What should we build a bike?

I went to this topic for two long years. Now I can not even believe that so much time has passed, but his race is inexorable. Perhaps Habr is not the most suitable place for such publications, far from IT, but I want those who are interested in the topic not to repeat my mistakes. And, perhaps, on the basis of my experience, someone from those who are interested will get something much better than mine. I will only be glad. The theme of electric transport is very popular among IT-Schnick, and for good reason.

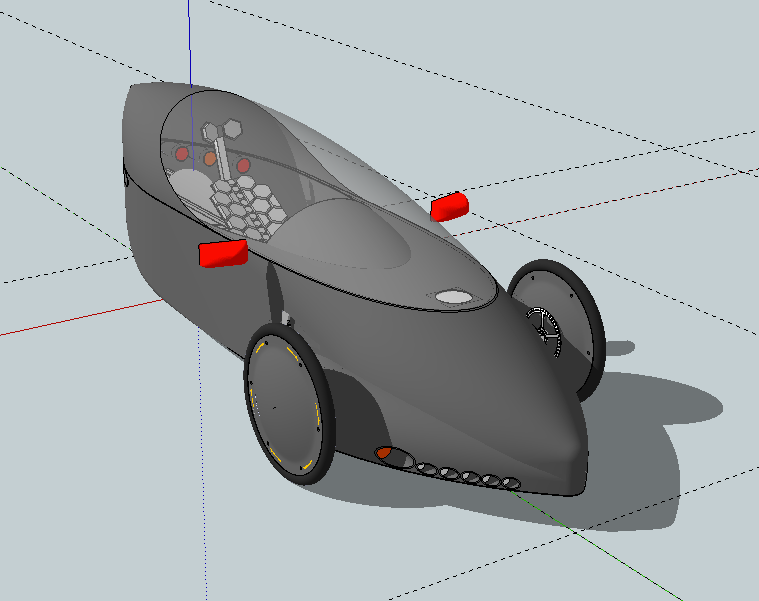

TL; DR - in two years a small team of 2 people (I as a builder, and my Moscow friend as chief designer) managed to design the frame and mechanics of a road electric bike, and also built its first prototype. Actually, at KPDV - this is the very prototype, yes. Video test pokatushek - at the end of the article.

')

If you are interested in the history of its creation - I ask for cat.

Beginning ...

A long time ago, in a far distant galaxy ... In general, it was always difficult for me to give in to something big, what I want to tell, well, to hell with it. Three years ago, I was brought to life in a rather remarkable community, in which, on the one hand, people gathered were sensible and reasonable enough to think about global changes, and on the other hand, as usual, very lazy and long on the rise. In general, everything came up against a banal fact - everyone talked, discussed, decided, argued, built intrigue-scandals, investigations, quarreled, put up, proved something to each other, but didn’t do anything to ensure that ideas global life change for the better somehow began to be implemented.

But, on the other hand, in every community there are good people with similar interests. It was there that I met my current friend and, as it now happened, my hobby partner. Quite quickly there were common points and extensive, interesting topics for discussion. My friend, like me, has already come to the conclusion about the “righteous inaction” of everyone around him, and already a little bit he, like me, began the process of moving away from active participation in the community. In general, everything was just in time.

On one of those old evenings, a sudden idea came to me to create something with my hands, and not just a “something”, but a four-wheeled, quite self-shifting vehicle. This kind of lightning, from constant reflection, "How long will we sit?" Instantly translates thoughts into the mainstream, "Damn! Its cool! This is what you need to do! Without hesitating a second! ”Books on the construction of Lotus Seven Colin Chapman’s replicas were found fairly quickly, the necessary literature was purchased and I went into long thoughts about how and what to do, where to start, what tool is needed. By the way, it will be said - at that time I had several screwdrivers and pliers from the tool. Everything. With such a set, it’s not that a car is hard to twist at home. And I myself am never a piece of iron. The most common pogromist on Habré is better known for his wild passion for canvas and Javascript.

