Say a word about organic photovoltaics. Part 2

In the first part of this long story, it was shown that it would be very difficult to overcome a crystalline silicon monster of photovoltaics, especially with organic molecules, but is it really so? What is there in the third generation of solar cells, which is not the previous two?

')

Of course, now it is difficult to talk about any specific figures, because the market itself is still being formed: supply and demand are not balanced, technologies are just being moved from laboratories to experimental factory sites. However, as we saw with the example of crystalline silicon, at such a time it is very difficult to talk about the future of technology (remember that the price of polycrystalline solar cells fell 3 times in 7 years ?!).

And according to this, I will try to describe more not the economy of production and operation of DSSC or organic solar cells (after all, the talk about EROI will begin again), but what potential they have and what technologies are used to make the price of end devices so small as far as possible.

3rd generation: the future is here!

Perhaps we will begin in the tradition, with some retrospective analysis of the effectiveness of solar cells, prepared by the NREL - The National Renewable Energy Laboratory .

Retrospective analysis of the best efficiency indicators of solar cells of all known types

The graph shows a whole class of “emerging PV”, i.e. those same group of alternative methods that, as mentioned in the first article, can fire at any moment. But let's start in order.

Roll-to-Roll process or print me like a newspaper

Perhaps one of the most significant characteristics of the third generation of solar cells is that they can be printed.

It is worth explaining. For the two previous generations of solar cells, in order to get a working panel, it is necessary to create, one way or another, pn-transition (see here for explanations), which means that high-vacuum equipment is needed, the production line is airtight, and so on through the list - everything is like in an adult of life. In this case, the plate travels along the conveyor from one end to the other, increasing pn-junctions and contacts. There is also the problem of combining (or alignment) of the masks used for etching and creating a 3D structure (in fact, as in processors, only the technical process is not nanometers, but micrometers and millimeters). And it would be nice to replace all this disgrace with something simpler ...

About a miracle, such a process has been used for decades to print printing products. With minor modifications, we could replace the ink with some photoactive organic molecules - semiconductors and conductors - and break the drawing on the drum into areas corresponding to individual photo cells. And voila, stamp - I do not want!

In this case, it is possible to significantly reduce both the weight of such elements and the amount of materials used, because silicon is both a substrate and an active component in a silicon battery, and it is impossible to make a substrate infinitely thin, it must have at least some minimum set of mechanical characteristics.

How does this work in practice? In the same KIT there is not the so-called “technology transfer center”, but a completely real and working one, in which the following is carried out:

a) research aimed at improving the characteristics of batteries, while there is a direct feedback with scientists and engineers who develop technologies;

b) prototyping site, which works out the fundamental scalability of the technology;

c) already a semi-industrial sector, where in a couple of minutes it is possible to make linear meters and hundreds of meters of solar cells.

The structure of technology transfer from the laboratory to production. KIT and TU Darmstadt with BASF, Merck

Notice that the center is not just with two universities, but manufacturers are actively participating in it, which may sooner or later launch these developments in their production.

The public, I think, got a little tired, so the video of the work of the above-mentioned laboratory live on YouTube:

And one of the most significant areas of application of this process is just organic photovoltaics.

Organic Photovoltaics

No matter how funny it sounded, but in the world of organic chemistry reigns its atmosphere of unbridled fun. For example, among organic molecules one can find insulators, conductors, semiconductors, and - even scary to think - superconductors. Some time ago it was generally believed that organic materials would force out everything, including concrete, and reinforcement, and the machines would be made of carbon ... but it did not work out ...

What would an organic cell look like ?! And what could be its thickness?

