An example of calculating a single lens lens in Zemax

It may happen that someone needs to calculate a simple photo lens for their insidious needs plans . And since I am an engineer-optician (beginner :-) by education and duty of the profession, I decided to share a little instruction on how to calculate a simple single-lens photographic lens.

Suppose that our future lens will be in geostationary orbit at an altitude of 35,786 km. The angular field of the lens must be such that the whole Earth falls into it. No more, no less. The receiver will be a photodiode with dimensions of 10mm x 10mm = 100mm2. The diameter of the entrance pupil (in this case, the diameter of the first surface of the first and only optical element) is 20 mm.

To construct an optical scheme, we need to determine the required angular field of the system and the focal length.

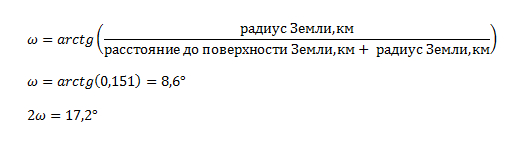

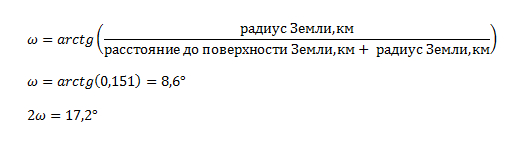

We know the distance from the surface of the Earth to the entrance pupil of our system and the average diameter of the Earth. From this data, you can calculate the angular field of the system.

')

The average value of the diameter of the Earth D = 12 742 km (R = 6 371 km)

Distance from the ground to the lens = 35 786 km

The angular field of our system is 17.2 degrees.

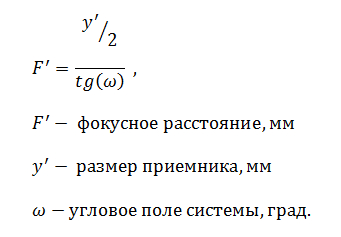

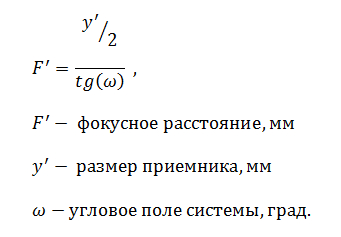

Now you need to calculate the required focal length of the system:

The focal length of this formula will be F '= 33.2 mm.

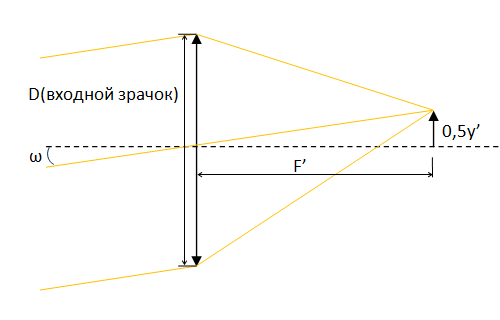

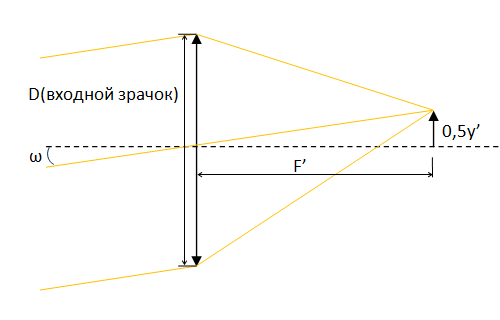

Fig. Schematic diagram

Fine! More than half the work has already been done.

First you need to check the available data.

We know:

- the number of curved surfaces of the system,

- diameter of the entrance pupil of the system,

- required system focus.

We do not know yet:

- the thickness of the optical component,

- brand of glass optical component,

- wavelength at which the optical system will operate.

You can select this data yourself. But let's imagine that we are working on some kind of advanced enterprise that masters space :-)

I was taught at the institute that the minimum thickness of the optical component along the axis should be at least 10% of the diameter value. If you count the optical component with a small negative foci (most likely it is a biconcave lens), then an axial thickness of 10% of the diameter will be enough. In our case, we have a collecting lens forming a real image (in the scattering lens an imaginary image) with a positive focus. Accordingly, it is necessary to choose the thickness of the lens, taking into account the arrows of the deflection of surfaces, which will increase the thickness of the component along the axis. For the first approximation, we take 20% of the diameter. In our case, the thickness of the component for calculations will be:

Lens thickness = 20mm x 20% = 4mm

Suppose that a radiation resistance specialist recommended the use of radiation resistant glass. A specialist teplovik recommended to use the glass material with the lowest rate of thermal expansion, since the frame for the lens will be made of titanium or superinvar. In general, they have not yet decided.

