3D printing of tiny Li-Ion batteries

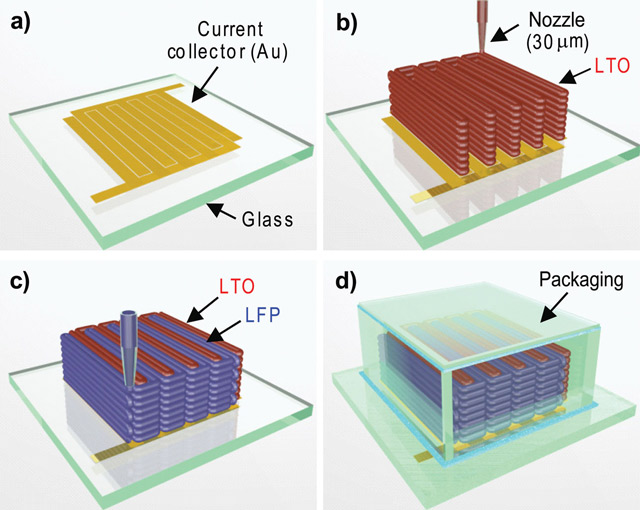

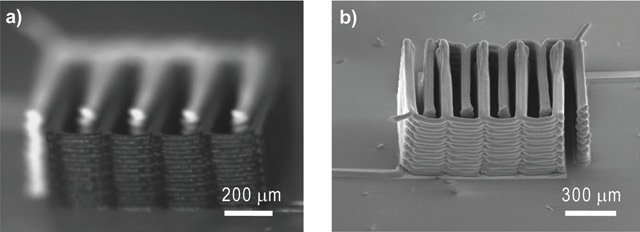

Engineers from Harvard and the University of Illinois at Urbana-Champaign were able to manufacture lithium-ion batteries less than 1 millimeter thick. Cathodes of lithiated iron phosphate LiFePO 4 (LFP) and anodes of lithium titanate Li 4 Ti 5 O 12 (LTO) are printed in layers on a 3D printer.

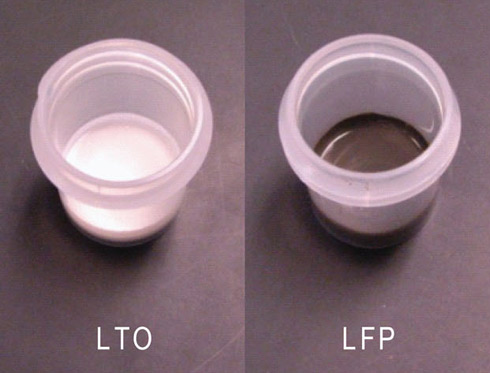

To get a print material that would have a viscosity like a toothpaste and instantly hardened in air, LTO and LFP nanoparticles were used, and they were mixed into a viscous solution.

')

The video shows the process of printing layers of lithium titanate with a print head with a nozzle of 30 microns, under a pressure of 105 psi (724 Pa), at a speed of 1 millimeter per second.

It is assumed that millimeter batteries will find application in miniature electronics, MEMS devices. The photo shows a prototype of a finished battery, filled with electrolyte and placed in a plastic case.

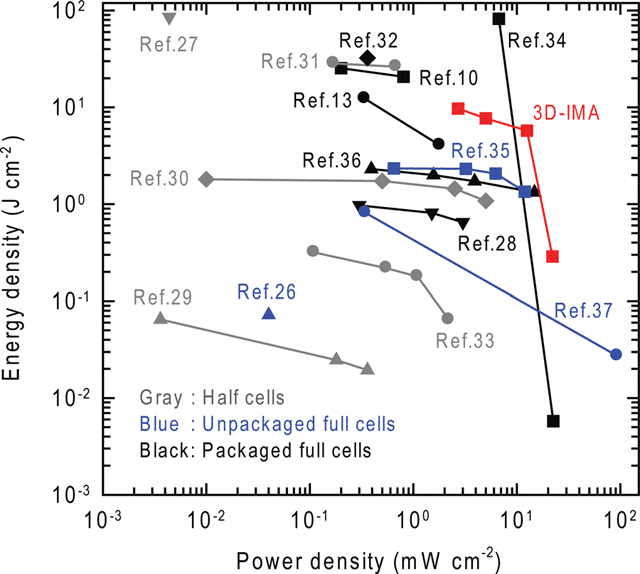

The manufacture of electrodes by the method of 3D printing allows increasing the specific power and energy density of nano-batteries. The graph shows a comparison of the characteristics of 3D-IMA with other experimental technologies for the manufacture of nanoaccumulators in terms of power density and energy density.

The scientific work "3D Printing of Comb Architectures of Li-Ion Microbattery" ("3D Printing of Interdigitated Li-Ion Microbattery Architectures") was published in the journal Advanced Materials June 17, 2013, DOI: 10.1002 / adma.201301036, pdf .

Source: https://habr.com/ru/post/183954/

All Articles