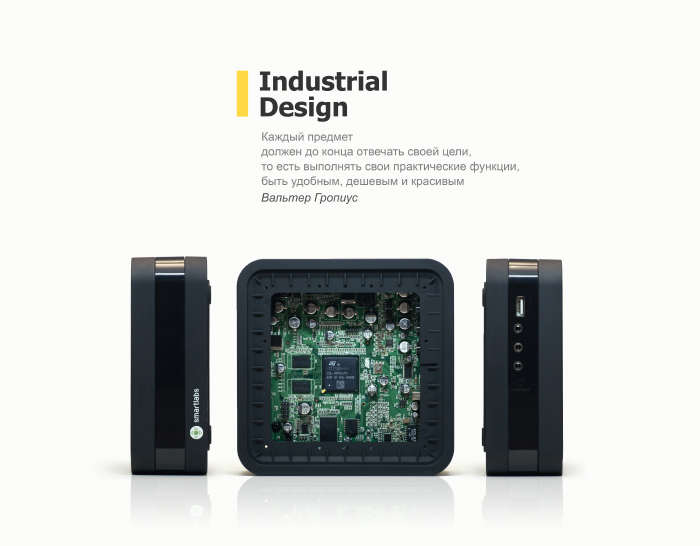

Industrial electronics design: how to design a device case

The development of the body is one of the main stages of creating a product for the electronics market. In the hands of industrial designers concentrated great power and responsibility: it is they who determine the appearance of the device, striving to make it attractive, stylish and comfortable.

Every day we use the results of industrial designers: smartphones, laptops, set-top boxes, keyboards, mice and other devices. Let's look at the process of creating all these things from the inside and answer the three most common questions that arise during the implementation of projects for the development of the housing for electronics:

- Industrial design: what is generally hidden under this word?

- Development of the design and design of the case: what does the project consist of?

- Work with industrial designers: how to organize cooperation and evaluate the results?

1. Industrial designers and graphic designers. Differences

It is important to understand the significant difference in the work of graphic and industrial designers: the first one creates, offers bold ideas and works in two-dimensional space, the second one analyzes the characteristics of the device, customer requirements and embodies them in a real device, creating their works in three-dimensional space.

')

The industrial designer has knowledge of technologies, materials, construction, ergonomics, so he draws not just a beautiful picture, but embodies his ideas with all the additional requirements. Indeed, without taking into account production technologies and cost parameters, even the best sketch of the case will remain on paper.

2. The design and construction of the body: the stages of development

The development of a housing for an electronic device is not only design (sketches, 3D models), but also design and documentation development for mass production.

As a rule, a design development project includes the following steps:

- Idea generation and conceptual development

- Development of original design and construction

- Selection of materials for the body

- Prototype and prototype housing

- Production setting

Starting from sketches and pre-design studies, it is important to take into account the technological and price features of the future device, so designers must work together with technologists and designers who do not fulfill production requirements and estimate the cost price.

The most difficult and long-lasting part of the work is a preliminary analysis and development of a draft proposal (concept). At these stages, the development team performs the following tasks:

- Study. The industrial designer collects information and plunges into the topic: analyzes the best experience of domestic and foreign companies that have designed similar products; studies structural and finishing materials, evaluates the rationality of their use; determines the requirements for the future product (ergonomic, functional, economic).

- Technical task. Further, according to the results of the research, it is possible to prepare TZ, which will indicate the operational, technical and aesthetic requirements for the product. To create a competitive product, they must be at or above market analogues. As a rule, TK is made together with the customer, taking into account his wishes.

- Idea generation. At this stage, the designer conducts a sketch search: makes sketches on paper or graphics tablet. The source of his inspiration is not only the material of research and TK, but also architecture, graphics, works of art, the natural world. Some element from this list can be a starting point for the subsequent shaping. As a result, the customer receives several concepts for the future of design.

- Three-dimensional modeling and visualization. The best design proposals are created by the industrial designer in the form of a three-dimensional model of the future object, including visualization and texture mapping. He also prepares final files for project coordination with the customer: 3D models and photorealistic 2D images.

- Design development. Based on the selected design, a hull structure is created. It takes into account production capabilities, assembly and material characteristics. This stage is performed in modern design automation systems (CAD), such as CREO (Pro / Engineer).

3. Work with industrial designers: management and delivery / acceptance of the project

Design design can begin at different stages. In some projects, the customer only knows about the technical stuffing of the future device, then the case design is created from scratch. It happens that the customer offers designers a ready-made concept that needs to be analyzed and refined.

In the process of working with industrial designers, it is useful to adhere to the following rules:

- We divide the project into clear stages, with specific goals and objectives. Consistently discuss all the preliminary results.

- We agree on personal meetings or videoconferences, communication only via email or Skype is less productive.

- We set goals: all project participants should have a clear understanding of the future device (target audience, functionality, price category, cost price). Without this design it is impossible to develop.

- The choice of design is better to entrust the opinion of several competent professionals, for a more objective assessment. The opinion of one person is not always objective.

When evaluating the results of the designer’s work, you should pay attention to the following characteristics:

- The appearance of the case. Forms, proportions of lines, color solution - all this should meet the needs of consumers.

- Form style. The design must comply with the general philosophy and policy of the company.

- Materials and production technology. Selected materials of the body must meet the requirements for the device, take into account the specified cost and production capabilities.

- Practicality. Use of the product should be safe, easy and intuitive.

- Convenience assembly and maintenance. The collectability of the product should be checked on prototypes, it is important to evaluate the possibility of repair and maintenance of the device.

We hope that these tips will help you run your project and get the expected result. In more detail, this topic is disclosed on our website: the development of industrial design in Promwad .

Source: https://habr.com/ru/post/188534/

All Articles