Hardware and software automation platform Tibbo

Good day, dear habrovchane!

This is my first post in the company Scancode, in which I will tell you about a new product represented on the Russian market. I want to warn you in advance that there will be no comparative analysis with competitors and deep technical details in the description - all this is a topic for a separate article. Here I will try to describe the basic functional principles of this system, how and with what it is necessary to use it.

Note: most of the pictures below are clickable.

Taiwanese company Tibbo Technology Inc. announced a new product line called the Tibbo Project System (TPS). TPS is a modular hardware platform for creating your own automation devices . It is the devices, not the individual elements. Under the platform, we mean a set of the following elements: a motherboard with a microcontroller installed, an I / O board, the body of the future device, and software that allows you to write the firmware under the created device. Moreover, at the stage of ordering the client chooses which items he needs and what will be in the package. But first things first.

')

Idea.

The key idea of the Tibbo Project System has been around for several years. It was observed that most automation devices can be divided into two broad categories: fixed devices that cannot be “modified” by the user and modular devices that can be assembled from “pieces” - I / O modules that are installed next to each other. on the rail.

The problem of the first category is that it is rarely possible to find a device with the desired specification. Vendors understand this and try to cover all the basic specifications, offering a dizzying number of models (configurations). For example, you open a nomenclature, and there is a table with 20 lines. Eight relays and four inputs. Four relays and eight inputs. Four relays, four inputs and a serial port, and so on. And what if you need six relays, two isolated inputs, four open-collector outputs, a serial port, temperature and humidity sensors, and a high-voltage solid-state relay? Nah There is no such configuration.

The problem of "composite" systems is that their cost is usually too high. The representative of any large industrial automation provider, with a serious expression on his face, will tell you, and it is quite reasonable that the device will cost “several thousand euros”! Good automation is expensive, and the client must be willing to pay big bucks for using their device. Right?

It is fair to say that there are available systems with customizable, expandable I / O, but they usually look "unfinished" - just a board, no normal case, unsightly wiring, etc.

But good automation should be flexible, pleasing to the eye and affordable. When creating the Tibbo Project System, the engineers at Tibbo Technology tried to make it all happen. For clarity, we write a simple formula and analyze its components:

TPS = PCB + Tibbits (input / output) + boxes

Boards (PCB).

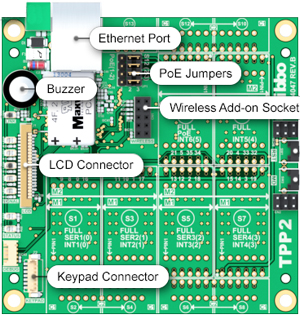

We start with the choice of a printed circuit board on which all the logic of the device will work in the future. At the moment there are two base boards, the differences between them are only in the number of seats for I / O modules (in one case these are 6 sites, in the other - 14). The board already has a chip with a frequency of 88 MHz (with PLL on), a full-featured Ethernet interface is implemented, connectors for connecting the Wi-Fi expansion module, an external display and a keyboard are prepared, a hardware reset button and a programmable button (MD) are installed capacitor for backup power, wired power circuit, LEDs and an audible indicator. The web server is already implemented on the chip. In fact, these boards are embedded EM1000 modules, which Tibbo has been releasing for quite some time. This time the modules were “turned inside out” and now it is already a printed circuit board with contact pads. Looking ahead, I will say that debugging of programs is carried out directly via the Ethernet interface. Thus, having a “bare” board, you can already connect to it and try your hand at programming, although it’s not so interesting yet.

Tibbits

Tibbits (from the English. Tibbo bits) - this is a small I / O board, placed in the case. Tibbits can be used both independently (they work with most well-known microcontrollers) and as part of the Tibbo Project System. The pitch between the pins is 2.54mm., Which makes it easy to install them on breadboard boards and carry out testing.

Tibbits are divided into two subtypes: functional boards proper and tibbits-connectors. Currently, more than 40 different tibbits are sold. These are ADC, DAC, PoE, backup power, RS232 / 485, various relays, isolated input, IR transceiver, tibbits sensors (temperature, humidity, shock sensor) and many others. The list will constantly expand. In the near future, it is planned to launch GSM, stepper motor control, etc.

Depending on the functions, Tibbits can occupy one contact pad or a full section (two platforms) on the board. Installation on the board is made elementary. As a pleasant plus, the manufacturer has foreseen the installation of a vibration protection plate - the plate “presses” the tibbits to the board, preventing them from jumping out during transport or use in conditions of increased vibration.

Thus, we have practically prepared the hardware of our device. Now you can safely run the programming environment and create your own firmware.

Boxes

The production of cases in piece quantities is an impermissible pleasure. Too high price. Even if there is a small-scale production of boards, the case still remains a headache for device developers. But the use of an open board at the facility is not always convenient, not aesthetically pleasing and leads to the risk of equipment failure. Therefore, it would be nice to place our entire system in the case. No sooner said than done. The manufacturer has provided several types of Tibbo Project Box universal enclosures: TPB2 - a case designed for a small motherboard; TPB2L is the same, but the LCD display and touch keys are mounted in this case; TPB3 - case for a large motherboard.