After receiving the recommendations, it was decided that quartz glass brand KU-1 is perfect. No sooner said than done!

It seems to be almost all the data eats. Caramba! But what about the spectral range of the system? We take the initiative and go to the developers themselves and get the necessary information. After that, wait a couple of days and do other useful things. On the third day, the developer comes in and says that they have decided to change the main wavelength for the lens. No sooner said than done! Working wavelength = 0.644 microns. Now we can continue our optical calculation.

Zemax software greatly simplifies the life of optical computing systems. This does not mean that the software itself will design a cool optical system for you. But when designing optical systems when it is necessary to analyze a sufficient number of options, Zemax helps to significantly reduce development time. I think that the program for accountants is irreplaceable. Of course, with one condition that you have purchased the original license ;-)

Now I will not go into the details of the descriptions of all the charms of the program, but immediately show it in action.

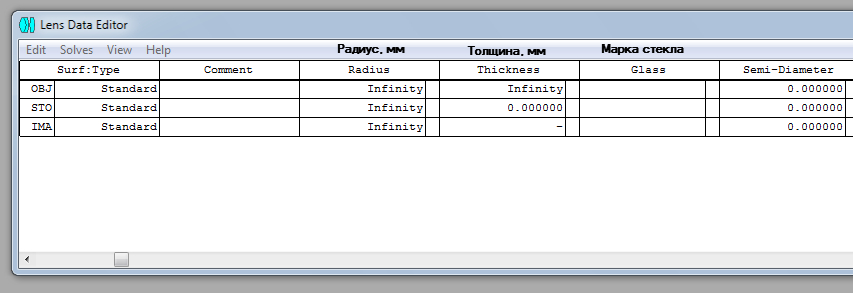

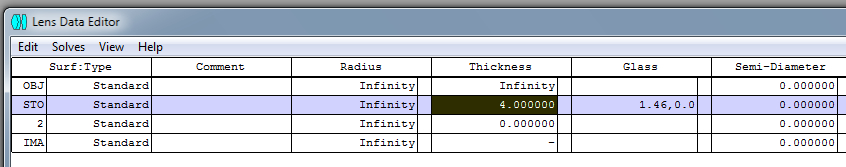

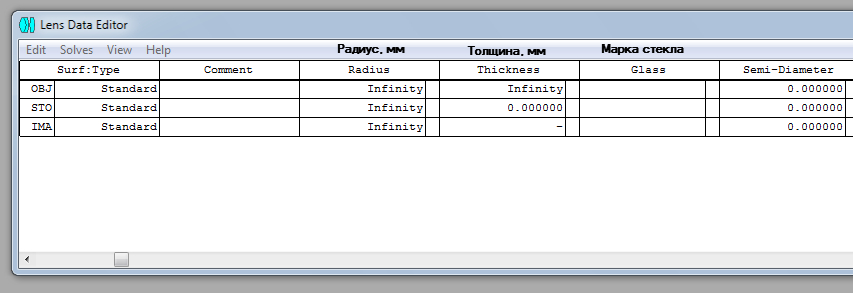

When downloading a program, first of all you need to familiarize yourself with the Lens Data Editor window:

This window contains information about the current optical system. The data set is similar to the format of the optical release, which, personally, I met at the institute :-)

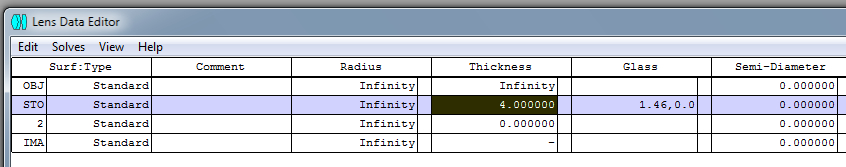

From the available data at the moment, we can indicate here so far only the number of surfaces for ray tracing, the thickness and the brand of glass. As a glass brand, we choose the data representation in the form of a model, in which it is necessary to set the refractive index for the selected wavelength for our glass. Since the brand of the selected KU-1 glass is from our national GOST, we must look for the data in it (in our case GOST 15130-86 “Quartz Optical Glass”).