Of course, after a few weeks of active thinking, donor selection, design and rework of different variations of the space frame, suspension arms, separation of all systems, re-planning, reading smart books, advising you never to take up building something of your own (and I honestly, now I absolutely support this opinion, but, on the other hand, glory to the monster that 2 years ago I didn’t find a second who could dissuade me) all my thoughts about moving somewhere, I began to accurately convey to my comrade with whom we, at that time, almost every day were in touch and often called up. There were even funny moments when my wife began to be jealous of me for a “Moscow friend.”

Oddly enough, my proposal to do something was greeted with enthusiasm and we, headlong, rushed into the study.

2 Years before release

Our plan was simple to madness - to build something that could be controlled by man and move thanks to our own power plant. Just at the same time, in our team, geeks in the office began to wander the same mood, the benefit of almost everything - either with cars or dreaming to purchase. I got a wonderful book “Build your own sports car on a budget”, so I and Roma (my Moscow friend) chose the following layout as the basis: a space frame based on the Lotus Seven roadster, a power plant from any donor, fine-tuning and launch. But, no matter how good our plan is, the harsh reality every day imposes its paw on all our attempts. After we finished building the frame, picked up the right donor, calculated all the costs at a minimum, we concluded that we simply wouldn’t draw on the construction of such a serious unit. It's no joke, only the hinge heads of suitable strength cost $ 30-40 per piece, and they needed, without taking into account losses, at least 8 pieces.

Another massive problem that came before us in full growth was a lack of experience. Now I am well aware why young engineers were sent to the workshop for several years, to work alongside the craftsmen, to look at the machines and absorb the production. The reason for this is the banal absence of any skills in mechanical and thermal processing of metals. I myself noticed for a very long time that when I looked at the blanks in the editor, I hardly feel the complexity with which these parts will be made later. The whole model seems to be a typical carton, which can be bent-broken-changed as soon as your heart desires, and angles of, say, 15.28 degrees are so easy! How many times after I caught myself thinking that I did not ask for help from the guys at the service station, just to see and try ... There are not enough fingers and toes.

Yes, and the maintenance of the ICE for Roma and me was a dark forest. No, of course, we quickly found the necessary theory and literature, but there was absolutely nothing to train and look at the results. At the same time, it was scary that acquiring a basic knowledge of the subject area for each engine is a separate song that has been gained over the years, and we could not afford it at all. Too hot heads and young hearts, we needed a result, and the sooner the better!

One of the first samples we wanted

Of course, almost every day we were in the active search phase. Crazy heads even considered any exotic type of hydrogen cells ... And it was at this point that someone from his comrades threw me a link not evtv.me. The electric drive had the effect of a bombshell in our heads. Even without listing all its advantages, first of all, I was pleased with the minimum of necessary details, minimum of maintenance and the possibility of a Direct Drive, i.e direct connection of the engine to the rear axle without a box, only through a gearbox. And it really impressed the two of us. No one knew that after this we would stop thinking about ICE and become infected with an electrical disease until the end of our days. But this disease is, in fact, very pleasant.

But the problem of price and the added problem with batteries has not gone anywhere or disappeared. We still sorely lacked neither money nor experience, and something had to be done about it. Having found several calculators on the network for calculating transport, we quickly found out that, depending on the weight and cross-section of transport, the required power and torque differ quite significantly. And in some magical way, both I and Roma came to the conclusion that you need to start completely from the car frame and not from the roadster. For the most elementary experience with metal, we decided to assemble a reverse trike. They abandoned the spatial frame, leaving a flat farm, decided to test the first samples with conventional gel batteries from ups, quickly found the "suitable", as it seemed to us, 1250-watt engine with one of the Korean bicycle sets and designed it all into a single design.

We spent a total of several winter-spring months on all the preparatory stages and by April last year we reached the project, which is about 80% ready for the base required for construction. Remained the case for small.

