Bioprinter do it yourself

From the translator: This guide will help you create a bioprinter from scrap materials (not to be confused with a 3D bioprinter !!! , more on that next time).

Bioprinting is a print of biological materials. Think of it as 3D printing, but compressed ingredients! Much work has been done by research laboratories and large companies, such as Organovo, dealing with the problem of printing human tissues and human organs, for the purpose of drug testing, and organ transplantation in humans.

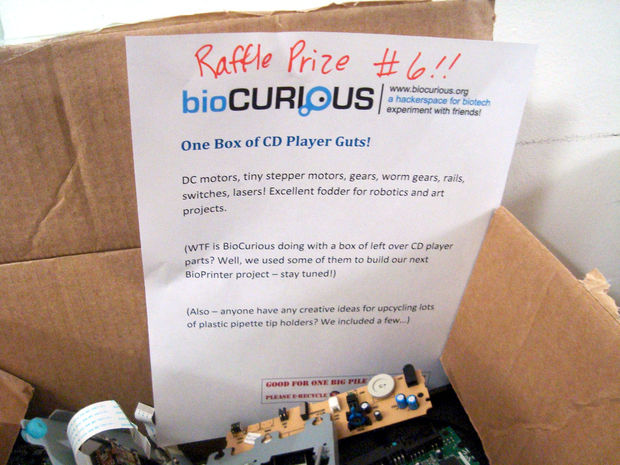

It all sounds incredibly difficult, but the fact is that the core technologies are widely available — all based on inkjet and / or 3D printing! So we decided to play BioCurious with this technology ourselves - and the BioPrinter Community project was born!

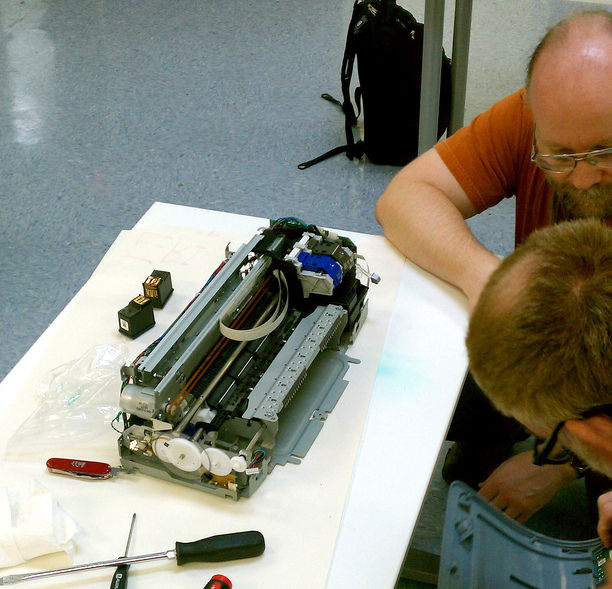

Step 1: Disassemble the Old Inkjet Printer

We take the old inkjet printer, in our case, the HP 5150, but almost anyone will do. You can simply tear off all the plastic covers, but make sure that the reset button on the front panel is still working.

It has a small high-speed switch that monitors whether the lid is open. After removing the cover, you need to lock this switch in the on position. manually, using a toothpick or gluing a small piece of plastic, in general, turn on the fantasy.

Also inside there is a high-speed switch of the paper feed mechanism, which determines whether the paper is loaded. You need to do the same with him.

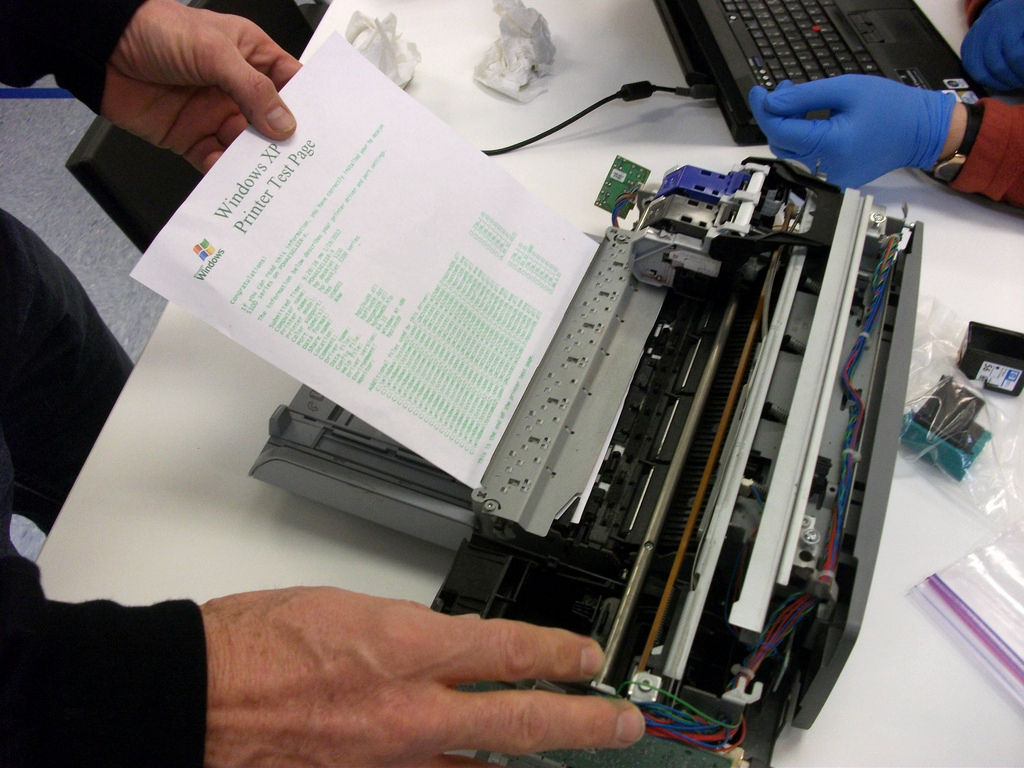

To make sure everything is done correctly, print a couple of sheets. Watching how a disassembled printer prints is in itself interesting.

The next task is to open the cartridge, to replace the ink with something more organic. It is better to take a new cartridge, in which the nozzles are not clogged yet, but you can try the old one, just turn on the head cleaning mode before use, if the printer software allows it.

After removing all the labels, you will see that most of the cartridges have a glued cover with a small ventilation hole for air supply during the outflow of ink. The cover must be removed with a knife or special tool, just keep in mind that in the future the cartridge will need to be inserted into the printer again.

As soon as you open the cartridge, you will see that the entire reservoir is occupied by a small sponge that holds the ink in place. Color cartridges have separate ink compartments with their sponges (usually cyan-magenta-yellow rather than red-green-blue, since printing colors on white paper is a process of subtracting color). You can squeeze out the remaining ink and save it for future experiments (for example, for paper chromatography). Then rinse, rinse, and once again rinse the cartridge with distilled and deionized water so as not to clog the printhead with mineral residue. Regardless of how well you wash it, it’s unlikely that you will be able to wash everything, so pour distilled water into the cartridge and print something, then another and more until the smallest ink particles stop coming out.

Now you need something to fill our cartridge. It all depends on your imagination. We decided to start with something simple, rather than jumping straight to the printing of living cells. We decided to print something using arabinose solution on filtered paper.

