Photo review of cabinets of KUB-Ukraine plant

If you think about it, then by and large the 19 ”cabinet is nothing more than a steel case, inside of which, at the“ right ”distance, there are guides for mounting equipment. With the counter in general, everything is simple.

If there are requirements to expand, the cabinet should have at a minimum: a lock in the door, removable side and rear walls, conveniently located cable entries, the possibility of organizing natural and forced ventilation of the internal space, the possibility of adjusting the 19 ”rails.

The cabinet must not be flimsy or, on the contrary, be a very heavy monolith of metal. The quality of painting parts, the quality of locking accessories (locks, handles, latches) is of great importance for the “level of perception” by the consumer.

')

If you competently develop a design with a clear and thorough approach to “work out” at least the points above, you will receive a product whose production can be successfully mastered in the domestic market, and not feed our friends from Europe and China, paying extra for delivery.

What does that require? It seems to be nothing supernatural:

1. Intellectual (design engineers) and raw materials (metal, paint, accessories) resources.

2. Production base.

With the proper formulation of the issue in Ukraine there are no problems with this. There are competent experts, they just need to find and properly "motivate". We supply metal to half the planet.

We do not live in the desert. There are enough places for production in the vacant industrial zone.

On the example of domestic cabinets "KUB", which we actually supply, let us examine the issue of trust to the domestic manufacturer. Let's look further, that it turned out from simple interest "to show" and to tell about this equipment. Next, I propose to examine all the pros and cons of this product. Standard telecommunication cabinets are gray, and server ones, as is customary in the market, are black.

FIG. 1 General view of 19 "form factor cabinets with protection class up to IP30.

As the manufacturer assures, the dielectric structural powder for painting is used by the European manufacturer. On personal experience, we have recently been convinced that the new painting technology makes it possible to achieve the quality level of global manufacturers (for comparison, they took Molex hardware). Honestly, they did not notice any significant differences :).

As for the system of locking the cabinet doors. Everything is clear, almost like a “Swiss watch”. A revolving handle with a built-in lock and a three-point locking mechanism is located on the viewing door. It locks the door in the central, upper and lower points.

There is no video yet, but in the photo you can view:

FIG. 2 Locking mechanism.

FIG. 3 An important parameter is the angle of opening the door.

The doors are removable and reversible with an opening angle of 270 °. Also, as an additional option, the possibility of replacing the door on solid or perforated. A similar option also applies to the rear wall, which can be replaced with a perforated, survey or blind door with a three-point barbell lock.

It is simple to install the equipment or to serve the “filling” of the locker when all 3 walls can be removed. The rigidity and stability of the frame of the floor cabinet is provided by the front and rear welded frames.

In order to get the cable inside, gaps are made both in the base and in the roof (FIG. 7) and the rear wall (FIG. 6). The cable entries themselves, as practice has shown, are not very convenient, because a design change has already taken place, and the manufacturer has increased the size of the cable entries. I think that in the near future, a photo report will be provided on innovations in the design of cabinets.

