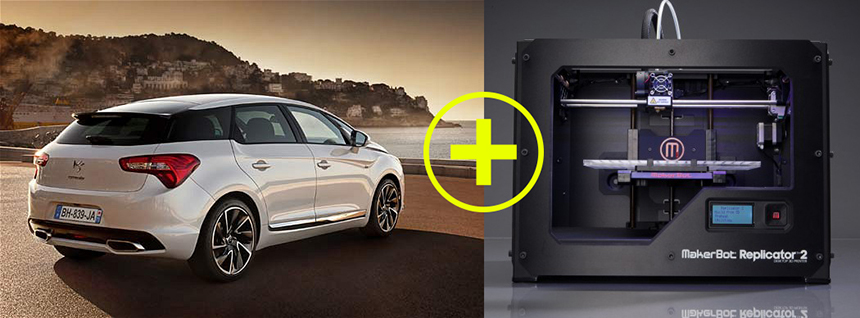

Repairing a car with a 3D printer

Introduction

3D printers are well known. Here, on Habré, publications of 3D subjects appear quite often. There is an active formation of the community around the bulk print, and we still have to understand why the common man needs all this. Some manufacturers and technology evangelists of affordable 3D printing believe that every housewife should have a 3D printer. This is the way Makerbot, the manufacturer of the most promoted printer Replicator 2 and partner of Microsoft. The company actively invests in its community Thingiverse, where users can share their models. There already now you can find many useful models, including spare parts for the printers themselves. And the inclusion of support for Replicators in Windows 8.1 speaks of the serious mood of Microsoft and Makerbot.

Why does a simple person need a 3D printer? It is believed that the inhabitant of the future will print the necessary household items directly at home on such a device. Also this person of the future will repair everything around with the help of a cunning device. I am lucky to have a personal Makerbot Replicator 2 printer for personal use, and in this article I will try to reveal its economic side with a bias in cars.

')

Situation 1 Citroen

The guys from the familiar auto service, specializing in noise insulation, when disassembling the cabin damaged part of the seat Citroen DS5. A tiny gear was broken, setting the seat's trapezium in motion. It was made, to the shame of the French, from fragile plastic.

A copy of the broken parts from the second chair:

It was decided to remove the spare part from the second working chair. Then the item was given to me, and it remained to take a caliper, measure and make a 3D model and print it with the highest quality on my Makerbot Replicator 2 from PLA plastic. Dimensions of detail: 12.5mm x 12.5mm x 15.5mm.

Model:

3D gear model in the GCode preparation program:

Original and its clones:

Cloned gear in the mechanism:

Health Check:

The printed copy fit perfectly into the mechanism and the chair started working again.

Situation 2 Skoda

In my own car, an unpleasant breakdown happened recently: the latch of the trunk shutter broke. Disassembling the hull and searches on the thematic forums opened up an interesting point: it turns out to be a children's disease of this car brand and in my case the previous owner replaced the latches with home-made parts, one of which broke.

It was decided to use a home 3D printer in the repair, since there is one. Dimensions were taken, a model was prepared and sent for printing, taking into account future loads on the part (appropriate temperature, layer thickness and color of plastic were chosen). Next was to paste the part in place.

Model of the simplest volume before printing:

Clamp mounted in the trunk:

Now you can safely leave things in the trunk!

findings

Already, the technology allows you to use 3D printing in everyday life, everything depends on your imagination and knowledge in 3D editors. 3D editors also do not stand still, the simplest one - SketchUP will take just a few hours to start creating printable models, and Blender editor generally free and open source.

Considering the extremely low cost of materials and offers on the market (a gram of a print made of PLA or ABS plastic costs around 30 rubles), it would be strange not to use the opportunities offered by bulk printing. The cost of the printers themselves is also rapidly falling: you can build a good machine in the range of $ 1000.

One can only imagine what a revolution will happen when printers printing with metal and other materials come onto the market!

Source: https://habr.com/ru/post/195810/

All Articles