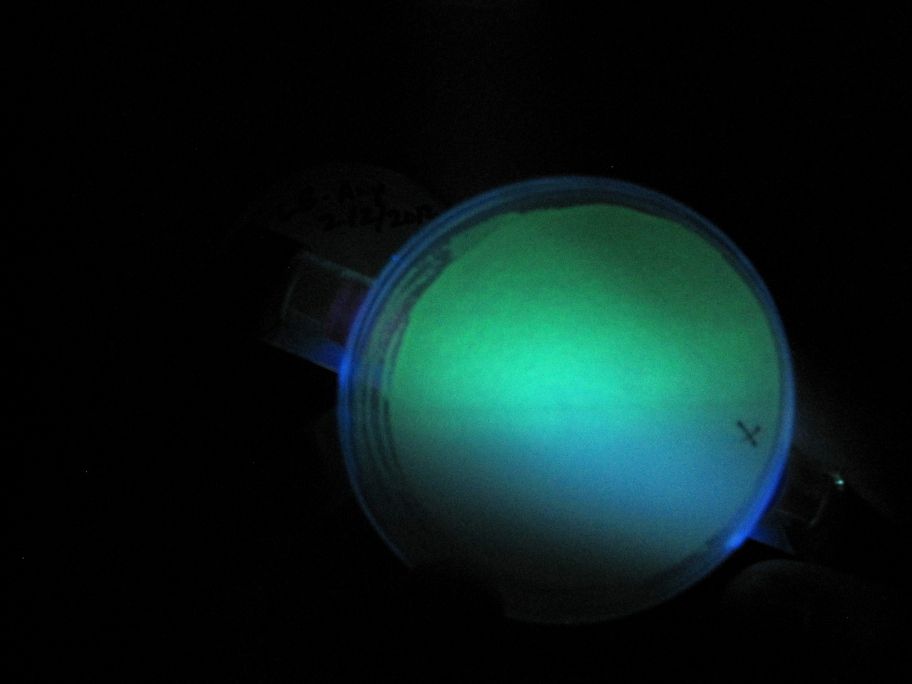

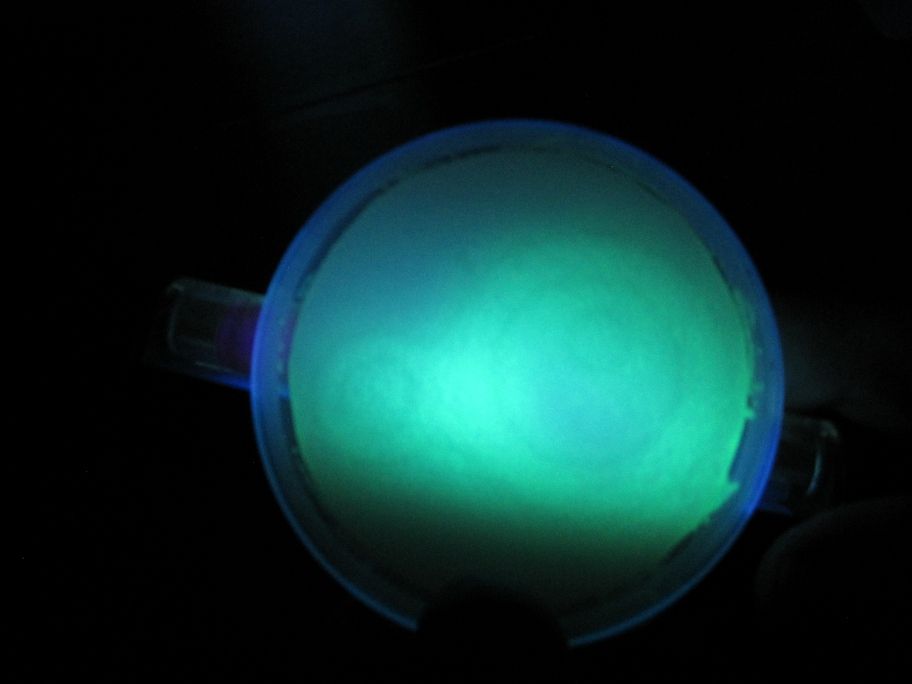

We decided to print with arabinose solution on filter paper. Then we cut it out and laid it on an agarose plate, with a grown film of E. coli, which provoked the transfer of pGLO plasmids. This plasmid contains a green fluorescent protein (GFP), under the control of an arabin-sensitive accelerator.

As a result, where we printed arabinose on filter paper, we saw green light emitted by E. coli under ultraviolet radiation! Please note that the beauty of this experiment lies in its simplicity ( approx. Translator: well, yes, well, yes ... we could come up with something more interesting ): we just had to type in a simple solution of sugar, not in bulk living cells, and on paper, so we don’t even have to change the paper handling technology. You can also try printing with antibiotics or even proteins, such as enzymes or growth factors.

In the first photo we printed half of the page in arabinose ( Note of the translator: you should take a closer look, I sympathize with the color blind. ).

And in this photo, we printed the logo of the eyeball. Unfortunately, the sharpness of the image leaves much to be desired.

