New sensory material for measuring strain, humidity, temperature, pressure ... and then what?

Hi Habra!

It so happened that I was born in the Soviet Union. It was in a small science town near Moscow, in a family of researchers. Grew up in the best traditions of the end of the Soviet era, studied in a regular school. Physics and mathematics were easy for me, but the humanities are not very. In high school, he began preparing for admission to college, and on weekends, he dug potatoes and collected Colorado potato beetles, but he himself dreamed of being a businessman and wearing a red jacket. As planned, I enrolled in a decent technical college, graduated from it and received a degree in engineering physics, like my father. But the desire to earn more than my parents left. Therefore, the career of physics did not please me. And now I work in the investment business. All would be nothing, but somehow we talked with parents about what they are doing now. It turned out that after 20 years of work, they came from theoretical to practical science. And it was here that we faced a very banal and simple problem - how to make a useful and selling product from a scientific discovery for a consumer? But first things first.

')

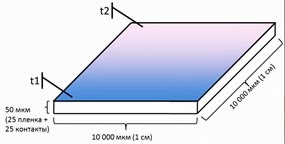

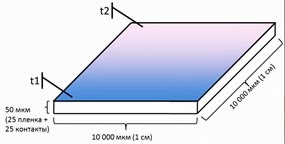

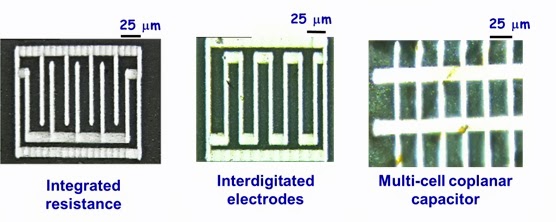

In order not to bore you with long, albeit colorful, stories, let's get straight to the point. In the scientific group in which my parents work, a new material was developed. No, this is not graphene, but also very interesting. This is a transparent organic conductive film, with a thickness of 5 to 25 microns, which has very high sensitivity for measuring temperature, pressure, humidity and deformation. The high sensitivity of the film compared to classic metals, laid the nature of the material itself. It is due to the soft crystal lattice, which can be deformed much more than the lattice of inorganic materials, and the response of the electrical resistance is significantly higher (compared to metals).

In addition, the Seebeck effect (thermopower) is observed in the film. This effect in the films was discovered relatively recently, t.ch. not yet fully studied and not optimized, but in the first approximation, the following is obtained:

Rin = 40 kΩ (different for different types of sensors)

Delta T = 10 degrees C

U = 500 µV

I = 500/40 000 = 0.0125 μA

The film thickness is indicated 25 microns, because It was for this measurement data was carried out. Theoretically, it may be minimal (about 5 microns), but then the question arises about the thickness of the contacts.

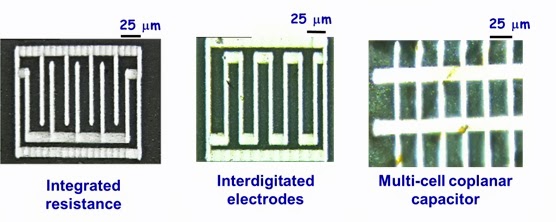

You can also use the properties of the film in a flexible electronics.

The use of films in flexible electronics allows us to avoid the problem of combining organic and inorganic materials. Due to the organic origin of the film, it is very easy to apply it to polymer organic matrices ( Young's modulus in this case will be of the same order), which increases the strength of relatively classic solutions based on metals.

In addition, due to the flexibility of the film, it can also be used in the textile industry, namely, stitching sensors directly into clothing.

