Budget UHF RFID reader and its development

Hello honorable ladies and gentlemen.

The cheapest UHF RFID reader or EPC Gen2 standard reader costs no less than $ 200.

How you can make a workable UHF RFID reader from parts for 10 USD, and how you could benefit from this, as described below.

Most modern RFID readers of the EPC Gen2 standard use specialized chips. They are produced by the company Impinj, AMS and Phychips. The cheapest chips cost around 20 USD in batches of 1000 pieces. RFID readers are excellent: powerful, nimble and long-range - but expensive.

In the spring of this year, an article entitled “ Simple Low Cost UHF RFID Reader ” appeared on the Internet about how to assemble a valid RFID reader from popular radio components costing about $ 5 at retail. The idea seems to be simple, but came to a realization only recently. The prerequisite for development is based on the fact that very often, close to the antenna, you need to slowly take a couple of tags, and it’s not worth paying a lot of money for a reader with a rate of fire of 200-500 tags per second. The block diagram of the reader is shown in the picture.

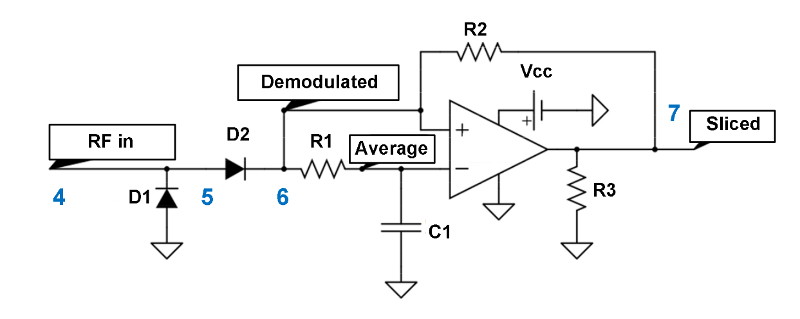

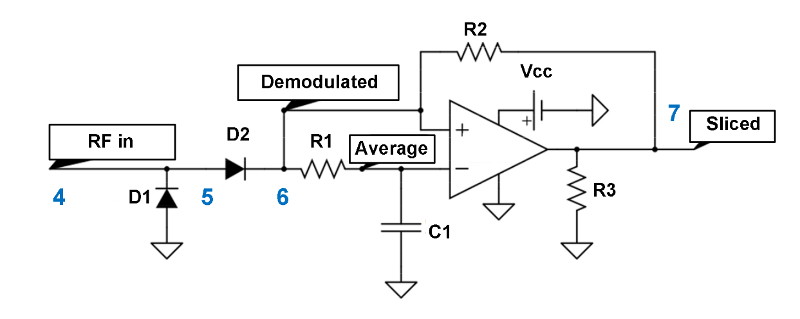

Her beauty in simplicity. The basis is a conventional microcontroller, which forms on the GPIO pin the signals of the EPC Gen2 standard, which are necessary for polling the label. Signals are transmitted to the Melexis TH72035 transmitter chip, then to the antenna via a coupler (Johanson 0910CF15B0100 coupler). The receiver is assembled on one MAX931 comparator as follows.

Logic signals from the receiver arrive at the other output of the GPIO microprocessor. We get a simple software UHF RFID reader. Of course, writing a software EPC Gen2 RFID reader is not a pound of raisins. But if you clearly define the goals and use only the desired subset of the EPC Gen2 protocol, the task is simplified significantly.

The authors of the described project are one of the goals of its further development, placing all components of the RFID reader on a single board. But wouldn't it be more interesting to go in the opposite direction? That is, divide the reader into physically isolated functional modules and then build an RFID reader with the necessary characteristics from different modules. Everything below is just an idea, without detailed elaboration.

It is clear that the main module is a microprocessor. Probably, you need to make it on the Cortex-M0, bring it to the UART and USB connectors in order to control the reader. To connect the transceiver module, use a 6-pin connector: Rx, Tx, 2 to power the transceiver, 2 GPIO. Such connectors can be made 2-4, as far as the conclusions of the microprocessor are enough.