Let the show begin

Month went in search of a suitable garage. As a result, they found a two-story box for two cars, but without any repairs. Naked sand on the floor, heh. However, we are not very demanding and this is quite enough for us. I purchased a welding machine and flux-cored (fluxed) wire to it, and for another month or more I dug into the small design of the garage, arranging, assembling any tables-chairs, purchasing the necessary tools and consumables. In general, our kit, assembled at the moment, is not so big in volume. Drill, small Bulgarian, sharpener, pipe cutter, welding machine, Chinese "milling" hobby machine tool and hand tools. At the same time, one of my acquaintances gave me his old sofa with an armchair and a coffee table, so that even a small soft seating area appeared in the garage. In the same month I studied welding. Youtube is truly a great thing for this, as many educational materials and people who are willing to share their practices on video, I probably have not found anywhere else. I have been told for a long time that, basically, their training in labor specialties and tytruba are simply made for each other, that either you watch the video, or you look for a long and tedious search for a benevolent master who will be ready to mess with you until you at least learn something, but I waved. And he was wrong. On a personal example, I myself have confirmed that more or less cooking on video tutorials is possible.

Along the way, Roma and I graduated from Mit's 6.002 course and became a little more knowledgeable in the issue of electrical circuits and the load calculation of all electrical viscera. By itself, the electrical circuit turned out to be simple - 8 batteries connected to a 4s2p, 48V, 18Ah, 18kg unit weight, all this is fed to the controller input, and the output is connected to the motor and accelerator handle. The engine itself, the controller and all that came with it was a Korean kit for converting a bicycle into an electric cycle (http://www.cyclone-tw.com/order-1chain.htm, at that time we took the most powerful of all available - 1200W / 48V, now there is a version at 1650W). For the test - the most it. Starting from the end of June, we plunged into building a frame, ordering chiseled parts (by the way - insanely expensive thing compared to the price of iron, then), learning all the tricks of cutting, welding, and treating steel in all possible and impossible manifestations, preparing for available tools and accessories (both desktops with steel tops in the garage are welded by me). A suitable metal with delivery was found on one of the metal warehouses with delivery by a cheerful driver Ashot on a dazed gazelle.

By the end of the construction they came to the conclusion that the flux-cored wire is complete, expensive flippers and angles, it’s better not to cook anything, or if there is absolutely nothing (in the field near the birch from the generator). I bought a filled carbon dioxide cylinder from the local uncles in the garage and arranged to give it to me in the garage. About how my friend and I dragged him to the second floor of the stairs - this is a separate song, which we had to crank again this year. Pleasure is not the best. For quite a long time I tormented myself with the steering - it was impossible to precisely and correctly cut, and then weld the steering knuckles, and for almost a month I waited for the console bushes to the “front” bridge. And after that, I was looking for a bicycle shop for a long time in which they would be talked about. But I did deserve some respectful views, when the bike master had two perfectly machined steel bushes in their hands with solid “sonorous” steel axles with a diameter of 15mm.

Along the way, I had to solve minor conflicts at home, I had time to get along with my wife, as I spent most of the weekend in the garage. Now I am sincerely grateful to her that she still tolerates all my antics and endures my absence at home. Everything spun tight enough, and I did not pay attention to a billion small problems. If earlier it seemed to me that driving the market to the other end of the city and buying some necessary trifle was a feat, now my trip began almost every Saturday. Constantly there were not enough fasteners, bolts, nuts, small sheets of iron, stubs, wires, wood, pipes, rods, adapters, fasteners ... This list is endless. As soon as you start to do something - always, always some trifles are not enough and you need to either put up with it, or engage in perfectionism and stretch the project "until better times" for years and years ...

