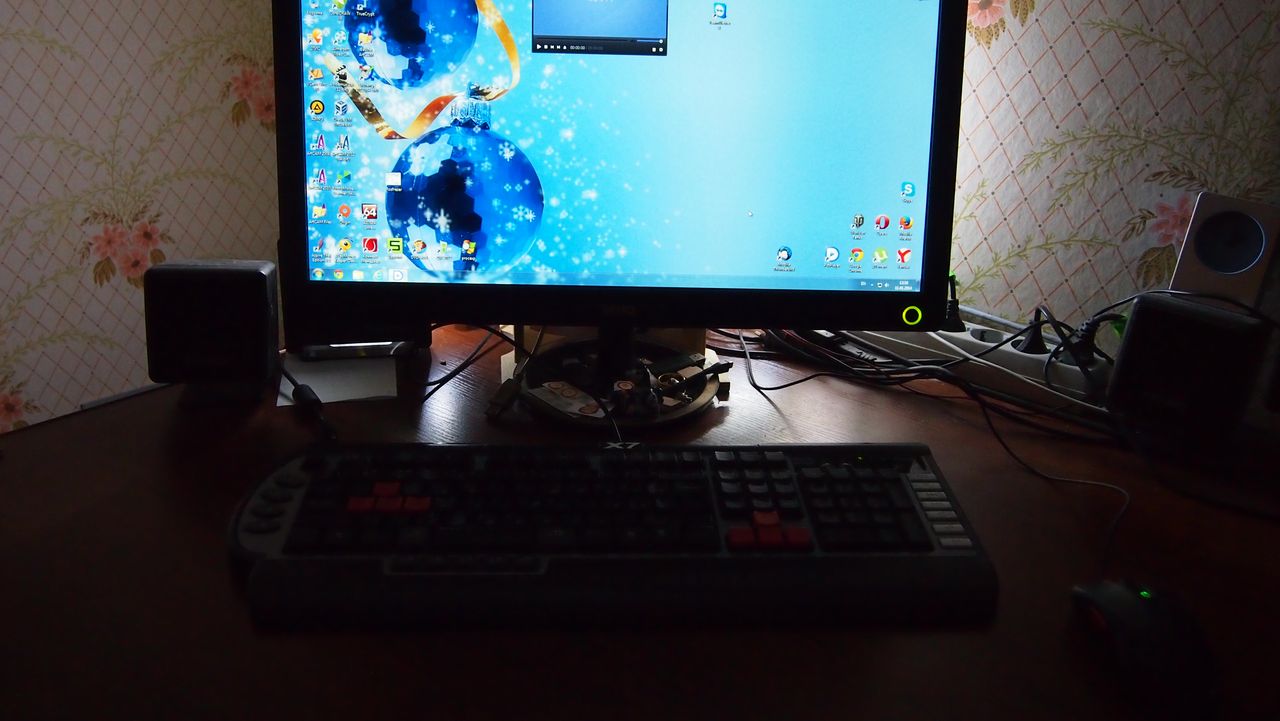

the backlight is on, the rest of the lighting in the room is off:

and general view of the workplace:

Conclusion. There are always areas where the CNC router will be more in demand. Next time I will be more closely put the stand to the monitor, so that standing at the table - the LED tape does not shine in the eyes of tall guests.

I hope it was interesting.

And now, having once read the article Home CNC milling cutter of the user vbifkol , I decided - this is it!

A year ago, when I was still a beginner and a greedy newbie, I decided that I could take something cheaper and trample me. I bought one machine, produced in small batches by one person. As a beginner machine, the machine was an acceptable choice. But as they say, the miser pays twice. Being a sociable person, he told friends to advertisers about a machine tool and immediately received the first trial order. And then it began, it is not so, it is not so - there is no speed, the accuracy is not the same, the working field is ridiculous (33 by 43 centimeters). Having rushed a little more than a year, it was decided to sell the machine and take the machine of industrial assembly. If you are interested in what happened in the end,

Since I am a humanist (a physicist by training), I began an active search by studying specialized forums. The links to these forums are not intentionally indicated, if it is interesting, then I will publish the links. Studying the forums - it came to an understanding of what I need - and what parameters need to be voiced by sellers.

')

So, the choice was limited to the following:

1. the control of the CNC should be carried out by the DSP processor;

2. The working field must be at least 90 to 60 cm, and the height of the workpiece at least 100mm;

3. the spindle must be water-cooled, at least 1.5kW;

4. the presence of the sensor tool for setting the height along the Z axis.

