IT systems support in the production area

IT systems in the production area

IT technologies in the modern world are developing at a rapid pace and are increasingly penetrating all areas of human civilization. Applied technologies and equipment are becoming more complex and incomprehensible for a person without specialized training. Not bypassed this trend and industrial enterprises. Among the main IT systems that are directly in production, the following should be highlighted:

• Intra-controller networks used in highly automated industries for communication within and between sites, for receiving data from field devices and automation elements;

• Industrial control system - a group of hardware and software solutions designed to automate the process equipment control at industrial enterprises. One of the key components of this system is SCADA;

• WMS - a management system that provides automation and optimization of all the processes of warehousing of a core enterprise;

• MES - specialized application software and hardware designed to solve problems of synchronization, coordination, analysis and optimization of production in any production;

• End-point ERP equipment - enterprise resource planning systems, which allow to create a unified information environment through a whole complex of integrated applications with the goal of automating all areas of an enterprise's business from planning business processes to controlling their implementation and subsequent analysis of achieved results.

The criticality of each of the systems from enterprise to enterprise may vary, but, in general, the order of bringing them higher corresponds to reducing the criticality for output (in the short term). And if for the last two there are many spare business processes, for example, the use of a sheet of paper and a pen, then in most cases we do not have a spare production line or a scheme for placing all the goods in the warehouse. Consider the systems supported exclusively by the personnel of the production area (intra-control networks and automated process control systems).

Current IT support schemes for production systems

')

The current requirements for high-performance production without downtime and with minimal production of defects, as well as fashionable “green” technologies require more and more IT penetration into production lines, but at the same time, reliability in the production environment must be at an absolutely high level (1 hour of downtime can cost 100k-2kk rub.). And, if in “office” organizations there is usually a system administrator who is directly responsible for the maintenance of IT systems, then in industrial (production) enterprises, as a rule, these duties are divided between a group of people responsible for specific areas in which besides IT functions there are many others.

This situation has arisen due to the relatively recent penetration of IT technologies into automated production lines and a certain amorphousness of management towards the allocation of new positions in IT support.

Consider typical support schemes for industrial IT systems for domestic (Russian and foreign) industrial enterprises, depending on the load of production lines.

1. In the production plans laid down "maneuvers" for downtime.

With this approach, the support of the main equipment is carried out by personnel engaged in its operation. Perhaps 2 pole options:

A. For the production of used high-tech equipment, well-trained educated personnel.

It is found in particularly specific areas of production, for example, scientific enterprises and laboratories.

B. Management is trying to save on specialized equipment and support, and, in fact, there is no dedicated system recovery department, and, therefore, support.

In this approach, IT outsourcing is used only for the introduction of new technologies and, rarely, short-term audits / projects in IT systems.

Production is characterized by the use of locally isolated IT systems with the absence of inter-controller networks, the impact of which on the main production is small. Registration of facts of service and quality control of the services provided is usually absent.

2. Downtime is quite critical, but there is a stock of production capacity.

Equipment support is provided by dedicated non-IT staff.

There are also options:

A. Support is provided by personnel responsible for the entire production as a whole and carrying out repairs for all types of breakdowns associated with "electrical appliances" (electrical engineering).

B. Support is provided by personnel responsible for a specific site and carrying out repairs of electrical appliances on its territory (electrical engineers).

B. Support is carried out by combining options A and B. With this approach, there is a separation of levels of support:

- the role of helpdesk is performed by electrical technicians who react to most appeals and solve typical tasks, for example, rebooting a device;

- the role of high-level support is performed by electrical engineers who perform all support tasks or delegate them to contractors.

In the second approach of supporting IT systems, organizations are beginning to actively use IT outsourcing in the implementation and support of the most complex systems, which is usually negotiated at the stage of ordering the system.

The practice of using a dedicated IT specialist for outstaffing in a contracting organization is practiced. This is due to the fact that the level of IT infrastructure of an enterprise has grown to be used in servicing IT specialists, but either the management consciously does not want to take on the risks and costs of hiring and maintaining an IT specialist, or the organization’s internal processes are too inert when approving a new position.

The approach is characterized by the presence of:

- initial support processes,

- decentralization in standardization of equipment, software and applied approaches to building systems,

- lack of known recovery time of services.

- partial use of good support practices, for example, the presence of at least one (not necessarily current) backup copy of a program from one of the support members.

The approach is possible with a low degree of IT influence on the main production, the use of locally isolated automated process control systems and the absence of WMS, MES, ERP components in the production areas.

