The perfect charger, or why we continue to use batteries

A great many of us have AA batteries (AAA, C, D, 9-volt) and a charger for them at home. These batteries are designed to replace a bunch of disposable batteries and save a bag of money. But here they are on the shelf, and I continue to buy batteries. I asked a friend - he says, I do not use it. Strange, it would seem a profitable business, but somehow too lazy to use it all. Do you use?

After thinking, the thought came:

The system batteries + charger less user-friendly interface than disposable batteries. Man prefers that which is more convenient, and not that which is cheaper.

Let's compare the necessary steps (we will consider the city dweller, carefully related to the environment):

Batteries:

- Buy in the store. Most likely done with regular visits to the supermarket - that they hang near the cash register, a few extra seconds and it's done.

- Houses can store stock. We unload the nets brought from the store, put the batteries on the shelf. (a few more seconds of time). The fact that the batteries in the package is a clear and understandable sign that they are fresh.

- We insert into the device, use, take out, put on the shelf.

- On occasion, we throw the batteries into the box at their reception in the same supermarket. A few seconds to take them from the shelf and a few seconds in the supermarket.

Batteries:

- Suppose that the battery charger and batteries are already there, you do not need to buy anything. 0 seconds.

- The stock of charge lies on the shelf in a yellow box. In the bucket - waiting for charging. For those who do not know - a sign of charge is not clear.

- We insert into the device, use, take out, put on a shelf in a bucket.

- We take from the bucket, we insert into the charger. Turn on the outlet. Few seconds.

- After 10 hours, remove from the charger, turn it off, put in a yellow box.

- Oh, yes, all the batteries in the bucket could not fit in the charger. Then go back to step 4.

And here, at the 5th step, the problem lies - the process of charging requires my background attention for 10 hours. This is another task that I have to remember, besides all the tasks at work in the bug tracker and all family tasks. Absolutely extra task.

- I have to plan my movements so that in these 10 hours I’ll be near my charger. And if I put them on charge in the morning, and at work I decided to go to the country and spend the night there?

- If I haven't told anyone, then no one else knows when I put them on charge and when to take them out.

- If you forget them there, the device left in the socket will be left unattended, which is not very good. If the charger is stupid, then all this time the charging current will be chased through the batteries (they will warm up, from which they obviously will not add the resource).

And in the case of batteries there is no such problem - all steps are taken at a convenient time for the user. I remembered that I had to hand over the discharged batteries - I took it with me to the store, I forgot - they would fail in the car until the next time.

So, we have the following problems:

- You need a presence near the charger in 10 hours.

- If you need to charge a lot of batteries, then you need to make several visits.

- There is no clear way for everyone how a full battery differs from an empty one.

In smart charging, the first problem has already been solved - at the end of the process, the charging current is removed from the battery (I wonder if the charger starts quietly discharging the battery if I leave it there for 10 days?).

True, the charging itself remains plugged in. Interestingly, are there any models with input relays that are completely disconnected from the network at the end of the process?

')

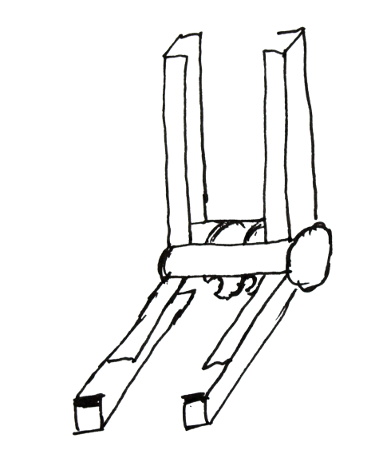

Here I would like to offer my concept of an “ideal charger” (only the main structural elements are shown in the figure):

Discharged batteries are loaded into the upper rails (in any orientation, the device will determine for itself where “+” and where “-”). The drum with a slot in the center captures them one by one, connects for charging. At the end of the process, the drum turns further and the battery rolls out onto the front rails. The process goes slowly, a couple of pieces per day, this is offset by the presence of a stock of charged batteries.

A device may have rear rails on which the device rolls out bad batteries.

After loading the batteries, you need to press the button to turn on the device (well, or this “button” is pressed from the presence of at least one battery in the upper rails). At the end of the process, the device itself is completely disconnected from the network.

In theory, it is mechanically possible for the device to eat both AA and AAA batteries. The remaining sizes are not supported.

The problem with which I do not know what to do is that if the user throws ordinary batteries into the device (they write that if they are charged, they can also explode). People who are not familiar with the technique can do this, I have seen. Can the charger determine electronically that the battery was slipped to it? Measure the temperature of the battery when charging? Or let it explode if anything - when charging it will be covered with a case and in theory it should not be dangerous?

User interface - we need batteries - we approach, we take from the front rails. Spent laid in the upper rails. And nothing else to think about is not necessary.

Well, actually the question is - I would like for me to have such a device. (Would you be interested in him)? It could be an open hardware device that can be printed on a 3D printer by soldering or buying control electronics.

If I had a 3D printer and a month of time, I would love to sit down and start developing. But I have neither one nor the other. What to do?

Source: https://habr.com/ru/post/187502/

All Articles