How does the prototype start

Good Friday everyone!

I would like to tell you a little about how prototypes are created. I am sure that many have come across this and know how it is done not by hearsay, it is unlikely that you will learn anything new from this article. This article is intended for those who are just starting their journey in DIY (do it yourself) and are designed to structure some fragmented information.

So, you decided to make a certain device. Usually, on this thought, everything ends, but sometimes it becomes the beginning of something bigger, wonderful and beautiful. It is not so important why you decided to make your device, and not to buy something ready - it is unique, not like others, you dreamed it, you decided to realize your childhood dream, you could not find what suits you best - the reasons are the most different, the main thing that the decision was made.

Before you start designing and implementing a dream, you need to decide on several points - the presence / absence of moving elements, whether you will collect it from the fact that you have or will not regret the forces and means for new parts, budget, terms, etc ...

')

A device with moving elements (small robot, machine tool, mousetrap) is a very interesting topic, it should be considered separately and in detail. Here a lot depends on the material from which you want to make elements. Naturally, the easiest and least time consuming option is to print them on a 3D printer. For sheet materials, laser cutting is best. If the material is dense and the product is volumetric or has many technological holes, it is worth ordering its manufacture on the CNC machine. If this is something "designer", use plastic for prototyping.

Prototyping from already existing parts is both more complicated and simpler. For example, you have 18 printers in your garage, 2 toasters and an old router and you want to make a 3D printer out of all this, a hexa-printer, and from the remnants a steampunk vase for your wife. All this, of course, is a good thing, but in practice, alas, only a few will have enough spatial thinking and technical view to see all this trash as a set of parts and imagine how they will be combined in a future design. Usually, it all comes down to the fact that out of 18 printers you get 3 bags of parts, the entire floor is studded with cogs and after that it’s easier to take these bags to the dustbin than to figure out what to do with them.

Budget and deadlines are sometimes key. Not many of us are ready to buy components for 2-3 thousand dollars and have been busy with it for the sake of the dreaming robo-cockroach. Usually, the idea is either realized within a few weeks or hopelessly forgotten (it is postponed for the distant future, when there is more time, money, and opportunities). But, however, the criterion of budget-timing plays a crucial role. It can be considered a criterion for the survival of the project If you do not mind the time to rethink the project so that its price becomes lower, and the number of errors during its implementation is less, then the likelihood that the idea is successfully implemented becomes higher.

Summarizing all of the above, we can draw the following conclusions:

1. When creating a prototype, it is necessary to maximize the use of existing elements and parts. This reduces the cost of construction.

2. If the available elements are not enough - use ready-made blocks that can be bought in stores for hobbies and amateur radio.

3. If possible, avoid self-manufacturing boards (especially controllers) - this is very cool and interesting, but if this is your first experience, it can seriously undermine the moral and fighting spirit, and also put an end to the future prototype. In addition, it is difficult to find the necessary components. In case of using ready-made modules and units, do not use sufficient solderless boards.

4. Always leave the opportunity to upgrade the device and the "margin of safety" elements. Do not do anything "back to back".

5. Before collecting the entire device, check the operation of individual elements. Read datasheets.

6. If you are not sure about the performance of the device, do not neglect the CAD programs. Drawing models, debugging circuits and firmware will save you time, money and nerves.

I want to tell a little about my experience. A few years ago, I was asked to design a device to control the AC load (it seems it was some kind of perverted lighting system for a shop window) with a timer. Photos unfortunately not preserved, instead I will try to describe in more detail. The task was not too complicated, and to create a prototype device, I decided to use ready-made modules. As it turned out, this was the best solution.

Because time and budget were far from endless, I decided to use the modules from the electronic designer Master KIT (now unfairly forgotten). Of course, these designers are a little expensive, but they almost do not need additional configuration after assembly, and there were no other alternatives at hand.

Without thinking, I took Arduino with an ATmega32 controller as the main controller.

I chose the NK150 module as the lighting control unit (only the relay was based on a more powerful load).

In order for the showcase to work on the clock, add a real-time module similar to the BM9319 .

