Picaso 3D-Builder - Made in Russia

Today's story will be about another very interesting and decent 3D-printer, which I had hardly ever mentioned before on Habré, and I recently had a chance to talk with the creators of it.

A distinctive feature of this printer is its Alma Mater, namely:

As I said earlier, the Picaso 3D-Builder is based on the classic Prusa Mendel, but with some improvements.

There are not many changes, but each of them is not very bad.

And all the production of the printer, as usual, is concentrated in the glorious city of Zelenograd.

')

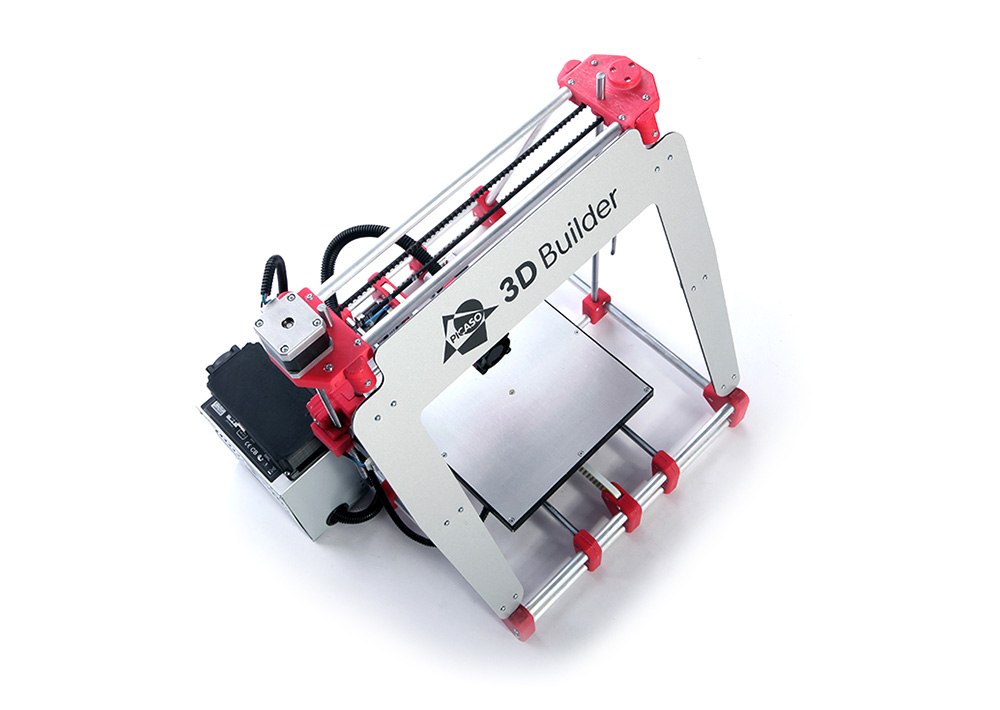

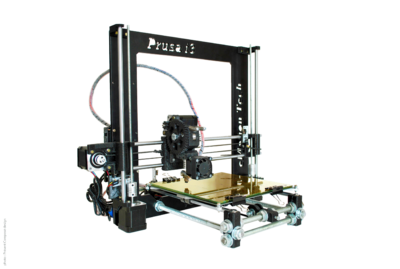

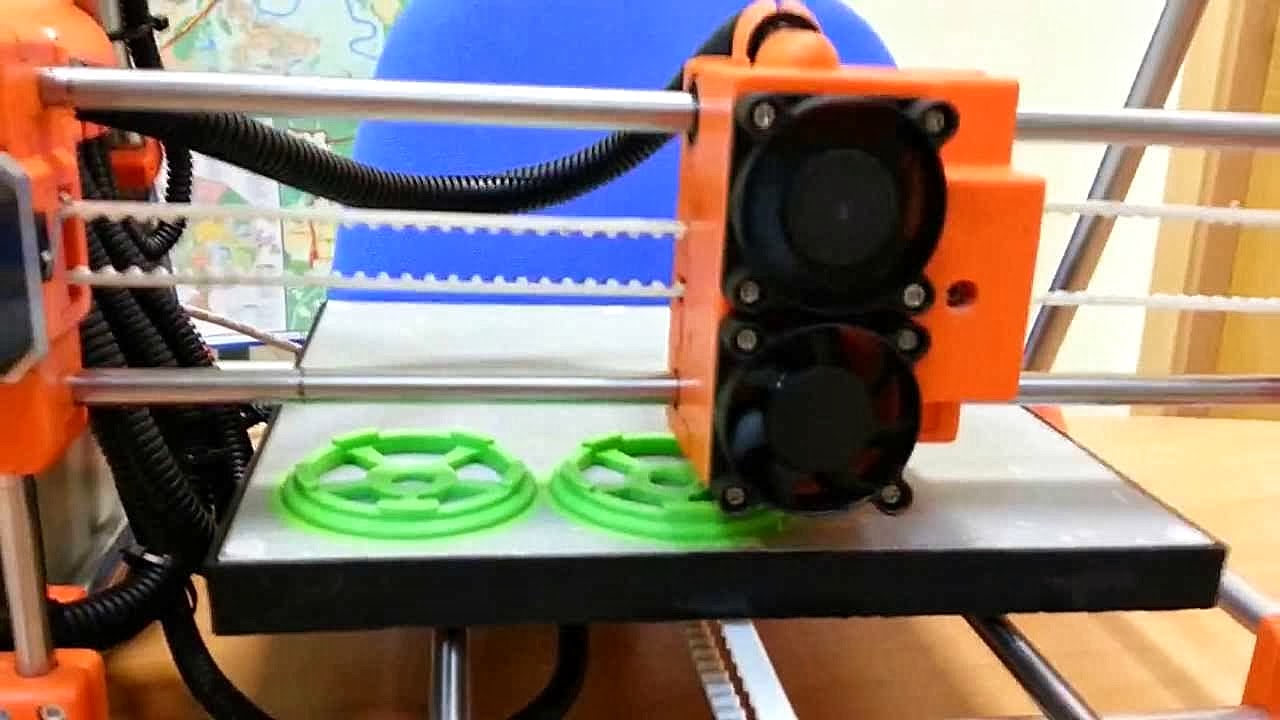

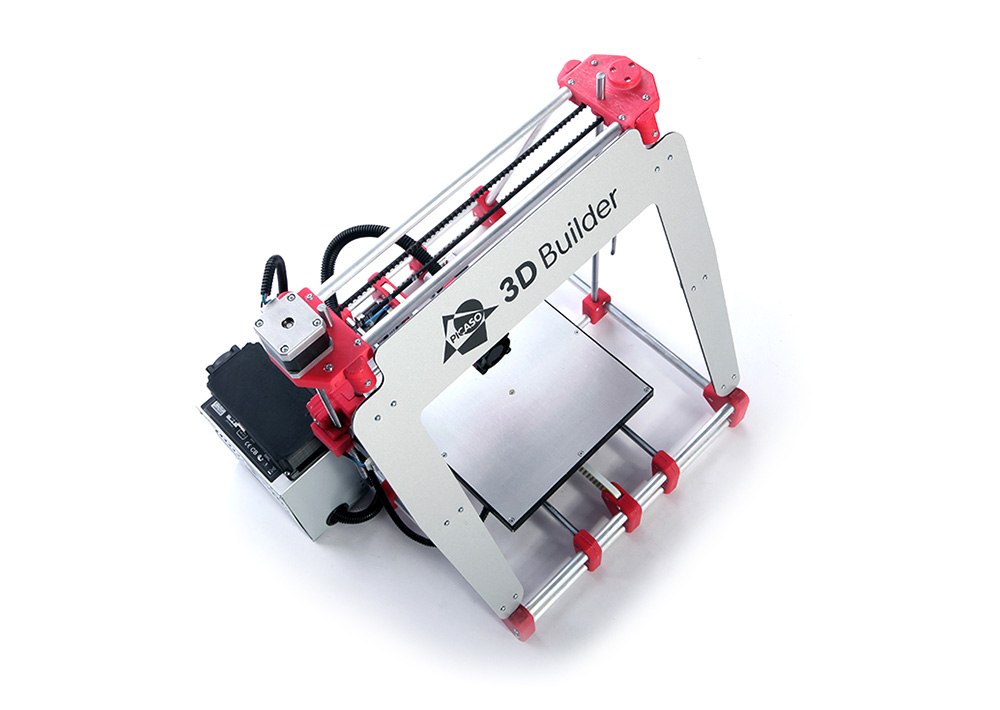

The farm itself is practically no different from Grandpa Mendel. Changes have undergone plastic parts farm. They have a pleasant orange