For example, if you want, then 1 micron thick (50 times thinner than a human hair!):

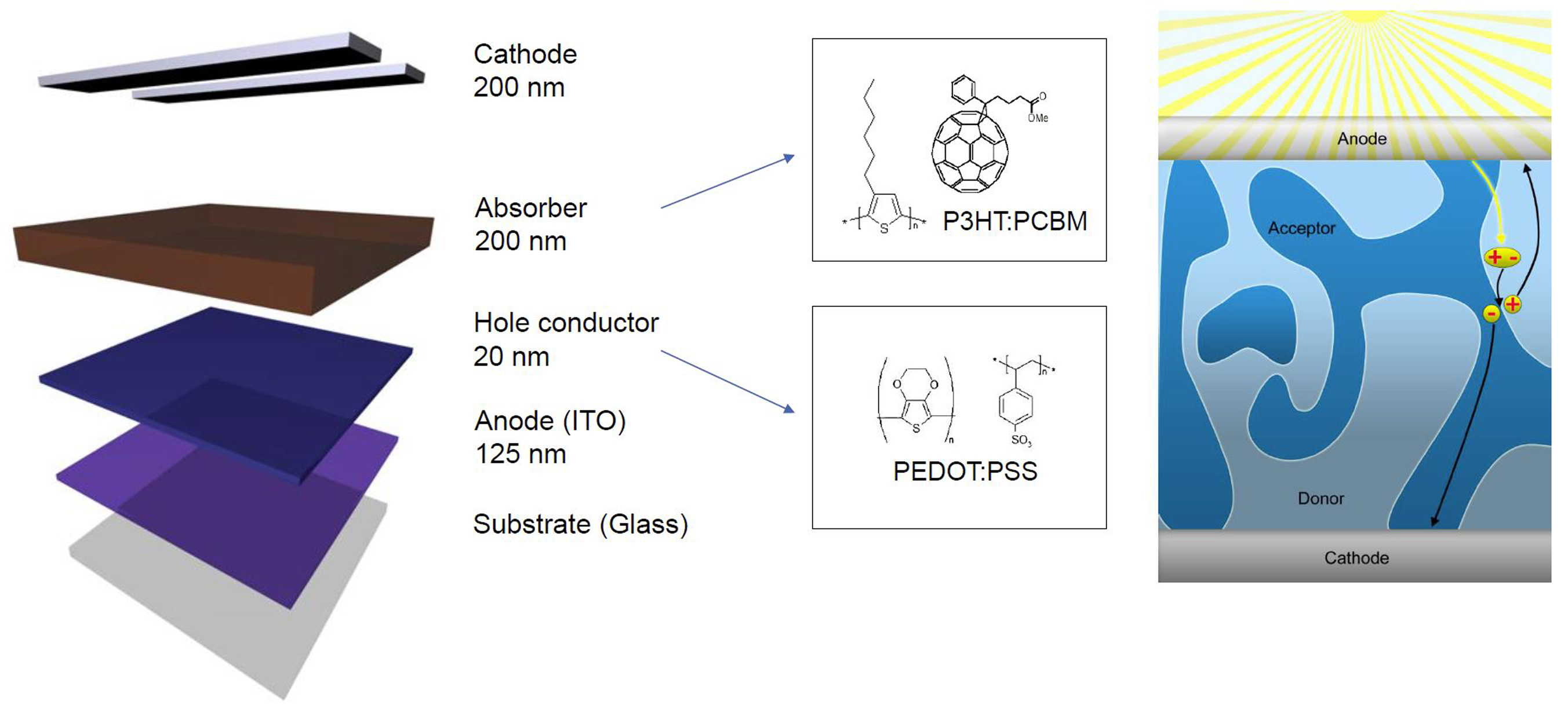

The device of a separate organic solar cell and the materials used to create it

Usually it is required that the electron acceptor (absorber) and the donor molecule (hole conductor) interpenetrate each other, forming the so-called bulk heterojunction. Since the separation of an electron-hole pair occurs on the surface, due to the mutual penetration of the two phases into one another, the effective contact area increases (shown in the picture to the right), and this in turn corresponds to the maximum efficiency of such a battery.

The substrate does not have to be glass: both the cathode and the anode can be made by any available technology, including those based on conductive polymers, which allows you to fully realize the advantages of the roll-to-roll process.