Step 2: Problem - Existing Printers Have Excessive Resolution

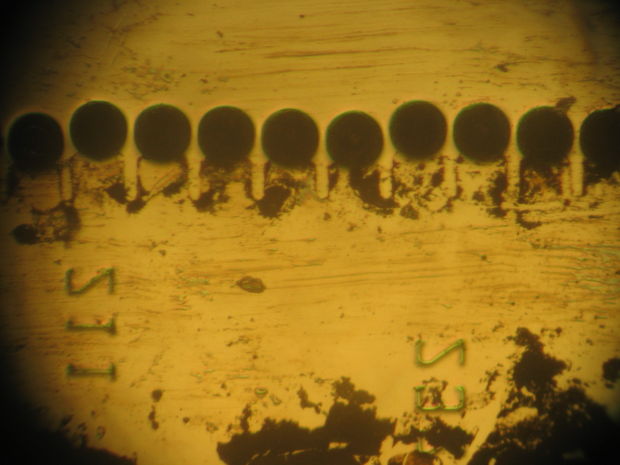

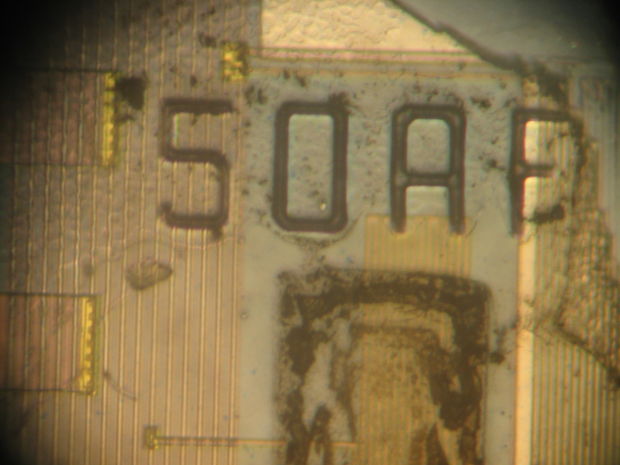

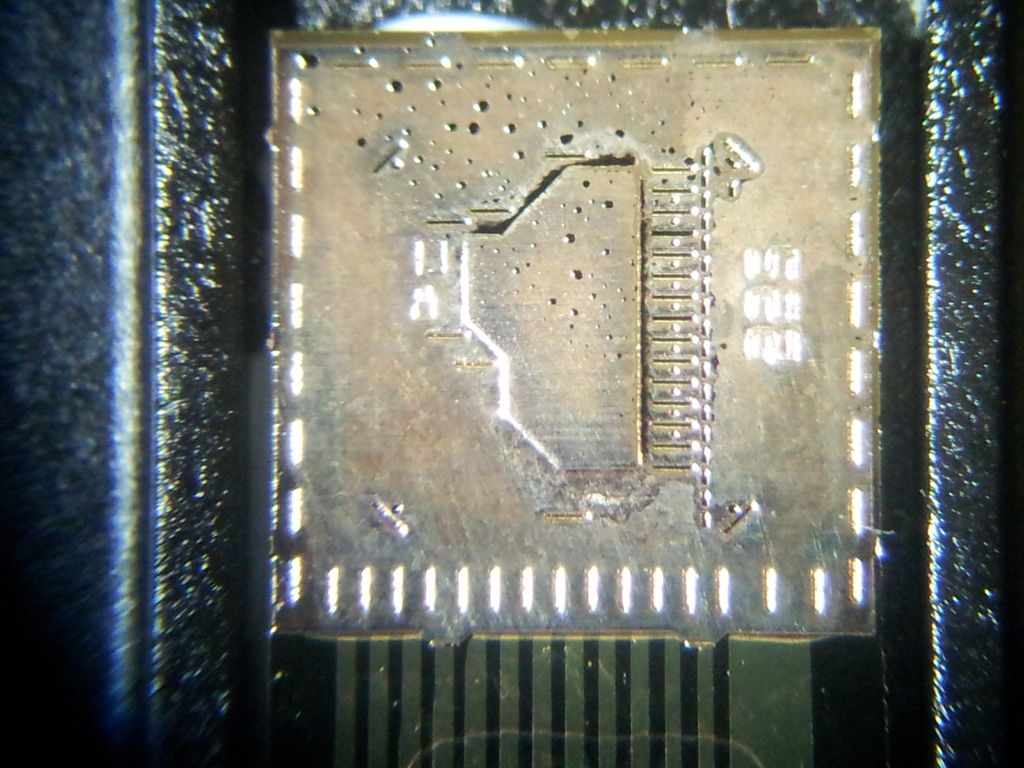

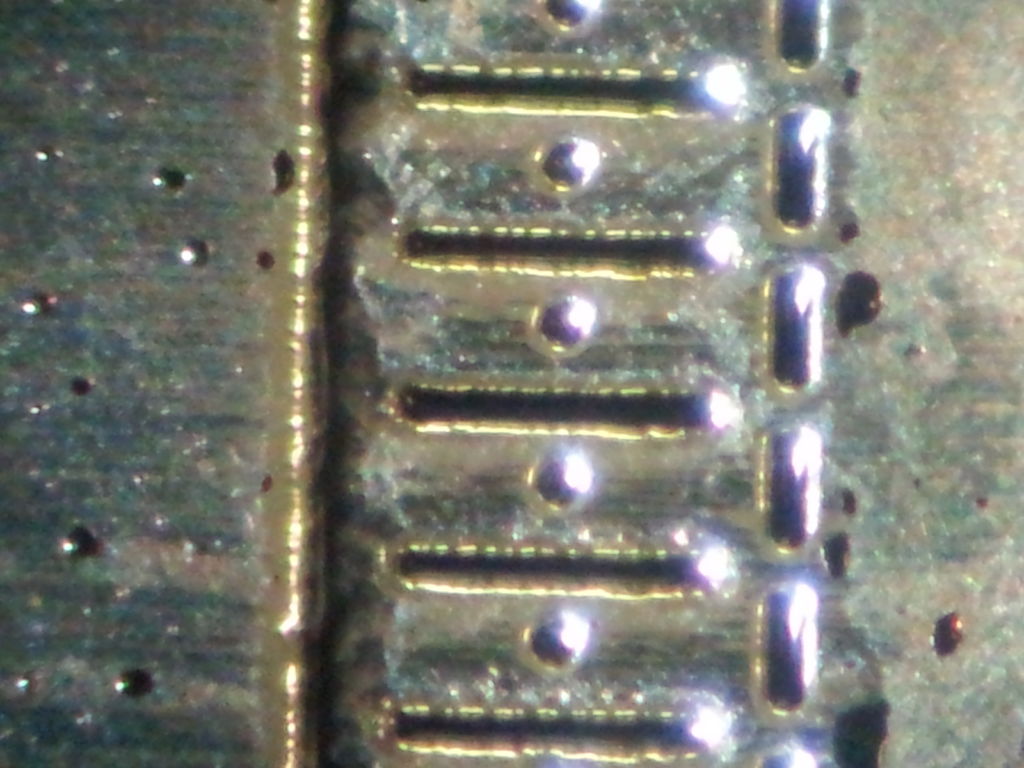

We spent a lot of time looking at the inkjet print heads under the microscope. The silver bar at the bottom of the cartridge is called the nozzle plate. These are just stainless steel tapes. In this cartridge, the nozzles are arranged in four rows, of which you can see two in the first image above. The nozzles are actually numbered from 1 to 416. The 416 nozzles in the printhead are about 1/3 inch out to 1200 dpi.

Now, 1/1200 per inch means an interval of 21 microns. In addition, the nozzles themselves are actually about 23 microns in diameter. This is the order of the size of a eukaryotic cell - oh oh! We should still be able to print E. coli cells that are much smaller (~ 1 micron in diameter) from this printhead, and possibly also yeast cells (~ 10 micron in diameter).

But wait - that's not all!

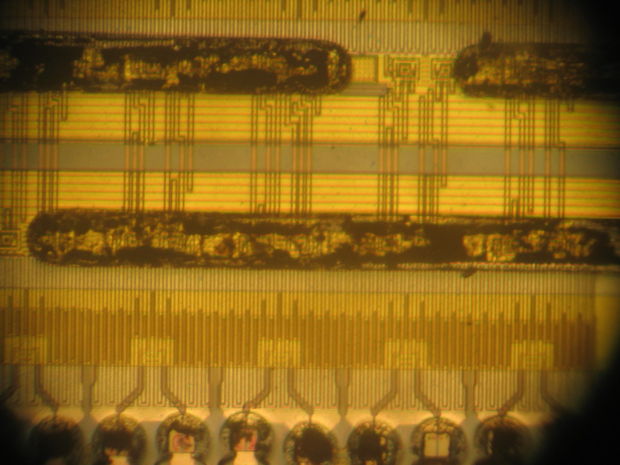

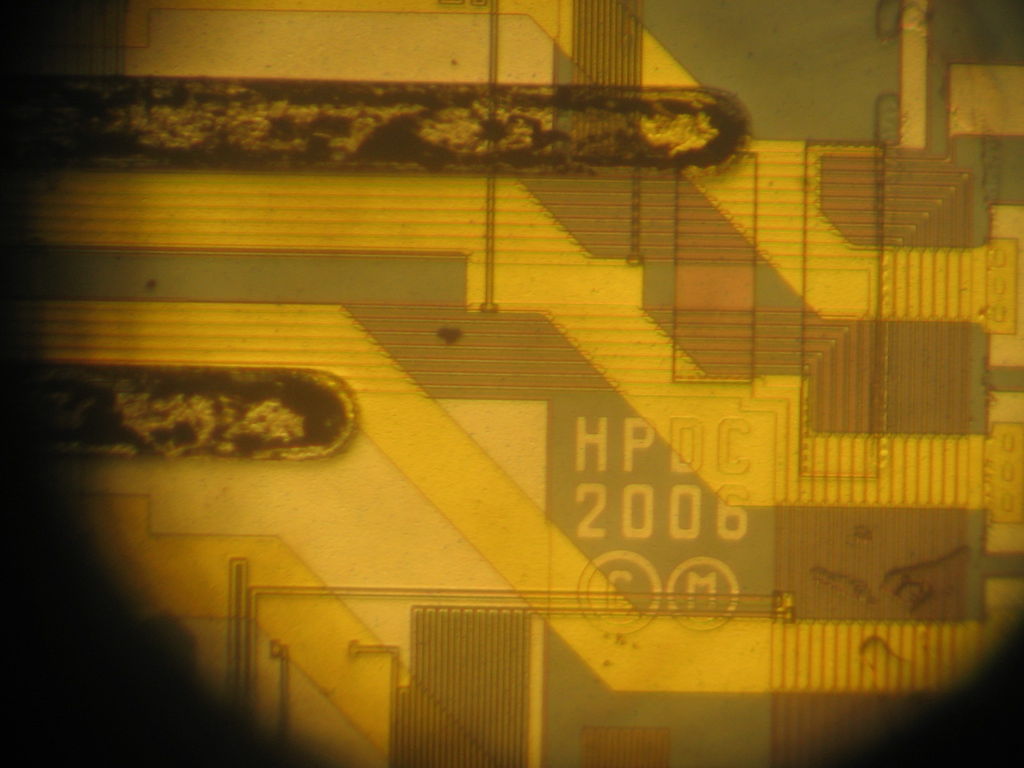

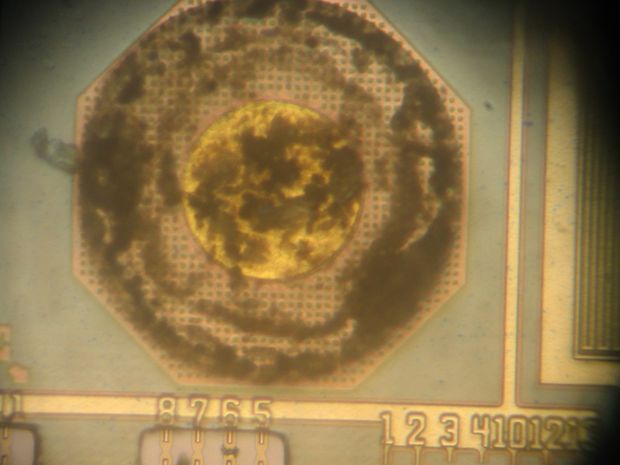

When you remove the metal plate of the nozzle, you actually get the capabilities of the printhead - a miracle of engineering silicon, which includes both filling, microscopic heaters that evaporate some of the ink in a thermal inkjet printer, and a bunch of embedded electronics. An excellent target for advanced microscopists!

The last image excites us much more. There seems to be a filter integrated into silicon, located between the ink tank and the print head! In the image from the microscope, we estimate the holes in the filter, about 3 microns in size, which may not be enough even for E. coli cells!

In addition, using a commercial printer will have to change the entire path of the paper, besides the existing drivers provide limited opportunities to control the print head, unless of course you adapt the driver for Linux.