| |||||

|  |  |  |  |  |

The design of the steering then caused me the most confusion. I learned exactly how to cook, and the process of assembling the helmsman was more like hellish flour and coaxing the bull to give birth to a kitten, but we did manage. With the brakes, it was decided not to bother too much and a pair of Avid Juicy 5, mounted directly on the steering knuckles through the plates welded to them, settled on the front wheels, the suspension was missing as a class. I didn’t get a thoughtful design of the engine mount assembly that caused me to simply have a monstrous storm of emotions, after which any error in the project I began to firmly associate with the phrase “Sharpener namodel #% & # @!”. The decision to use the BMX wheel was an error - the engine torque with 7/9 gear ratio was not enough for the driving dynamics to be at least acceptable and we did not burn the engine, so we had to change the rear hub from the BMX driver to a regular overtaking clutch (freewheel ) for 24 teeth. Having thus increased the moment, consider, almost 3 times, we were able to achieve acceptable results. The final chord was the welding of the stand under the chair, the assembly of the chair itself and the final assembly and connection of the electrical circuit of our apparatus.

On September 22, after an evening attempt to ride, they found slipping of chain links under load. The next day, in the morning, I quickly profiled from a piece of steel corner mount under the chain tensioner, we welded it successfully and went to the test. And now the test was a success.

A couple of days with Roma, we were just in euphoria. What we have been discussing for so long, designing, remaking, arguing and quarreling because of it - has finally begun to live! It was just indescribable. All the next week I devoted to fine-tuning and skating around the surrounding courtyards. Scared grandmothers and mummies peacefully walking stupid polls how to get to the school stadium, or where you can turn around. But it was very fun and unforgettable! I do not even know what it looks like ... Primordial joy of creation, when it begins to work what you thought so long and what you did for so long, pride in the work done, though not very high quality, but strong and whole, the pleasure from simple pokatushek, explosions of adrenaline on the slopes ... Uff, to describe the whole range of emotions can be infinite. But it needs to be tried, no words will convey what you feel at that moment.

| |||||

|  |  |  |  |  |

Brace yourself! Winter is coming!

Gradually, nevertheless, we returned to the usual working course and, as a result, we found a very, very large number of problems that practically put an end to the further development of this particular frame. The first, and most importantly - just a huge weight. The profile tube 60x30x3 was not just heavy - it turned out to be monstrous and slow, it was very hard to lift the frame itself, and when batteries were added - write was gone. I even lifted my trike by the tail with effort. We did our best to compensate for the absence of the suspension with a double layer of thick foam rubber on the seat in a leather case, and this helped. At least, the fifth point and the back after pokatushek hurt not so much ^ _ ^ Well, the problem in the power plant. She obviously lacked such a weight, the engine overheated several times and turned off, a frankly weak power reserve and lead batteries - all this was horror and did not give the current frame a drop of hope for the continuation of the banquet.

The final characteristics that we have achieved:

Mileage: 30-35km

Max. speed: 40km / h

Weigh:> 60kg

General description of the structure

little ride

From this moment begins the story of the bike on KPDV. One evening, after another re-planning of the frame, and then, when we added the suspension and were actively looking for a new power unit, I came across a link to the American electric Stealth bikes. “Roma, damn it, I have an idea! We can freely make the same bike in just a couple of months! And I will be very pickup transport ride on the market. It needs to be done, really! ”Of course, Roman, already quite strongly turned on trikes and assimilating past mistakes, took my idea without enthusiasm and was generally against it, but I insisted on it and I managed to convince him to make a draft for me . And our goal, in the end, was not just building a bike.We decided to collect a bike powerful enough to not feel defective when entering a hill (the trike with a driver weight> 80kg refused to go uphill, and I was not very willing to carry me with my 58kg bird weight). travel distance> 50km.

At this point, I was digging into the reading of endless-sphere.com quite strongly and already knew perfectly well what exactly we needed in terms of the power unit. Despite the exorbitant cost, we chose the solution, which, at the moment, is the most powerful bike available. We decided to build our bike on the back of the motor-wheels Greyborg Cromotor, aka Hubzilla. The mk2 version, which was on sale at the time, was declared as an engine with a maximum constant power of 6KW and a peak power of 10KW. In general - for the eyes. For the greater distance, we decided to try the Chinese batteries NCR18650B, good, I went to a reliable supplier.