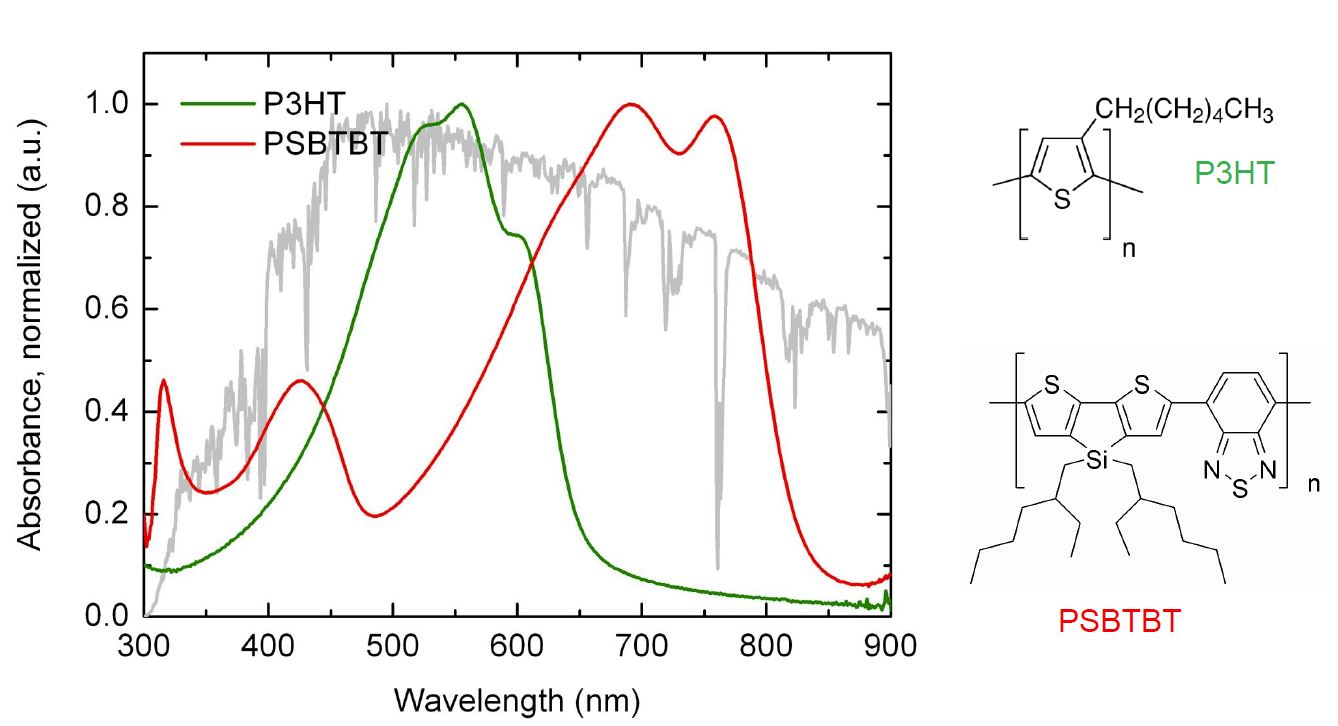

Yes, unfortunately, I must state that the efficiency of these batteries is not great up to 7-8%, but this is all due to the fact that the above molecular motifs do not absorb in the entire wavelength range from UV (ultraviolet, 300-400 nm) to infrared (infrared 800-1000 nm).

On the one hand, this is a problem, it is necessary to invent more cunning schemes with two combined batteries, the so-called tandem solar batteries, or simply to make the battery translucent and stick it on the window.