color, are more massive and are produced by casting, and not printed on the printer itself, which has a positive effect on quality. At the same time, the manufacturer has 3D-models of these parts and can provide * .STL files to users for self-printing, if necessary, for repair, for example.

Also, the farm is reinforced with a U-shaped aluminum frame. Moreover, the frame is not mounted in the plane of the Z-axis, as on the new Prusa i3 , but on the leading edge of the side triangle.

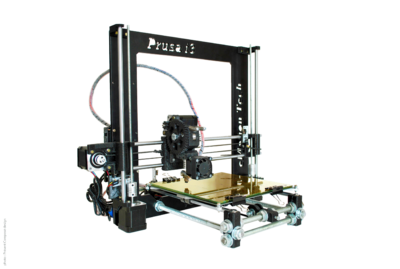

Prusa i3 3D Builder

Here the question is more of a design. Combined with orange details, 3D-Builder looks nicer than Prusa i3 and even has more rigidity, because it has kept triangular trusses on its sides.

This is where our craftsmen did their best.

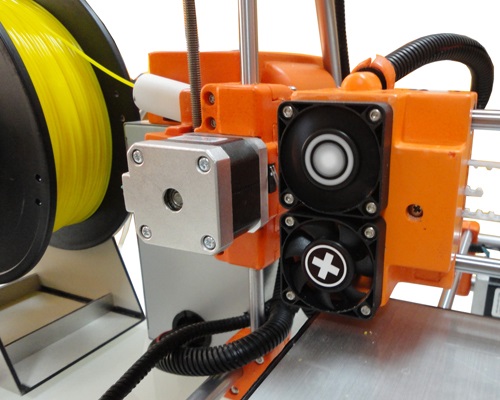

First, let's talk about the extruder.

