3d printer will print space structures directly in orbit

Instead of making designs on Earth, and then disassembling them into small pieces to pack into a launch vehicle, NASA engineers implement a radically different approach.

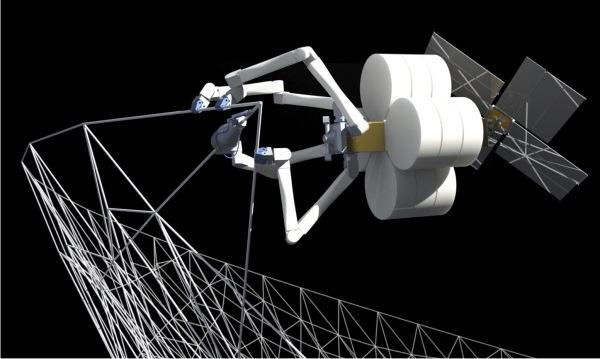

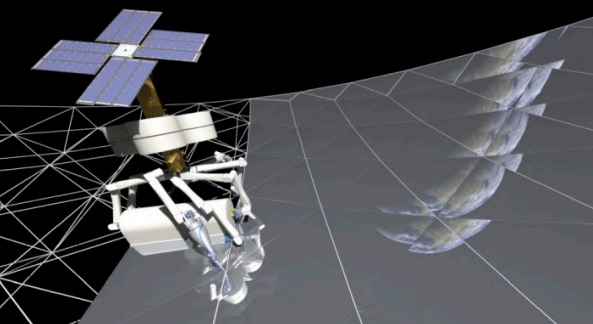

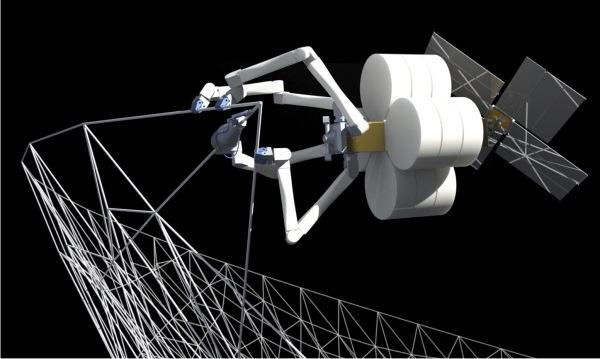

They plan to send a 3d printer, robots and a bunch of raw materials into orbit, and then "print" the parts and assemble them right in space.

This will allow, according to the developers, to create structures in kilometer scales.

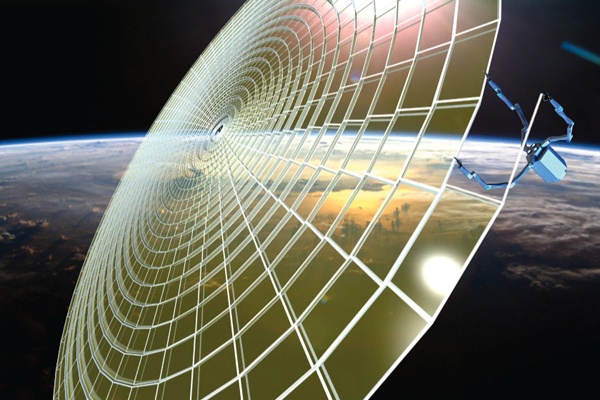

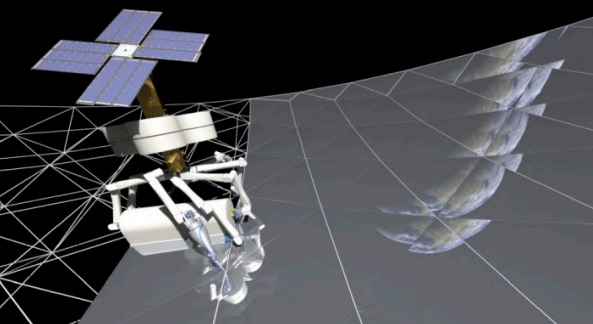

A month ago, NASA announced that they are investing in a company that is developing SpiderFab technology for building large objects in open space.

')

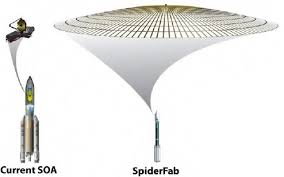

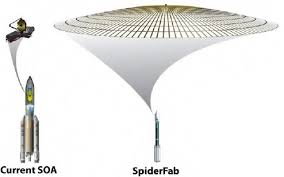

Currently, if you need to launch a large object into orbit, the method used is to build this object on the ground, developing it in such a way that it can be “packed” into a rocket. This approach is very expensive, and the size of the objects is strictly limited by the size of the launch vehicle.

Comparison of existing technology and projected

Spiderfab

NASA has a contract with Tethers Unlimited, Inc. (TUI) for $ 500,000 to continue the development of technology that will allow the use of a 3d printer and a robotic assembly for the production and connection of large components right in orbit.

SpiderFab technology will allow you to create objects on a kilometer scale.