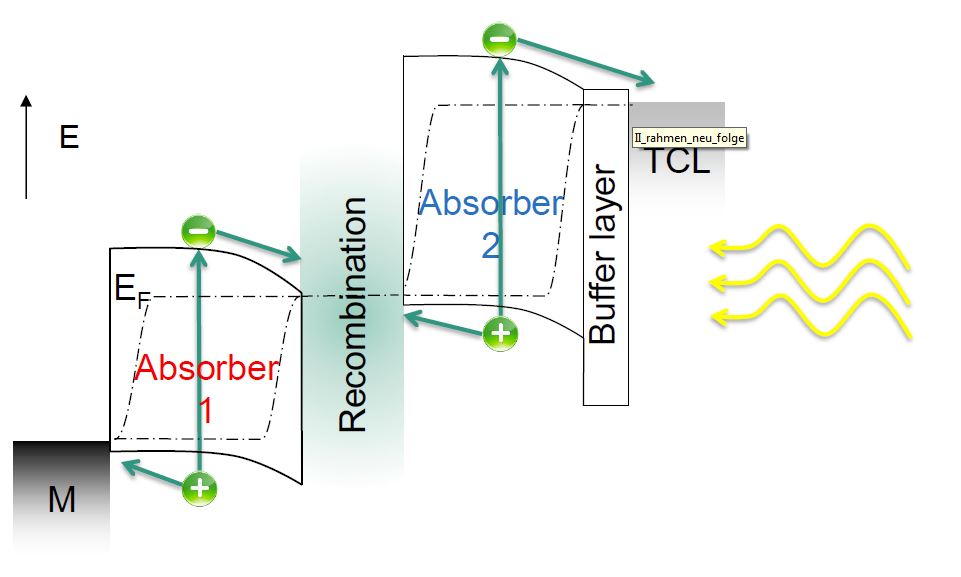

In the case of tandem solar cells, we simply have two series-connected solar cells that absorb in two different ranges, for example, green and red. Due to this, efficiency actually doubles, because more photons are converted into EMF and current. However, the main problem in this case is the intermediate layer, which is necessary for combining excess charges. It is clear that if a layer accumulates a charge, then due to internal losses this will reduce the efficiency.

The principle of operation of a tandem solar battery: two series-connected organic solar cells

An example of the absorption spectrum of two organic substances used in the production of tandem solar cells

At this point, it would be possible to delve into materials science, but I will not do this, I just want to say a few words in defense of high-performance batteries and the process of developing them, that this is not a waste of budget funds. You can’t just take it, spread the paste with an even layer on the substrate, then the second layer, the third one, stick the contacts and say that it’s ready, saying: “Okay, and it will do!” But behind each percentage of effectiveness are patents, special additives that change the packing of molecules in such a way as to achieve the best penetration of one compound into another. In order to describe such processes, why substance A helps, but substance B does not, a fundamental science with all its flaws, defects and attitudes, worth millions and billions of dollars, is urgently needed.

Dye Sensitized Solar Cell (DSSC)

Solar cells, sensitized or “activated” dye, known to the world for a long time. However, only recently, as mentioned in the previous article , were they able to successfully take a psychologically important barrier of 15% efficiency. At present, this is an absolute record among the solar cells of this class. The principle of operation of the batteries is presented in detail in the above publication, so we will not dwell on it.

Usually, DSSC requires a glass substrate with a conductive coating, such as ITO (tin oxide, doped with indium) or FTO (tin oxide, doped with fluorine), which consumes a significant portion of production costs. However, it is fair to say that these batteries can potentially be adapted to printing through the roll-to-roll process, discussed above.

And once again I want to repeat that the field of application of such batteries is not the generation of MW of electricity, but rather aesthetically-practical, as is the case with transparent organic batteries - reducing overall energy consumption, while maintaining high standards of living. That is, the battery was stuck on the window, it charged you for a day, the battery charged, for example ...

While this article was being prepared, the news unexpectedly came up with an urgent notice to the room!

Breaking news

The EPFL ( SwissTech ) conference center currently under construction will be equipped with a DSSC-based glass facade. Transparent multicolored solar cell panels Gratzel are currently installed on the western side of SwissTech center, the opening of which is scheduled for April 2014. Solar panels, the total number of which is 1,400 pieces with dimensions of 35 by 50 cm, will equip more than 300 m 2 of the building's facade. The elements themselves are made in five shades of red, green and orange, which, according to architects and designers, creates a warm and at the same time lively appearance.

