Microwave Repair Experience

One fine day, the grandmother rang and a voice in the tube told a scary story about a fire in the microwave. It turned out the following, deciding to wash the microwave oven, the grandmother had the idea to quickly dry it, for this microwave was turned on at all power - empty.

The result is smoked gut and panic.

At first, the idea was to just throw out the unit and put a new one, the price is simple, the models are not expensive, but then curiosity got the upper hand, because you didn’t have to go inside the microwave, it became interesting how it worked inside and whether it is possible to revive the unfortunate device.

After a little study of the theory, it turned out that the microwave oven has a fairly simple device in the base. This is a cooking chamber, a magnetron, a waveguide connecting the magnetron and a camera, a high-voltage power binding of the magnetron, a control unit.

Inside, everything turned out to be smoked; there were drops of molten plastic. Immediately it became clear and the culprit of this outrage. The microwave field burned and melted the cover protecting the waveguide and magnetron.

')

Once she was like that.

Dismantling the oven turned out to be a simple matter, unscrew the 6 screws and here they are the insides.

Right in the center of the magnetron, on the right a cooling fan, on the bottom a high-voltage transformer, on the left a backlight and control “twists”.

The first thing you need to remove the magnetron and check its status.

Remove the green terminal and unscrew the 4 screws securing the magnetron to the camera.

Here is the waveguide.

And here are the consequences of the inclusion of microwave without load.

Charged as a result of the breakdown of the wall of the waveguide.

Inspect the magnetron and immediately see the melted cap of the antenna

.

Now we need to understand whether the magnetron is alive and a little about what it actually represents.

Quote from wiki.

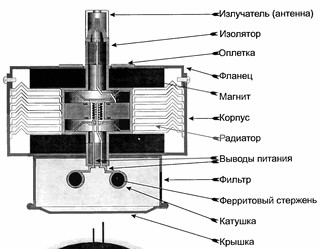

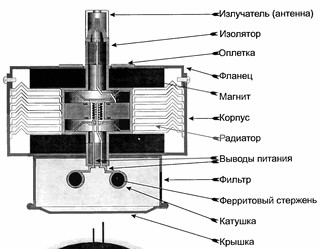

The design of the magnetron

It is necessary to make sure whether the vacuum was preserved in the magnetron and whether the burnout was limited only to the cap. Carefully removing the cap, we must ensure the integrity of the pin.

The tube should not be melted and if this happened, the magnetron can be discarded, it has already lost the vacuum.

Yes, and in fact often the whole idea of repair is meaningless, because the new magnetron can already be compared with the cost of the entire furnace.

But I was lucky. No damage was found. Now you have to decide what to do with the cap. It turned out that such caps are not frequent guests of household appliances spare parts stores. The Google search gave advice: either to turn it on a lathe, or to make it from an old from an old electrolytic capacitor. The second option seemed more affordable.

Let's get started We take K50 electrolyte of suitable diameter (about 16 mm), cut off the blank along the length and drill a hole. It is important to keep all sizes as accurate as possible. For the best conductivity of the microwave current, the surface is carefully equated to zero (and polishing is generally desirable).

Before the fine finish.

Finally, wipe our new cap with a cloth with a solvent and put it tightly on the magnetron.

Now it's up to the waveguide. Here I had to suffer. Waveguide must be thoroughly sanding from carbon, then remove all particles of abrasive and, in general, any foreign inclusions. The situation is complicated by the complex configuration of the waveguide and it is not so easy to reach the remote burnt corners. The vacuum cleaner helped me in the final cleaning, putting the hose into the hole of the waveguide, managed to remove all the trifles. Finally, we restore the restoration of the waveguide by wiping it with a cloth with a solvent.

Ideally, it would also be good to paint over the cleared areas, but in the search he expressed the opinion that not every paint can be friends with the microwave, local absorption and heating may occur, so he left it.

Finally it's up to the protective cover of the waveguide. The best solution would be to abandon the plastic in favor of mica. Mica is radio transparent and withstands high temperatures. If there is a grill, then this is practically the only good solution. Since there is no grill in my model, I decided to use a homemade polypropylene cover.

Quote from wiki

It is from this material that food containers for microwave ovens are usually made.

If you are not sure of the material we are looking for such an icon.

Then everything just cut the desired shape and put on the screws.

We assemble the entire oven in the reverse order, put a glass with water, turn it on and check the performance.

In the end, everything worked, the water heats up, there is no arcing, the waveguide screen is cold.

Ps. By the way, while studying the issue, I came across 2 links related to microwave.

