RepRap: 3D printers that print 3D printers. Another successful project

In 2005, the project was founded RepRap, whose goal - the creation of such a 3D printer that could "print" their own fellows. This project was founded by British engineer Adrian Bowyer. Since then, the project has grown into a community in which many technical specialists work. An ideal printer for the community seems to be such a device that could reproduce its own kind without the need to purchase additional details. But this is ideally, which is hardly achievable in the near future. However, successful projects of this type are, and about one of them - below.

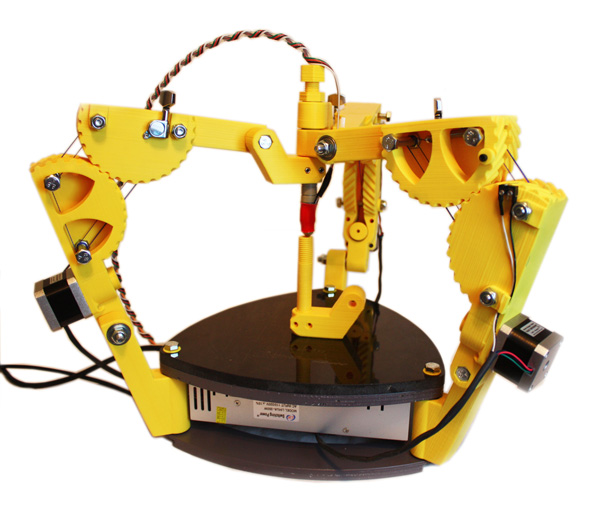

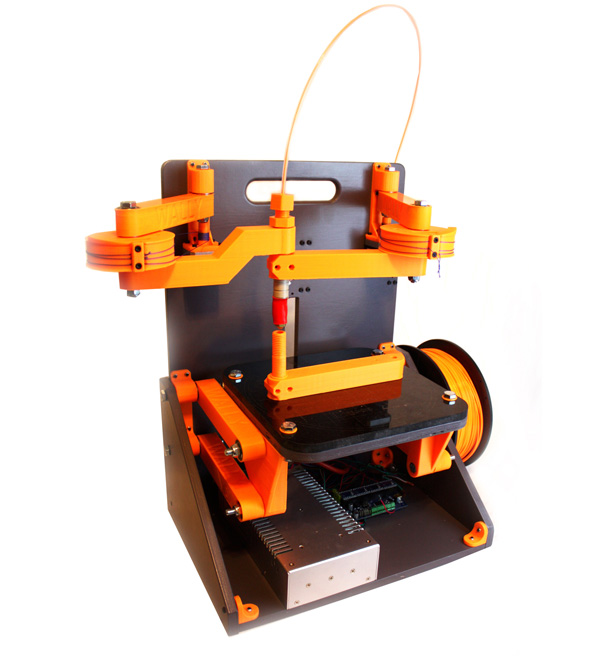

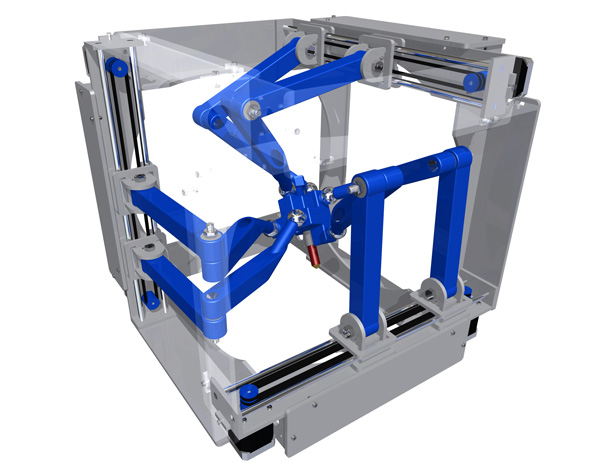

So, Nicholas Syward, the founder of Concept Forge , created a device that can reproduce its own kind, with a minimal amount of additional fasteners and electronics. At the moment, he created several variants of 3D printers of his own design, and even gave them the names: Morgan, Simpson and Wally.

')

At the moment, according to the creator, his devices have the highest rate of duplicate parts, relative to the total number of parts needed to create a new printer. In order to build a new printer with these devices, you need 60 hours, plastic for $ 20, electronics for $ 150, and some more money for bolts, screws, nuts, and so on.

Nicholas is going to launch a campaign on Kickstarter, the purpose of which is to get funds for mass production of the printers he has already created. According to him, a set of parts for collecting the printer will cost $ 450, and a functional, already assembled device will cost $ 600.

Drawings of the devices created by him will be available on the Web within a week, after Suard “reaches out” all the necessary elements.

Via dvice

Source: https://habr.com/ru/post/194890/

All Articles