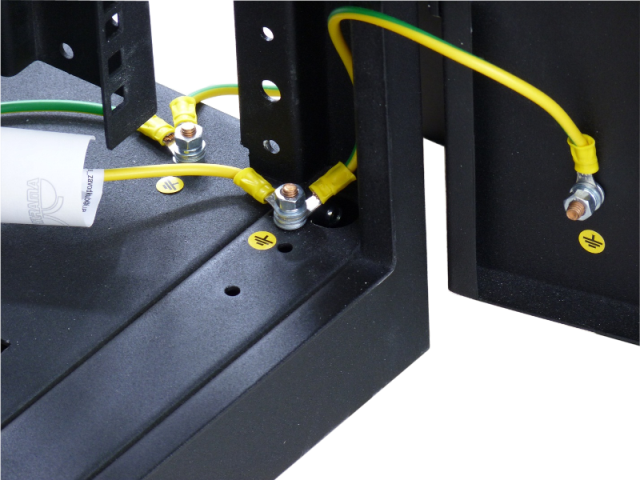

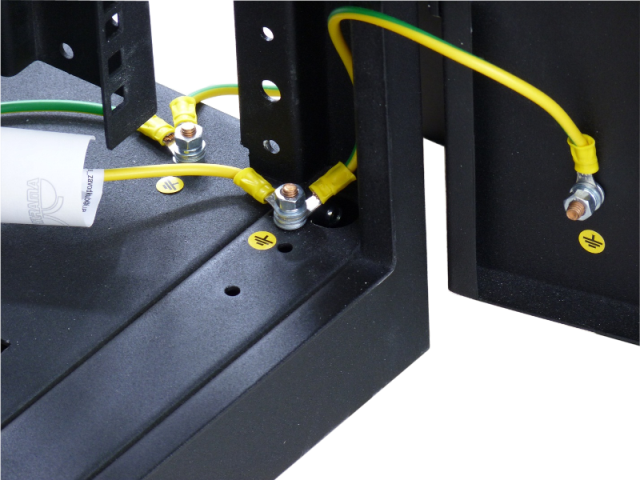

FIG.5 Electrical safety is an integral part of good equipment.

The provided ground loop can be connected to the external bus, and allows installation of equipment in the cabinet with a total current consumption of up to 600 A.

FIG.6 Surface coating

Let's get acquainted with the material used for the production of cabinets, it is sheet steel of different thicknesses:

- frame frame, base, carrier rack, base (100 mm): steel sheet 2.0 mm;

- door, roof: sheet steel 1.5 mm;

- walls: sheet steel 1.2 mm;

- vertical guides 19, mounting tires: galvanized sheet steel 2.0 mm.

Load capacity is determined by the materials and is: for the communication cabinet - 600kg, and for the server - 900kg.

Next, we consider other components of the cabinets design on the example of a gray, switching floor cabinet.

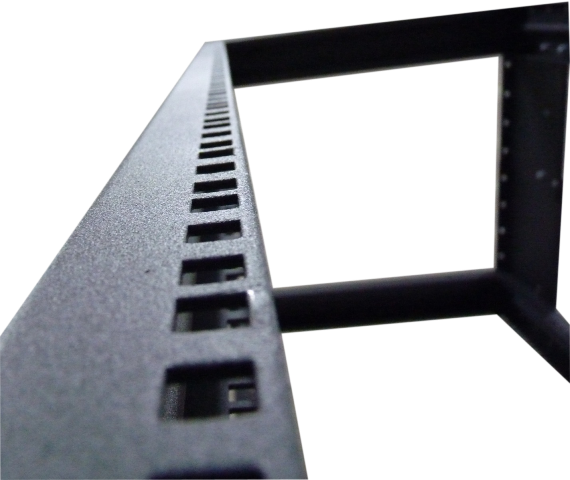

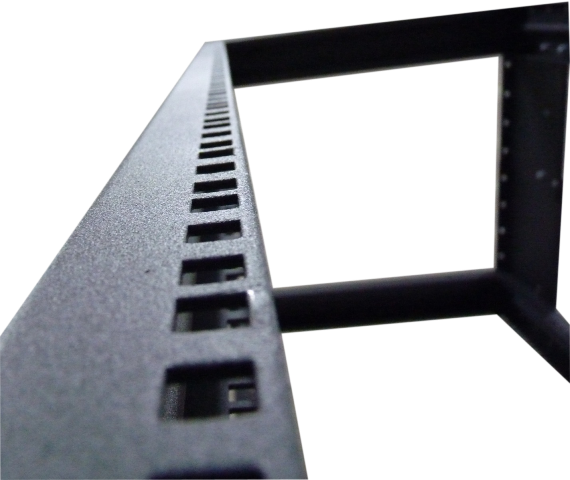

FIG. 7 Vertical guides

In other series, vertical 19 "guides, mounting tires have a zinc coating. Resistance to external mechanical stress of at least IK08 (or impact energy ≤ 5 J), in accordance with IEC62262.

