We extract gold from old electronics

Each of us has accumulated dozens of unnecessary and broken gadgets. It turns out that all these devices are able to bring a little benefit before their destruction.

An engineer and chemist, Joseph Murchison, published on the Instructables website step-by-step instructions on how to smelt gold from old electronic devices that you were going to throw into landfill: old laptops, phones, cameras, printers, scanners and other unnecessary junk.

')

Each electronic board contains a few milligrams of platinum, gold, silver and copper, which can, if desired, be retrieved from electronic debris.

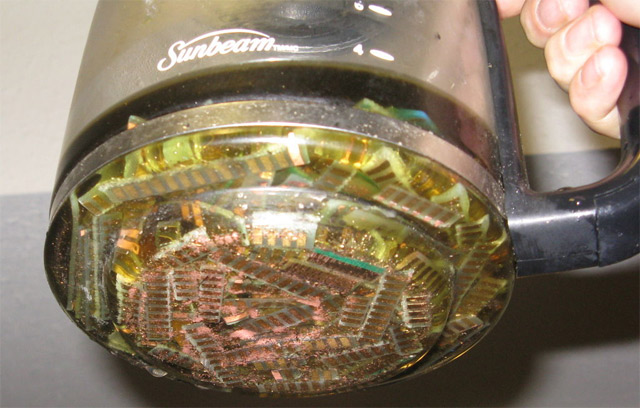

The most profitable is to mine gold. Joseph Murchinson says that the older the electronics, the more gold there can be. First you need to collect all the gold-bearing parts together. For several months, everyone can gather up a lot of such details. The photographs show what Joseph managed to assemble in three months.

Parts need to be sorted and with the help of a magnet to remove gold-plated steel, which requires a separate process technology.

Gold plates that have been cleaned of dirt are lowered for one week into a solution of hydrochloric acid (two parts) and hydrogen peroxide (one part). Every day, a pot of acid should be lightly stirred.

After a week, the solution darkens and floating flakes of exfoliated gold become visible. They must be passed through a coffee filter and rinsed with methyl alcohol.

Next you need to fuse the scales in one ingot. The melting point of gold is 1063 ° C, so an ordinary burner cannot cope with the task. But if gold is treated with sodium tetraborate (borax), the melting point decreases.

Next, melt a mixture of borax and gold.

Having received an ingot, you need to weigh it to assess profits. Here such an ingot weighs a little more than a troy ounce (31.1 g) and costs from 600 to 1600 dollars

A good addition to the scholarship for three months of work.

Source: https://habr.com/ru/post/202922/

All Articles