The refractive index for KU-1 glass for a wavelength of 0.644 μm is 1.4567. It is worth noting that it is at a temperature of +20 degrees Celsius. And we have just on board heating up to +20 degrees :-)

Total, at the moment we have:

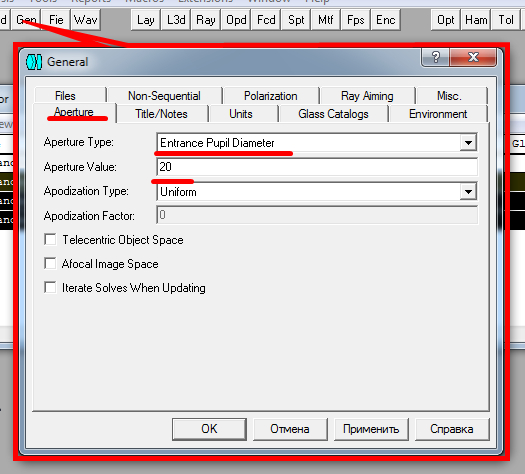

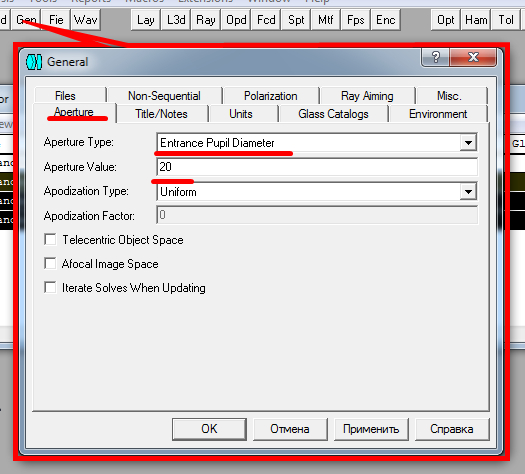

In the General window in the Aperture tab, specify the diameter of the entrance pupil 20mm:

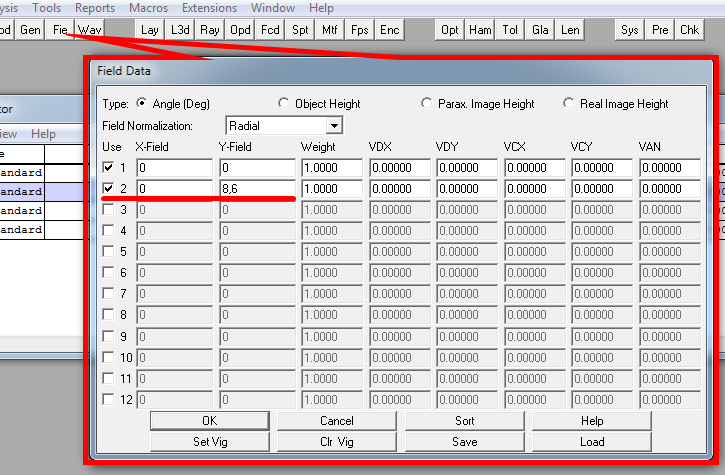

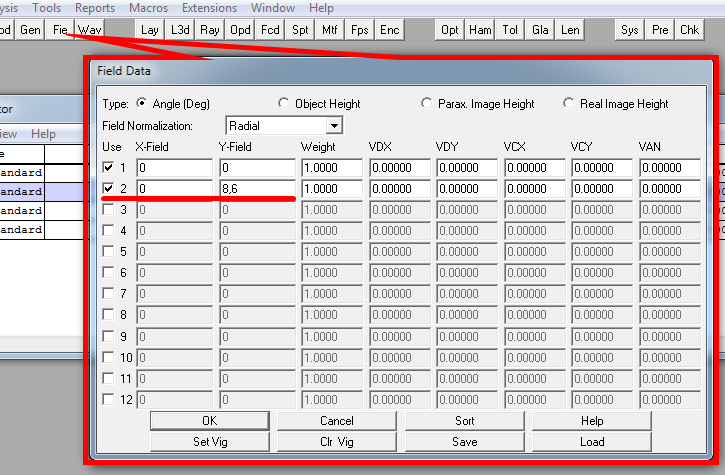

Specify the angular field of the system:

