Give the remote multicopter!

Model aircraft, as a hobby, for decades . And in the market of radio control equipment, their leaders and standards have long been formed. Multicopters began humbly using existing remote controls from airplanes and helicopters.

How safe are such flights? And why does the copter need its own remote?

')

The post contains instructions for changing the mechanical part of the Futaba T8FG RC transmitter. With minor deviations, this instruction can be applied to most transmitters commercially available.

Perhaps following the instructions, you will lose the warranty on the console or the console itself in general, but you will have a multicopter. Perhaps without following the instructions, you will lose the multicopter, but the remote will remain with you.

I recommend reading if:

1) You are going to make / purchase a multicopter

2) You fly a multicopter using the aircraft remote control

3) Want to be aware of the features of the control model aircraft

Introduction Standard remote control.

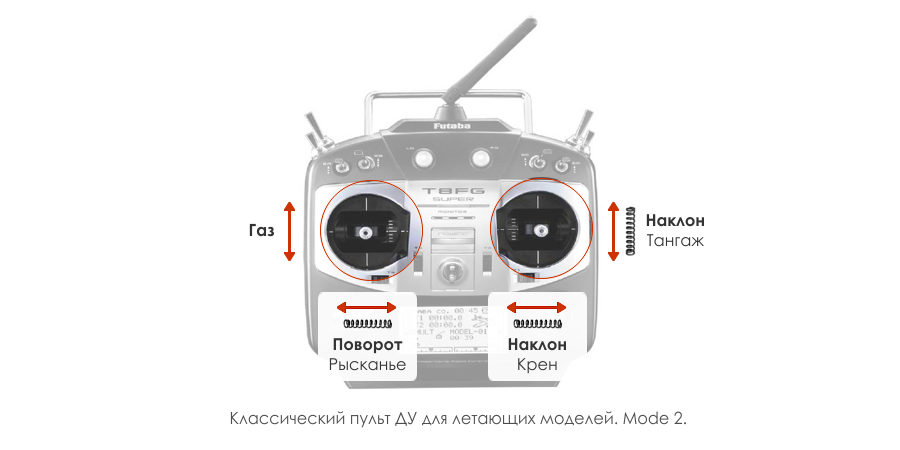

Before proceeding to the description of the problem, I give a brief overview of the typical flight console. The standard remote control of a flying model looks like this:

As you can see, such a device has two main knobs ( called sticks ). Usually, the throttle and turn knob is on the left. Pull up: rise , right-left: turn . The handle tends to take a central position horizontally ( fitted with a spring ). But there are 2 vertical solutions: aircraft ( with a ratchet on the throttle handle ) and helicopter ( without it ). Moreover, in both cases, the vertical spring is not used. And, actually, why?

Many manufacturers made sure that the owner could independently convert the aircraft version into a helicopter and vice versa. It also provides for the possibility to change the control Mode1 / Mode2 ( that is, change the knobs in places, like the steering wheel in the car ). By the way, the second handle tends to occupy a central position in both directions (it has horizontal and vertical springing ) and controls the roll and pitch, which is equally suitable for both airplanes and helicopters, and multikopter. But with the management of the gas channel is not so clear.

Part 1. Immersion in problem.

Flight Controller Functions

As is known, the multicopter is controlled by a flight controller . This device incorporates the necessary sensors ( gyroscopes, accelerometers, barometer, compass, GPS application, etc. ) and brings the multikopter control closer to the control of a conventional coaxial helicopter. After all, if it were not for the controller, it would be necessary to control 4 or even 8 screws separately, which would make multicopter the most common type of garbage in the garbage dumps after the falls.

Controllers are different. The cheapest stabilize the device only on the horizon. At the same time, it can “float” up, down or sideways at an arbitrary speed if you have thrown the handles. I will not consider the management of such devices, as this is the lot of advanced pilots who will do everything correctly without the remote control. Let us dwell on the more common models, equipped with at least a function of keeping the height (a clear demonstration of the mode on the video ).

The most popular of the suitable systems, perhaps, is Naza from the company DJI Innovations . In her example, we consider the adaptation of the console.

The problem of controlling the height of flight

After installing such a controller on a multicopter, the gas control knob is essentially transformed into a flight height regulator that holds the device in place with its average ( knob ) position. Pull up - fly up, returned to the center - stop. If you use a standard remote control, then the middle position of the handle sometimes has to be controlled by looking at it and distracting from piloting.

The situation becomes more complicated when you start an FPV flight around the camera. For example, you need to fly around an object several times in a circle with a camera toward an object at a height of 25 meters, provided that there are trees 20 meters high on the way. When using the display, it is still possible to switch attention to the handle or to the model, but in the video glasses it remains only to peer at the height and vertical acceleration indicators if the OSD system superimposing the flight information on the video is installed at all. The finger of the position of the stick does not feel strictly vertically.