To record the facts of service, either a work log or an electronic system is used, for example, a module in MES or ERP systems.

To control the quality of service, a KPI system is typically used for internal IT services.

3. Production works at its maximum capacity, and the presence of idle time is guaranteed to lose money.

Equipment support is provided by IT staff. There are the following options:

A. Adding to Option 2B (electrical technicians + electrical engineers) an IT specialist (s) as a third level of support. Main characteristics:

- a centralized approach to the maintenance and implementation of systems;

- availability of documentation (not necessarily relevant, sufficient and used);

- fundamentally known recovery time of each of the systems after failures;

- the usual use of some good support practices (for example, centralized backup).

B. Use of IT department:

- a centralized approach to the maintenance and implementation of systems;

- availability of documentation (mainly relevant and sufficient);

- the recovery time of each system after failures is known and agreed with the production;

- good support practices are widely used (for example, testing system recovery from failures according to the documentation and current processes);

- if possible, use modern software and equipment;

- exactly known used for IT budget.

In the third approach, IT outsourcing, in most cases, is used quite widely in all its forms, except for outsourcing IT equipment (resource outsourcing).

To register the facts of the maintenance of IT systems, either a module in MES or ERP systems or a dedicated system for recording applications can be used.

To control the quality of IT services, internal and external support typically uses SLA and KPI.

Prospects for the development of industrial IT systems

At the moment, there is a gradual integration of IT infrastructures of production and office into global systems of organization level or holdings with the penetration of office technology to the factory level:

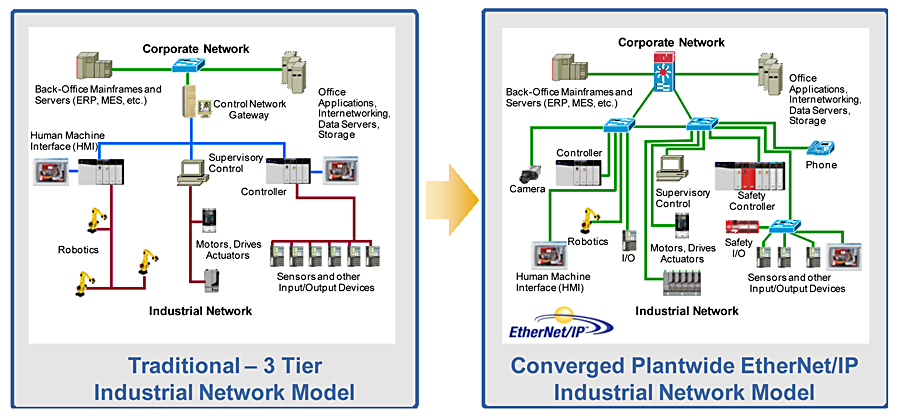

- Intra controller networks using Ethernet are becoming more and more popular, gradually replacing networks with ModBus, Profibus, DeviceNet and other technologies (if we are not talking about highly critical systems, for example, fire extinguishing). For example, in a typical Rockwell control system design, there is a gradual transition from the three levels of Ethernet / IP-ControlNet-DeviceNet to the use of Ethernet / IP only:

The use of fiber as a transmission medium in the production area is also not uncommon, due to resistance to EMI, increasing distances and data transfer volumes.

- SCADA systems headed for the client-server architecture of the line level with redundancy and maintenance of virtualization systems instead of local solutions: Wonderware System Platform (~ 2MB pdf), FactoryTalk (~ 5MB pdf).

For example, if a previously locally isolated Rockwell SCADA architecture looked like this:

Then the current best practices in building SCADA on the technologies of this company look like this:

- in the production of high-intelligence and industrial-protected network equipment, manufacturers of network line devices, for example, Hirschmann, use an operating system similar to Cisco IOS in their devices, Rockwell Automation has in general entered into a partnership agreement with Cisco and are going to build Converted Plantwide Ethernet. And the network topologies in production go from the bus / tree topology to the ring or even the double star.

findings

Industrial IT systems are developing in the direction of integrating with networks of the enterprise level, increasing fault tolerance, introducing best practices of global equipment manufacturers, as well as more frequent use of systems that are difficult to support by electricians. Their support will gradually be transferred to professionals in various IT areas and, most likely, to specialized outsourcing companies, due to their advantages in technical training.

PS If anyone is interested in SCADA-PLC-Factory Networks-MES topics, then I’m ready to write a number of articles. Thanks for attention!

Source: https://habr.com/ru/post/186360/

All Articles