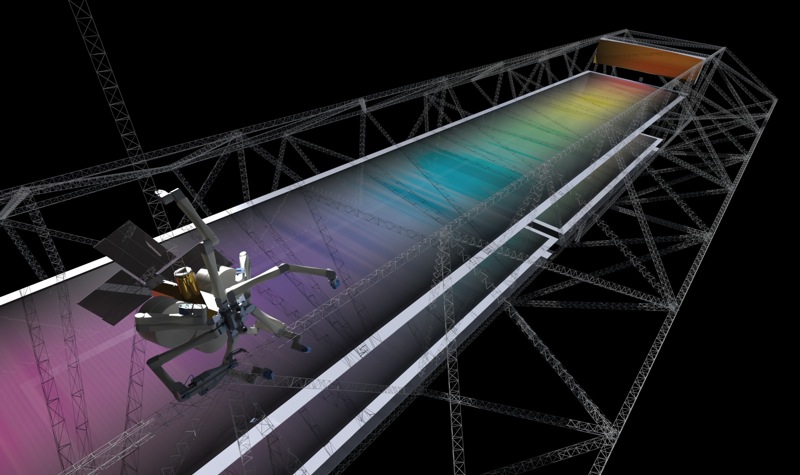

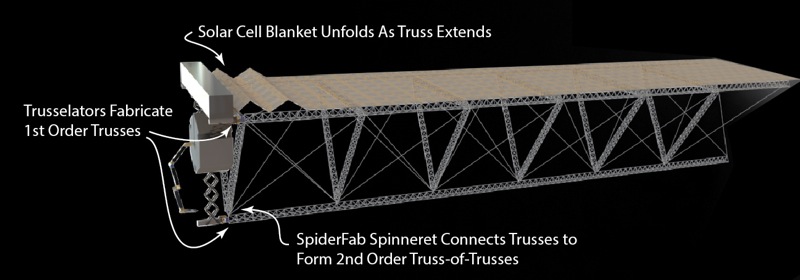

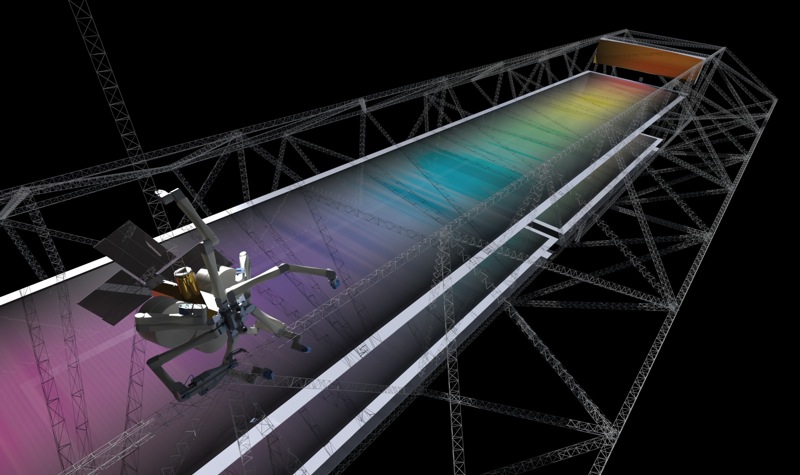

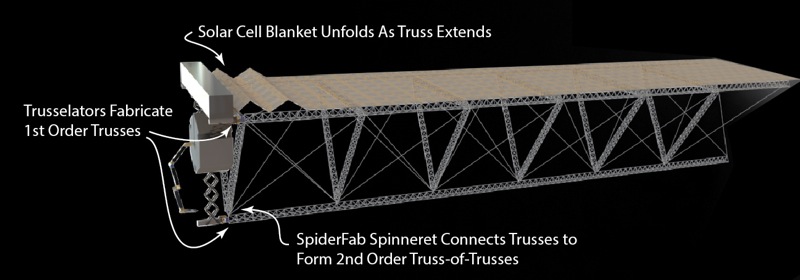

Trusselator

In parallel with SpiderFab, Trusselator is developing a device that will create pivot systems for the construction of large solar cells.

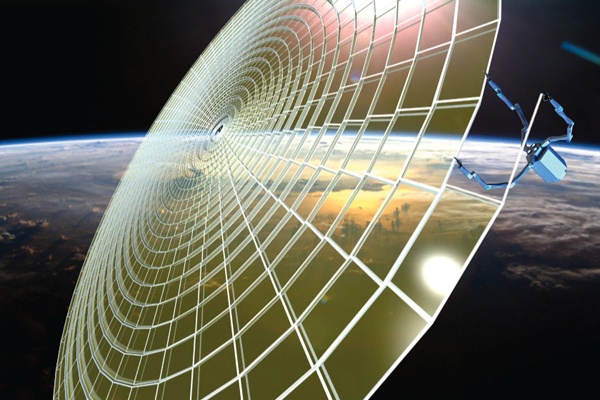

NASA plans to create antennas and telescopes the size of a football field to search for exoplanets like Earth and look for evidence of extraterrestrial life.

Presentation of the project in PDF

Radiation protection printed on 3d printer

They plan to send a 3d printer, robots and a bunch of raw materials into orbit, and then "print" the parts and assemble them right in space.

This will allow, according to the developers, to create structures in kilometer scales.

A month ago, NASA announced that they are investing in a company that is developing SpiderFab technology for building large objects in open space.

')

Currently, if you need to launch a large object into orbit, the method used is to build this object on the ground, developing it in such a way that it can be “packed” into a rocket. This approach is very expensive, and the size of the objects is strictly limited by the size of the launch vehicle.

Comparison of existing technology and projected

Spiderfab

NASA has a contract with Tethers Unlimited, Inc. (TUI) for $ 500,000 to continue the development of technology that will allow the use of a 3d printer and a robotic assembly for the production and connection of large components right in orbit.

SpiderFab technology will allow you to create objects on a kilometer scale.

Trusselator

In parallel with SpiderFab, Trusselator is developing a device that will create pivot systems for the construction of large solar cells.

NASA plans to create antennas and telescopes the size of a football field to search for exoplanets like Earth and look for evidence of extraterrestrial life.

Presentation of the project in PDF

Radiation protection printed on 3d printer

Source: https://habr.com/ru/post/195696/

All Articles