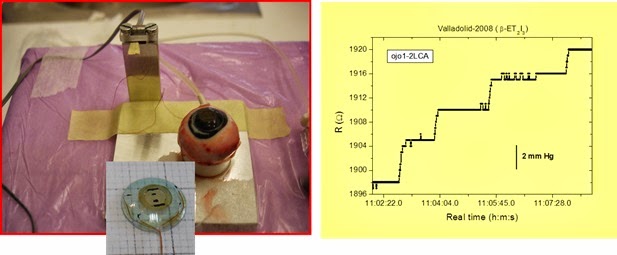

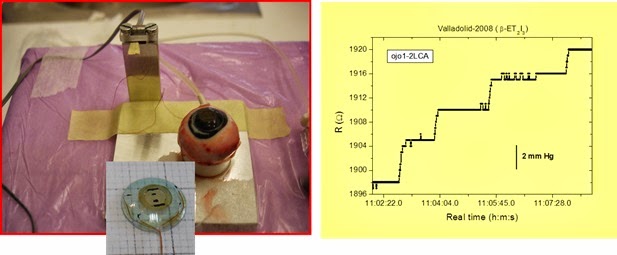

All technical calculations and links to articles will be below. But this is all in theory, but what about in practice? Where can all these wonderful properties be applied? The first thing that came to mind was medicine. I forgot to mention that the film is fully biocompatible (there are relevant certificates), this means that the film is not rejected by the human body. Why medicine? It's simple, parents work in Europe, and here the most money is in this sector. But the crisis began, and funding was frozen. By that moment, there had already been some groundwork. For example, a device for measuring intraocular pressure using a contact lens was developed, and the matter remained small - wireless transmission of the signal to be removed. But there is no “electronic engineer” in the team and a lot of problems follow from this. No funding, so you can not hire an outside specialist. So it is impossible to bring to the "box" the product without an order for development from the side. As local doctors say, measuring and monitoring intraocular pressure is very important for determining glaucoma at an early stage, when it can still be cured. I am not an expert in this field, t.ch. No comments.

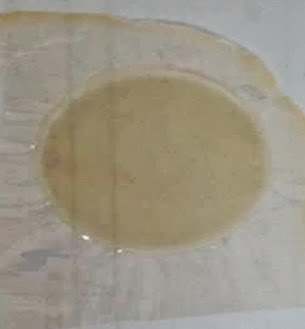

In this experiment, a pig eye was used, I hope animal advocates will not be offended in their feelings by the picture below.

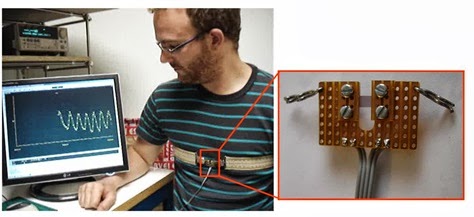

Next was the idea to develop a system for monitoring human activity, capable of taking on-line all the main indicators: pulse, temperature, pressure, respiration, movement, etc. But again, everything was fixed on the electronics, and the output of the signal, say to a smartphone via Bluetooth, with the possibility of transmitting data further over cellular networks. I think it makes no sense to write the scope of such decisions.

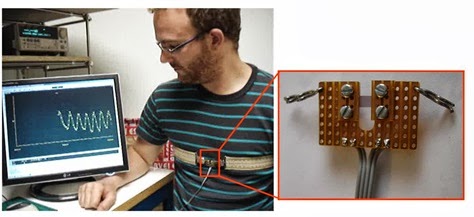

Measuring pulse sensor. Lab development. Yes, this is all already in one form or another, but do not forget about the unique properties of the film, such as biocompatibility, flexibility, cheapness, sensitivity and ease of use.

The ability to measure breathing:

Laboratory sample device. The film is installed here.

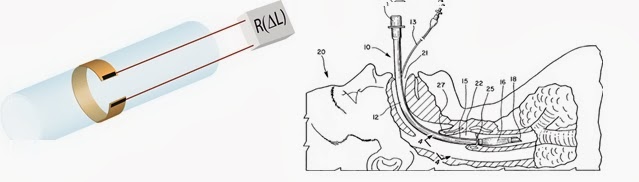

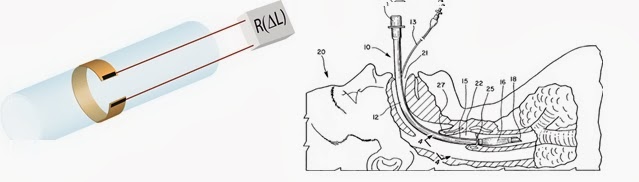

But it was decided to start with more local and simple devices - we modified the endotracheal tube. The principle is very simple; a small strip of film is glued to the inner surface of the tube, which very accurately measures the pressure of the air coming in and out of the lungs. Such a system avoids damage to the lungs due to too high pressure in the system of life support.

Around this stage, I learned about the work aimed at the commercialization of research data. Naturally, I tried to find investors in Russia (thanks to the specifics of my work, there are exits for both rich people and owners of large enterprises), but none of those I met were interested in medical investments, which is generally very characteristic of all emerging markets such as Russia. And to what I have come, there is a new interesting patented material, which is cheap to produce (in the laboratory, 1 sq. Cm. Costs about 1.5 eurocents) is on the one hand. And there are investors who are ready to invest a lot of money as well as a lot of money in production, but the production of the finished product, and not the film itself, is on the other side. But the problem is that there is no product.