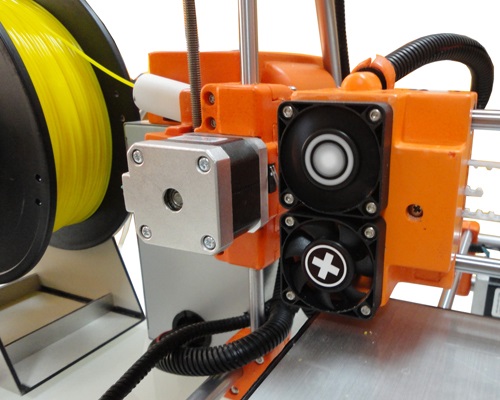

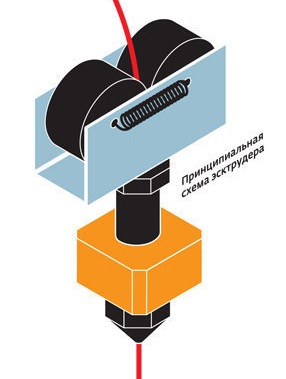

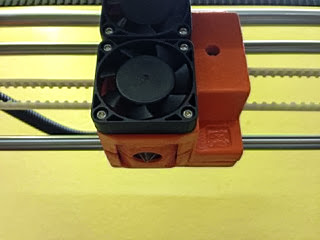

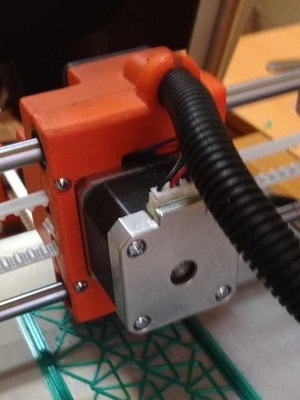

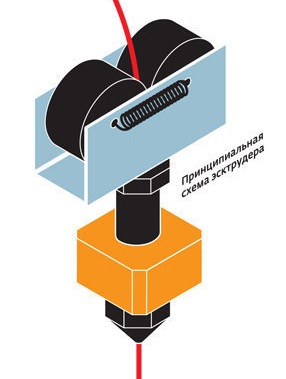

As can be seen in the picture, all the moving elements of the extruder are closed by the print head housing. This is a definite plus, since dust does not fall on the gear pairs. The extruder is not "straight-through", in contrast to the more budgetary and increasingly popular options, where the ribbed bolt is attached directly to the motor shaft, but on the contrary, it has two ribbed rollers and both are driven through a gearbox.

With such a scheme, a bar jam or “obstruction” is practically excluded.

A "straight-through" extruder, no matter how you conjure with the motor driver, stretches the bar in jerks, which of course will affect the quality of your model. The gearbox, to some extent, allows to minimize this effect. If you still decide on a straight-through extruder, check that the driver for the stepping motor supports 1/32 steps or higher.

For comparison - a new wooden straight-through extruder Printrbota.

Now about the hot end and auto-calibration.

Here everything is really interesting. The hot end, along with part of the printhead and sensors on the Z axis, form the original auto-calibration system. Which one, the developer does not disclose, referring to the know-how, and I haven’t succeeded in disassembling the 3D-Builder myself. Autocalibration itself takes place before each printing start, as an element of parking. Thus, whatever happens to your table and nozzle, whenever you change the nozzle and whatever geometry it has, whatever Kapton or other table cover you use, the height of the nozzle tip above the table will always correspond to the set parameters, with any circumstances.

For its hot ends, Picaso offers several different nozzles, from 0.30 mm (note, from 0.30 mm!) For fast printing, to 0.15 mm for high-quality printing.

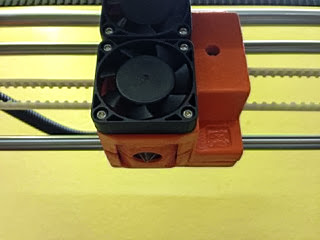

I especially liked the ventilation.

But only its lower part.

The top fan, as usual, in the old fashioned way, blows onto the hot end itself and creates a temperature gradient in its upper part, minimizing the size and influence of the “plug” on the process of passing the bar ( more details can be found here in the section “Interesting rheology”). However, as I wrote in previous articles, the gradient is already created due to local heating of the rod, and the use of a fan can be replaced by using a more massive hot end, preferably a ceramic one, like the Ubis Hot End . But, this moment will remain on the conscience of developers.

Much more interesting bottom fan!

Through a system of channels in the print head housing, it creates a ring and uniform blowout of the model directly in the print area. And just in contrast to the fans located on the brackets on the side of the extruder - it does not create any gradients in the print zone and allows the plastic to solidify evenly in all directions and with minimal deformation.

From my own experience, I will say that any separately placed fan causes defects in printing, for example, such structures.

In the case of my Printrbot, where the fan is brought forward from the extruder, the rear "horns" of thin-walled models all the time tend to bend forward in the process of printing. In some cases, this leads to oblong horns or the disruption of the entire model from the table when the nozzle hits an excessively curved horn.

Basically, I type and give examples of PLA plastic. It is safer than ABS, non-toxic and biodegradable. PLA models always look more rough than ABS, and in the case of transparent plastic - the effect is visually enhanced.

It's all in line with the best fashion trends in LandOn houses. The table is made from a single piece of aluminum, and the heater is located inside. Thus the table is not deformed when heated, heats up very evenly and keeps the temperature.

Aluminum is really thick.

Another feature of the table is the material with which it is covered. This is not Kapton, but some synthetic material with even greater adhesion to ABS and PLA. The manufacturer keeps the composition of the material a secret, but sells it as it is worn by 3D-Builder users. Here is such an exclusive.

And yet, yes, the table has a size of 20 x 20 cm, which favorably distinguishes the printer from its competitors for the better. Size, Mother Russia, has always been rich, on that stand.