It is worth noting that a project of this kind is the first in the world. Solar cells are designed in such a way that they do not lose their effectiveness when the angle of sunlight falling on them changes, and they not only allow to generate electricity, but also protect the interior from direct sunlight, which will reduce the need for air conditioning. It is also reported that at least 11 manufacturers have already received a license to manufacture Gratzel’s solar panels.

And lastly, in order not to be unfounded, I will give a few examples of companies that work in the field of alternative solar cells:

Konarka . The company existed from 2001 to 2012 and was engaged in both DSSC and organic fullerene-based solar panels. During its existence, the company has created 350 patents in this area, has attracted more than $ 150 million in private investment and $ 20 million in government grants for the development and organization of production. Were designed solar cells with a guaranteed service life of 3 years with a registered efficiency of 8%. Unfortunately, in mid-2012, the company declared bankruptcy .

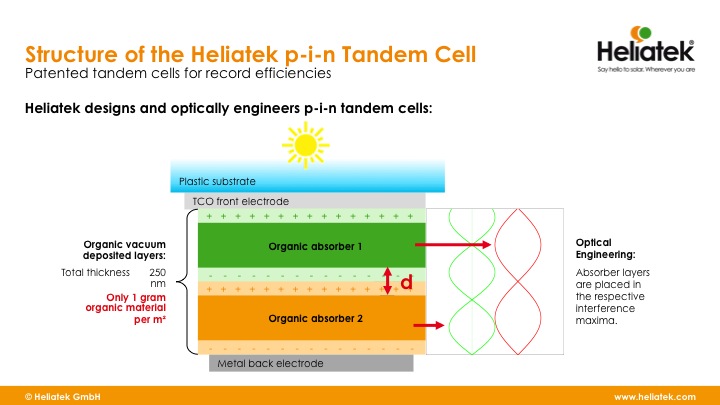

Heliatek . The company was founded in 2006 and specializes in organic photovoltaics, but it keeps afloat more successfully. Among other achievements, tandem batteries with an efficiency of 12% due to properly selected geometry:

Slide from the site of the company Heliatek

And by the way, in the next 4 years, the efficiency is planned to increase to 16%:

Slide from the site of the company Heliatek

As for DSSC, even such giants as Sony and Samsung are turning their attention towards DSSC, and it is planned that mass production will reduce the cost of modules to 1 / 3-1 / 5 compared to conventional silicon batteries. In the United Kingdom there are many companies involved in this topic ( for example ), so I’ll keep silent about the craftsmen from the Middle Kingdom ( for example ).

Instead of conclusion

At first, I wanted to write a three-dimensional conclusion that there should be an “alternative” non-silicon photovoltaic, that technologies are important, and how they tie together different areas of knowledge in the final product, but ...

Of course, I agree with BarsMonster that the main problem of today's alternative energy (anyone !!!, I ask you to notice) is the storage of the generated electricity and, most importantly, the cost of such storage. Or in other words, the uncertainty of this source. This is not a nuclear power plant, with which in Belgium the roads are illuminated even during the day. However, it seems to me that we are not quite correctly considering the structure of energy consumption from our current point of view, this is where the main flaw of all holivars on this topic lies. You need to change your mind and look at the problem with an abstracted eye.

But, no matter how paradoxical and pretentious it sounded, we live in an era of truly great transition from the age of silicon, to the age of carbon; and the tendencies that we are now witnessing (graphene, CNTs, organic light-emitting diodes and organic photovoltaics) are powerful evidence of this. It will take quite a bit more time, and not a single building will be designed (at least in the EU, USA, Japan) without Gratzel solar panels on the windows, which can significantly reduce and virtually zero the energy balance of the facilities. The back panel of the iPhone or of my Xperia Z will cover 2 micron organic batteries, which will recharge the phone wherever there is a light source, and electric cars will generally turn into one big moving solar battery. And I would like to be in this energy paradise, where the energy of the Sun is available to one and all ...

And you?!

Sometimes briefly, and sometimes not so much about the news of science and technology, you can read on my Telegram channel - welcome;)

Source: https://habr.com/ru/post/202836/

All Articles