One of the ideas for starting work in Russia was to combine film and RFID tags. Those. creating not just tags, but tags that can provide on-line information on temperature and / or humidity in each package / container (storage). Or biometrics to measure the "average temperature of patients in the hospital" at the touch of a button. Another solution (proposed by one large corporation, but still remaining at the “interesting development” stage) is the use of tags in automobile tires for pressure measurement. One can fantasize quite a lot about the combination of film and RFID technology, especially if we recall the effect of thermoEMF, which makes it possible to theoretically improve (?) The performance of passive tags. But the problem is the same, there is no person who could at least on his knees connect RFID and film and show how it works. Not to mention the fact that there is no programmer who can write the necessary software.

Here we come to why I decided to write this post. Actually I found Habra herself in search of information about RFID. I honestly tried to figure it out myself, but I realized that all physics and electronics had been too long in my life and now I’m closer to such things as IBIDTA, ROE, etc. Of course, I still have friends who did not go into the business, but remained in R & D and we have already begun to cooperate with them in this area, but everything is moving very slowly and it’s not yet a fact that it will end with something really interesting. But I really want the path from the laboratory to production to be as short as possible, and not delayed for several decades, as is usually the case.

Recently, I like crowdsourcing more and more to solve any problems. So I decided to write a post here. On the one hand, there are a lot of Habré professionals who know how to work with their hands (not once convinced of this by reading various articles) and maybe someone wants to try to make a sensor using these films. On the other hand, many of you are working in those industries where the use of films can be an interesting solution, both for introducing a new monitoring system and for optimizing existing solutions. And of course, it will be interesting to hear your ideas about how to use such films. And if there are people from R & D who will be interested in cooperation at the level of scientific groups, then I will be only too happy.

In other words, I invite everyone to take part in one of the most interesting phases of developing something new - in bringing new material from the laboratory to mass production. And what the hell is not joking, if something interesting happens, then besides those potential investors about whom I wrote above, there are always kickstarter and other similar resources.

Well, a little more for the flight of fancy: the sensitivity of the film (size 1 square centimeters at a consumption of 25 mW) allows you to measure the temperature change in an isolated room (a room of 20 squares) when a person appears there. There were ideas to equip gamepads for PS and Xbox with sensors, to measure player's pulse and hand humidity, but they just released new devices, although if there are people from Sony or Microsoft, I will be glad to cooperate. Also, high sensitivity allows you to think about the use of films in inclinometers. This film is a synthetic material that allows you to change its structure and properties (within reason) depending on the goals. For example, by slightly changing the structure of the film, we get a sensor that is sensitive to deformation and stably operates in a wide range of temperatures (from 140 K to 350 K). Or by changing a little more structure, we obtain a humidity sensor operating from 10% to 100% humidity. There is no need to “dry” the sensor after use. And at the end I wanted to add that these films are quite durable - some samples have been working for about 15 years, i.e. almost from the moment of their synthesis.

For other technical data and proofs please follow the links below:

Links to some articles:

1. Ultrasensitive Piezoresistive All-Organic Flexible Thin Films

2. Highly piezoresistive textiles

3. Linked Crystallites in Polymer Bilayer Films: Controlled by Micro-Nanocrystallites

4. Direct micro-patterning of TTF-based organic conductors on flexible substrates

5. All-organic pressure sensor for measurement

Disclaimer: as I already wrote, I am now very far from science as a whole, so if somewhere I have written something not quite right, I ask you not to blame and give your comments in a personal, I will correct. In general, I will forgive you to consider this article as a translation from a scientific language to a less common language. If there are questions on the merits, well, I will try to answer myself, and if I fail, I will redirect them to competent people.

