Superhydrophobicity in life or available nanotechnology. Continuation

Hi, Habr!

Some time ago I wrote about the possibility of using various chemical compounds in everyday life, which make it possible to achieve the hydrophobicity of the treated surface. I present you the first test of the NeverWet.

The standard and unattainable at that time was the composition of "NeverWet", not available for sale, but which has been rumored for several years. Not so long ago, he began retailing (previously, only barrels could be bought (~ 500 thousand rubles for a barrel of two) on special order and it was all extremely difficult), which I took advantage of.

')

I ordered a “minimum” set on the Ebay online auction (such a lot ), costing about $ 35, shipping is different everywhere, but even if you pay the same 30 bucks, it is worth it. Most sellers send these kits from the UK and Ireland - curious ...

I bring to your attention the first experiments.

As a basis, I decided to take plain paper - it is plastic, rough and hygroscopic - all those properties that negatively affect the hydrophobic films created by different compositions similar to the subject, and, in case of successful completion of the experiment, tell about the effectiveness of the coating.

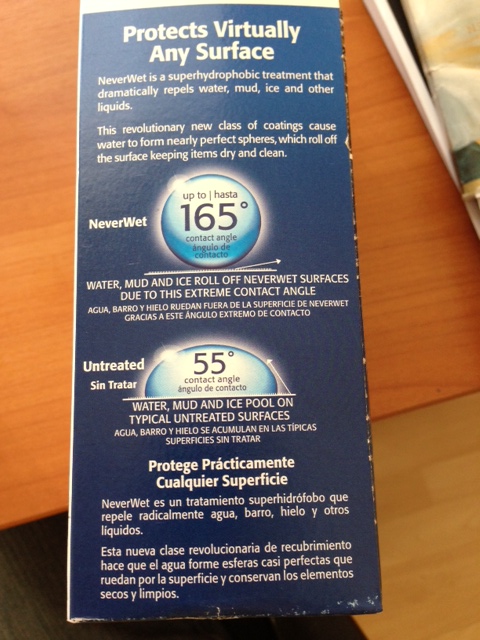

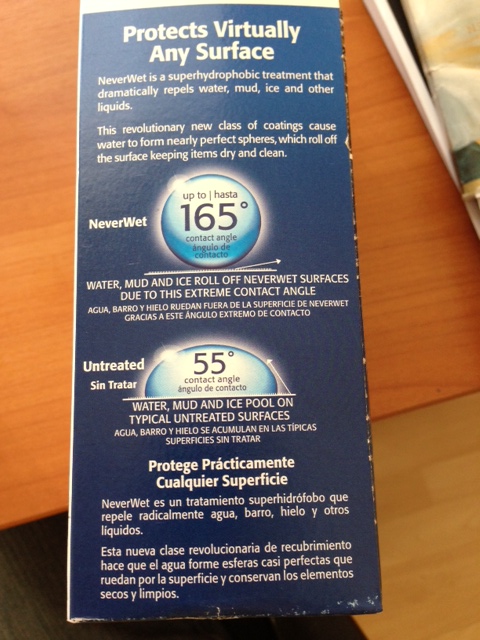

So, the box looks like this.

In her two spray - layers. The first one is basic, the second one is finishing. One set of hawatite per 10-15 sq.ft. - 1 square. m

The solvent (or rather, the carrier fluid) is an extremely volatile substance and may seem to many… suffocating. As for me - the usual smelly solvent - you can tolerate.

These are the characteristics ... an incredible 165 ͦ wetting angle ... promising!

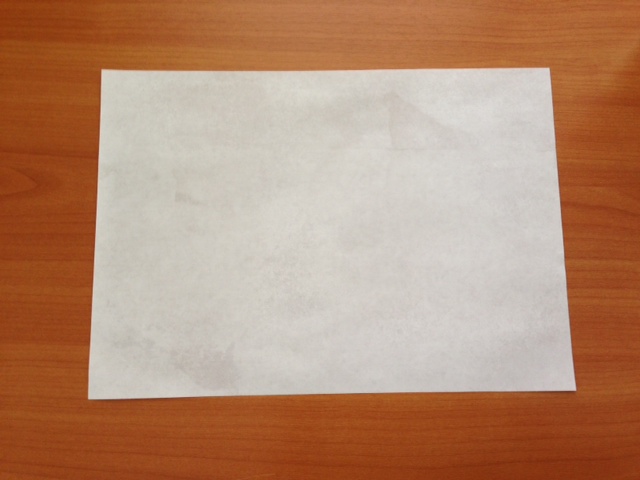

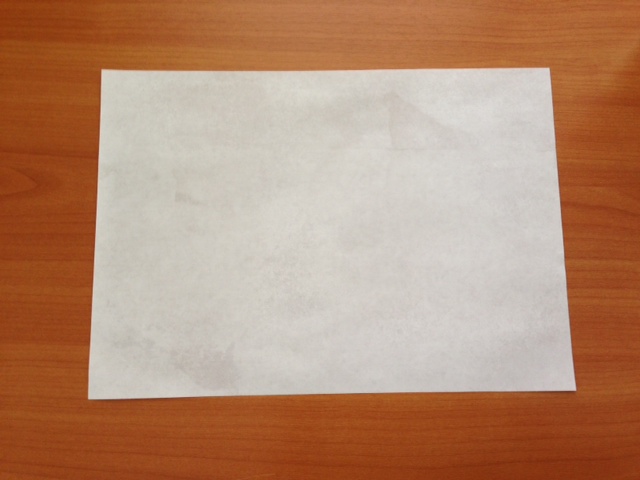

Sheet after applying both layers on it

What a!