Here I want to say only that one motor is used along the Z axis. The second screw (since the design of the farm is U-shaped) is driven by a belt drive. The design, in my opinion is not the best. The belts are not absolutely rigid, and when they begin to deteriorate, the lag of the second screw will be more and more noticeable, which can lead to misalignment of the horizontal axes and introduce corresponding defects into the geometry of the models.

Everything is pretty nice here. The printer is powered by a standard ATX power supply, which in turn is an integral part of the design, which is good news. The controller board is located in a separate compartment that is attached to the power supply. All wires are collected in flexible cable channels. The board has a connector that allows you to connect an LCD display, but the manufacturer does not supply the display itself. WiFi, unfortunately, is not supported.

Simple and tasteful.

As I said, the printer has a 100% Russian production cycle.

Plastic parts of the truss are molded on in-house facilities and some structural elements are produced, the final assembly of the printer and packaging are carried out.

The controller board is also printed in Russia, and the model is printed in Zelenograd. There is also an aluminum U-shaped frame and a hot table.

Stepper motors, of course, Chinese.

As a result, the manufacturer has its own service and technical support, and a virtually unlimited supply of original spare parts. Again, if you make any changes to the design (of course, and only improve), you can quickly order and receive a new part directly, so to speak, from the machine. From my own experience I will say that technical support is adequate enough, well knows their product and software to the printer. In any case, the master’s voice never broke in 20 minutes, no one dropped the phone, but calmly and distinctly explained how the auto-calibration works and why software presets are needed.

Even in the production section, I would mention the bar. The manufacturer supplies a lot of different colored bars ABS and PLA made in China. Why Chinese? Because, according to the manufacturer, at the printer development stage, they tried many suppliers, both Russian and German, and, ultimately, settled on a Chinese supplier, reliable and high-quality. I can not yet say anything about this. I ordered myself a couple of reels of PLA, I will try, write it off. But the bar really is always available in any color. The Middle Kingdom in this regard has not yet failed, Arbeiten is Stakhanovist, so to speak.

