Incredible new polymer that heals itself with 97% efficiency.

Spanish scientists, not for nothing called the "Terminator" they developed a polymer. Like the T-1000, torn to shreds, it is able to recover spontaneously and independently without any external intervention.

Scientists have already achieved that the nanoparticles themselves collected in a certain order , and even created a microchip, which itself can be restored. But this polymer is the first of its kind.

This is a breakthrough that can ultimately be used to create materials that improve the safety and durability of plastic parts in electronics, cars and homes.

')

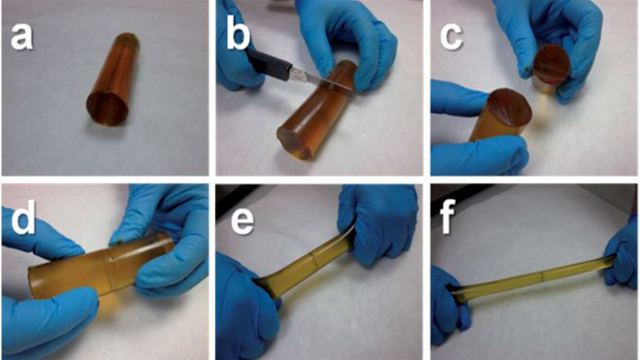

In this video, you can observe how a solid cross-linked elastomer (made from polyurea and polyurethane) is cut in half, and then completely restores its integrity.

The material behaves like velcro, showing 97% recovery efficiency (Wow !!!) for just two hours. Even after cutting, the material “heals” itself to a state in which it cannot be damaged even by strong stretching.

To create a "miracle-plastic" researchers used thermosetting materials. The ability to heal they give aromatic disulfides, which interacting at room temperature causes regeneration.

Read the full study: Catalyst-free room-temperature self-healing elastomers based on aromatic disulfide metathesis.

Update: As suggested by the ru1z, the reduction reaction occurs due to the restructuring of SS bonds (non-catalytic disulfide metathesis) and the reorganization of the urea fragments as they approach. In the polymer (initial uncut), the cross connection (exchange) of SS bonds occurs continuously.

Source: https://habr.com/ru/post/194808/

All Articles