So let's create our own printing platform over which we will have complete control.

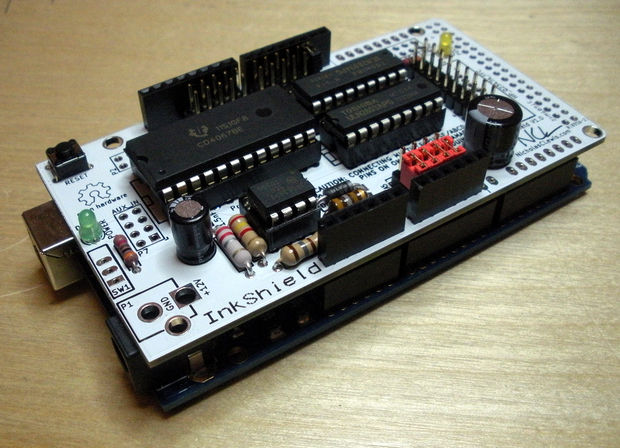

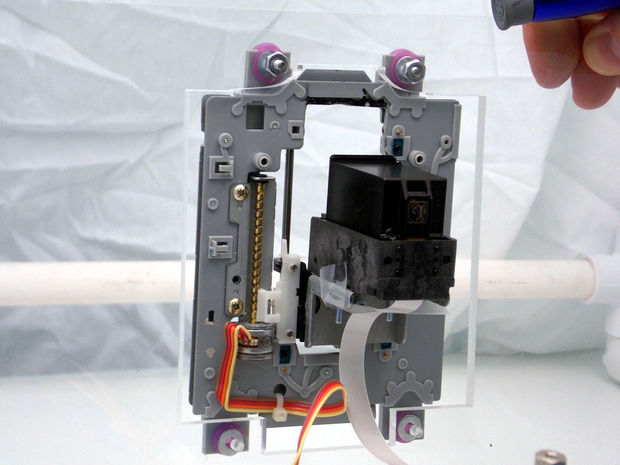

Step 3: Use the InkShield Printhead

')

So, it seems that we will not be able to print anything that is more yeast cells using the latest generation of inkjet printers. And we are not able to print even yeast or E.coli cells using an inkjet cartridge on this printer!

Another way is to use ancient HP printers with a resolution of 300 dpi, and nozzles are supposedly about 80 microns in size or so, which should be enough for printing human cells. For example, HP DeskJet 500, come down to us their 90s. Good luck in finding this antiques.

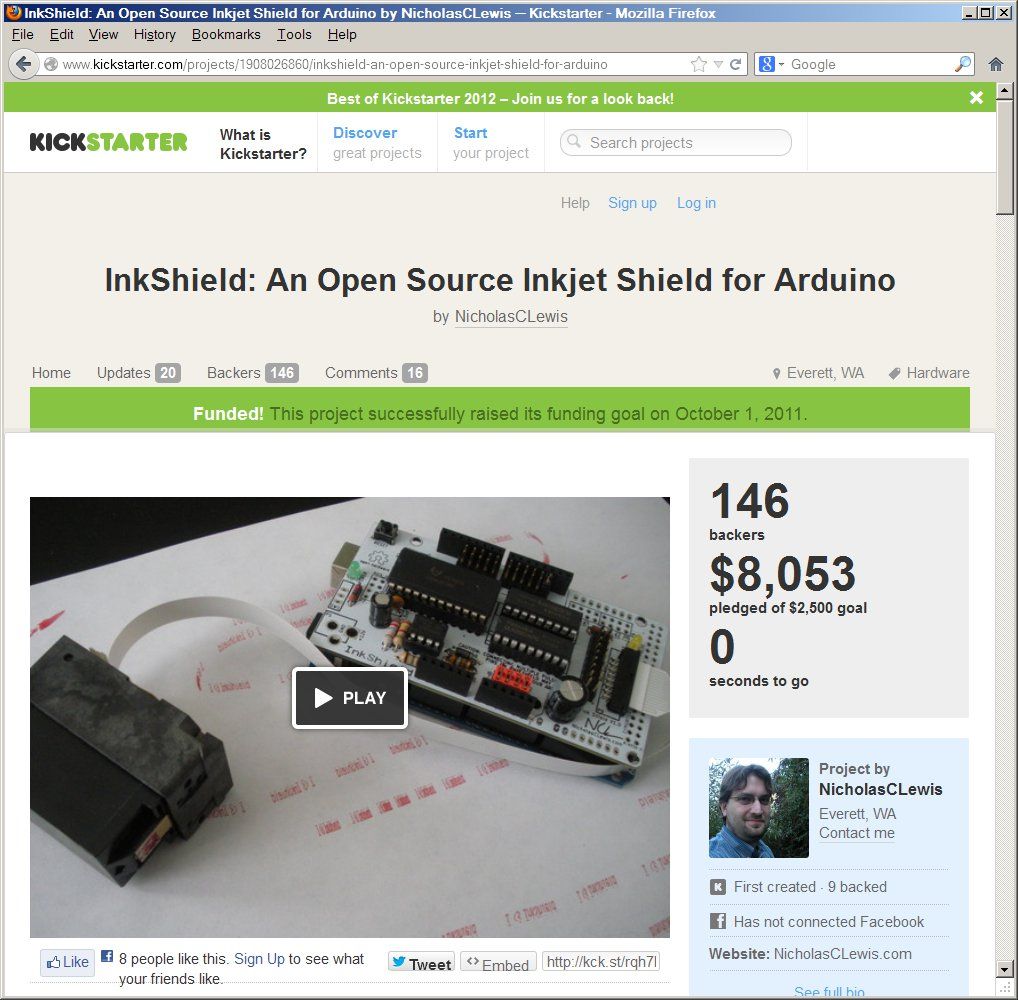

Now, the Parallax development kit for inkjet printers and the HP 51604A cartridge allows you to print with a resolution of 96 dpi, the problem is that they were discontinued several years ago.