We postponed the idea of making a fairing for the trike until better times. The unheated garage absolutely did not allow anything to be done inside, just the wildest cold. Therefore, all winter time we have been planning and assembling funds.

Approximately in the winter Roma and I visited, as it seemed to us, the most ingenious idea - what if we take it, and it’s not easy to order battery packs, but print them yourself? 3d-printers are already quite stable and common thing, printed ABS-plastic is strong enough for our naruzok. In general, why not? Of course, the one who does nothing is not mistaken, but now I know for sure that I will contact further with RepRap only because I have studied their design with my hands up and down. But I would not advise starting my acquaintance with printers, being aimed at some specific result. Will not work.Just as it did not work for me.

Having purchased the assembly kit at Blomker Industries and assembled our MendelMax fairly precisely from the very first days of printing, we encountered problems that we could not solve until now. Any large workpiece stroked to stick out at the edges and bent in an arc. Our blanks were long enough - 176mm in length, and it was the holy faith in the “work area” that let us down very much. The parts were spoiled, even if they were glued with cyanoacryl directly to the table on which they were printed. At the same time, the matter is not fast, it is not very pleasant to spend a few hours to get a marriage in the end. I earned the unfinished print syndrome and started waking up at 3-4 am, checking the printer, and went to sleep. All weekend passed in front of this bad piece of iron in the hope that the next change in settings will help something, but all my hopes and tactics,advised in the forums simply did not work. The printer as printed samples that can not be used - and continued to print, completely ignoring all my attempts. Along the way, I managed to completely grind off the bolt with the thread in the extruder, re-solder the contacts several times, spent almost 2 kg of ABS plastic, caught glitches of software under the macos ...

| |||||

|  |  |  |  |  |

One of these glitches put an end to further attempts to use the printer. One night, when I got tired of waiting for the result and went to sleep, my printer turned on the table to heat the workpiece and ... Pronterface fell into the bark. At the same time, the printer itself stopped printing, but did not turn off the heating circuits. In the morning I sat down to count the losses. The loss turned out to be mainly electronics - one of the stepper motors jammed with temperature, 2 control loops burnt out, the extruder turned into a fused mash. Epic Fail worth almost $ 900.

New future

The remains of the printer went to the cabinet, but this failure did not stop us. Starting from March, we began to collect all the necessary components, since part of the design and general calculation was already almost completed. We managed to buy an engine, bought all the necessary batteries in two batches of 100 pieces with a difference of 2 months, waited for the controller to arrive from the USA and at the end of August it was finally the assembly time of the entire kit that we purchased. During the same month, we waited for a wide rim and rubber for it from Germany, and for about a week we were looking for a master who could properly speak the engine to the wheel. More than a dozen craftsmen in different stores simply refused, explaining that with everything. But I did find a store in which they helped me, even if it cost 3 times as much as usual,but I was willing to pay more, so that my little wheel would speak. These same masters later acquired all the parts for assembling the steering and assembled the front wheel.

The remaining cycle components (fork, shock absorber, brakes) were acquired through the flea market x-bikers.ru. Problems with the purchase and receipt did not arise in principle, but it is rather the merit of those who sell.

In general, everything was assembled and I began to spend more days off in the garage. Taking all the groove (steering glass and sleeve for bearings for mounting the pendulum), he marked and cut all the pieces under the frame, welded it, set to the pendulum ... And after welding, I realized that the engine simply does not fit. We literally made a mistake of 5 mm, without taking into account the flanges for the overrunning clutch and disc brake, and because of this, we had to “reinvent the wheel” in a new way. After discussing the problem with Roma, I neatly cut the pipes, bent each one 5 degrees and boiled what I cut through, adding two stiffening ribs passing through the weld seam from above. The response mount for the engine was decided by the same sheet bending 5mm thick. At the same time, I ran out of gas, which slowed down the assembly for about a week and the pendulum was assembled after refueling.

| |||||

|  |  |  |  |  |

After working the frame and adding fasteners to the shock absorber, it was determined that the spring 350x3.25 was weak and something more was needed. I threw the ad on the same x-bikers. A very strange situation, but the springs for bicycle shock absorbers are generally not found in the Ukrainian bicycle tires. There are only shock absorbers already complete with springs, which in the presence of an amort on my arms did not suit me at all. A suitable spring had to be ordered on a kettle (slang name chainreactioncycles.com). But the necessary spring, thanks to the kind people from the forum, was found about a month after I threw a message on the topic of sale and exchange of springs. She set it for now.