UPD 1: As promised, I post additional material. Presentation with some technical details

UPD 2: Do not think for PR, but because Received a few messages from the friends of habrauser not having the opportunity to write here, I think it would be right to leave my mail for questions: i.laukhin at gmail.com

UPD 3: Dear habra people, unfortunately I could not send / give samples of the material to everyone the first time. But at the end of the year I am planning a second "distribution of elephants", t.ch. if someone is still interested in a personal email, comments here or on the mail i.laukhin@gmail.com

It so happened that I was born in the Soviet Union. It was in a small science town near Moscow, in a family of researchers. Grew up in the best traditions of the end of the Soviet era, studied in a regular school. Physics and mathematics were easy for me, but the humanities are not very. In high school, he began preparing for admission to college, and on weekends, he dug potatoes and collected Colorado potato beetles, but he himself dreamed of being a businessman and wearing a red jacket. As planned, I enrolled in a decent technical college, graduated from it and received a degree in engineering physics, like my father. But the desire to earn more than my parents left. Therefore, the career of physics did not please me. And now I work in the investment business. All would be nothing, but somehow we talked with parents about what they are doing now. It turned out that after 20 years of work, they came from theoretical to practical science. And it was here that we faced a very banal and simple problem - how to make a useful and selling product from a scientific discovery for a consumer? But first things first.

')

In order not to bore you with long, albeit colorful, stories, let's get straight to the point. In the scientific group in which my parents work, a new material was developed. No, this is not graphene, but also very interesting. This is a transparent organic conductive film, with a thickness of 5 to 25 microns, which has very high sensitivity for measuring temperature, pressure, humidity and deformation. The high sensitivity of the film compared to classic metals, laid the nature of the material itself. It is due to the soft crystal lattice, which can be deformed much more than the lattice of inorganic materials, and the response of the electrical resistance is significantly higher (compared to metals).

In addition, the Seebeck effect (thermopower) is observed in the film. This effect in the films was discovered relatively recently, t.ch. not yet fully studied and not optimized, but in the first approximation, the following is obtained:

Rin = 40 kΩ (different for different types of sensors)

Delta T = 10 degrees C

U = 500 µV

I = 500/40 000 = 0.0125 μA

The film thickness is indicated 25 microns, because It was for this measurement data was carried out. Theoretically, it may be minimal (about 5 microns), but then the question arises about the thickness of the contacts.

You can also use the properties of the film in a flexible electronics.

The use of films in flexible electronics allows us to avoid the problem of combining organic and inorganic materials. Due to the organic origin of the film, it is very easy to apply it to polymer organic matrices ( Young's modulus in this case will be of the same order), which increases the strength of relatively classic solutions based on metals.

In addition, due to the flexibility of the film, it can also be used in the textile industry, namely, stitching sensors directly into clothing.

All technical calculations and links to articles will be below. But this is all in theory, but what about in practice? Where can all these wonderful properties be applied? The first thing that came to mind was medicine. I forgot to mention that the film is fully biocompatible (there are relevant certificates), this means that the film is not rejected by the human body. Why medicine? It's simple, parents work in Europe, and here the most money is in this sector. But the crisis began, and funding was frozen. By that moment, there had already been some groundwork. For example, a device for measuring intraocular pressure using a contact lens was developed, and the matter remained small - wireless transmission of the signal to be removed. But there is no “electronic engineer” in the team and a lot of problems follow from this. No funding, so you can not hire an outside specialist. So it is impossible to bring to the "box" the product without an order for development from the side. As local doctors say, measuring and monitoring intraocular pressure is very important for determining glaucoma at an early stage, when it can still be cured. I am not an expert in this field, t.ch. No comments.

In this experiment, a pig eye was used, I hope animal advocates will not be offended in their feelings by the picture below.

Next was the idea to develop a system for monitoring human activity, capable of taking on-line all the main indicators: pulse, temperature, pressure, respiration, movement, etc. But again, everything was fixed on the electronics, and the output of the signal, say to a smartphone via Bluetooth, with the possibility of transmitting data further over cellular networks. I think it makes no sense to write the scope of such decisions.

Measuring pulse sensor. Lab development. Yes, this is all already in one form or another, but do not forget about the unique properties of the film, such as biocompatibility, flexibility, cheapness, sensitivity and ease of use.

The ability to measure breathing:

Laboratory sample device. The film is installed here.

But it was decided to start with more local and simple devices - we modified the endotracheal tube. The principle is very simple; a small strip of film is glued to the inner surface of the tube, which very accurately measures the pressure of the air coming in and out of the lungs. Such a system avoids damage to the lungs due to too high pressure in the system of life support.

Around this stage, I learned about the work aimed at the commercialization of research data. Naturally, I tried to find investors in Russia (thanks to the specifics of my work, there are exits for both rich people and owners of large enterprises), but none of those I met were interested in medical investments, which is generally very characteristic of all emerging markets such as Russia. And to what I have come, there is a new interesting patented material, which is cheap to produce (in the laboratory, 1 sq. Cm. Costs about 1.5 eurocents) is on the one hand. And there are investors who are ready to invest a lot of money as well as a lot of money in production, but the production of the finished product, and not the film itself, is on the other side. But the problem is that there is no product.

