Autodesk Simulation CFD 2014 Quick Start Guide

Good day.

It so happened that in my work I recently had to face the task of calculating the thermodynamics of a heat exchanger drawn in 3D.

And after a brief search, my choice fell on Autodesk Simulation CFD 2014.

Yes, there are a lot of English-language tutorials on YouTube, but the user had to look for some aspects to make life easier for a long time.

I want to share this research with you today, maybe someone will come in handy.

(It will be long and tedious so for the patient)

So first, briefly about the task before me.

I was given a heat exchanger drawn in 3D (in Autodesk Inventor), which was a furnace of red-hot smoke, which was supposed to pass through a pipe network, to heat other air that was used further for its intended purpose. All the original data were set and wondered if the heat exchanger of this configuration would be effective, that is, what air temperature would be at the outlet.

')

Step one.

Open our 3D body by selecting the path to it and specifying the name of our new project, then click Create new design study.

Next, we will have this window

In the first tab of which we will be asked to remove small corners that interfere with the program, in the second tab we will indicate the extra small objects that the program does not consider necessary to take into account. (To be fair, if your detail is drawn correctly without gaps and intersections, these tabs will be empty and unused.)

In the third tab indicated on the screen, we indicate the program of the void that needs to be filled with air or liquid, that is, its working media, depending on the simulation you need. The fact is that the program does not perceive voids in the pipes themselves as an environment, it needs to have a counterpart of corresponding sizes instead of emptiness, it can of course be drawn manually, but this is long, tedious and wrong when the program can do it itself in 3 clicks.

So, as shown in the video being in the open third tab, we alternately select the inputs and outputs of our voids by pressing the build surface after each selection, when a closed red outline appears, after both or all of the outputs of one of our voids are constructed so we press fill void, which will automatically create a new part in the emptiness between its two surfaces we just built.

As for the fourth tab, this is the construction of the part around your part, let's say the wind around the car, but I won't stop here this time.

Next, closing the geometry tools window, we will find ourselves in the next step of our simulation, the choice of materials. On the top of the main panel, the materials tab will be marked blue, which means that now we have to assign materials to all parts located in our assembly. I have 4 of them on the screen, one of which is already highlighted.

Selecting all the parts that will consist of one material (in my case it is air), click on the edit button and first select the solid / liquid / resistance medium, etc., according to the list, and then choose what is the medium in my case air.

Further, we also assign materials for other parts in my case, steel for the heat exchanger body. After assigning all the materials to the left in the materials window, there should be no details with unsigned inscription, otherwise the program will be cursed during the simulation.

So go to the boundary conditions tab, where we select the inputs of our environments in turn and assign them the parameters we need (temperature, pressure, force and volume of flow, etc.), in my case it is air with a temperature of 10 degrees and a flow rate of 22000 m3 / h The parameters for each input must be assigned alternately, for each value, each time clicking accept after input, otherwise it will only remember for example the temperature or pressure for one input.

It is necessary to allocate air or liquid outlets and assign pressure to them leaving zero in the graph value, so the program will understand where to move the gas.

The boundary conditions tab is more responsible for the state of the materials in your simulation, the initial conditions for the properties of the media, but also setting all the parameters in the boundary conditions also works.

(I’ll make a reservation that my task was different from calculating just heat exchange between two environments, I had a stove with an open fire, but I just didn’t have to set it, I had to assign a constant temperature to the walls of the combustion chamber at 300 degrees, and they already gave heat to the air.)

After you have assigned all the parameters to media and materials, you can go to the next tab mesh sizing, this tab is responsible for building if I understand the point clouds on the solid-state model, in general, it creates a grid on the basis of which it will do its calculations.

Here you only need one autosize button, if your model is drawn correctly, then everything will be fine.

If, as for me, at first, the model was built difficult with a lot of intersection occurrences, then during simulation the program may not start complaining about the impossibility of building a grid. Then enter the edit tab and pre-select the entire model and use the slider to change the grid size, which is responsible for the accuracy of the simulation. It is also important to tick the surfacrefinment, gap refinment and click refin.

Then you can set the movement of someone in the motion tab if you have any.

Finally go to the simulation.

The solve tab is responsible for it; in the first tab, you can specify the number of frames that will be responsible for calculating media movements inside the part, I was more interested in temperature, so I lowered them from 100 to 15.

On the second tab, we tick the box in heat transfer and below where autoconvection is. Also there in the graph is gravity, there will be three zeros, they correspond to the coordinates x, y, z in my case, the axis of the game should be set to -1, since gravity goes back to the axis of the game.

And press the Solve button.

So after we clicked the “solve” button, CFD 2014 will start building a grid and sharing information with the server, an Internet connection is required. (why I do not know)

Go to the grid creation process, server sharing, etc. which may take from 5 to 30 minutes.

Ideally, we will see this window for calculating simulation processes. Another 30 minutes.

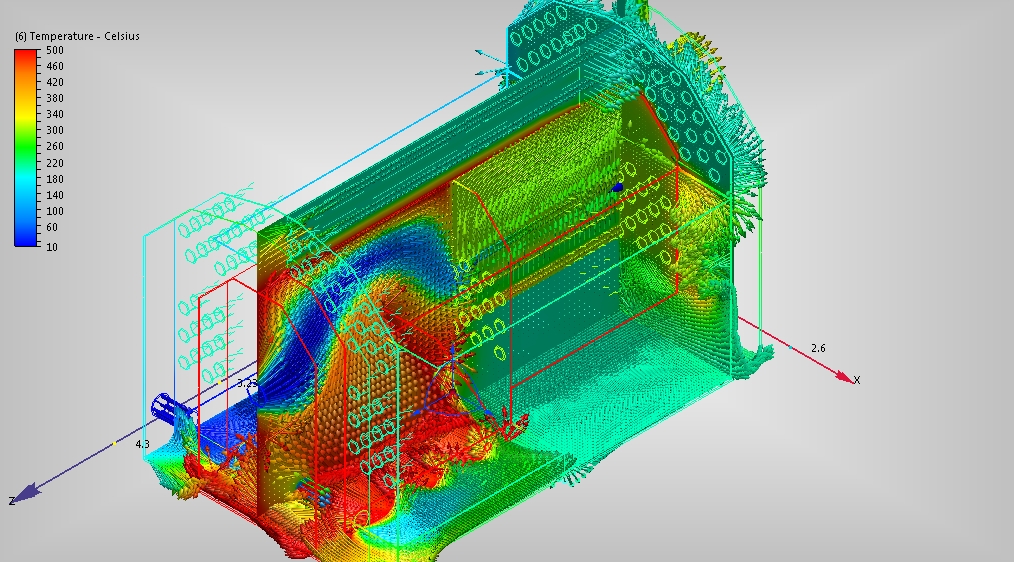

Then we get our results.

We appear here in this window, where the global tab shows the different characteristics of all our details.

The planes tab allows you to cut our part along any axis, and also change the displayed result depending on the characteristics (temperature, pressure, flow rate) to do this, click the add button (big green plus), and for clarity, you can show the direction of movement with arrows flows in environments in the vector tab, choosing the velocity vector and changing the size of the arrows in the edit / vector settings tab.

Also on the points tab, the add button adds a point anywhere in the model where you can measure all its parameters and add this point to the final report.

And for the sake of what the simulation is done is a report.

It can be found and saved on the tab summary file.

You can also show the movement of flows schematic lines.

And for clarity, a complete video of creating a simulation of this model:

Source: https://habr.com/ru/post/207116/

All Articles