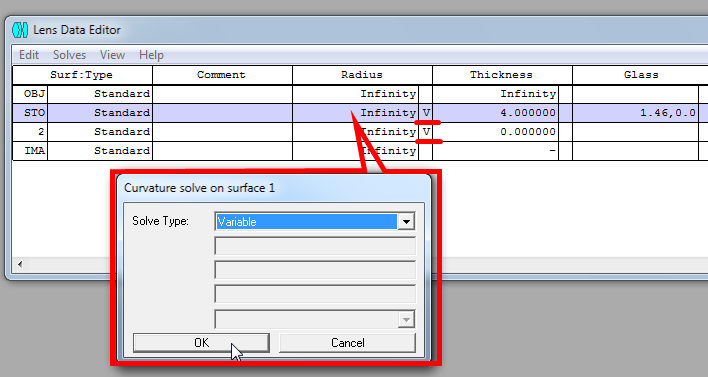

When calculating the system, we use Optimization , which is built into Zemax.

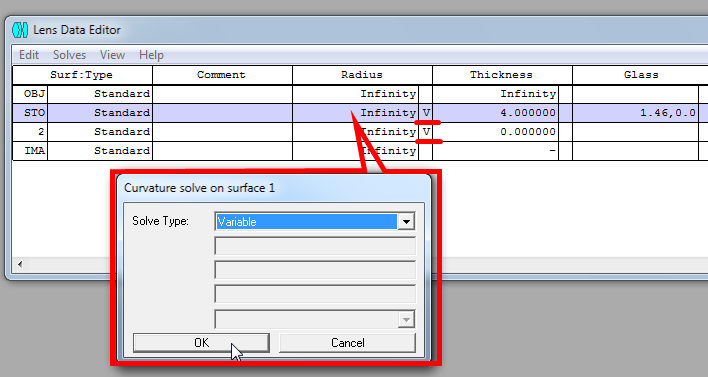

First, we specify the parameters that we can change during the optimization. In our case, these are the radii of curvature of the lens surface:

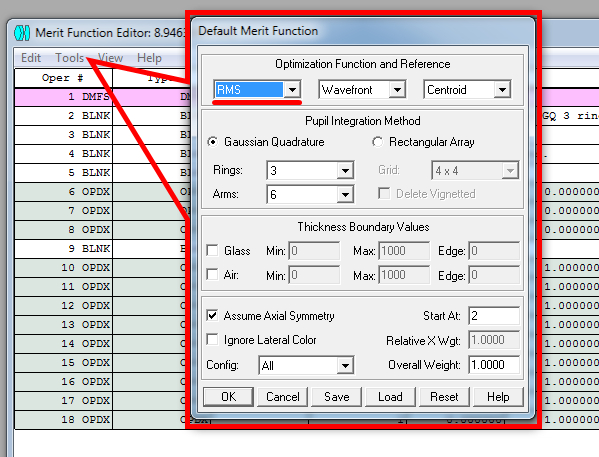

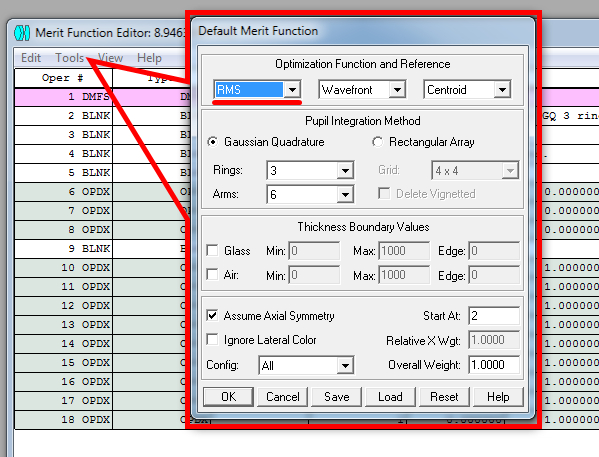

Secondly, it is necessary to form an evaluation function of the current system (Default Merit Function).

We form an evaluation function based on RMS. Here, this parameter shows the root-mean-square deviation of the wavefront rays during ray tracing.