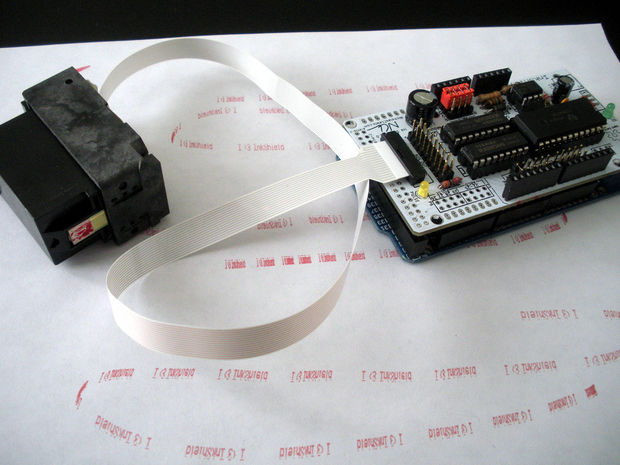

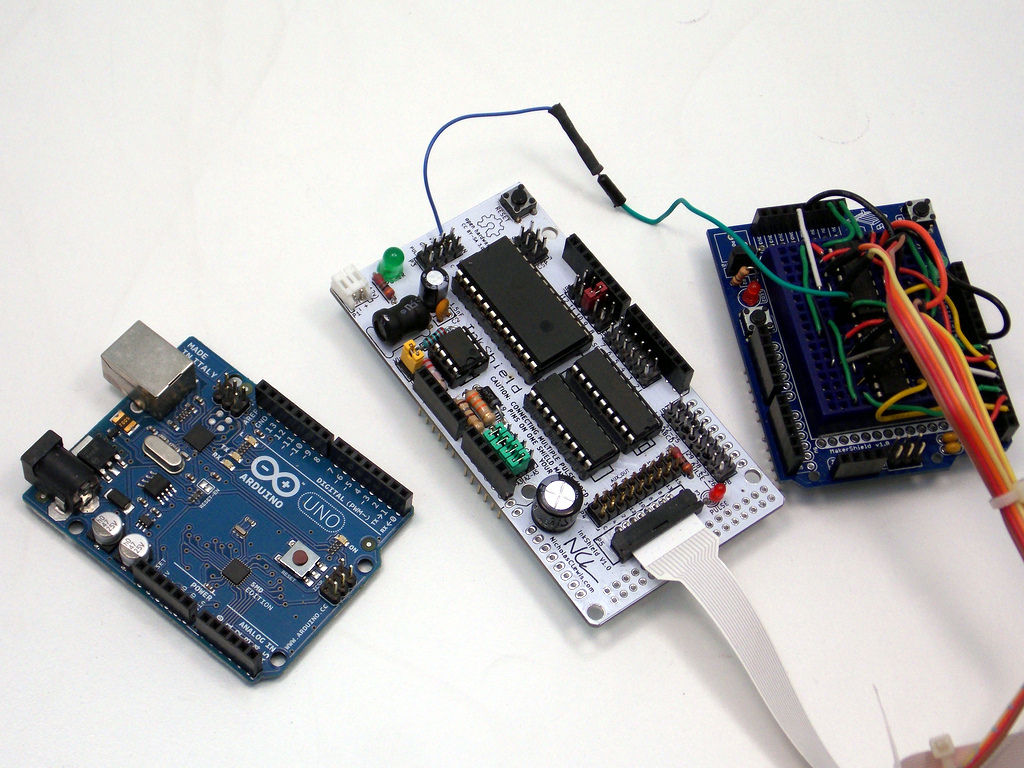

Fortunately for us, Nicholas Lewis recognized the need for a DIY inkjet printing platform, and started an Inkshield campaign on Kickstarter: An Open Source Inkjet Shield for Arduino. InkShield is built around an HP C6602 inkjet cartridge, with 12 nozzles and 96 dpi, designed to print labels on things like cables. 96 dpi equals 265 micron pitch. As you can see in the last image, the actual diameter of the nozzle is only about 1/3 of the distance between the points, or about 85 microns - just perfect for our purposes!

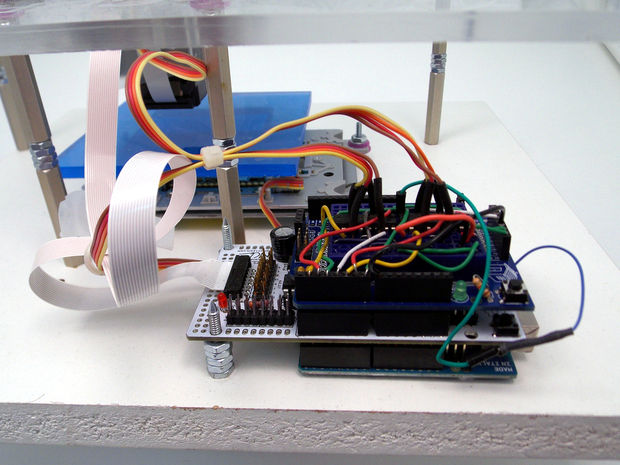

InkShield is designed to control the Arduino, but needs a higher voltage than the 5V Arduino it receives from USB. Thus, you must provide 9-12V power through a special power connector on the InkShield or through the power connector on the Arduino.

Step 4: Version 2: Hackteriabot!

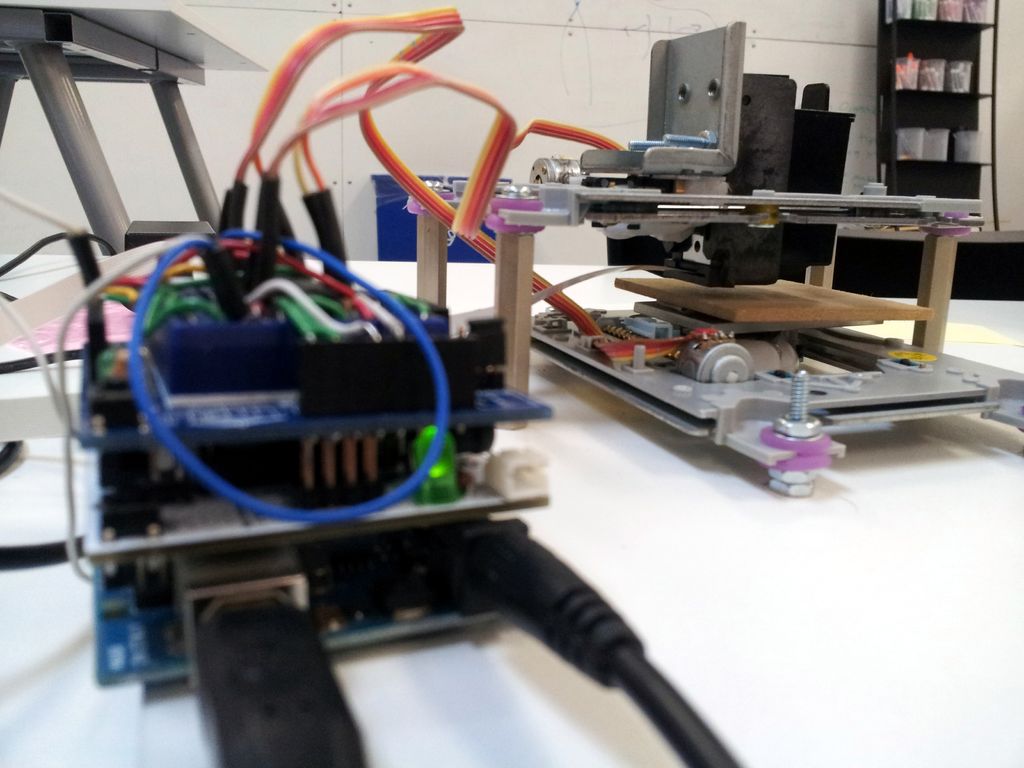

For our second bioprinting platform, we built an XY platform from a pair of old CD drives, inspired by the beautiful DIY laser cutter / microfluido platform from our friends from Hackteria:

hackteria.org/wiki/index.php/HackteriaLab_2011_Commons#Micro_Manipulator

hackteria.org/wiki/index.php/DIY_Micro_Dispensing_and_Bio_Printing

hackteria.org/wiki/index.php/DIY_Micro_Laser_Cutter

hackteria.org/wiki/index.php/DIY_Microfluidics#Advanced_DIY_Microfluidics

hackteria.org/?p=1186

diybio.org/2012/06/12/gaudilabalgaepicker

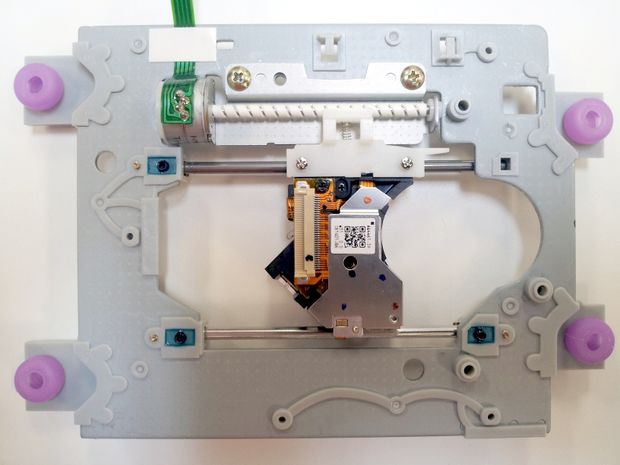

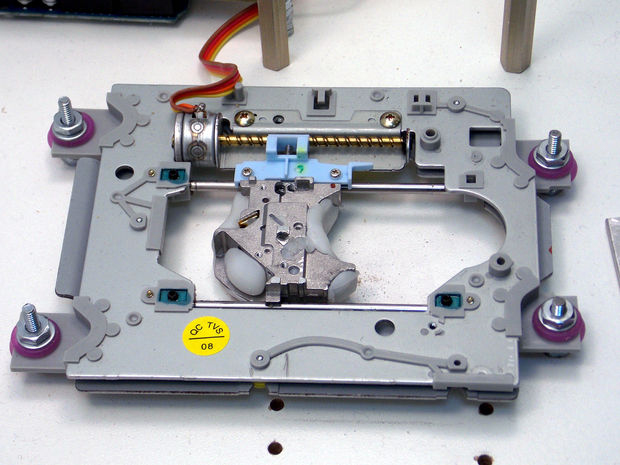

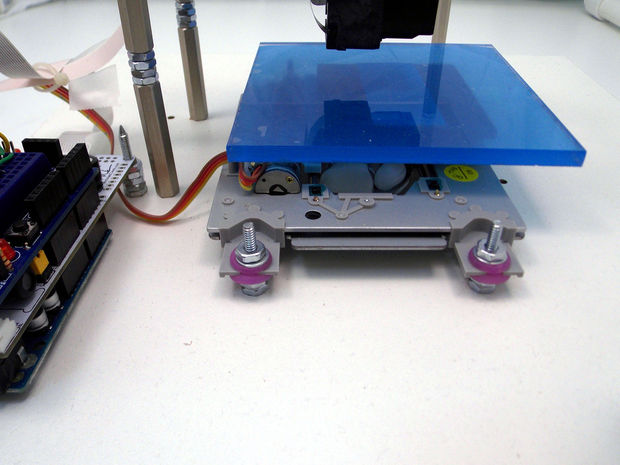

Arranging moving mechanisms that move the head in a CD / DVD drive, at an angle of 90, we get an XY platform with a very small construction area, but with a very high positioning accuracy

