Investigation of the properties of a model printed on a 3D printer

The widespread use of 3D printing has allowed us to try to print something useful with high demands on geometry and weather resistance.

This article is about the feasibility of using this technology for the manufacture of high-precision models and analysis of its behavior over time.

')

Introduction

I decided to evaluate the properties of the critical venturi nozzle, the diameter of the critical section of which exactly corresponds to a certain flow rate. To date, critical nozzles are ideal dispensers and are used in all primary gas flow reference settings.

Material - ABS plastic; ABS plastic properties

Accuracy of printing - 150 microns.

To determine the flow rate, the “EU-3” installation was used, which is part of the State primary standard for units of volumetric and mass flow rates of gas GET 118-2006 , with an expanded uncertainty of 0.11% (k = 2).

The working environment is air, the duration of the experiment: 76 days.

Estimated estimated consumption of the drawing - 10 m 3 / h.

Expectations

Tapering device was designed with a toroidal throat, to test the ability of the printed nozzle to have the same features as high-precision expensive products, made on CNC machines. The difference in the cost of production is much less.

The more precisely the surface is made, the less energy is lost to create a pressure drop.

In general, the natural balance is perfectly observed: it was expended during production - it saved us some time.

Realities

The nozzle turned out ribbed, with pronounced steps in the throat. The color of the plastic is gray.

And, of course, it let in air from all possible places (the layer structure was like this). And who ever promised airtightness, scratching the back of my head, I thought?

Measures were taken to eliminate the leakage of the nozzle and to give a glossy surface

Senselessly smearing the product with clay, for some reason I thought that he would correct the situation by filling the gap, he remembered the article Available technology for smoothing 3D printing objects .

Smoothed squirrels looked great. I'll try ...

A day later

The surface has changed significantly for the better. In general, here you can experiment for a long time by selecting the time, direction and location of the model in a tank with pairs. I did not want to immediately receive large deformations, so I often checked the process and reinsured.

The intermediate goal was achieved and the model was no longer a siphon.

Refrain from stressing the model for the first week.

For three days I “dried” the product under the fan, and the nail marks still remained on the surface.

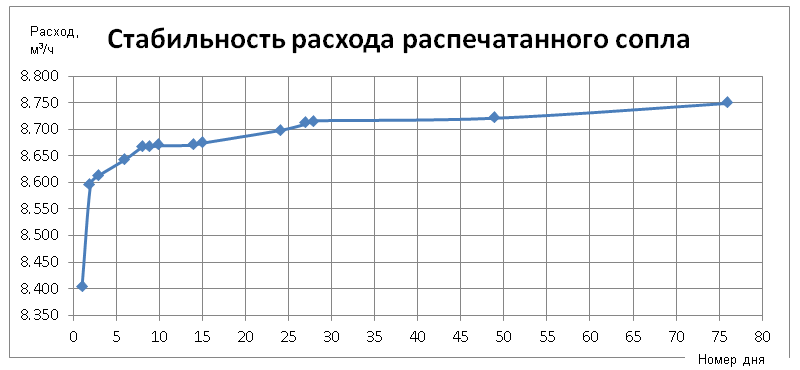

Over the next 76 days, the diameter of the neck changed in a positive direction and still floats along the course known to him alone.

The nozzle never reached the calculated volumetric flow rate due to the “melting” of the throat walls of the narrowing device, which led to a decrease in the critical section. General proportions are preserved.

Conclusion

1. Printing a model, the geometry of which is standardized, with ABS plastic on 3D inkjet type printers is not advisable;

2. The model turned out to be leaky. Without additional processing it can not be used. And after processing, a change in geometry in time negatively affects the geometrical parameters;

3. It takes ~ 3 weeks in a well-ventilated area to fully cure;

4. Proteins are excellent.

Source: https://habr.com/ru/post/183690/

All Articles