During optimization, we will indicate the only parameter to which we will strive - the required focal length. To do this, add the EFFL parameter and specify the following settings:

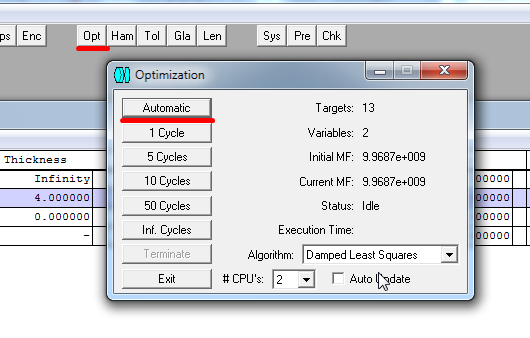

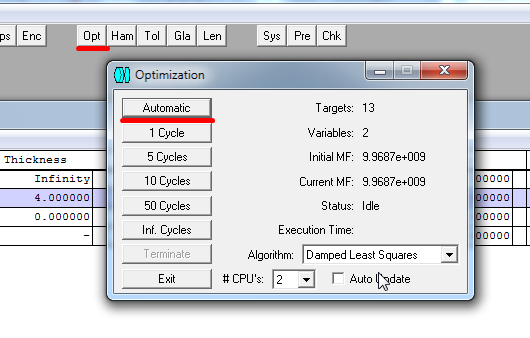

Now that all parameters have been set, an optimization function can be used.

In this window, you can manually control the number of iterations when selecting the best option. Or you can use automatic calculation to find the best option.

Optimize. Click Exit .

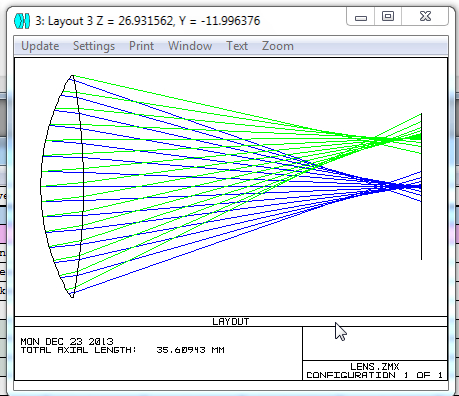

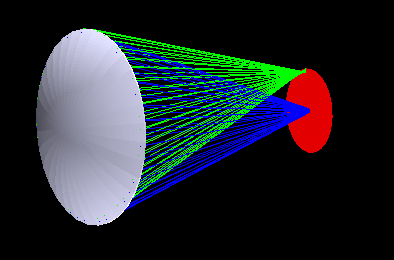

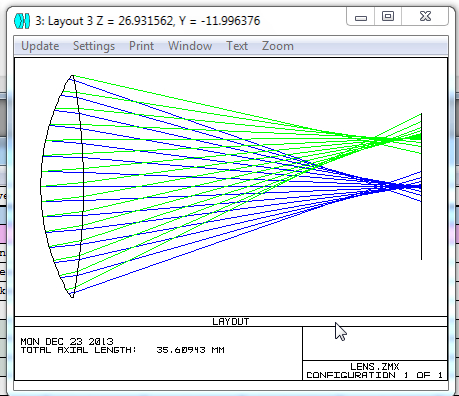

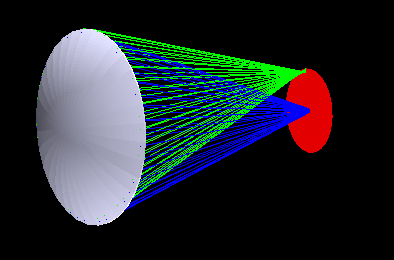

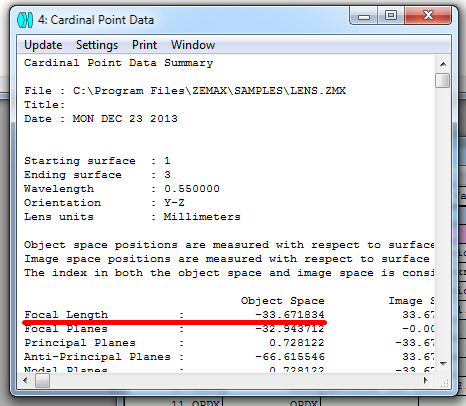

Now you can see what happened.