One of the ideas for starting work in Russia was to combine film and RFID tags. Those. creating not just tags, but tags that can provide on-line information on temperature and / or humidity in each package / container (storage). Or biometrics to measure the "average temperature of patients in the hospital" at the touch of a button. Another solution (proposed by one large corporation, but still remaining at the “interesting development” stage) is the use of tags in automobile tires for pressure measurement. One can fantasize quite a lot about the combination of film and RFID technology, especially if we recall the effect of thermoEMF, which makes it possible to theoretically improve (?) The performance of passive tags. But the problem is the same, there is no person who could at least on his knees connect RFID and film and show how it works. Not to mention the fact that there is no programmer who can write the necessary software.

Here we come to why I decided to write this post. Actually I found Habra herself in search of information about RFID. I honestly tried to figure it out myself, but I realized that all physics and electronics had been too long in my life and now I’m closer to such things as IBIDTA, ROE, etc. Of course, I still have friends who did not go into the business, but remained in R & D and we have already begun to cooperate with them in this area, but everything is moving very slowly and it’s not yet a fact that it will end with something really interesting. But I really want the path from the laboratory to production to be as short as possible, and not delayed for several decades, as is usually the case.

Recently, I like crowdsourcing more and more to solve any problems. So I decided to write a post here. On the one hand, there are a lot of Habré professionals who know how to work with their hands (not once convinced of this by reading various articles) and maybe someone wants to try to make a sensor using these films. On the other hand, many of you are working in those industries where the use of films can be an interesting solution, both for introducing a new monitoring system and for optimizing existing solutions. And of course, it will be interesting to hear your ideas about how to use such films. And if there are people from R & D who will be interested in cooperation at the level of scientific groups, then I will be only too happy.

In other words, I invite everyone to take part in one of the most interesting phases of developing something new - in bringing new material from the laboratory to mass production. And what the hell is not joking, if something interesting happens, then besides those potential investors about whom I wrote above, there are always kickstarter and other similar resources.

Well, a little more for the flight of fancy: the sensitivity of the film (size 1 square centimeters at a consumption of 25 mW) allows you to measure the temperature change in an isolated room (a room of 20 squares) when a person appears there. There were ideas to equip gamepads for PS and Xbox with sensors, to measure player's pulse and hand humidity, but they just released new devices, although if there are people from Sony or Microsoft, I will be glad to cooperate. Also, high sensitivity allows you to think about the use of films in inclinometers. This film is a synthetic material that allows you to change its structure and properties (within reason) depending on the goals. For example, by slightly changing the structure of the film, we get a sensor that is sensitive to deformation and stably operates in a wide range of temperatures (from 140 K to 350 K). Or by changing a little more structure, we obtain a humidity sensor operating from 10% to 100% humidity. There is no need to “dry” the sensor after use. And at the end I wanted to add that these films are quite durable - some samples have been working for about 15 years, i.e. almost from the moment of their synthesis.

For other technical data and proofs please follow the links below:

Links to some articles:

1. Ultrasensitive Piezoresistive All-Organic Flexible Thin Films

2. Highly piezoresistive textiles

3. Linked Crystallites in Polymer Bilayer Films: Controlled by Micro-Nanocrystallites

4. Direct micro-patterning of TTF-based organic conductors on flexible substrates

5. All-organic pressure sensor for measurement

Disclaimer: as I already wrote, I am now very far from science as a whole, so if somewhere I have written something not quite right, I ask you not to blame and give your comments in a personal, I will correct. In general, I will forgive you to consider this article as a translation from a scientific language to a less common language. If there are questions on the merits, well, I will try to answer myself, and if I fail, I will redirect them to competent people.

UPD 1: As promised, I post additional material. Presentation with some technical details

UPD 2: Do not think for PR, but because Received a few messages from the friends of habrauser not having the opportunity to write here, I think it would be right to leave my mail for questions: i.laukhin at gmail.com

UPD 3: Dear habra people, unfortunately I could not send / give samples of the material to everyone the first time. But at the end of the year I am planning a second "distribution of elephants", t.ch. if someone is still interested in a personal email, comments here or on the mail i.laukhin@gmail.com

Source: https://habr.com/ru/post/188226/

All Articles