1. A good neighbor and uses the "microwave gun" from a converted furnace to jam the hated music centers.

vrtp.ru/index.php?showtopic=13506

2. The effects of microwave radiation on humans.

www.radioscanner.ru/info/article30

So be careful with your household appliances, and with your neighbors through the wall.

The result is smoked gut and panic.

At first, the idea was to just throw out the unit and put a new one, the price is simple, the models are not expensive, but then curiosity got the upper hand, because you didn’t have to go inside the microwave, it became interesting how it worked inside and whether it is possible to revive the unfortunate device.

After a little study of the theory, it turned out that the microwave oven has a fairly simple device in the base. This is a cooking chamber, a magnetron, a waveguide connecting the magnetron and a camera, a high-voltage power binding of the magnetron, a control unit.

Inside, everything turned out to be smoked; there were drops of molten plastic. Immediately it became clear and the culprit of this outrage. The microwave field burned and melted the cover protecting the waveguide and magnetron.

')

Once she was like that.

Dismantling the oven turned out to be a simple matter, unscrew the 6 screws and here they are the insides.

Right in the center of the magnetron, on the right a cooling fan, on the bottom a high-voltage transformer, on the left a backlight and control “twists”.

The first thing you need to remove the magnetron and check its status.

Remove the green terminal and unscrew the 4 screws securing the magnetron to the camera.

Here is the waveguide.

And here are the consequences of the inclusion of microwave without load.

Charged as a result of the breakdown of the wall of the waveguide.

Inspect the magnetron and immediately see the melted cap of the antenna

.

Now we need to understand whether the magnetron is alive and a little about what it actually represents.

Quote from wiki.

A magnetron is a powerful electron tube that generates microwaves when a flow of electrons interacts with a magnetic field.

The design of the magnetron

It is necessary to make sure whether the vacuum was preserved in the magnetron and whether the burnout was limited only to the cap. Carefully removing the cap, we must ensure the integrity of the pin.

The tube should not be melted and if this happened, the magnetron can be discarded, it has already lost the vacuum.

Yes, and in fact often the whole idea of repair is meaningless, because the new magnetron can already be compared with the cost of the entire furnace.

But I was lucky. No damage was found. Now you have to decide what to do with the cap. It turned out that such caps are not frequent guests of household appliances spare parts stores. The Google search gave advice: either to turn it on a lathe, or to make it from an old from an old electrolytic capacitor. The second option seemed more affordable.

Let's get started We take K50 electrolyte of suitable diameter (about 16 mm), cut off the blank along the length and drill a hole. It is important to keep all sizes as accurate as possible. For the best conductivity of the microwave current, the surface is carefully equated to zero (and polishing is generally desirable).

Before the fine finish.

Finally, wipe our new cap with a cloth with a solvent and put it tightly on the magnetron.

Now it's up to the waveguide. Here I had to suffer. Waveguide must be thoroughly sanding from carbon, then remove all particles of abrasive and, in general, any foreign inclusions. The situation is complicated by the complex configuration of the waveguide and it is not so easy to reach the remote burnt corners. The vacuum cleaner helped me in the final cleaning, putting the hose into the hole of the waveguide, managed to remove all the trifles. Finally, we restore the restoration of the waveguide by wiping it with a cloth with a solvent.

Ideally, it would also be good to paint over the cleared areas, but in the search he expressed the opinion that not every paint can be friends with the microwave, local absorption and heating may occur, so he left it.

Finally it's up to the protective cover of the waveguide. The best solution would be to abandon the plastic in favor of mica. Mica is radio transparent and withstands high temperatures. If there is a grill, then this is practically the only good solution. Since there is no grill in my model, I decided to use a homemade polypropylene cover.

Quote from wiki

Polypropylene has a higher melting point than polyethylene, and, accordingly, a higher decomposition temperature. Pure isotactic polypropylene melts at 176 ° C. The maximum operating temperature of polypropylene 120-140? C. All products made of polypropylene withstand boiling, and can be subjected to steam sterilization without any change in their shape or mechanical properties.

It is from this material that food containers for microwave ovens are usually made.

If you are not sure of the material we are looking for such an icon.

Then everything just cut the desired shape and put on the screws.

We assemble the entire oven in the reverse order, put a glass with water, turn it on and check the performance.

In the end, everything worked, the water heats up, there is no arcing, the waveguide screen is cold.

Ps. By the way, while studying the issue, I came across 2 links related to microwave.

1. A good neighbor and uses the "microwave gun" from a converted furnace to jam the hated music centers.

vrtp.ru/index.php?showtopic=13506

2. The effects of microwave radiation on humans.

www.radioscanner.ru/info/article30

So be careful with your household appliances, and with your neighbors through the wall.

Source: https://habr.com/ru/post/194516/

All Articles