According to numerous advice from friends and acquaintances who evaluated the frame, additional kerchiefs added to the pipe joints to increase strength, pressed the bearings into the pendulum mount and received from the turner their axis, which later had to be adjusted with a file and 1000th emery paper, as it simply I did not want to enter the bearing unit, as I had planned. It is now up to small things - to assemble and secure the battery packs. For this, I prepared a small manual welding machine for spot welding with alternating current, successfully tested it and welded all the batteries into blocks of 14 pieces.

Along the way, in one of the hobby stores, I purchased a suitable charger in all respects for my needs - the Hyperion 720 Super DUO3, and also went to the daughter of the Zaporozhye plant of radioelectronic devices and took from them a test sample of a laboratory BP 30V / 40A. Already after I realized that such a powerful power unit needed to be purchased, but at the time of the acquisition I still doubted strongly. As the first charge showed, the total charge current of 32 amperes is not a joke.

Separate remarks are worthy of American sellers of parts and components. I have never received such a detailed description of what I receive with all possible and impossible schemes and descriptions anywhere else. Moreover, when I ordered the controller, the seller, before sending, took a small video with testing of my controller, put it on the tube and sent it to me as confirmation of its performance. I was at this moment, to put it mildly, surprised by this level of service. Upon receipt of the controller, I checked the serials with the video - everything matched. And, most importantly - the guys selling over the hill are very responsive and ready to help with the problems that arise in the process of tuning and launching.

In the process of assembling I was waiting for another unpleasant news. No, even two news. The first, not the saddest, but rather unpleasant - nickel tape 5mm wide turned out to be too narrow and thin, therefore, as a transitional solution, I decided to weld the thick conductor under high current, which gave rise to the following problem - the batteries simply did not fit into the prepared ones. forms. Yes, I cut the forms themselves in one of the Kiev advertising agencies from transparent ABS plastic, after gluing it together and I got a fairly strong construction. All blocks had to be separated by spacers of 5mm thickness - they had to be milled to 3mm so that the conductors could fit freely and still make it possible to assemble the entire compound.

We found out the second news already after we had assembled the whole structure into a combat state. I will make a small remark about how we came to the NCR18650B batteries. In order not to crap and not to wash the seat after the first tests, Roma and I decided to start using the engine in the most gentle mode - 48 volts. At the same time, according to the passport, the engine consumes up to 40A on a flat surface and up to 60A by 10% rise. That is, it turns out that the maximum current of up to 60A must pass through each of the 14 blocks, which, in terms of one cell, is 4.28A. The maximum allowable current consumption for the NCR18650B is 2C, i.e. up to 7.5 amps We had less, which pleased us, as the batteries will not be subject to significant degradation during operation. But the main ambush was that each cell had its own protection circuit, limiting the current through the element to 1,5A. After the first tests, me and my friend Dima, with whom we often hung out in the garage and who helped me mess around with all my hobbies, felt the obvious smell of burning electronics, after which all the blocks had to be sorted out and removed from each element of this protection. By the way - on some cells the burned out circuits simply closed the circuit, dropping the battery almost to zero. I had to replace them from the "repair kit" for 10 cells, additionally purchased in reserve.I had to replace them from the "repair kit" for 10 cells, additionally purchased in reserve.I had to replace them from the "repair kit" for 10 cells, additionally purchased in reserve.