It seems to be nice :-)

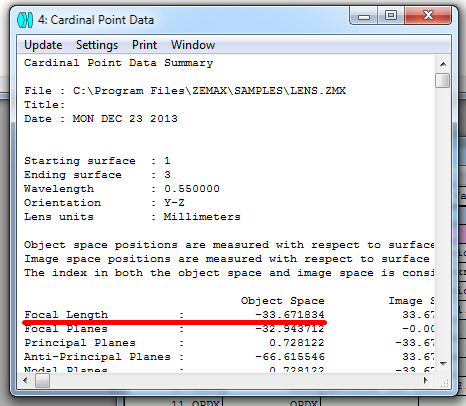

But the final focus of the system is 33.67 mm, which is slightly different from the target - 33.2 mm.

The higher the Weight value in the EFFL parameter, the higher the priority of this parameter in the calculation.

With the Weight = 100,000 parameter, my optimized focus turned out to be 33.21 mm. I do not provide a sequence, as it is similar to the above.

The requirements are met. Hooray! :-)

PS I have not had time to master all the functionality of the program. Yes, and optical systems, I have not really calculated a lot for all the time, so I apologize if something is wrong. Comments and comments are welcome :-)

PPS This is my first post, so I did not know which topic is better to place. If not right, then tell me where to move. Thank.

Task setting and baseline data

Suppose that our future lens will be in geostationary orbit at an altitude of 35,786 km. The angular field of the lens must be such that the whole Earth falls into it. No more, no less. The receiver will be a photodiode with dimensions of 10mm x 10mm = 100mm2. The diameter of the entrance pupil (in this case, the diameter of the first surface of the first and only optical element) is 20 mm.

Optical layout

To construct an optical scheme, we need to determine the required angular field of the system and the focal length.

Corner field system

We know the distance from the surface of the Earth to the entrance pupil of our system and the average diameter of the Earth. From this data, you can calculate the angular field of the system.

')

The average value of the diameter of the Earth D = 12 742 km (R = 6 371 km)

Distance from the ground to the lens = 35 786 km

The angular field of our system is 17.2 degrees.

Now you need to calculate the required focal length of the system:

The focal length of this formula will be F '= 33.2 mm.

Fig. Schematic diagram

Fine! More than half the work has already been done.

Collection of additional parameters for the calculation

First you need to check the available data.

We know:

- the number of curved surfaces of the system,

- diameter of the entrance pupil of the system,

- required system focus.

We do not know yet:

- the thickness of the optical component,

- brand of glass optical component,

- wavelength at which the optical system will operate.

You can select this data yourself. But let's imagine that we are working on some kind of advanced enterprise that masters space :-)

Optical component thickness

I was taught at the institute that the minimum thickness of the optical component along the axis should be at least 10% of the diameter value. If you count the optical component with a small negative foci (most likely it is a biconcave lens), then an axial thickness of 10% of the diameter will be enough. In our case, we have a collecting lens forming a real image (in the scattering lens an imaginary image) with a positive focus. Accordingly, it is necessary to choose the thickness of the lens, taking into account the arrows of the deflection of surfaces, which will increase the thickness of the component along the axis. For the first approximation, we take 20% of the diameter. In our case, the thickness of the component for calculations will be:

Lens thickness = 20mm x 20% = 4mm

Choosing a glass brand

Suppose that a radiation resistance specialist recommended the use of radiation resistant glass. A specialist teplovik recommended to use the glass material with the lowest rate of thermal expansion, since the frame for the lens will be made of titanium or superinvar. In general, they have not yet decided.

After receiving the recommendations, it was decided that quartz glass brand KU-1 is perfect. No sooner said than done!

Wavelength selection

It seems to be almost all the data eats. Caramba! But what about the spectral range of the system? We take the initiative and go to the developers themselves and get the necessary information. After that, wait a couple of days and do other useful things. On the third day, the developer comes in and says that they have decided to change the main wavelength for the lens. No sooner said than done! Working wavelength = 0.644 microns. Now we can continue our optical calculation.

Calculation of the system using Zemax

Zemax software greatly simplifies the life of optical computing systems. This does not mean that the software itself will design a cool optical system for you. But when designing optical systems when it is necessary to analyze a sufficient number of options, Zemax helps to significantly reduce development time. I think that the program for accountants is irreplaceable. Of course, with one condition that you have purchased the original license ;-)

Now I will not go into the details of the descriptions of all the charms of the program, but immediately show it in action.

