The first silicon ionistor

Everyone knows the properties of ionistors - these electrochemical devices combine the properties of capacitors and chemical batteries. They are able to very quickly charge / discharge and store much more energy than ordinary capacitors, due to the unique feature - a double layer of ions and counterions, which act as electrolyte lining.

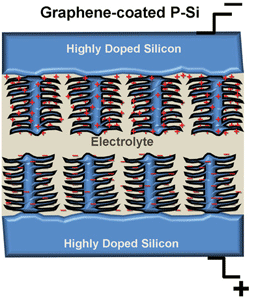

Everyone knows the properties of ionistors - these electrochemical devices combine the properties of capacitors and chemical batteries. They are able to very quickly charge / discharge and store much more energy than ordinary capacitors, due to the unique feature - a double layer of ions and counterions, which act as electrolyte lining.No one before could have imagined that it is possible to create ionistors from silicon, without the use of a chemical electrolyte. However, a scientific article in the journal Scientific Reports dated 10.22.2013 indicates that scientists from Vanderbilt University managed to do this. They were the first in the world to create a silicon ionistor by etching a silicon substrate and coating a wafer with graphene.

It is difficult to even describe what prospects this promises for mobile electronics, because now you can store the charge directly on the chip, without the need to charge a chemical battery! Imagine solar panels that charge and produce electricity around the clock. A mobile phone or laptop that charges in a few seconds and works for a week without recharging, or, conversely, can be discharged in a second, like a taser. And these are only the most obvious examples.

“If you asked an expert if it was possible to create a silicon ionistor, he would immediately tell you that this is a crazy idea,” said Cary Pint, an associate professor from the department of mechanical engineering at Vanderbilt University, who conducted the research (in the photo). “But we managed to find an easy way to do it.”

“If you asked an expert if it was possible to create a silicon ionistor, he would immediately tell you that this is a crazy idea,” said Cary Pint, an associate professor from the department of mechanical engineering at Vanderbilt University, who conducted the research (in the photo). “But we managed to find an easy way to do it.”')

The unique properties of electrochemical ionistors have already allowed them to find commercial applications. True, only in some narrow niches. For example, they are used to accumulate kinetic energy from braking in Formula 1 cars and some commercial vehicles, buses and electric vehicles. These are systems like KERS: they soon give up accumulated energy to the wheels, adding torque during acceleration. Ionistors put on the turbines of large windmills, which need to be fed with energy at the moments of changing the force and direction of the wind.

Ionistors are still inferior in energy density to chemical batteries such as lithium-ion batteries, so they are too cumbersome for most mobile devices, but quickly eliminate the lag.

The diagram shows the energy density (watt-hour per kg) and specific power (watts per kg) of porous silicon ionizers (P-Si), commercial carbon ionistors and porous silicon ionistors with graphene coating

It should be noted that recently experiments with ionistors from graphene or nanotubes are widely heard, so the new work of engineers from Vanderbilt University is somewhat out of the general flow.

The simplicity of their approach lies in the use of porous silicon, a material with controlled properties that can be easily obtained by etching "waffles." Engineers have discovered that by coating a material with a layer of graphene, its properties as an ionistor are drastically improved.

“We had no idea what would happen [when we started the experiments],” says Pint. “Usually, researchers grow graphene from silicon carbide at temperatures above 1,400 ° C, so at lower temperatures of 500–600 ° C we didn’t expect anything like it to grow.”

When the engineers took the silicon waffle out of the furnace, they saw that its color was no longer orange, but purple, sometimes black. The study under an electron microscope showed that porous silicon is coated with a thin layer of carbon several nanometers thick.

The structure of porous silicon without coating with graphene (left) and coated (right)

Tests have shown that the graphene coating acts as a protective layer, and when charging an ionistor, the maximum energy density has increased 25 times.

The authors of the study say that the purpose of their work is not to create ionistors with a record energy density, but to integrate them into ordinary microchips, which are made using a standard technical process. The most logical option is to install ionistors on the reverse side of solar panels and sensors. More and more devices around us require electrical energy: “The better we can integrate energy storage into existing materials and devices, the more compact and efficient they will become,” says Pint.

Source: https://habr.com/ru/post/199312/

All Articles