I repeat, this problem exists only for those copters that have a barometer and a height-hold function. If you do not have such a function, then the average position of the stick is of no use to you - the device will still “float” vertically.

Motor shutdown problem

Naza, like some other controllers, has a mode in which the motors turn off when the gas is less than 10%. The mode is good because in the event of an accident or danger even a not very experienced pilot will instinctively turn off the motors, which can seriously alleviate the consequences of the disaster.

On the other hand, it causes newbies to worry about dropping from a great height. We slightly lower the handle, and we are in free fall. They were reinsured - and they lost battery power when they went down too slowly. This is especially important with ultra-high flights around the camera, when the descent occurs on the last breath of the battery, and the sound of the motors is not heard if you do not have headphones. Free fall more than 5 seconds, and the engines will not start when the gas increases, they now need to include a special command ( CSC ). Try to figure out the fall of what is happening there at all.

There are, of course, modes that do not disable commands at all ( by command or by switch ), but this is not the safest way for beginners. For example, we so broke the screw and spoiled the floor during the test in the office. The copter began to tumble to the side, and the milliseconds of the search for the combination of switching off the motors led to sad consequences. They would disconnect when the gas was discharged, and everything would be fine. Conversely, once a problem in the technique led to an emergency landing of the copter on the field in the distance. It was necessary to disconnect at the first touch of the grass for the softest landing. Everything went off with a bang, as the stop mode was selected when the gas was discharged.

Everyone, of course, chooses the shutdown mode himself, he personally is more comfortable for me to use the gas discharge. And the problems of stopping the engine accidentally need to be solved somehow.

Springing gas knob

On the one hand, I would like to have a spring-loaded gas knob, leaving it in the middle position, similar to the pitch control. Moreover, in most consoles there is the possibility of such a refinement. Then the copter, if you release the handles, would always stabilize in the air. An ideal device, especially when connecting GPS and turning on 3-dimensional stabilization! But this is gas! On the aircraft! We can not use a spring that raises the stick to the center position - this is dangerous.

Part 2. The search for solutions.

The first few days of the flight, I was tormented by the controls, fearing to muffle the motors during the descent, then crash into a tree, without noticing a slight systematic decrease. It seemed to have to get used to, but in my head the requirements for management gradually loomed:

1) locking the handle in a central position with a click

2) Additional force when reducing gas is less than 10%

3) Spring on the handle, somehow not reducing the safety of using the remote

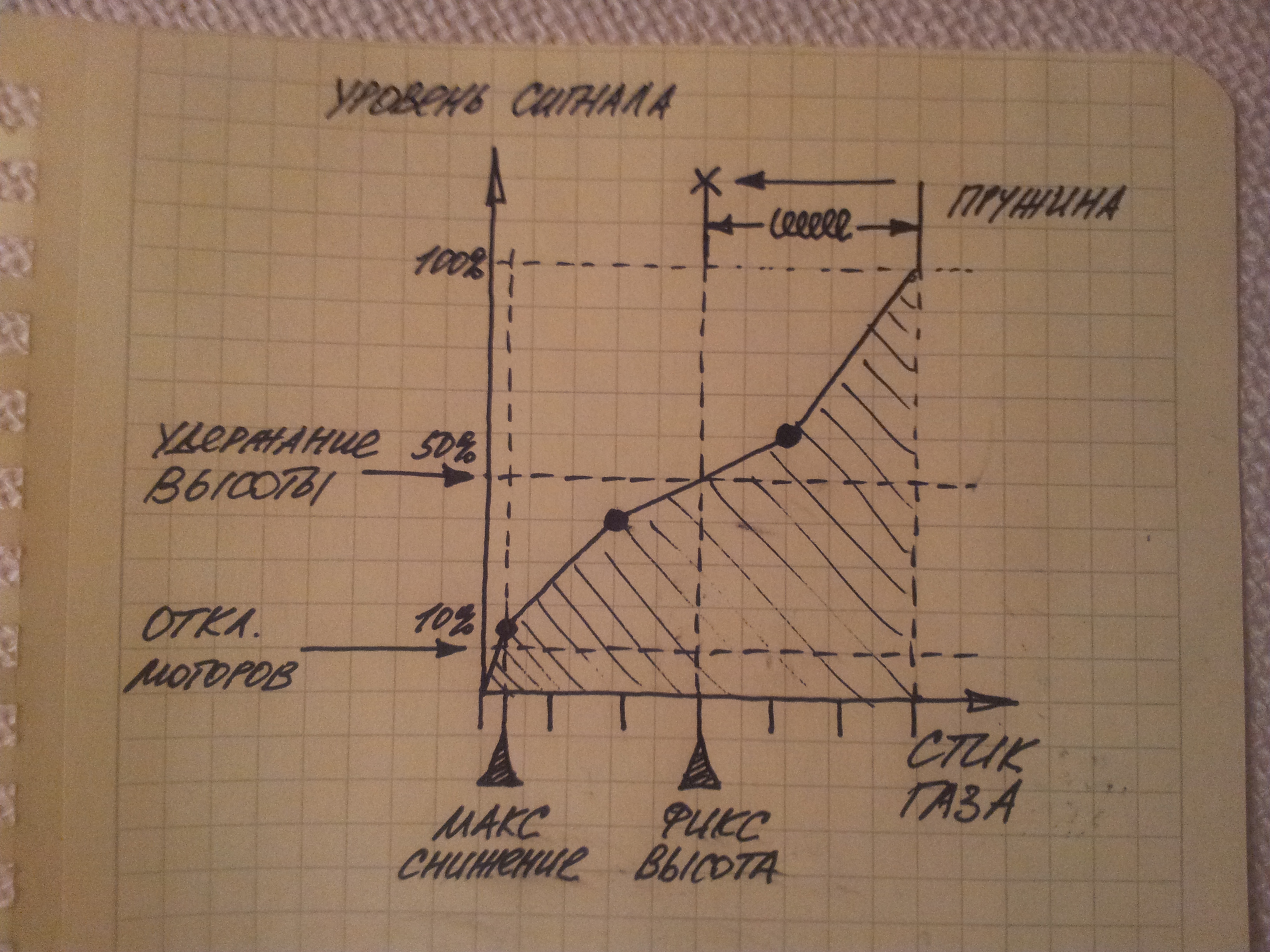

Here's what I got:

On the horizontal axis, triangles mark the places where the handle should click when moving. Top shows how the spring should work. It brings the handle to the center position only from the “above center” state. That is, flying up to the obstacle, we pull the handle up, wait and release it. The handle returns to its normal position. Kopter, rising up, continues to move at a new predetermined height. Conveniently. When lowering, the spring should not work, so that the gas knob can be safely moved downward at the end of the flight.

Part 3. Mechanical transmitter upgrade

It so happened that I use one of the most common Futaba T8FG remotes , using which I will write the instructions. If you have another model, sure the insides are very similar. The only difference may be that in the mechanism of the gas knob sometimes there is simply no spring, and sometimes it is blocked by a special pin. If you are unlucky, then you need to get a spring.

- Important! If you are worried about even the reversible design change of the legendary Futaba console, read no further, it can cause moral injury.

- If you use the remote and to fly on an airplane, refuse to spring up and lower click. Surely, you have enough experience to stop the motors with a toggle switch. The average click, I think, does not interfere with flying on an airplane.

- If you use a helicopter flight, the clicks will not work anyway, since you, in theory, should have a nozzle on the teeth.

- The changes are reversible specifically for my T8FG Super model. Of course, I didn’t check it on other models, but everything should work out.

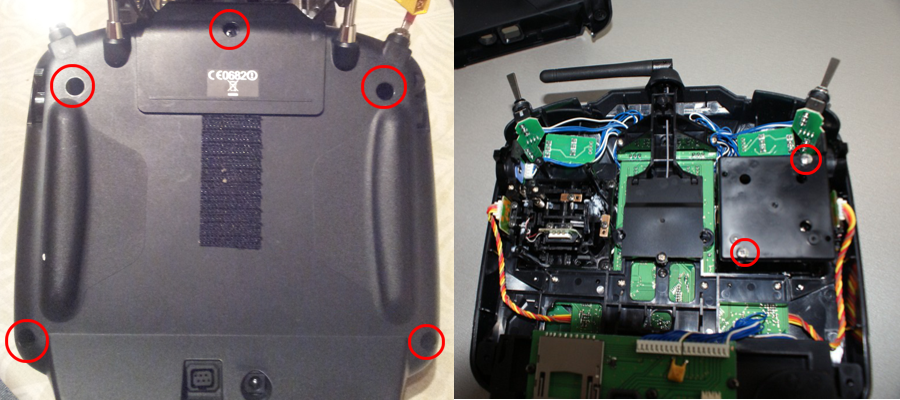

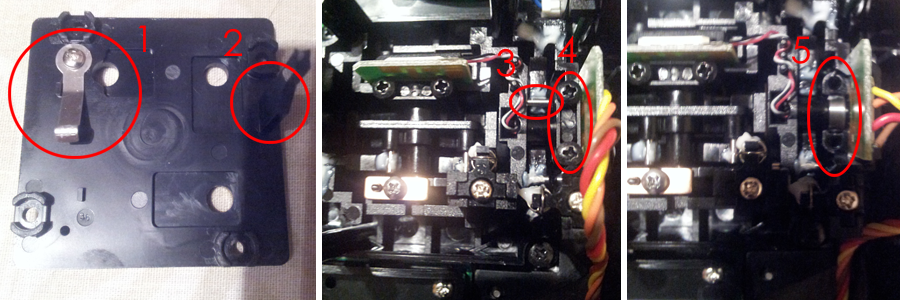

So, remove the cover and ratchet from the throttle:

In my console it turned out ( photo below ) that the ratchet pad ( 1 ) at the same time blocked the springs with a special plastic pin ( 2 ). Oh, a miracle - without this platform, the gas began to spring itself! Pulling the handle, I realized that in order to spring it up only in the upper position, it is necessary to remove the specified metal pin ( 3 ), after unscrewing the screws and removing the plastic mount ( 4 ) so that it does not interfere with removing the pin with forceps. The result ( 5 ) is seen in the far right image. Glue the metal pin with adhesive tape to the console cover from the inside, it can be useful when you roll back the changes. Having returned the mount ( 4 ) to its place and cut off a piece of plastic pin ( 2 ) with nippers, the problem of the springs was finished.

No matter how I twisted the pad with the ratchet ( 1 ), I could not avoid biting off the plastic pin ( 2 ). The manufacturer has foreseen the possibility of its ( pad entirely ) mounting at an angle of 90 degrees, but then the ratchet moves along with the pin. It is not possible to leave the ratchet in place, but it is not possible to move the pin. Maybe your console is implemented more flexibly. Ultimately, it's not at all scary. You can glue this pin back when the change rolls back, there is no load and friction on it. You can do it easier and disconnect the vertical spring, then the pin will not be needed at all. Secure it just in case with scotch tape on the lid of the remote control, it may come in handy.

Now how to fix the handle and click. Ratchet clings to a semicircular plate with teeth moving together with the handle. On this plate, you need to cut one hole between the teeth in the center position of the handle and the second closer to the bottom position of the handle ( I cut the opening between the 2nd and 3rd teeth ) in the direction of the stick (handle). An ordinary cheese knife was used as a saw. The most crucial moment here is to correctly find the opening of the center position of the handle. Doubt - just not much nagging.

In your remote there is another plate with teeth on the other handle, it is not used. When selling a remote or, if necessary, you can swap the handles in places by removing clicks.

Part 4. Software part

All that is left to do is to adjust the gas so that the bottom click corresponds to a value just above 10%. Then your pen will have a free motion with an aircraft ratchet from 10% of gas ( maximum speed of a decrease in the copter ) to 50% ( hanging at a given height ), limited by two noticeable clicks. Above, the spring is activated, and below, the motors are turned off.

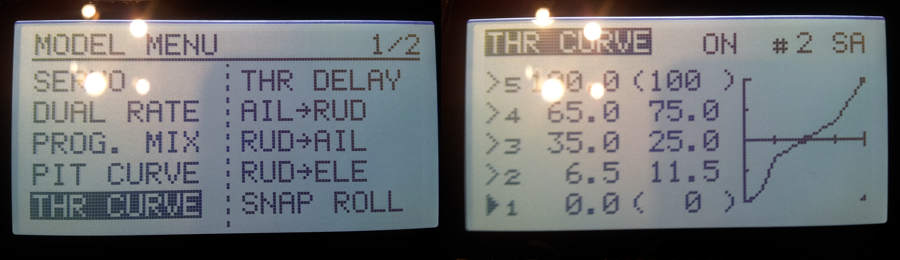

Go to the hardware menu and adjust the gas exponent ( Futaba T8FG: Model menu> THR curve ). We check everything several times on the motion monitor serv ( Futaba T8FG: Model menu> Servo ). I got 12% gas at the bottom click with the following settings:

Conclusion

That's all. Now you can comfortably fly at a given height, just forgetting about gas control. This will allow you to focus on shooting objects, for example. And you can fly into the clouds and control the shutdown of the motors on the descent. It turned out very convenient. The stick in the initial position seems to have a power switch that has a short stroke. This does not significantly reduce the stick stroke from the central to the lower border ( at least, I didn’t feel any changes at all ) and in the middle position there is a light but tangible fixator that does not affect the accuracy of the vertical positioning of the stick. The fixation is well complemented by the upper springing. Without it, in the cold, for example, when the hands are less sensitive, you can stretch the stick and go past, so that the planes, apparently, do not interfere.

Is it a crutch? Good question. It depends on what is considered a crutch. At least this is a mechanical crutch. The rest, such as toggle blockers of the 50% gas position, will be a functional crutch, which will provide a result with side effects and very tangible effects. I think that the time of multikopter has not yet come, and eminent manufacturers simply do not include an adapter for copters, focusing on helicopter-airplane and Mode 1-2 adaptations of their equipment. Special copter consoles begin to be gradually equipped with similar mechanisms, such as the console from the second version of the Phantom from DJI.

I hope not knowingly spent half a day, and someone this post is useful. Have a good flight!)

Source: https://habr.com/ru/post/195746/

All Articles