Using the laser head positioning from the CD drive mechanism to build a high-precision XY platform is not a new idea: builders.reprap.org/2010/08/selective-laser-sintering-part-8.html

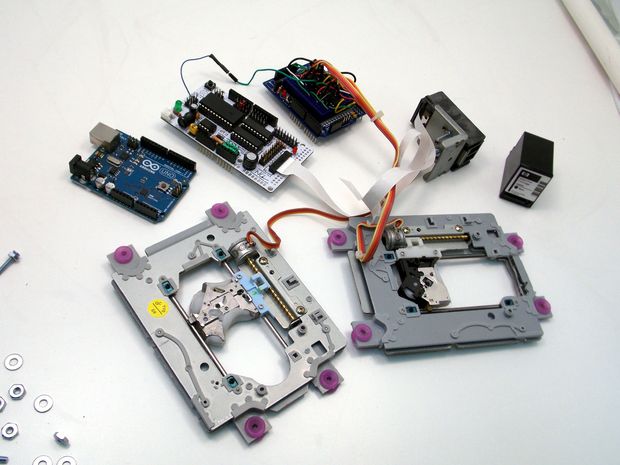

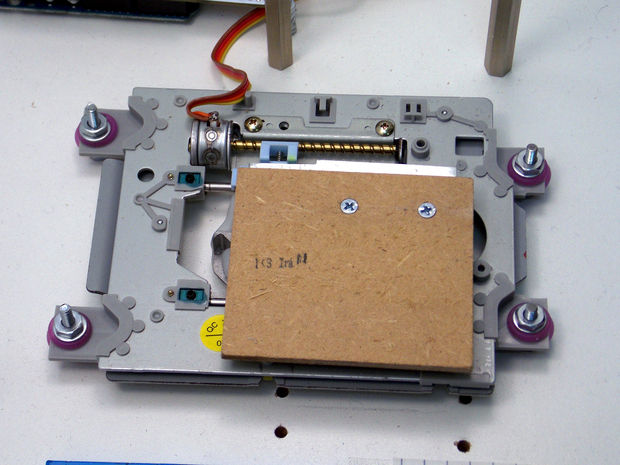

Step 5: Build the XY Platform from the Used Ear CDs

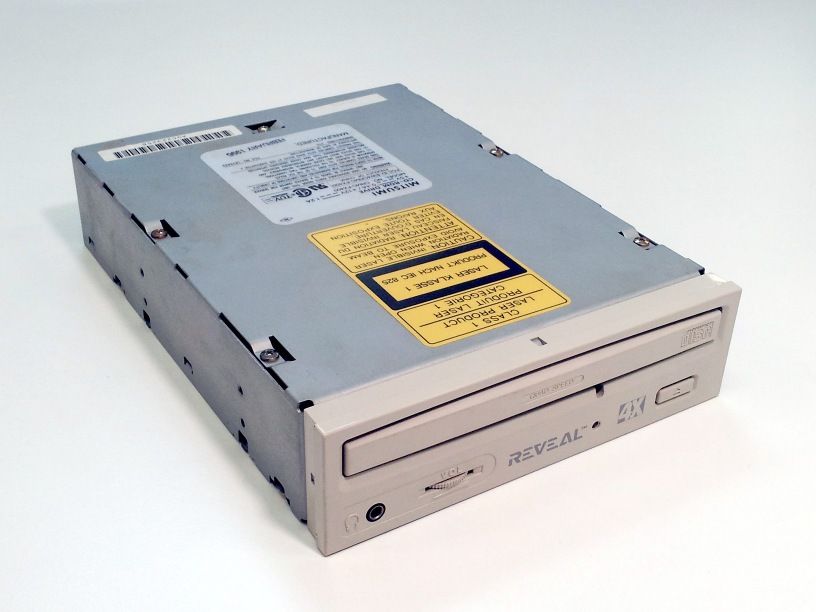

First we collect a stack of old drives. Open the tray with a clip. You may have to go through several drives before you find it with a stepper motor. At least half of those that we disassembled had a DC motor. If someone knows how to distinguish them by sight, then let us know.

They are easily distinguished from each other by disassembling the drive: DC have two wires, and the Stepper 4 and a short cable.

Unlike direct current, stepper motors are designed to move a certain number of steps, where each step is a part of a complete revolution. This makes it convenient for high-precision positioning, without the need to create a feedback system that checks the position of the head. For example, 3D printers typically use stepper motors to position the printhead.

After checking some serial numbers online, we stumbled upon a well-documented bipolar stepper motor, labeled PL15S-020. The remaining engines found are very similar to it, so they probably have the same parameters.

Technical Specifications: robocup.idi.ntnu.no/wiki/images/c/c6/PL15S020.pdf

This stepping motor makes 20 steps per revolution (not much, but enough), and the lead screw has a pitch of 3 mm per revolution. Thus, each step is equal to 150 microns moving the laser head - not bad!

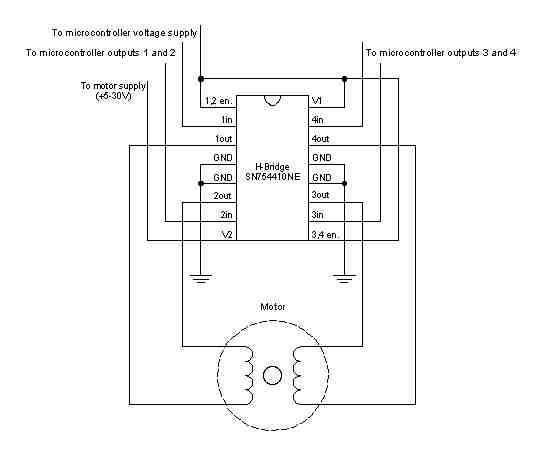

On the Arduino.cc website, we found diagrams for bipolar stepper motors, as well as sample code for controlling them. We ordered several SN754410NE H-bridges to implement the circuit shown in the last picture.

Old CD / DVD drives have many other interesting parts! Including the opening / closing mechanism tray containing a low-speed DC motor, a spindle motor that rotates a CD, typically has a high-performance brushless DC motor that can be used in toy airplanes and helicopters. Plus, lots of switches, potentiometers, damn lasers, and even solenoids! In general, remove everything !!!

