Can we weave new electronics from the web covered with nanotubes?

The cobweb is the strongest known material produced by living organisms, and even Kevlar is inferior to it more than 10 times . Now scientists have strengthened it with carbon nanotubes, making it stronger than the usual web, and increasing its electrical conductivity, which could lead to the creation of a new web-electronics.

The natural strength of the thread makes it potentially valuable for commercial use in many areas. Researchers are already exploring its medical potential, for example, when creating artificial skin or tendons .

In addition, the web can be greatly reduced, we believe this property can be useful in the production of artificial muscles for robots or prostheses. For example, a web only 1 mm thick can lift a weight of 5 kg, which is 50 times more than what our muscles of the same thickness can lift.

Note Translator: Apparently there is a supercontraction :

When the cobweb gets wet, it is greatly reduced (this phenomenon is called supercontraction). This is because the water molecules penetrate the fiber and make the disordered hydrophilic areas more mobile. If the cobweb is stretched and sagged from insects, then on a wet or rainy day it contracts and at the same time regains its shape.

Great strength and flexibility makes it an attractive material for use in electronics, but this application depends on how compatible it is with electrically conductive materials made by scientists. That is why they combined a web with carbon nanotubes, whose electrical conductivity has attracted researchers for decades.

Carbon nanotubes are hollow carbon tubes whose diameter is measured in nanometers. And although they are comparable in width to the DNA strand, they are 100 times stronger and 6 times lighter than steel, and their electrical and thermal conductivity competes with metals.

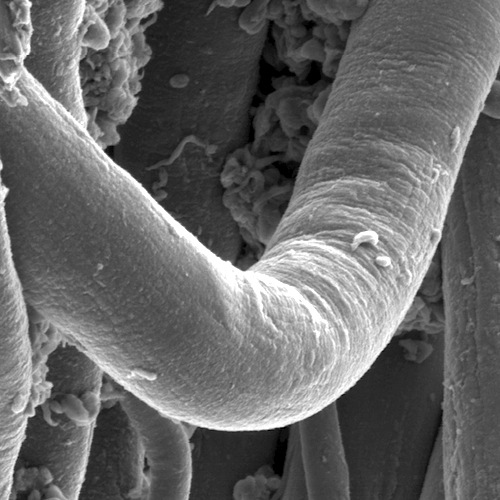

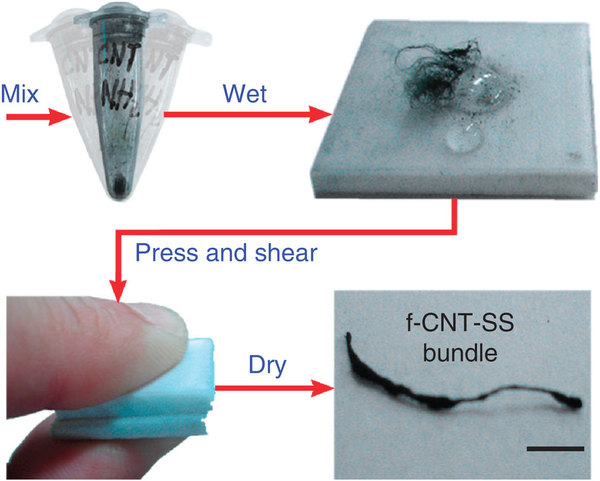

Although the web itself is zhetskaya, it becomes soft if it is moistened. Researchers mixed a web collected from a golden spike (Nephila clavipes), a web with a dry powder of carbon nanotubes, wetted this mixture with a few drops of water and ground them together.

"We were surprised at how easy it was to cover the thread with nanotubes," said Stephen Eden, a physicist at the National High Magnetic Field Laboratory in Tallahassee, Florida. “At first we tried to use traditional methods of coating with a variety of chemicals and high-temperature processing, but later we found that water and pressure were sufficient.”

After drying, the thread was cut and covered with a uniform layer of nanotubes. “This coating is very high quality and very uniform,” said Stephen.

This hybrid material is not only electrically conductive, but also 3 times stronger than a regular web. From the experiments it follows that this material is suitable for use as artificial muscles, no less than ordinary web.

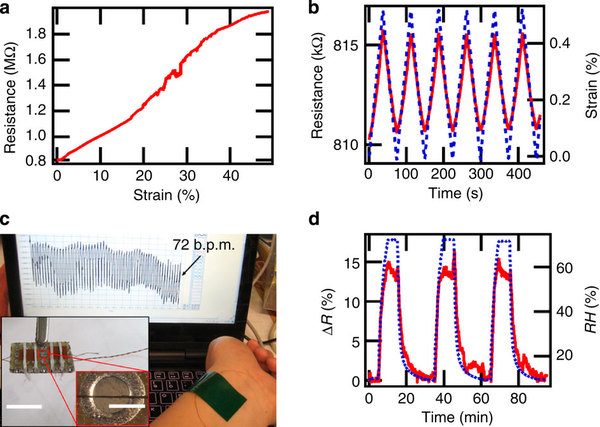

“The electrical conductivity was maintained even when the thread was stretched by 50%,” said Stephen.

The researchers noted that the electrical conductivity of their new web may depend on humidity and the amount of physical activity. As such, they can find application in sensors of humidity and deformation, and in fact, they have already developed a pulse meter using new threads. Using gold plating or a thicker layer of nanotubes can make electrical conductivity less dependent on moisture levels.

Currently, scientists are trying to develop a synthetic web, which will already include nanotubes. “The versatility of this material means that it can find many uses,” said Stephen.

Scientists have described their results on September 10 in the journal Nature Communications.

Note translator: in general, the study on the link is very complete and interesting, most of the images are taken from there.

')

Source: https://habr.com/ru/post/195862/

All Articles