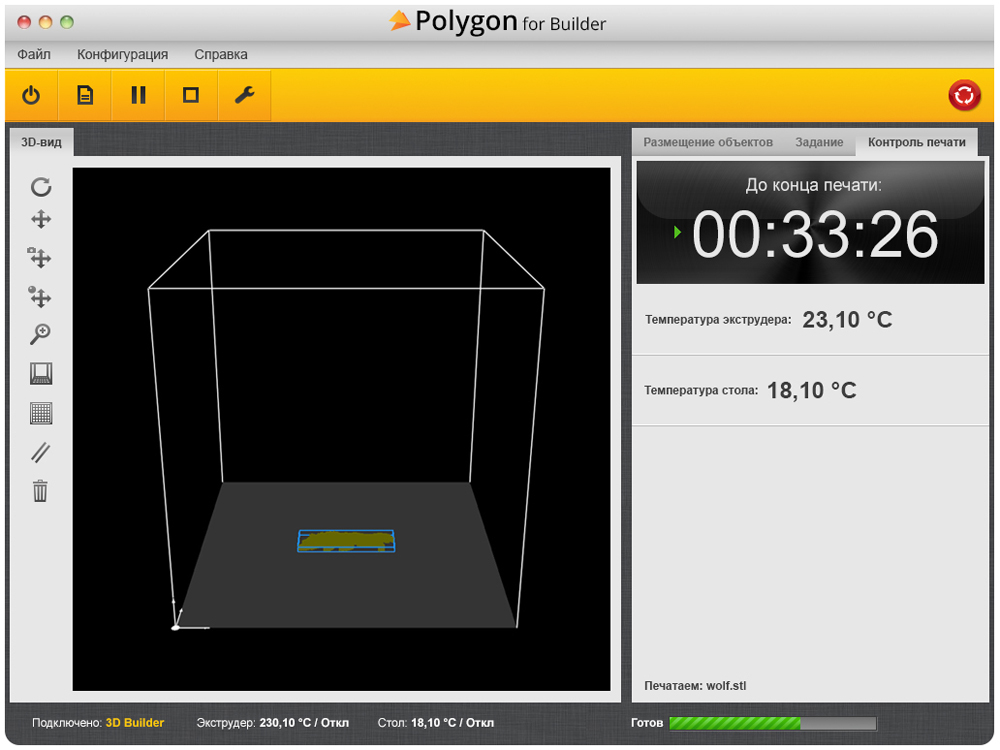

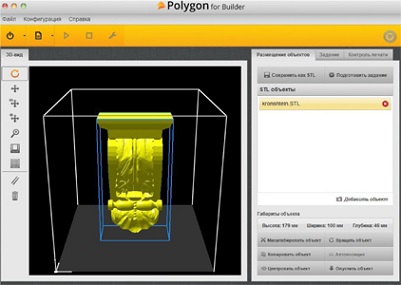

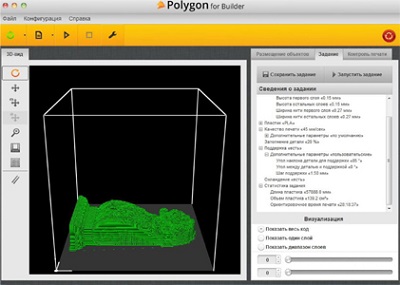

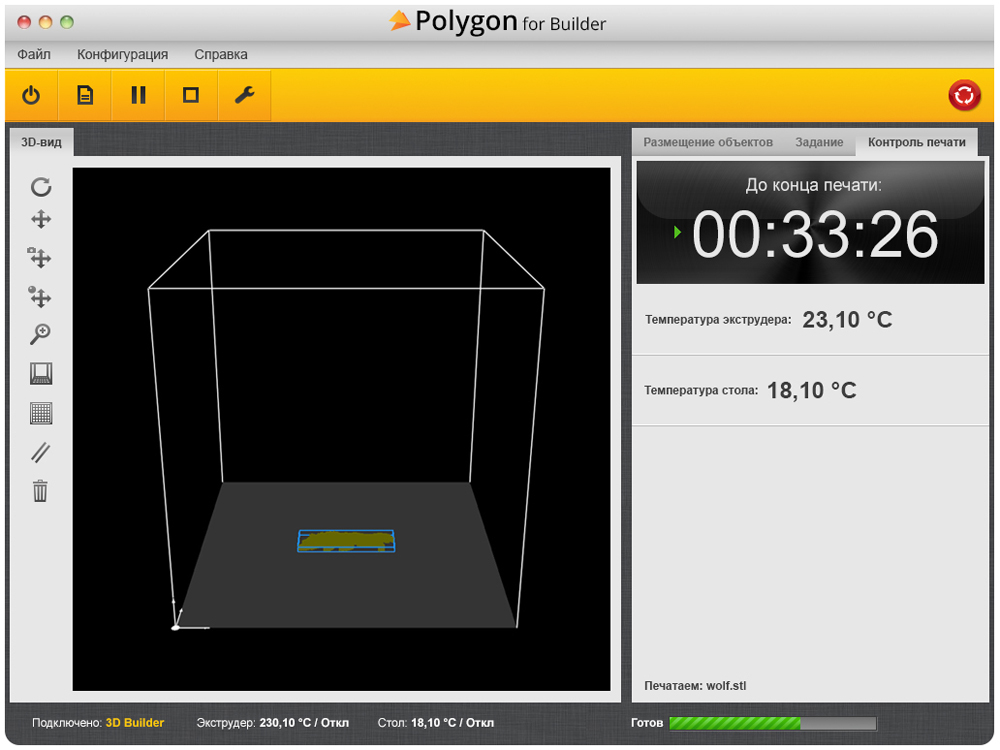

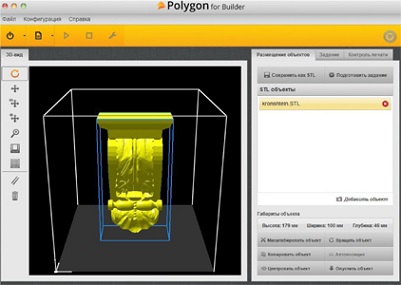

And here, perhaps, the most interesting. The manufacturer has in its arsenal its own software, like Repetier-Host , i.e. Add-on Slicer Slic3r.

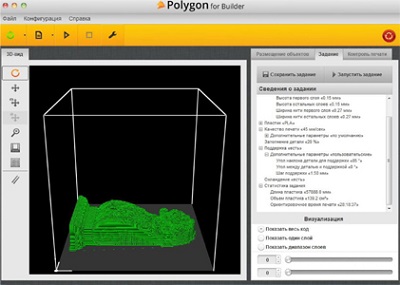

In this case, not all Slic3r parameters are displayed in the Polygon, but only the most common and most frequently edited ones — print speed, layer thickness, percent fill, and some more. All the rest of the set of parameters "sewn" in the presets, which the manufacturer recommends to choose, depending on the specific task. But this, of course, is for ordinary lay people, for those who want to simply print and in advance qualitatively. And for Lefty - please, you can delve into the settings of Slic3r directly, it is not forbidden. Slic3r is replaced by simply copying a new version of the slicer into the same folder.

With the presets, the developer really surprised ... the quality of thin-walled structures, the truth of ABS, delivers.

At Printrbot, I haven’t succeeded in this yet ... shaman, ma. And the size does matter.

In addition to the presets, the Polygon for Builder software contains separately called typical operations for the printer, for example, nozzle replacement — the printer will heat the extruder, command when you can replace the nozzle, then run out some plastic, calibrate, cool. Or the supply of a new bar will warm up, take the bar, stretch, calibrate, cool. And so on.

In general, the very approach to software, despite the austere design, was pleasantly surprised. As if for himself.

Unfortunately, the software is closed. It is not very clear why, because the community could successfully modify and refine it, and the variety of CC licenses would allow it to monetize, where necessary, for example, in the B2B market.

And the conclusion, in fact, this - 3D-Builder surprised!

Indeed, on the sly, nowhere on display, he was born on the Russian land, grew up and took his rightful place among foreigners, in the best traditions of ancient Russian fairy tales. Moreover and with autocalibration and ring blowing of model. Mdja ... I want to give one such AvtoVAZ.

If anyone knows, I am the owner of Lada Grants.

Having amused your and our, so to say, self-love and patriotism, as goose cracklings for Velvet, and for the modest low-calorie from Palych, I hurry to inform you of the most interesting news that the next assembly and packaging of the 50th new printers Picaso 3D-Builder, and they will be implemented, starting this week, with a small discount, about 10-12%.

For the Christmas sale, so to speak, not otherwise.

There is no such information on the Picaso site yet, but orders at a discount are already being accepted.

It is on this positive note about such an extraordinary and original novelty of our country, and I am not ashamed of this word - high-tech production, let me finish it.

But for those who are interested in my further creative explorations with Printrbot, I can report the following.

