SPS IPC Drives 2013 Visit Report - a bit about real industrial robots

Habré has published many reports on visiting the major exhibitions of the IT industry - CeBIT, CES, MWC. I decided to write a post about SPS IPC Drives 2013, recently held in Nuremberg. Also a big exhibition, 60,000 visitors - almost like at MWC. I have been driving SPS / IPC / Drives for the third year already (I live nearby, and it is useful for work), and in this post I will try to describe what trends in the industry I paid attention to this time. Intel doesn’t have its own booth at this exhibition, so I personally like this exhibition most of all - I don’t have to stand at the booth for several days in a row, studying the surroundings during short trips, when I’m replacing my colleague, but you can thoughtfully take pictures and talk with the participants.

Habré has published many reports on visiting the major exhibitions of the IT industry - CeBIT, CES, MWC. I decided to write a post about SPS IPC Drives 2013, recently held in Nuremberg. Also a big exhibition, 60,000 visitors - almost like at MWC. I have been driving SPS / IPC / Drives for the third year already (I live nearby, and it is useful for work), and in this post I will try to describe what trends in the industry I paid attention to this time. Intel doesn’t have its own booth at this exhibition, so I personally like this exhibition most of all - I don’t have to stand at the booth for several days in a row, studying the surroundings during short trips, when I’m replacing my colleague, but you can thoughtfully take pictures and talk with the participants.The name of the exhibition - SPS / IPC / Drives is translated into Russian as “Programmable logic controllers, industrial PCs, and servo drives.” These three product categories, and all associated with them, make up the majority of products and services that are shown by one and a half thousand participating companies.

As in all IT exhibitions, where most of the visitors are men, companies hire beautiful girls to lure visitors to their stands. I didn't take pictures of girls this time, but only robots, like this musician on the title picture. Of course, humanoid robots were an overwhelming minority, and those that were, did not do anything useful.

')

Is it true industrial robots:

This draws on the model (feedback from the camera, which is not included in the picture). In general, feedback is always required for control. In industrial robots, it is traditionally implemented in servomotors of the “joints” of the robot arm. However, lately, I increasingly see attempts to attach a video camera to the hand or next to it, or even more than one. So there were a lot of sensors on SPS / Drives this year. I recently spoke with a colleague from Windriver, and he also noticed that this time the huge pavilion was dedicated only to sensors. He did not notice that there were actually two such pavilions. In one, manufacturers of traditional sensors sat - temperatures, pressures, all sorts of compasses, gyroscopes, GPSs, light and motion sensors, etc., etc. And in the second there was everything to create the “eye of robots”.

This draws on the model (feedback from the camera, which is not included in the picture). In general, feedback is always required for control. In industrial robots, it is traditionally implemented in servomotors of the “joints” of the robot arm. However, lately, I increasingly see attempts to attach a video camera to the hand or next to it, or even more than one. So there were a lot of sensors on SPS / Drives this year. I recently spoke with a colleague from Windriver, and he also noticed that this time the huge pavilion was dedicated only to sensors. He did not notice that there were actually two such pavilions. In one, manufacturers of traditional sensors sat - temperatures, pressures, all sorts of compasses, gyroscopes, GPSs, light and motion sensors, etc., etc. And in the second there was everything to create the “eye of robots”.The exhibition shows

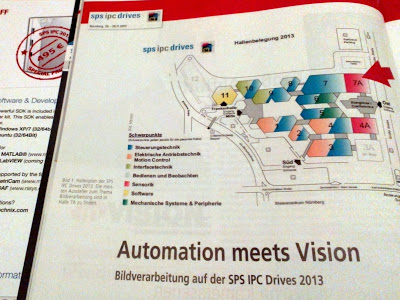

that most of the space was given to manufacturers of control systems without feedback, in the second place - the motion control, and in the third - the sensors. Officially, the main theme this time was " Automation meets vision ". A lot of special cameras. This is not webcam'y and other well-known household 3D cameras! The average FPS is 120 and so on up to 280, but the price is appropriate. Compare, for example, Kinect and one of its industrial counterparts for ~ 500 euros. Nevertheless, almost all of this special hardware can be connected to a PC via ordinary USB and Ethernet.