The transceiver module will connect to the microprocessor module directly or via a short cable. Perhaps, it is necessary to make several variants of transceiver modules with different power and price, but the same connector. The 5th pin of the connector can be used to turn on the transceiver, and the 6th can be used as a sensor if necessary. It makes sense to make a PCB transceiver with metallized butt half holes. Then it can be soldered to printed circuit boards with different antennas or a printed circuit board with a coaxial SMA connector.

So, connecting the microprocessor module and the transceiver module, we get an RFID reader. But just for the sake of this fuss is not worth it. Let's go further. Plug in a 6-pin microprocessor module connector instead of a transceiver board with an RS422 driver and an RJ45 socket (pair 1 - receive, pair 2 - transfer, 3 - power, 4 - GPIO). The same stick in the transceiver. It is clear that now you can connect a microprocessor module and a transceiver using any patch cord or use an office SCS to connect. In general, the antenna from the microprocessor module can be located very far. And no coax.

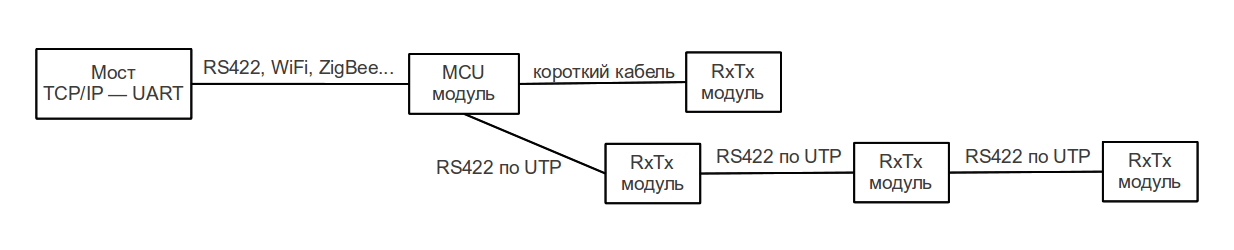

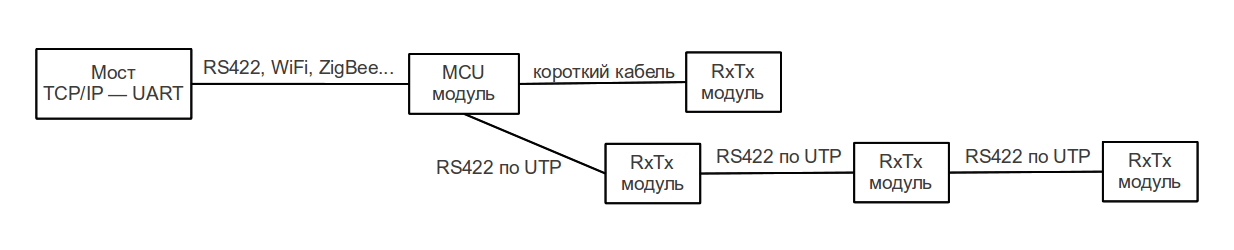

Well, that's not all :) RS422 is a bus. In the transceiver, you can place the D-trigger chip. Transceiver modules connected in series patch cords. True, you need a second RJ45 connector or a T-splitter, if you place a synchronous counter instead of a D-flip-flop. With the help of two GPIOs in the fourth UTP pair, you can select the desired transceiver. It turns out distributed RFID reader, as in the picture.

Why do we need USB: but in order to be able to connect the reader to the tablet with Android.

')

The solution is applicable where you do not need a large tag reading speed and long range.

1. For grocery stores is not suitable. These are RFID stores of the future. And the RFID stores of the present are department stores (shoes and clothes). There, RFID readers are already being used in the fitting rooms (together in an interactive display), at the cash registers and smart shelves with goods.

2. Warehouses with euro pallets (a chain of transceiver modules where the left corners of the pallet are located).

3. Access system to various mass events.

4. Surely somewhere else.

Your opinion?

The cheapest UHF RFID reader or EPC Gen2 standard reader costs no less than $ 200.