Recently released candidate release Slic3r. It includes two interesting options for generating perimeters and generally updated this algorithm. The smoothness of the models has increased significantly, and even to the naked eye.

The old problem with the beginning of the perimeter over the precipice - has disappeared. But there were, as usual, new ones. Now the slicer increases the slicing time exponentially depending on the number of printed objects (ie, loaded STL files). If slicing a single object takes 1-2 minutes, then slicing ten such objects took me more than 120 minutes, i.e. geometric progression with a denominator of 1.6 - 1.65. If you save all 10 objects in a 1 * .STL or * .OBJ file and then reload it into a slice, but as a single object, then the time of slicing decreases to 40 minutes. Obviously, this is some kind of bug resulting from the constant recalculation of previous layers of separately loaded models.

In addition, if any accelerations are set for the perimeters and filling, then the slicer now swears at “0” in acceleration by default, now I put it 9000 mm / s / s.

But Muza Isaakovna strongly advises not to lose hope and hope for a quick final release of Slic3r.

What we inspire and follow.

With the onset of stable cold weather in Moscow, it was possible to test the long-standing idea of the influence of ambient temperature on the quality of the models produced. Printrbot Jr was brought to the balcony and charged with a five-hour model at an air temperature of about 6 degrees.

The result was quite predictable:

As a result, it became possible to achieve some painless increase in print speed by 20% and layer thickness up to 0.25 mm (for a nozzle 0.35 mm), while maintaining external quality at the level of printing in a warm room, but with a layer of 0.20 mm. Those. reduced printing time and a little bar.

On the left 0.25mm in the cold, on the right 0.20mm in the heat. The “cold” model visually and to the touch looks smoother and has fewer defects.

All in the garden, in the winter! (WITH)

That's all.

The end.

Picaso 3D-Builder

A distinctive feature of this printer is its Alma Mater, namely:

- although, as it is not hard to guess, looking at the picture, the classic Prusa Mendel was taken as the basis, all subsequent “file processing” was planned exclusively by the Russian team;

- The printer has a 100% Russian production cycle. Yes, yes, do not be surprised, it really is. And what advantages and disadvantages followed such a decision, I just tell you further;

- and the printer is equipped with its own software for Picaso Polygon . The software is closed and resembles Repetier-Host , but unlike the latter, it contains a set of presets specifically for Picaso 3D-Builder.

First, let's talk about the design features.

As I said earlier, the Picaso 3D-Builder is based on the classic Prusa Mendel, but with some improvements.

There are not many changes, but each of them is not very bad.

And all the production of the printer, as usual, is concentrated in the glorious city of Zelenograd.

')

So - farm

The farm itself is practically no different from Grandpa Mendel. Changes have undergone plastic parts farm. They have a pleasant orange color, are more massive and are produced by casting, and not printed on the printer itself, which has a positive effect on quality. At the same time, the manufacturer has 3D-models of these parts and can provide * .STL files to users for self-printing, if necessary, for repair, for example.

Also, the farm is reinforced with a U-shaped aluminum frame. Moreover, the frame is not mounted in the plane of the Z-axis, as on the new Prusa i3 , but on the leading edge of the side triangle.

Prusa i3 3D Builder

Here the question is more of a design. Combined with orange details, 3D-Builder looks nicer than Prusa i3 and even has more rigidity, because it has kept triangular trusses on its sides.

Printhead

This is where our craftsmen did their best.

First, let's talk about the extruder.