On the part of the iron, everything agreed perfectly, I had to tinker a bit with the firmware, but it didn’t take much time either. In any case, making every element from scratch would have to mess around a week over the build and a couple more weeks over debugging each device individually, searching for errors, finding similar rakes on forums, etc. Packing everything in a beautiful box and getting the rest of the money from the customer has traditionally expressed a desire for further cooperation. We continued to cooperate in a few months. A new light appeared on the window and, accordingly, it also needed to be automated. Glad of my forethought, I simply stretched the wires from the new light to the relay terminals. A month later, 2 more of them appeared; 7 of 8 relays ended up busy. Then a dedicated Internet line appeared, and with it the need to manage the showcase remotely (in case of the sellers' forgetfulness, so that it could be forcibly turned off remotely). This also turned out to be easier - I connected the Arduino USB port to the USB printer port of the router.

For readers, it will probably be interesting to know how I set up the router, gateways and which one I flooded the firmware. But this is not my story, because The client sysadmin was setting up the router and access.

Perhaps the specialists will find the scheme rough, clumsy and not at all ideal (if not worse), but it worked well and steadily, repeatedly spent the money spent on it, I added additional modules several times and everything continued to work as stable without additional tricks for almost a year (until the customer's business is bent).

If you passionately want to create, create and test devices and mechanisms, you should refer to the following resources.

RadioKot

Roboforum

Master KIT

EasyElectronics and special thanks to DIHALT

RoboCraft

PS

I am sure that everyone has their own experience in creating devices, it would be interesting to learn about it. If you have encountered any inaccuracies or if you disagree with anything, express your constructive opinion.

For beginners, I want to say once again that my methods are not the only correct ones, but they proved themselves more than once in practice. Creating a new device is an incomparable pleasure, an opportunity to feel your capabilities and test yourself. To some extent it is freedom, because you can translate into reality almost everything you can imagine! And by following these simple rules, you will minimize frustration from failed projects and more often experience joy and freedom.

Thanks for attention!

I would like to tell you a little about how prototypes are created. I am sure that many have come across this and know how it is done not by hearsay, it is unlikely that you will learn anything new from this article. This article is intended for those who are just starting their journey in DIY (do it yourself) and are designed to structure some fragmented information.

So, you decided to make a certain device. Usually, on this thought, everything ends, but sometimes it becomes the beginning of something bigger, wonderful and beautiful. It is not so important why you decided to make your device, and not to buy something ready - it is unique, not like others, you dreamed it, you decided to realize your childhood dream, you could not find what suits you best - the reasons are the most different, the main thing that the decision was made.

Before you start designing and implementing a dream, you need to decide on several points - the presence / absence of moving elements, whether you will collect it from the fact that you have or will not regret the forces and means for new parts, budget, terms, etc ...

')

A device with moving elements (small robot, machine tool, mousetrap) is a very interesting topic, it should be considered separately and in detail. Here a lot depends on the material from which you want to make elements. Naturally, the easiest and least time consuming option is to print them on a 3D printer. For sheet materials, laser cutting is best. If the material is dense and the product is volumetric or has many technological holes, it is worth ordering its manufacture on the CNC machine. If this is something "designer", use plastic for prototyping.

Prototyping from already existing parts is both more complicated and simpler. For example, you have 18 printers in your garage, 2 toasters and an old router and you want to make a 3D printer out of all this, a hexa-printer, and from the remnants a steampunk vase for your wife. All this, of course, is a good thing, but in practice, alas, only a few will have enough spatial thinking and technical view to see all this trash as a set of parts and imagine how they will be combined in a future design. Usually, it all comes down to the fact that out of 18 printers you get 3 bags of parts, the entire floor is studded with cogs and after that it’s easier to take these bags to the dustbin than to figure out what to do with them.

Budget and deadlines are sometimes key. Not many of us are ready to buy components for 2-3 thousand dollars and have been busy with it for the sake of the dreaming robo-cockroach. Usually, the idea is either realized within a few weeks or hopelessly forgotten (it is postponed for the distant future, when there is more time, money, and opportunities). But, however, the criterion of budget-timing plays a crucial role. It can be considered a criterion for the survival of the project If you do not mind the time to rethink the project so that its price becomes lower, and the number of errors during its implementation is less, then the likelihood that the idea is successfully implemented becomes higher.