How you can make a workable UHF RFID reader from parts for 10 USD, and how you could benefit from this, as described below.

Most modern RFID readers of the EPC Gen2 standard use specialized chips. They are produced by the company Impinj, AMS and Phychips. The cheapest chips cost around 20 USD in batches of 1000 pieces. RFID readers are excellent: powerful, nimble and long-range - but expensive.

In the spring of this year, an article entitled “ Simple Low Cost UHF RFID Reader ” appeared on the Internet about how to assemble a valid RFID reader from popular radio components costing about $ 5 at retail. The idea seems to be simple, but came to a realization only recently. The prerequisite for development is based on the fact that very often, close to the antenna, you need to slowly take a couple of tags, and it’s not worth paying a lot of money for a reader with a rate of fire of 200-500 tags per second. The block diagram of the reader is shown in the picture.

Her beauty in simplicity. The basis is a conventional microcontroller, which forms on the GPIO pin the signals of the EPC Gen2 standard, which are necessary for polling the label. Signals are transmitted to the Melexis TH72035 transmitter chip, then to the antenna via a coupler (Johanson 0910CF15B0100 coupler). The receiver is assembled on one MAX931 comparator as follows.

Logic signals from the receiver arrive at the other output of the GPIO microprocessor. We get a simple software UHF RFID reader. Of course, writing a software EPC Gen2 RFID reader is not a pound of raisins. But if you clearly define the goals and use only the desired subset of the EPC Gen2 protocol, the task is simplified significantly.

The authors of the described project are one of the goals of its further development, placing all components of the RFID reader on a single board. But wouldn't it be more interesting to go in the opposite direction? That is, divide the reader into physically isolated functional modules and then build an RFID reader with the necessary characteristics from different modules. Everything below is just an idea, without detailed elaboration.

It is clear that the main module is a microprocessor. Probably, you need to make it on the Cortex-M0, bring it to the UART and USB connectors in order to control the reader. To connect the transceiver module, use a 6-pin connector: Rx, Tx, 2 to power the transceiver, 2 GPIO. Such connectors can be made 2-4, as far as the conclusions of the microprocessor are enough.

The transceiver module will connect to the microprocessor module directly or via a short cable. Perhaps, it is necessary to make several variants of transceiver modules with different power and price, but the same connector. The 5th pin of the connector can be used to turn on the transceiver, and the 6th can be used as a sensor if necessary. It makes sense to make a PCB transceiver with metallized butt half holes. Then it can be soldered to printed circuit boards with different antennas or a printed circuit board with a coaxial SMA connector.

So, connecting the microprocessor module and the transceiver module, we get an RFID reader. But just for the sake of this fuss is not worth it. Let's go further. Plug in a 6-pin microprocessor module connector instead of a transceiver board with an RS422 driver and an RJ45 socket (pair 1 - receive, pair 2 - transfer, 3 - power, 4 - GPIO). The same stick in the transceiver. It is clear that now you can connect a microprocessor module and a transceiver using any patch cord or use an office SCS to connect. In general, the antenna from the microprocessor module can be located very far. And no coax.

Well, that's not all :) RS422 is a bus. In the transceiver, you can place the D-trigger chip. Transceiver modules connected in series patch cords. True, you need a second RJ45 connector or a T-splitter, if you place a synchronous counter instead of a D-flip-flop. With the help of two GPIOs in the fourth UTP pair, you can select the desired transceiver. It turns out distributed RFID reader, as in the picture.

Why do we need USB: but in order to be able to connect the reader to the tablet with Android.

')

The solution is applicable where you do not need a large tag reading speed and long range.

1. For grocery stores is not suitable. These are RFID stores of the future. And the RFID stores of the present are department stores (shoes and clothes). There, RFID readers are already being used in the fitting rooms (together in an interactive display), at the cash registers and smart shelves with goods.

2. Warehouses with euro pallets (a chain of transceiver modules where the left corners of the pallet are located).

3. Access system to various mass events.

4. Surely somewhere else.

Your opinion?

Source: https://habr.com/ru/post/194408/

All Articles