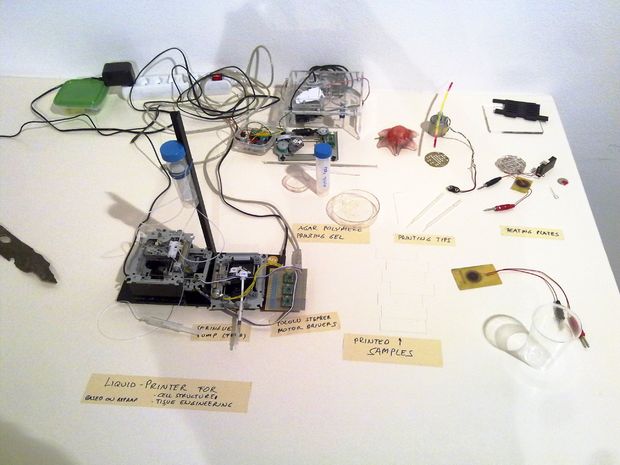

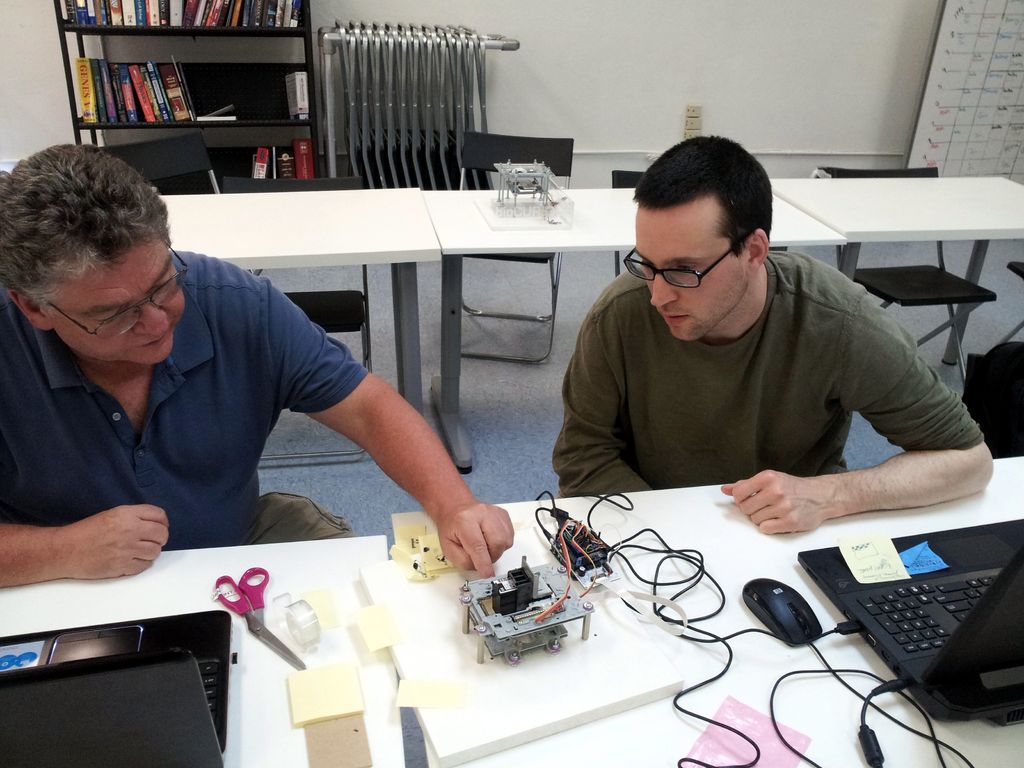

Step 6: Put it all together

Materials:

- Two mechanisms for moving a laser head with stepper motors (preferably the same) from old drives. Cost: a few dollars apiece.

- One InkShield kit, with cartridge and cartridge holder. Cost: $ 57

- Optional: optional HP C6602 inkjet cartridge. Cost: $ 17

- Arduino Uno. Cost: $ 30

- Two SN754410NE H-Bridge Motor. Cost: $ 5

- Arduino prototype kit and / or tiny prototyping board. Cost: $ 4-21

- Wires, screws, racks, enclosures. Cost: from free to $ $ $, depending on imagination.

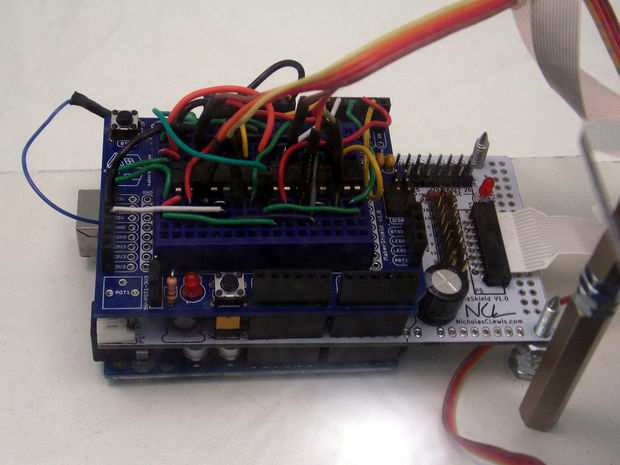

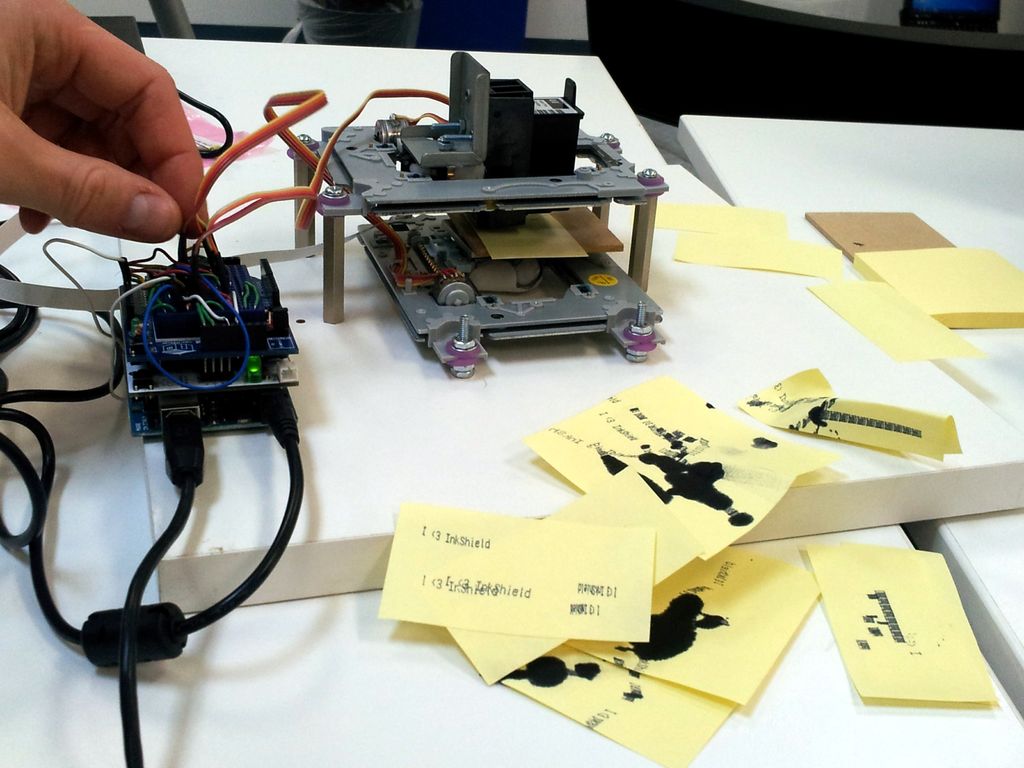

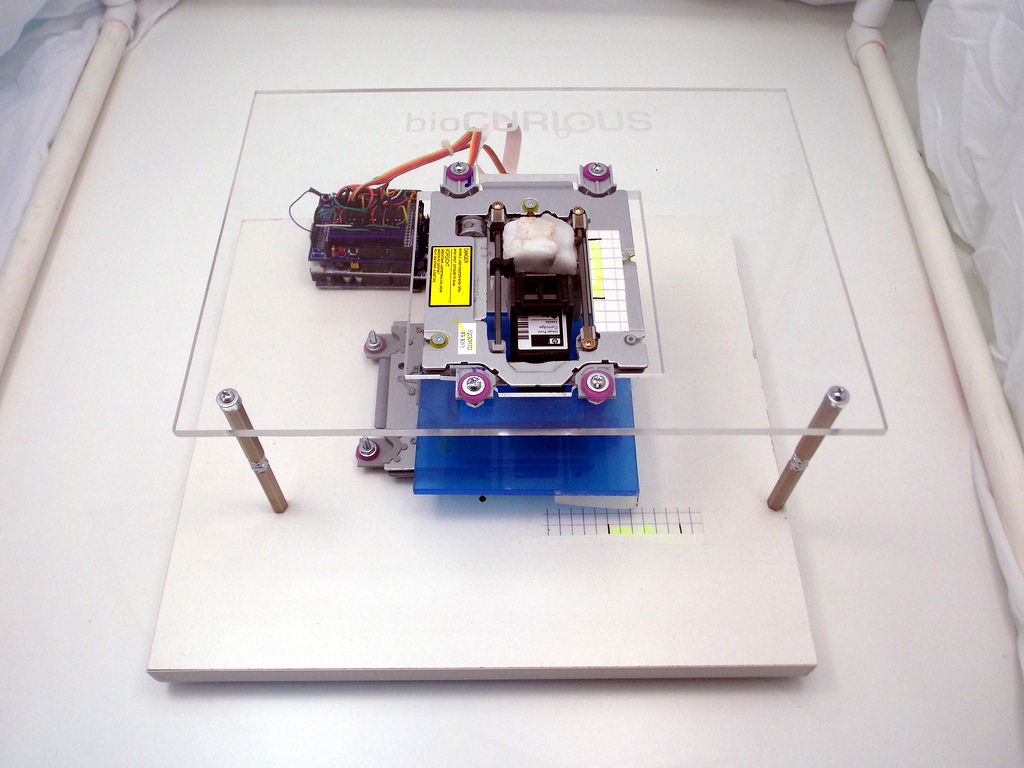

Total production costs amounted to about $ 150, including the cost of shipping and processing parts. Above the photo shows two different models. The second version has a top plate of high-quality acrylic and a large internal space.