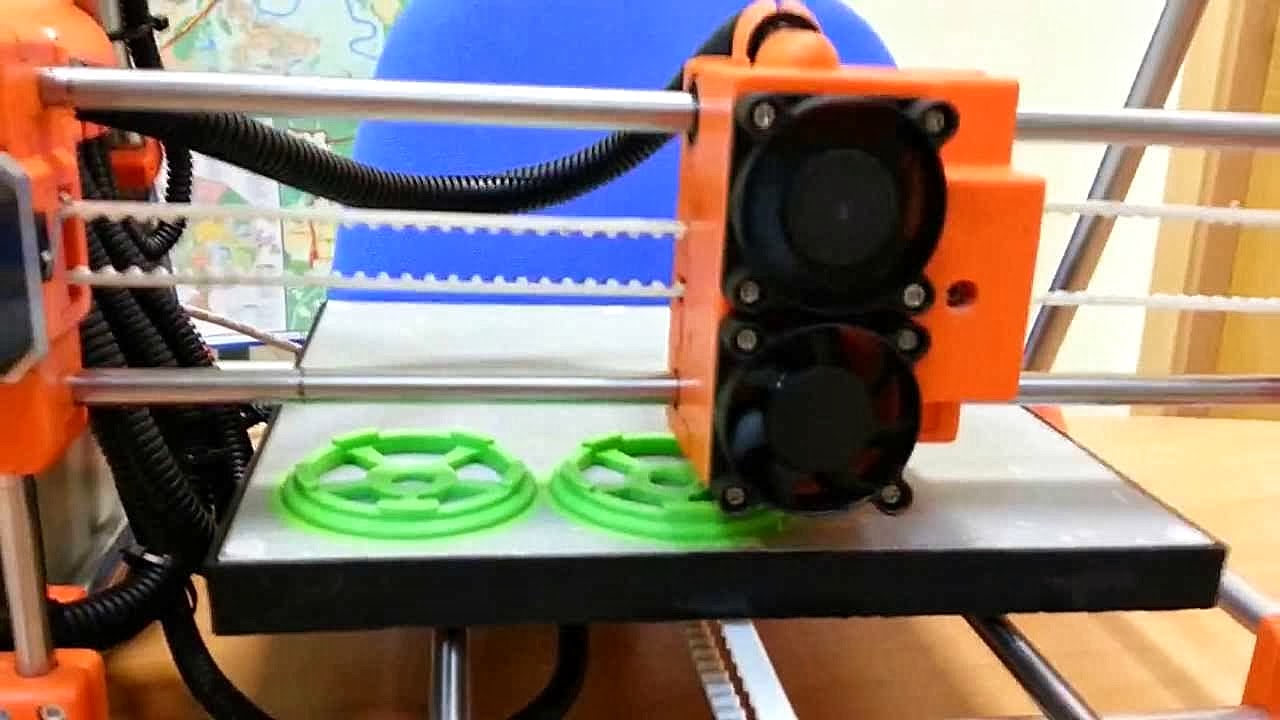

As can be seen in the picture, all the moving elements of the extruder are closed by the print head housing. This is a definite plus, since dust does not fall on the gear pairs. The extruder is not "straight-through", in contrast to the more budgetary and increasingly popular options, where the ribbed bolt is attached directly to the motor shaft, but on the contrary, it has two ribbed rollers and both are driven through a gearbox.

With such a scheme, a bar jam or “obstruction” is practically excluded.

A "straight-through" extruder, no matter how you conjure with the motor driver, stretches the bar in jerks, which of course will affect the quality of your model. The gearbox, to some extent, allows to minimize this effect. If you still decide on a straight-through extruder, check that the driver for the stepping motor supports 1/32 steps or higher.

For comparison - a new wooden straight-through extruder Printrbota.

Now about the hot end and auto-calibration.

Here everything is really interesting. The hot end, along with part of the printhead and sensors on the Z axis, form the original auto-calibration system. Which one, the developer does not disclose, referring to the know-how, and I haven’t succeeded in disassembling the 3D-Builder myself. Autocalibration itself takes place before each printing start, as an element of parking. Thus, whatever happens to your table and nozzle, whenever you change the nozzle and whatever geometry it has, whatever Kapton or other table cover you use, the height of the nozzle tip above the table will always correspond to the set parameters, with any circumstances.

For its hot ends, Picaso offers several different nozzles, from 0.30 mm (note, from 0.30 mm!) For fast printing, to 0.15 mm for high-quality printing.

I especially liked the ventilation.

But only its lower part.

The top fan, as usual, in the old fashioned way, blows onto the hot end itself and creates a temperature gradient in its upper part, minimizing the size and influence of the “plug” on the process of passing the bar ( more details can be found here in the section “Interesting rheology”). However, as I wrote in previous articles, the gradient is already created due to local heating of the rod, and the use of a fan can be replaced by using a more massive hot end, preferably a ceramic one, like the Ubis Hot End . But, this moment will remain on the conscience of developers.

Much more interesting bottom fan!

Through a system of channels in the print head housing, it creates a ring and uniform blowout of the model directly in the print area. And just in contrast to the fans located on the brackets on the side of the extruder - it does not create any gradients in the print zone and allows the plastic to solidify evenly in all directions and with minimal deformation.

From my own experience, I will say that any separately placed fan causes defects in printing, for example, such structures.

In the case of my Printrbot, where the fan is brought forward from the extruder, the rear "horns" of thin-walled models all the time tend to bend forward in the process of printing. In some cases, this leads to oblong horns or the disruption of the entire model from the table when the nozzle hits an excessively curved horn.

Note

Basically, I type and give examples of PLA plastic. It is safer than ABS, non-toxic and biodegradable. PLA models always look more rough than ABS, and in the case of transparent plastic - the effect is visually enhanced.

Hot table

It's all in line with the best fashion trends in LandOn houses. The table is made from a single piece of aluminum, and the heater is located inside. Thus the table is not deformed when heated, heats up very evenly and keeps the temperature.

Aluminum is really thick.

Another feature of the table is the material with which it is covered. This is not Kapton, but some synthetic material with even greater adhesion to ABS and PLA. The manufacturer keeps the composition of the material a secret, but sells it as it is worn by 3D-Builder users. Here is such an exclusive.

And yet, yes, the table has a size of 20 x 20 cm, which favorably distinguishes the printer from its competitors for the better. Size, Mother Russia, has always been rich, on that stand.

Stepper motors

Here I want to say only that one motor is used along the Z axis. The second screw (since the design of the farm is U-shaped) is driven by a belt drive. The design, in my opinion is not the best. The belts are not absolutely rigid, and when they begin to deteriorate, the lag of the second screw will be more and more noticeable, which can lead to misalignment of the horizontal axes and introduce corresponding defects into the geometry of the models.

Electrician

Everything is pretty nice here. The printer is powered by a standard ATX power supply, which in turn is an integral part of the design, which is good news. The controller board is located in a separate compartment that is attached to the power supply. All wires are collected in flexible cable channels. The board has a connector that allows you to connect an LCD display, but the manufacturer does not supply the display itself. WiFi, unfortunately, is not supported.

Simple and tasteful.

Now a little about the production

As I said, the printer has a 100% Russian production cycle.

Plastic parts of the truss are molded on in-house facilities and some structural elements are produced, the final assembly of the printer and packaging are carried out.

The controller board is also printed in Russia, and the model is printed in Zelenograd. There is also an aluminum U-shaped frame and a hot table.