FIG.8 Shelf, as an additional and necessary option

An important feature of this type of equipment is the availability of accessories, such as: shelves, fan units, blank panels, etc.

Load with different models of shelves from 5kg (with fasteners in one plane) to 100kg (with a series of shelves with fasteners in two planes).

As for the ventilation system and air circulation, at the moment it’s just a possibility to install a fan assembly (available for two, four and six fans) and a thermostat. But the manufacturer assures that in the near future, more advanced systems are possible.

FIG. 9 Ventilation

In the upper roof (FIG. 9), the base (FIG. 4) are provided grilles that provide the ability to control the process of uniform cooling equipment, and establish a directional flow of cold and hot air outflow.

FIG. 10 side walls

The side walls are easily removable, with two latches and one / two cylindrical locks. You can also count the lack of design and the lack of "drowning" in the side walls for locks. Over time, this deficiency will be refined by the manufacturer.

Highlights on the cabinets considered. Next, we study the rack. Here everything is much simpler (by design) than the cabinets. Because quickly run through the main features.

Painting is similar to cabinets. The distance between the frames is adjusted by shifting on a perforated support with a 200mm pitch. Additional strength of the structure is given by 4 pairs of horizontal bridges connecting the frames in the upper central part.

FIG. 11 The material of the racks is sheet steel with a thickness of 2 mm.

FIG.12 All conductive parts are grounded to each other. Also note that the rack supports are mounted on adjustable screw supports with the possibility of mounting on rollers. Rollers are available as an option.

FIG.13 Similar to cabinets, accessories are available: shelves, etc.

FIG. 14

In conclusion, I would like to add that I can say a lot about “the domestic industrial crisis” and about any such thing, but I, as they say, have convinced myself with my own hands that they can do good things in Ukraine.

MUK-Service - all types of IT repair: warranty, non-warranty repair, sale of spare parts, contract service

If there are requirements to expand, the cabinet should have at a minimum: a lock in the door, removable side and rear walls, conveniently located cable entries, the possibility of organizing natural and forced ventilation of the internal space, the possibility of adjusting the 19 ”rails.

The cabinet must not be flimsy or, on the contrary, be a very heavy monolith of metal. The quality of painting parts, the quality of locking accessories (locks, handles, latches) is of great importance for the “level of perception” by the consumer.

')

If you competently develop a design with a clear and thorough approach to “work out” at least the points above, you will receive a product whose production can be successfully mastered in the domestic market, and not feed our friends from Europe and China, paying extra for delivery.

What does that require? It seems to be nothing supernatural:

1. Intellectual (design engineers) and raw materials (metal, paint, accessories) resources.

2. Production base.

With the proper formulation of the issue in Ukraine there are no problems with this. There are competent experts, they just need to find and properly "motivate". We supply metal to half the planet.

We do not live in the desert. There are enough places for production in the vacant industrial zone.

On the example of domestic cabinets "KUB", which we actually supply, let us examine the issue of trust to the domestic manufacturer. Let's look further, that it turned out from simple interest "to show" and to tell about this equipment. Next, I propose to examine all the pros and cons of this product. Standard telecommunication cabinets are gray, and server ones, as is customary in the market, are black.

FIG. 1 General view of 19 "form factor cabinets with protection class up to IP30.

As the manufacturer assures, the dielectric structural powder for painting is used by the European manufacturer. On personal experience, we have recently been convinced that the new painting technology makes it possible to achieve the quality level of global manufacturers (for comparison, they took Molex hardware). Honestly, they did not notice any significant differences :).

As for the system of locking the cabinet doors. Everything is clear, almost like a “Swiss watch”. A revolving handle with a built-in lock and a three-point locking mechanism is located on the viewing door. It locks the door in the central, upper and lower points.