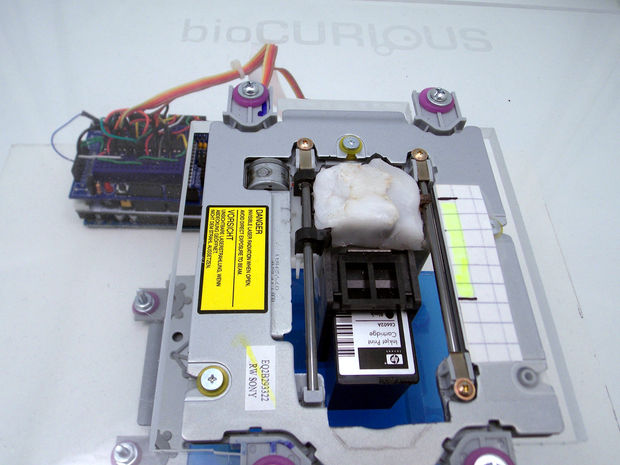

The mechanism for moving the CD drive, located at the bottom, moves the blue plate on which you print something (for example, an agarose plate). The top drive mechanism, mounted at right angles, moves the inkjet printhead. We used a Shapelock and some screws to fasten the lower platform to the laser head, and fix the cartridge holder to the upper laser head. The electronics consist of an Arduino Uno at the bottom, a white InkShield (connected to an inkjet cartridge holder with a nice white ribbon cable), and a proto-card with stepper motors at the top.

Paper strips made of squared paper on the lower and upper platforms allow us to track the position along the X and Y axes. The total print area is about 1.5 inches in both directions, with a resolution of 150 microns in one step. It should be noted that the resolution of the stepper motors is similar to the resolution of the printhead: 96 dpi 265 micron pitch, but the points of the printed printhead are clearly separated - more like 150-200 microns.

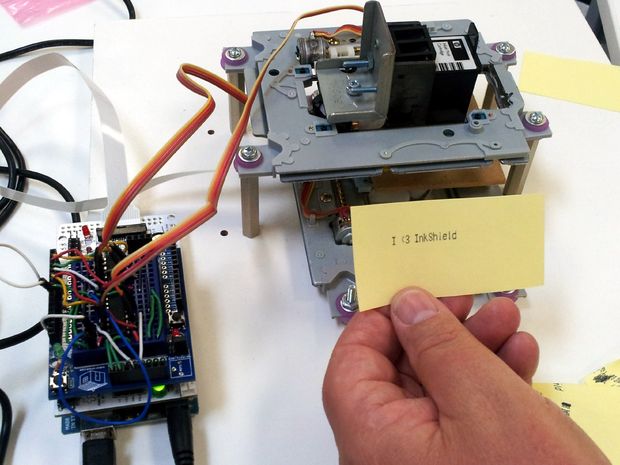

Step 7: Success

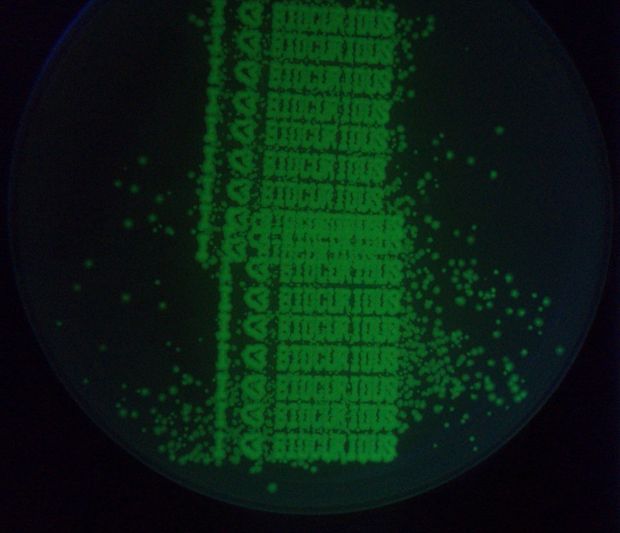

This is our first truly-working Bioprinter . We refilled the cartridge of liquid culture of E. coli + pGLO. Slightly modified “I <3 InkShield” DEMO Arduino, which came with InkShield, and printed a couple of lines “I <3 BioCurious” again and again on the agar plate. The agar was filled almost to the top to minimize the printing distance.

As you can see, the live E.coli cell printing works great! We probably gave colonies of bacteria to grow longer than necessary, so the letters blur a little. We received a spray of small colonies at the corners of the cage, probably due to some spray from the jet head. We can improve the quality by adjusting the viscosity or density of cultured cells loaded into the cartridge.

But overall, not bad for the first time!

After printing, we disinfected the surface and the inside of the cartridge with bleach, and then we missed a little bleach through the head. Then washed everything with distilled water.

It would probably be a good idea to invest in an ultrasonic jewelry cleaner that can destroy even organic matter in the most inaccessible places.

Step 8: Lesson learned and future plans

We turned to this project with almost zero experience with BioPrint, stepper motors, inkjet cartridges, and even Arduino programming! Therefore, naturally, not all of our actions were optimal. Here are some things that we might do differently next time:

“Studying the work of stepper motors, we got a really valuable experience, but we could save a lot of time and effort by adapting some of the RAMPS (RepRap Arduino MEGA Pololu Shield) technologies that were already well developed for this purpose in the 3D printing community. In particular, the Pololu stepper motor already had built-in micro-stepping capabilities.

- Building your own XY platform is great! But we use these stepper motors for what they were never intended for, that begins to show itself. We already get some problems with the sometimes skipping lower step, apparently due to frequent manual discharges that wear plastic parts. It was easy enough to buy new stepper motors to hold them, add some microswitches for the end stops, and a code for the function to reset the position in the software.

“As soon as you start searching for new stepper motors and RAMPS electronics, the question arises why not start right away with 3D printers instead? If we are tired of our current version of bioprinter, then, probably, because of the chosen direction. The cost is likely to increase by an order of magnitude and so, although ...

- The presence of one printhead has its limitations. If we really wanted to do some kind of tissue engineering, we would like to be able to print several types of cells. We could potentially put two inkjet cartridges to each other. The solution of Big Boys in this area is the use of syringe pumps. Imagine having several syringe pumps near the printer, each of which feeds its material to the press through a thin tube, and the needles are set on the print head. Keep for updates…

Now the elephant is in the china shop ... What the hell are you doing with your own bioprinter ?! I do not think that BioCurious will ever compete with companies such as Organovo in terms of printing human tissues or organs. On the one hand, the maintenance of animal cells takes much more effort. It’s much easier to work with plant cells! I don’t want it to be ruined, so watch out for some of our next tutorials!

Meanwhile, here are a few ideas:

- Printing nutrient gradients and / or antibiotics on a layer of cells to study combinatorial interactions - or even to select different isolates from an environmental sample.

- Printing patterns of growth factors on a layer of eukaryotic cells to study cell differentiation.

- Print two or more species of microorganisms at different distances from each other to explore metabolic interactions.

- Set up a computational problem as a 2D model of building a microorganism on an agar plate.

- Study of reaction-diffusion systems

- Printing 3D structures using reprint layers. Now you can consider making everything higher in 3D!

- Print cells into sodium alginate solution, impregnated with calcium chloride on the surface, to create 3D gel structures (by analogy with the process of spherification in molecular gastronomy)

- Any more ideas? Leave them in the comments!

Step 9: Added: So what do you want to do for real science?

The bioprinter shown here is obviously just a prototype. But since we had very serious requests for using this in academic laboratories, here are some recommendations:

- The Dolphin Dean Group at Clemson University is working on Bioprinting using a modified HP DeskJet 500. Check out their video on the JVE Using a Standard Inkjet Printer definitely! , , , , , 3D .

— , HP C6602 . , . …

— , , .

- Wrap the electronics in cling film or build a casing to keep it dry and clean. Everything else can be wiped with bleach after use.

D'haeseleer, P. (2013, January 22).

Source: https://habr.com/ru/post/194638/

All Articles