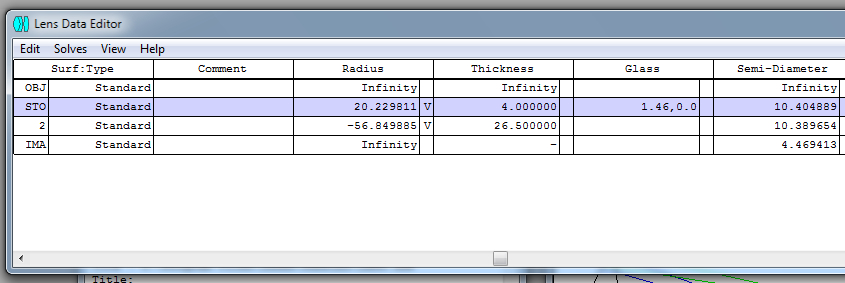

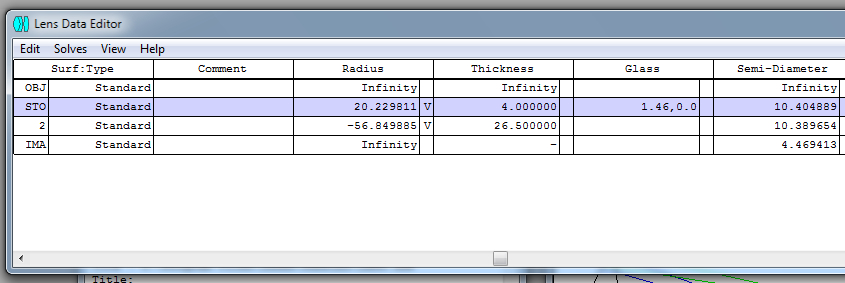

When downloading a program, first of all you need to familiarize yourself with the Lens Data Editor window:

This window contains information about the current optical system. The data set is similar to the format of the optical release, which, personally, I met at the institute :-)

From the available data at the moment, we can indicate here so far only the number of surfaces for ray tracing, the thickness and the brand of glass. As a glass brand, we choose the data representation in the form of a model, in which it is necessary to set the refractive index for the selected wavelength for our glass. Since the brand of the selected KU-1 glass is from our national GOST, we must look for the data in it (in our case GOST 15130-86 “Quartz Optical Glass”).

The refractive index for KU-1 glass for a wavelength of 0.644 μm is 1.4567. It is worth noting that it is at a temperature of +20 degrees Celsius. And we have just on board heating up to +20 degrees :-)

Total, at the moment we have:

In the General window in the Aperture tab, specify the diameter of the entrance pupil 20mm:

Specify the angular field of the system:

Adjustment of automatic optimization

When calculating the system, we use Optimization , which is built into Zemax.

First, we specify the parameters that we can change during the optimization. In our case, these are the radii of curvature of the lens surface:

Secondly, it is necessary to form an evaluation function of the current system (Default Merit Function).

We form an evaluation function based on RMS. Here, this parameter shows the root-mean-square deviation of the wavefront rays during ray tracing.

During optimization, we will indicate the only parameter to which we will strive - the required focal length. To do this, add the EFFL parameter and specify the following settings:

Now that all parameters have been set, an optimization function can be used.

In this window, you can manually control the number of iterations when selecting the best option. Or you can use automatic calculation to find the best option.

Optimize. Click Exit .

Now you can see what happened.

It seems to be nice :-)

But the final focus of the system is 33.67 mm, which is slightly different from the target - 33.2 mm.

How to get the required focus?

The higher the Weight value in the EFFL parameter, the higher the priority of this parameter in the calculation.

With the Weight = 100,000 parameter, my optimized focus turned out to be 33.21 mm. I do not provide a sequence, as it is similar to the above.

Total

The requirements are met. Hooray! :-)

PS I have not had time to master all the functionality of the program. Yes, and optical systems, I have not really calculated a lot for all the time, so I apologize if something is wrong. Comments and comments are welcome :-)

PPS This is my first post, so I did not know which topic is better to place. If not right, then tell me where to move. Thank.

Source: https://habr.com/ru/post/207066/

All Articles