Almost 2 weeks spent on correspondence with 3 sellers, in the process of conversation reducing the number of sellers and specifying all sorts of subtleties, including such as shipping, packing machine, availability of a guarantee and so on. Due to the peculiarities of the rented premises and the lack of regularly transporting almost 200 kg, it was decided to take a desktop version of the machine (the desktop one is conditional, since the table was welded, the so-called bed).

Characteristics of the selected machine

| XYZ working area | 600 x 900 x 150 mm |

| Clearance portal | 120 mm |

| Accuracy | 0.1mm |

| Repeatability | 0.05 mm |

| Frame structure | Cast iron casting |

| Table structure | T-slot reinforced |

| XYZ Linear Motion | Profile guide PMI in all axes |

| XYZ axis drive | Ball screw |

| Maximum idle speed | 15 m / min |

| Maximum working speed | 10 m / min |

| Acceleration | 1200mm / sec2 |

| Type of axle drive motors | Stepper |

| Motor driver | Yako 2608 |

| Spindle | 1.5kw, liquid cooled, 4 bearings |

| Collet Type | ER16 |

| Maximum spindle speed | 24,000 rpm |

| Inverter | Delta |

| Operating voltage | AC220V / 50-60Hz |

| Control code | G - codes |

| Computer interface | USB 2.2 |

| Software | ArtCAM Express 2012 rus |

| Control system | DSP A11 (Digital Signal Processor) |

| Machine size | 1300 x 1000 x 930 mm, 225 kg |

| Packed machine size | 1450 x 1100 x 1100 mm, 270 kg |

Having paid almost 200 thousand rubles through a bank transfer, he began nervously to expect a letter from the seller to receive the money. 3 days later I received the message "the machine was sent to the transport company, wait for the call." When receiving time was spent 4 friends, the jeep of one of the friends was shot down - at the wrong time the pickup door was open.

A week later, after reading the article about home cnc router, it was decided to finally do something useful for the house. Being an active PC user, I was constantly concerned about the issue of workplace lighting. A table lamp, equipped with an energy-saving lamp, gave too little light, and the lamp burned out with frightening regularity. Changing a lamp at the price of 90 rubles 2-3 times a month turned out to be a very sad process.

So, the implementation of the topic was a matter of decision.

The choice of material and design

I thought for a long time how to solve the issue of organizing the background lighting behind the monitor. There was an option - to glue the LED tape on the back panel of the LCD monitor, but then this option was discarded:

1. the tape heats up quite noticeably, and I decided that for the monitor such heating would not be good;

2. The power supply for the LED strip will still hang on the table uncontrollably;

3. there is a high-tech unit;

4. P1-P2 in combination will look very impartial, and P3 did not give a reason to do so at all.

As a material, it was decided to choose 10mm plywood. Plywood is quite convenient material for processing on the CNC router, the price is very budget. A plywood sheet was bought at the nearest hardware store for 450 rubles (1.5m x 1.5m)

Electronics was purchased:

1. 1 meter of LED tape (I don’t remember the name, it was just the brightest tape in the store) - 260 rubles;

2. power supply 12 watts - 320 rubles;

3. plug for connecting to the network - 25 rubles;

4. meter of wire to connect the power supply to the mains 220V - 12 rubles.

Total: 617 rubles.

Assembly process

Having spent a lot of time, following the principle of 7 times, 1 cut off, the necessary dimensions were chosen (looking ahead, I say, I still missed).

The whole process of cutting parts for the stand took about 15 minutes. Slightly less than 30% of the time was spent on fixing plywood on the desktop.

Stand details:

So, I prepared, opened the tube of glue "Moment" and the process went:

After waiting an hour with deprive took off the clamp, and here it is, stand:

back view

she's in full face

Making sure that the glue grabbed and the halves of the supporting structure do not diverge, it was decided to glue the LED tape:

on one of the side racks was mounted power supply:

Having completed the installation of LED strip, power supply and sockets, conducted a trial run of the structure:

(The camera made its decision, and the trick "floated away." The use of the wire was due to the fact that the complete 2-sided adhesive tape had very low adhesion to plywood, and when heated, the free end of the LED strip began to sag)

Making sure that everything is normal, it was decided to install this design for permanent residence for the monitor:

The result is a day off, about 700 rubles of money and this is what happened at the exit:

It was:

1. my workplace without lighting:

2. My workplace, with a desk lamp:

3. My workplace with a desk lamp and a chandelier (controlled through a dimmer, so the background lighting is so dim):

It became:

the backlight is on, the rest of the lighting in the room is off:

and general view of the workplace:

Conclusion. There are always areas where the CNC router will be more in demand. Next time I will be more closely put the stand to the monitor, so that standing at the table - the LED tape does not shine in the eyes of tall guests.

I hope it was interesting.

Source: https://habr.com/ru/post/208968/

All Articles