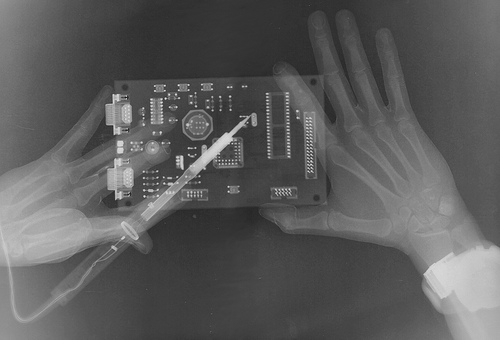

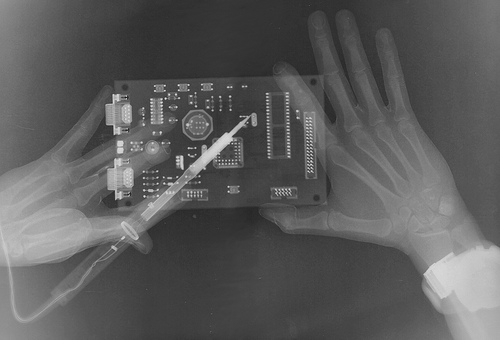

As Suvorov used to say, “The theory without practice is dead,” so let’s proceed to the illustrative examples.

Summarizing all of the above, we can draw the following conclusions:

1. When creating a prototype, it is necessary to maximize the use of existing elements and parts. This reduces the cost of construction.

2. If the available elements are not enough - use ready-made blocks that can be bought in stores for hobbies and amateur radio.

3. If possible, avoid self-manufacturing boards (especially controllers) - this is very cool and interesting, but if this is your first experience, it can seriously undermine the moral and fighting spirit, and also put an end to the future prototype. In addition, it is difficult to find the necessary components. In case of using ready-made modules and units, do not use sufficient solderless boards.

4. Always leave the opportunity to upgrade the device and the "margin of safety" elements. Do not do anything "back to back".

5. Before collecting the entire device, check the operation of individual elements. Read datasheets.

6. If you are not sure about the performance of the device, do not neglect the CAD programs. Drawing models, debugging circuits and firmware will save you time, money and nerves.

I want to tell a little about my experience. A few years ago, I was asked to design a device to control the AC load (it seems it was some kind of perverted lighting system for a shop window) with a timer. Photos unfortunately not preserved, instead I will try to describe in more detail. The task was not too complicated, and to create a prototype device, I decided to use ready-made modules. As it turned out, this was the best solution.

Because time and budget were far from endless, I decided to use the modules from the electronic designer Master KIT (now unfairly forgotten). Of course, these designers are a little expensive, but they almost do not need additional configuration after assembly, and there were no other alternatives at hand.

Without thinking, I took Arduino with an ATmega32 controller as the main controller.

I chose the NK150 module as the lighting control unit (only the relay was based on a more powerful load).

In order for the showcase to work on the clock, add a real-time module similar to the BM9319 .

On the part of the iron, everything agreed perfectly, I had to tinker a bit with the firmware, but it didn’t take much time either. In any case, making every element from scratch would have to mess around a week over the build and a couple more weeks over debugging each device individually, searching for errors, finding similar rakes on forums, etc. Packing everything in a beautiful box and getting the rest of the money from the customer has traditionally expressed a desire for further cooperation. We continued to cooperate in a few months. A new light appeared on the window and, accordingly, it also needed to be automated. Glad of my forethought, I simply stretched the wires from the new light to the relay terminals. A month later, 2 more of them appeared; 7 of 8 relays ended up busy. Then a dedicated Internet line appeared, and with it the need to manage the showcase remotely (in case of the sellers' forgetfulness, so that it could be forcibly turned off remotely). This also turned out to be easier - I connected the Arduino USB port to the USB printer port of the router.

For readers, it will probably be interesting to know how I set up the router, gateways and which one I flooded the firmware. But this is not my story, because The client sysadmin was setting up the router and access.

Perhaps the specialists will find the scheme rough, clumsy and not at all ideal (if not worse), but it worked well and steadily, repeatedly spent the money spent on it, I added additional modules several times and everything continued to work as stable without additional tricks for almost a year (until the customer's business is bent).

Thanks and links

If you passionately want to create, create and test devices and mechanisms, you should refer to the following resources.

RadioKot

Roboforum

Master KIT

EasyElectronics and special thanks to DIHALT

RoboCraft

PS

I am sure that everyone has their own experience in creating devices, it would be interesting to learn about it. If you have encountered any inaccuracies or if you disagree with anything, express your constructive opinion.

For beginners, I want to say once again that my methods are not the only correct ones, but they proved themselves more than once in practice. Creating a new device is an incomparable pleasure, an opportunity to feel your capabilities and test yourself. To some extent it is freedom, because you can translate into reality almost everything you can imagine! And by following these simple rules, you will minimize frustration from failed projects and more often experience joy and freedom.

Thanks for attention!

Source: https://habr.com/ru/post/198074/

All Articles