Stepper motors, of course, Chinese.

As a result, the manufacturer has its own service and technical support, and a virtually unlimited supply of original spare parts. Again, if you make any changes to the design (of course, and only improve), you can quickly order and receive a new part directly, so to speak, from the machine. From my own experience I will say that technical support is adequate enough, well knows their product and software to the printer. In any case, the master’s voice never broke in 20 minutes, no one dropped the phone, but calmly and distinctly explained how the auto-calibration works and why software presets are needed.

Even in the production section, I would mention the bar. The manufacturer supplies a lot of different colored bars ABS and PLA made in China. Why Chinese? Because, according to the manufacturer, at the printer development stage, they tried many suppliers, both Russian and German, and, ultimately, settled on a Chinese supplier, reliable and high-quality. I can not yet say anything about this. I ordered myself a couple of reels of PLA, I will try, write it off. But the bar really is always available in any color. The Middle Kingdom in this regard has not yet failed, Arbeiten is Stakhanovist, so to speak.

Software Picaso Polygon .

And here, perhaps, the most interesting. The manufacturer has in its arsenal its own software, like Repetier-Host , i.e. Add-on Slicer Slic3r.

In this case, not all Slic3r parameters are displayed in the Polygon, but only the most common and most frequently edited ones — print speed, layer thickness, percent fill, and some more. All the rest of the set of parameters "sewn" in the presets, which the manufacturer recommends to choose, depending on the specific task. But this, of course, is for ordinary lay people, for those who want to simply print and in advance qualitatively. And for Lefty - please, you can delve into the settings of Slic3r directly, it is not forbidden. Slic3r is replaced by simply copying a new version of the slicer into the same folder.

With the presets, the developer really surprised ... the quality of thin-walled structures, the truth of ABS, delivers.

At Printrbot, I haven’t succeeded in this yet ... shaman, ma. And the size does matter.

In addition to the presets, the Polygon for Builder software contains separately called typical operations for the printer, for example, nozzle replacement — the printer will heat the extruder, command when you can replace the nozzle, then run out some plastic, calibrate, cool. Or the supply of a new bar will warm up, take the bar, stretch, calibrate, cool. And so on.

In general, the very approach to software, despite the austere design, was pleasantly surprised. As if for himself.

Unfortunately, the software is closed. It is not very clear why, because the community could successfully modify and refine it, and the variety of CC licenses would allow it to monetize, where necessary, for example, in the B2B market.

Conclusion

And the conclusion, in fact, this - 3D-Builder surprised!

Indeed, on the sly, nowhere on display, he was born on the Russian land, grew up and took his rightful place among foreigners, in the best traditions of ancient Russian fairy tales. Moreover and with autocalibration and ring blowing of model. Mdja ... I want to give one such AvtoVAZ.

Note

If anyone knows, I am the owner of Lada Grants.

Well, and for sweet

Having amused your and our, so to say, self-love and patriotism, as goose cracklings for Velvet, and for the modest low-calorie from Palych, I hurry to inform you of the most interesting news that the next assembly and packaging of the 50th new printers Picaso 3D-Builder, and they will be implemented, starting this week, with a small discount, about 10-12%.

For the Christmas sale, so to speak, not otherwise.

There is no such information on the Picaso site yet, but orders at a discount are already being accepted.

It is on this positive note about such an extraordinary and original novelty of our country, and I am not ashamed of this word - high-tech production, let me finish it.

PS

But for those who are interested in my further creative explorations with Printrbot, I can report the following.

About Slic3r

Recently released candidate release Slic3r. It includes two interesting options for generating perimeters and generally updated this algorithm. The smoothness of the models has increased significantly, and even to the naked eye.

The old problem with the beginning of the perimeter over the precipice - has disappeared. But there were, as usual, new ones. Now the slicer increases the slicing time exponentially depending on the number of printed objects (ie, loaded STL files). If slicing a single object takes 1-2 minutes, then slicing ten such objects took me more than 120 minutes, i.e. geometric progression with a denominator of 1.6 - 1.65. If you save all 10 objects in a 1 * .STL or * .OBJ file and then reload it into a slice, but as a single object, then the time of slicing decreases to 40 minutes. Obviously, this is some kind of bug resulting from the constant recalculation of previous layers of separately loaded models.

In addition, if any accelerations are set for the perimeters and filling, then the slicer now swears at “0” in acceleration by default, now I put it 9000 mm / s / s.

But Muza Isaakovna strongly advises not to lose hope and hope for a quick final release of Slic3r.

What we inspire and follow.

About cold

With the onset of stable cold weather in Moscow, it was possible to test the long-standing idea of the influence of ambient temperature on the quality of the models produced. Printrbot Jr was brought to the balcony and charged with a five-hour model at an air temperature of about 6 degrees.

The result was quite predictable:

- the number of defects in difficult places has decreased;

- roughness dropped;

- geometric dimensions have become more accurate;

As a result, it became possible to achieve some painless increase in print speed by 20% and layer thickness up to 0.25 mm (for a nozzle 0.35 mm), while maintaining external quality at the level of printing in a warm room, but with a layer of 0.20 mm. Those. reduced printing time and a little bar.

On the left 0.25mm in the cold, on the right 0.20mm in the heat. The “cold” model visually and to the touch looks smoother and has fewer defects.

All in the garden, in the winter! (WITH)

That's all.

The end.

Source: https://habr.com/ru/post/203698/

All Articles