that most of the space was given to manufacturers of control systems without feedback, in the second place - the motion control, and in the third - the sensors. Officially, the main theme this time was " Automation meets vision ". A lot of special cameras. This is not webcam'y and other well-known household 3D cameras! The average FPS is 120 and so on up to 280, but the price is appropriate. Compare, for example, Kinect and one of its industrial counterparts for ~ 500 euros. Nevertheless, almost all of this special hardware can be connected to a PC via ordinary USB and Ethernet. At the exhibition there were many imitations of production lines on which something moved, packed, moved. It even got a little boring. But several lines were knocked out of the general row. For example, on one of the booths, the automatics brewed an imitation of beer, everything boiled and boiled in vats, then the result was bottled, the bottles were closed, and then opened again, the beer poured back into the container and everything went in the next round. It is interesting that such a large imitation of beer production was set at the booth by a company selling mainly PLC programming environments.

At the exhibition there were many imitations of production lines on which something moved, packed, moved. It even got a little boring. But several lines were knocked out of the general row. For example, on one of the booths, the automatics brewed an imitation of beer, everything boiled and boiled in vats, then the result was bottled, the bottles were closed, and then opened again, the beer poured back into the container and everything went in the next round. It is interesting that such a large imitation of beer production was set at the booth by a company selling mainly PLC programming environments.Walking through the pavilions, it was easy to assess who is who in this business.

Simply sort by the area occupied by the exhibition. No. 1 is definitely Siemens - it took almost a whole pavilion just to show its products - both SPS, and IPC, and Drives. Even a life-size rover fit. I did not know that Siemens was involved in the Curiosity project. And there were also Siemens corners in Fielbus (Profinet), OSADL (Linux). GE, Rockwell, Mitsubishi, ABB, Bosch Rexroth, Schneider Elektrik had large areas. A little smaller, but also serious in Beckhoff, KUKA, B & R, Phoenix Contact, Sick, Wago. The following type of companies - manufacturers of control iron - Kontron, Congatech, Advantech. And software for developers - Codesys, KW, National Instruments.

Simply sort by the area occupied by the exhibition. No. 1 is definitely Siemens - it took almost a whole pavilion just to show its products - both SPS, and IPC, and Drives. Even a life-size rover fit. I did not know that Siemens was involved in the Curiosity project. And there were also Siemens corners in Fielbus (Profinet), OSADL (Linux). GE, Rockwell, Mitsubishi, ABB, Bosch Rexroth, Schneider Elektrik had large areas. A little smaller, but also serious in Beckhoff, KUKA, B & R, Phoenix Contact, Sick, Wago. The following type of companies - manufacturers of control iron - Kontron, Congatech, Advantech. And software for developers - Codesys, KW, National Instruments.In the Siemens pavilion, a new-released CPU module for High End PLC was shown - CPU 1518-4PN / DP with which architecture can be guessed. Unfortunately, the page on the performance of various CPU modules for the PLC has not yet been updated.

Of course, everything at the exhibition is designed for specialists in industrial automation. But there was something for education in this area.

For example, open hardware / open source robot hand ... for 5k euros. Interesting stands with Phd works of students from leading German specialized universities. Also surprised the number of students among visitors. For them, there are usually discounts on the last day of the exhibition, but many prefer to come early, when there are still any small gifts on the stands. In Germany, of course, Machinenbau’s specialty is traditionally considered prestigious enough, and after the exhibition, I understood why: it’s enough to compare the salaries of programmers in IT and in embedded development .

I took a crooked but short clip with moving robots on my mobile phone to convey the atmosphere of the exhibition, where on every second stand something moves. I imagine that the organizers should bring so much electrical power to each stand. This is not CES :)

It is surprising that there were no 3d printers, not even expensive industrial ones. There were a few simple ones that used to print plastic stuff / prototypes. I wonder why?

I already wrote that the industrial automation market is adopting technologies from IT, and a large number of SPS / IPC / Drives2013 exhibits confirm this thesis, now not only in fieldbus, but also in perceptual computing. I look forward to Embedded World 2014 and Hannover Messe 2014 .

Source: https://habr.com/ru/post/204154/

All Articles