Shells consist of several components. The bottom cover on which the board is installed, the side walls, the top cover of the device. Tibbit connectors successfully "fit" into the side walls and the device body. A distinctive feature is that a transparent plastic

So, the board is selected, the tibbits are placed, all of this is successfully located in the case - the hardware of the device is ready.

IP68

One nuance. Everything looks beautiful, but what to do with protection? Objects often present an aggressive external environment. TPB base housings are clearly not suitable for such conditions. In this case, we can use enclosures from the previous product line of the Tibbo Technology DS10xx company . These housings are made of extruded aluminum and, when using an external protective cover, have an IP68 degree of protection (full dust and water resistance). Special boards have been developed for connecting Tibbits and installations in these enclosures. And now a spoonful of tar. Not all Tibbits can be installed on these boards. It is logical that the light sensor or IR transceiver is unlikely to cope with their tasks under the protective cover of the device.

Online configurator.

For convenience and to facilitate the process of selecting components of the device, the online configurator Tibbo Project System was developed. In the configurator, we work with our projects (which we can save on a local machine), where we select printed circuit boards, available Tibbits, and make a convenient layout. The configurator logic will not allow you to make a mistake, place the tibbits nearby, which should be spaced on the board and will track the current consumption of the entire device. Having created your project, you can order the components of the resulting system directly from the configurator, and, if necessary, order an already assembled device. At the same time, the configurator does not oblige you to anything; you can always order any component from this system, regardless of whether it is a tibbit, a board, or just a case element.

After saving the project on the local machine, you can open it in the programming shell and the environment will automatically load all the libraries necessary for working with your device to your software project.

Programming.

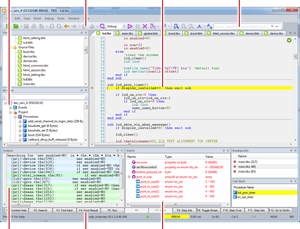

For programming devices using their own environment TIDE (this is not washing powder, TIDE - Tibbo Integrated Development Environment). As I said, programming and debugging is done directly over a local area network (Ethernet). The environment is loyal to the user, convenient, has all the necessary functions, including breakpoints and the ability to step through the program. Web interface can be programmed here.

Programming language - Tibbo Basic. Do not be afraid, this is not the classic basic that many have seen even in school. This is a typed object-oriented event programming language from the manufacturer. Who is still accustomed to the language "C" should not be disappointed. The compiler “C” is already ready, the stage of writing documentation is completed. In the near future we are waiting for the release of the compiler.

A little about the principle of the firmware.

The chip is loaded with an operating system (TiOS - Tibbo OS), which allows for network debugging and monitors the critical parameters of the controller. The firmware works in the interpretation mode (the compiler translates the program into mnemonic code, which we fill into the crystal).

When a system event occurs (pressing a button, received data on the serial port, the line status changed, the system timer, etc.), an event handler for this event occurs, where further logic is implemented.

The manufacturer’s website publishes the open source of some projects and libraries, which will help the programmer quickly get started and write their own application.

How to manage it from the outside?

First, you can integrate the resulting device into any system, personally writing the data exchange protocol. Also, the manufacturer can order the development of drivers for the device. You write TZ, the manufacturer implements the software part. Strictly speaking, the manufacturer can give development to the whole program part in general.

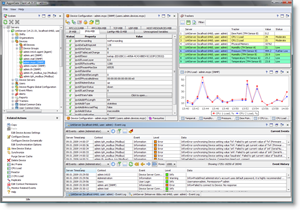

By connecting the AggreGate Agent library, which is distributed free of charge, you can connect your device to the AggreGate platform from Tibbo Technology - this is a software automation platform. AggreGate has already implemented flexible SCADA / HMI configurations, access control, building automation, etc. I will not dwell on this, this platform deserves a separate article.

And, finally, the OPC server is expected to be released soon, which allows you to connect the device to any SCADA system installed on your site.

Summing up ...

We get a functional automation platform, made in a stylish design and at an affordable price. Tibbo Project System can be used as a simple designer to create your own devices, even if you do not have enough experience in this area. Given the flexibility, functionality, scalability, the system can be perceived as a professional solution for system integrators and the field of automation in general. Together with the AggreGate platform, we get all the necessary functionality to create turnkey systems. Whether it is monitoring (for example, monitoring meter readings), remote control facilities or an independent automatic control system.

Among other things, the manufacturer and the official distributors provide technical support services for the use of the platform, advice from the vendor on design work, warranty obligations, an authorized service center. You can simply write to us about your task, and we will help you to solve it.

Source: https://habr.com/ru/post/194862/

All Articles