Some short videos

As it turned out, it creates not so much a film as sputtering. That is, the liquid evaporates, leaving (attaching) nano-dust to the first layer of the nodule.

I conducted an abrasion test - I scratched the paper heavily with my fingernail. A white powder remained on the nail, but this did not affect the hydrophobic properties of the paper. However, it is probably characteristic of similar materials with high roughness and surface area - paper, swelling, increases the surface area, passing particles between the fibers. The same is waiting for the fabric. But this is a topic for further testing.

Later, the composition was in order of a quick demonstration (the authorities did not like the smell, and became interested in what I was doing in the workplace. It turned out that I was looking for ways to save the company money for cleaning roofs from ice and snow in the winter =)) on the window sill from the street - right on the paint. There remained unpresentable whitish streaks, which, with moderately persistent scratching, were used up and hydrophobicity went away with them. The documentation was advised to wait at least half an hour or an hour after the first layer was applied - even with the appearance of dryness, there is a liquid in the composition that deteriorates the hydrophobic properties. The optimal waiting time before use is 24 hours.

The possibility of using a variety of coatings - fabrics, leather, wood, metals (including electroplating), vinyl, plastics, asphalt, concrete ... is stated. The spectrum of use is slightly more than very wide, the most important is to eliminate the maximum physical impact on coating. As a living example - to cover the insides of electrical appliances, which I will do after testing with a cloth.

A couple of words about toxicity.

On the packaging in small print it says that it contains a cancer causing chemical.

Updates will follow later.

Questions, tips and suggestions write in the comments, I will try to answer whenever possible

Some time ago I wrote about the possibility of using various chemical compounds in everyday life, which make it possible to achieve the hydrophobicity of the treated surface. I present you the first test of the NeverWet.

The standard and unattainable at that time was the composition of "NeverWet", not available for sale, but which has been rumored for several years. Not so long ago, he began retailing (previously, only barrels could be bought (~ 500 thousand rubles for a barrel of two) on special order and it was all extremely difficult), which I took advantage of.

')

I ordered a “minimum” set on the Ebay online auction (such a lot ), costing about $ 35, shipping is different everywhere, but even if you pay the same 30 bucks, it is worth it. Most sellers send these kits from the UK and Ireland - curious ...

I bring to your attention the first experiments.

As a basis, I decided to take plain paper - it is plastic, rough and hygroscopic - all those properties that negatively affect the hydrophobic films created by different compositions similar to the subject, and, in case of successful completion of the experiment, tell about the effectiveness of the coating.

So, the box looks like this.

In her two spray - layers. The first one is basic, the second one is finishing. One set of hawatite per 10-15 sq.ft. - 1 square. m

The solvent (or rather, the carrier fluid) is an extremely volatile substance and may seem to many… suffocating. As for me - the usual smelly solvent - you can tolerate.

These are the characteristics ... an incredible 165 ͦ wetting angle ... promising!

Sheet after applying both layers on it

What a!

Some short videos

As it turned out, it creates not so much a film as sputtering. That is, the liquid evaporates, leaving (attaching) nano-dust to the first layer of the nodule.

I conducted an abrasion test - I scratched the paper heavily with my fingernail. A white powder remained on the nail, but this did not affect the hydrophobic properties of the paper. However, it is probably characteristic of similar materials with high roughness and surface area - paper, swelling, increases the surface area, passing particles between the fibers. The same is waiting for the fabric. But this is a topic for further testing.

Later, the composition was in order of a quick demonstration (the authorities did not like the smell, and became interested in what I was doing in the workplace. It turned out that I was looking for ways to save the company money for cleaning roofs from ice and snow in the winter =)) on the window sill from the street - right on the paint. There remained unpresentable whitish streaks, which, with moderately persistent scratching, were used up and hydrophobicity went away with them. The documentation was advised to wait at least half an hour or an hour after the first layer was applied - even with the appearance of dryness, there is a liquid in the composition that deteriorates the hydrophobic properties. The optimal waiting time before use is 24 hours.

The possibility of using a variety of coatings - fabrics, leather, wood, metals (including electroplating), vinyl, plastics, asphalt, concrete ... is stated. The spectrum of use is slightly more than very wide, the most important is to eliminate the maximum physical impact on coating. As a living example - to cover the insides of electrical appliances, which I will do after testing with a cloth.

A couple of words about toxicity.

On the packaging in small print it says that it contains a cancer causing chemical.

Updates will follow later.

Questions, tips and suggestions write in the comments, I will try to answer whenever possible

Source: https://habr.com/ru/post/190732/

All Articles