There is no video yet, but in the photo you can view:

FIG. 2 Locking mechanism.

FIG. 3 An important parameter is the angle of opening the door.

The doors are removable and reversible with an opening angle of 270 °. Also, as an additional option, the possibility of replacing the door on solid or perforated. A similar option also applies to the rear wall, which can be replaced with a perforated, survey or blind door with a three-point barbell lock.

It is simple to install the equipment or to serve the “filling” of the locker when all 3 walls can be removed. The rigidity and stability of the frame of the floor cabinet is provided by the front and rear welded frames.

In order to get the cable inside, gaps are made both in the base and in the roof (FIG. 7) and the rear wall (FIG. 6). The cable entries themselves, as practice has shown, are not very convenient, because a design change has already taken place, and the manufacturer has increased the size of the cable entries. I think that in the near future, a photo report will be provided on innovations in the design of cabinets.

FIG.5 Electrical safety is an integral part of good equipment.

The provided ground loop can be connected to the external bus, and allows installation of equipment in the cabinet with a total current consumption of up to 600 A.

FIG.6 Surface coating

Let's get acquainted with the material used for the production of cabinets, it is sheet steel of different thicknesses:

- frame frame, base, carrier rack, base (100 mm): steel sheet 2.0 mm;

- door, roof: sheet steel 1.5 mm;

- walls: sheet steel 1.2 mm;

- vertical guides 19, mounting tires: galvanized sheet steel 2.0 mm.

Load capacity is determined by the materials and is: for the communication cabinet - 600kg, and for the server - 900kg.

Next, we consider other components of the cabinets design on the example of a gray, switching floor cabinet.

FIG. 7 Vertical guides

In other series, vertical 19 "guides, mounting tires have a zinc coating. Resistance to external mechanical stress of at least IK08 (or impact energy ≤ 5 J), in accordance with IEC62262.

FIG.8 Shelf, as an additional and necessary option

An important feature of this type of equipment is the availability of accessories, such as: shelves, fan units, blank panels, etc.

Load with different models of shelves from 5kg (with fasteners in one plane) to 100kg (with a series of shelves with fasteners in two planes).

As for the ventilation system and air circulation, at the moment it’s just a possibility to install a fan assembly (available for two, four and six fans) and a thermostat. But the manufacturer assures that in the near future, more advanced systems are possible.

FIG. 9 Ventilation

In the upper roof (FIG. 9), the base (FIG. 4) are provided grilles that provide the ability to control the process of uniform cooling equipment, and establish a directional flow of cold and hot air outflow.

FIG. 10 side walls

The side walls are easily removable, with two latches and one / two cylindrical locks. You can also count the lack of design and the lack of "drowning" in the side walls for locks. Over time, this deficiency will be refined by the manufacturer.

Highlights on the cabinets considered. Next, we study the rack. Here everything is much simpler (by design) than the cabinets. Because quickly run through the main features.

Painting is similar to cabinets. The distance between the frames is adjusted by shifting on a perforated support with a 200mm pitch. Additional strength of the structure is given by 4 pairs of horizontal bridges connecting the frames in the upper central part.

FIG. 11 The material of the racks is sheet steel with a thickness of 2 mm.

FIG.12 All conductive parts are grounded to each other. Also note that the rack supports are mounted on adjustable screw supports with the possibility of mounting on rollers. Rollers are available as an option.

FIG.13 Similar to cabinets, accessories are available: shelves, etc.

FIG. 14

In conclusion, I would like to add that I can say a lot about “the domestic industrial crisis” and about any such thing, but I, as they say, have convinced myself with my own hands that they can do good things in Ukraine.

MUK-Service - all types of IT repair: warranty, non-warranty repair, sale of spare parts, contract service

Source: https://habr.com/ru/post/185434/

All Articles