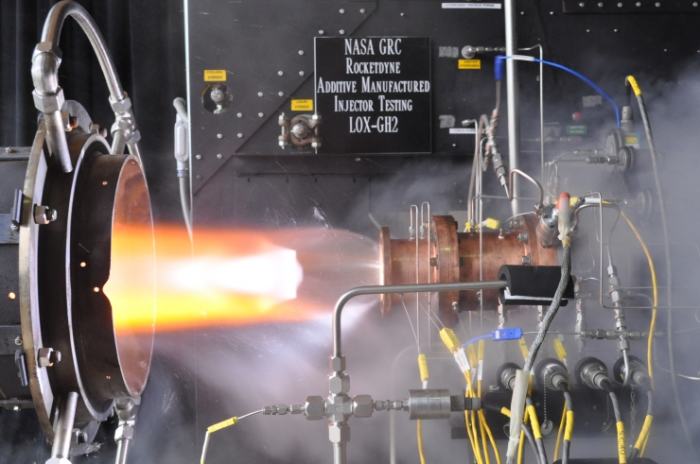

NASA conducted successful tests of the “printed” rocket engine injector

The other day, NASA announced the successful testing of another model of a rocket engine injector. Probably many of you have seen photos or videos of similar tests. If not, then you can look at the moment of the test above, where the announcement photo is placed. So, the interesting point in all this is not so much the fact that the tests were successful, as the fact that the injector was “printed out” using a special technology that can be considered one of the varieties of 3D printing.

The process itself is called selective laser melting. The essence of the process is that high-energy laser beams affect fine metal powder, powder. As a result of selective melting (very accurate, by the way), we obtain the necessary detail. Energy costs for such a process are quite high, but it is likely that time is saved here to create complex parts. And not only time, but also money is saved here, since the number of production stages of the rocket engine injector is minimized. Accordingly, operating costs are reduced.

')

The cost of producing such an injector with the help of a new technology is only 30% of the cost of production using traditional technology. In general, not bad, especially if you consider the cut NASA budget.

According to the head of the NASA Space Technology Directorate, Michael Gazarik, the implementation and widespread use of such technologies on Earth, and especially in space, greatly expands the prospects of space missions. The technology allows to reduce the time and cost of production of engine parts and spacecraft parts.

Via DVICE

Source: https://habr.com/ru/post/186882/

All Articles