At the same time, I did find a Ukrainian seller of nickel tape, which I was extremely happy about. Literally the next day after the order, I dropped a whole kilogram of tape 175x0.1, which was enough to completely cover the entire battery pack and leave the language to connect to neighboring batteries. In general, this is how I assembled this compound, throwing out spacers and simply gluing the entire plastic box with cyanoacryl.

The final cut

| |||||

|  |  |  |  |  |

Stages of the final assembly

The first tests were literally a couple of days ago. Just at the time of the final assembly, my friends stopped me in the garage to go through one of them with an RS-ovsky plug, and at the same time see what I did.

Version 0.12 alpha did, and went very vigorously. Approximately the same as I expected. Not very fast, like a motorcycle, but for training and primary tests - just perfect. We slightly fell short of the year since the launch of the previous prototype. It didn’t work out in a couple of months, but it was no longer important. The main thing - we did have our way, our bike went on its own and after testing and running in the garages all Sunday I walked happy, like an elephant after a good wash and polish.

As a summary, electric transport can and should be built, tested and looked to the future.

Approximate performance characteristics, which we now have on hand:

Weight: about 50kg (engine weight - 14kg, battery weight - 12kg)

Power reserve: 80-100km (approximately 45Ah with recovery)

Max.speed: up to 50km / h on a flat surface

Suspension travel - 160mm at the rear, 120mm at the front

Financial costs:

Batteries: 200 pieces NCR18650B, about $ 1,700 two supplies from China

Engine: Greyborg Cromotor Mk2, $ 565

Controller: LYEN 18Fet, was bought with it cable for programmer and accelerometer - $ 265

Fork: RockShox Argyle 302 2009, new, $ 280

Shock absorber: Fox Van R, used $ 130

Brakes: Avid Elixir 5R, front + rear kit with rotors, $ 180

Rear wheel: order on custom-cycles.de, instead of with knitting needles $ 200

Front wheel: $ 80

Steering equipment: $ 60

"Sources" frame: $ 50

Turning parts: $ 120

Cycle Analyst: $ 170

Charger: $ 375

BP for charger: $ 300

It seems nothing is forgotten.

The total cost came out, to put it mildly, transcendental. It is better for the spouse not to show ^ _ ^. And all this is due to the fact that we tried to take the best from the available and did not stop at half measures. There are many ways to make a bike cheaper and more practical, but this will have to adjust the performance characteristics - reduce the range, adjust power. In general, move away from the original idea of "ultra-long bike". And this, one way or another, will have to be done, since with such a cost of some far-reaching plans even stuttering is not necessary.

Plans

The inquisitive reader has already managed to look at the post tags and see Open Source there.

And for good reason. Thinking long with Roma about our plans for the future, we came to the conclusion that it’s still worth taking a course on openness and free distribution.

Therefore, after the final, the so-called. The “pre-production” sample will leave our hearths - we will publish all the blueprints, calculations, assembly schemes, plans for our welding slipways, and the entire process map on github under the MIT license. All this will be plentifully flavored with our advice and remarks, so, I think, to assemble a replica of such a bike in the garage on my knee will not be a problem.

At the moment, our small team is engaged in testing what has happened. I need to get on a flat surface and check the range data, adjust the Cycle Analyst, glue the fiberglass fiberglass and protect the bike from the rain. The plans a little further - the assembly of the new frame, the transfer of batteries below, learning argon welding, replacement of batteries, increasing the voltage and changing the main components. At least I want to put a fashionable double-corona fork. Without it, not at all good.

And yet, yes, I can not now objectively assess what we have achieved. So far we have received a very, very expensive toy that needs refinement, like air. But we have something to make a start from, and this makes me very happy.

If you read this line - thanks. The bed sheet was impressive, yes. But I really wanted to share my joy with geeks, whom I read with pleasure every day. Once again, many thanks to my partner Romka, although you are bad, but very cool, and to my wife, Lena, for your titanic patience.

Stay tuned!

Source: https://habr.com/ru/post/192218/

All Articles