Superhydrophobicity in life or available nanotechnology

Good afternoon, Habr!

Today's brief review is devoted to formulations that make it possible to achieve super-hydrophobicity of the treated objects at home.

For a long time there is a lot of talk about the potential of nanotechnology, in particular, about nanotubes, graphene, fullerenes and their applications, which are able to solve all our problems. In short, another technological breakthrough is about to come. However, there are years and special accessible "revolutionary" movements are not observed. In this connection, I decided to conduct a small study of the western market in order to distribute new materials, thanks to which it will be possible to simplify my life. But first things first.

')

The task was set simply: to find a means for coating the surface to achieve maximum hydrophobicity, i.e. maximum reduction of the wettability of the treated medium with water (in my case, the coloring fluid, based on water). The simplest, and, from the point of view of production, profitable, are powdery emulsion systems and compositions that, upon drying, create and / or leave a surface of scanty roughness (due to filling cracks and dimples in the material with nanometer-sized particles) and with low-intensity properties of molecular interaction of substances surface (deposited) phase and liquid medium.

Thus, the task is technically to ensure that the specific free surface energy at the interface between the media is extremely small.

At the moment there are a lot of products of this kind, ranging from car waxes and Umbrella-type coatings to shoe care products (water-repellent coatings), but none of the tools I used have had a satisfactory effect.

In this regard, I remembered the long-standing project (www.neverwet.com ) of an American metallurgical company Ross Technologies and its subsidiary Ross Nanotechnologies, which won the Grand Prix Award at the prestigious American exhibition INPEX 2011 (The Invention & New Product Exposition).

This small company from Philadelphia produces all kinds of steel products. The crisis gave everyone a light, and the management needed to urgently resolve the issue of the safety of overproduced products, as a result of which Ross Nanotechnology was created.

The essence of the material is that it creates a layer of superhydrophobic material on the surface of the treated object. An AF is declared up to 175◦ wetting angle, which is, in general, incredibly cool.

You can see the results of such low wettability on the attached videos.

The most complete video:

and additionally from the manufacturer’s website:

As a result, we obtain not only a surface that is resistant to wetting with water, which can cover not only clothing and electronics, but also an anti-icing, anti-bacterial, anti-corrosion self-cleaning surface. Just imagine: to treat the inner surface of the pipes, the hull of the ship, to cover shoes for maximum tightness and preserve the appearance, to cover electronic boards, to cover the surface of the aircraft fuselage, avoiding costly "washing" before each flight ... Do not find ideas for using the material.

And everything would be fine, but this product, as it turned out, is impossible to obtain. Calls were made, attractive letters were written in various content. The answer is one - “Leave a request on the site, we will consider it. There are no retail sales yet. ” Dates of retail sales were constantly postponed on the site, which could not help but raise doubts, at least, about the environmental friendliness and toxicity of the product. With the understanding that in reality you can find it on the wound, I went to foreign forums, sales sites, with the hope that someone has probes or is “cast in a jar home,” but everyone is looking for and no one offers.

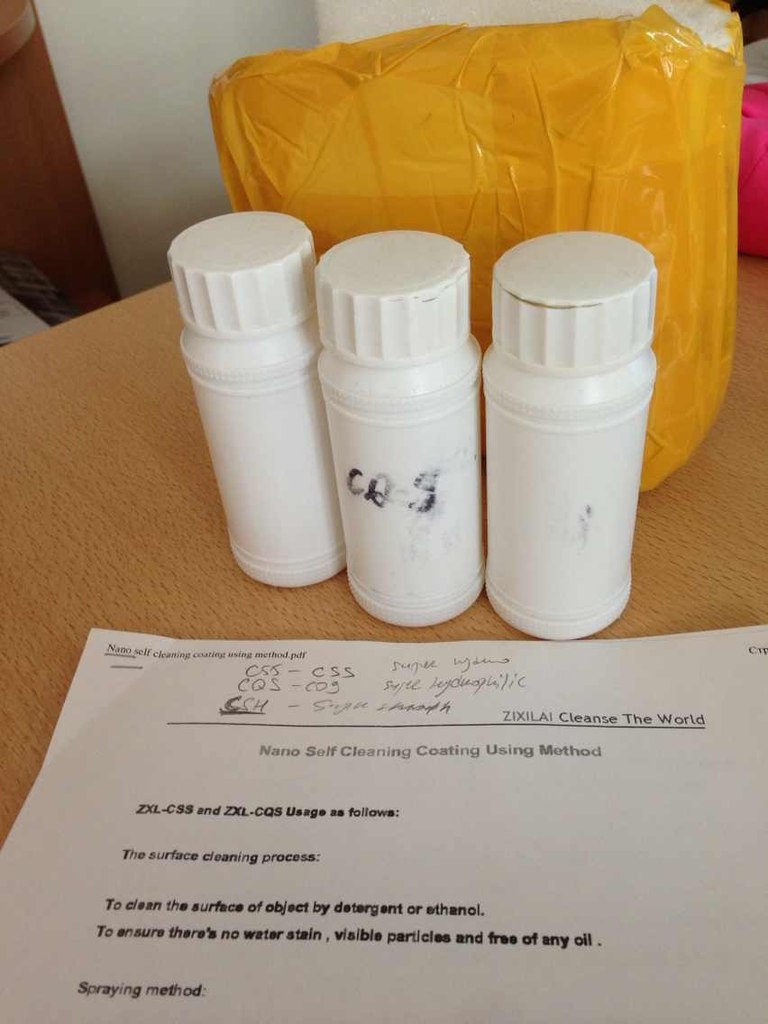

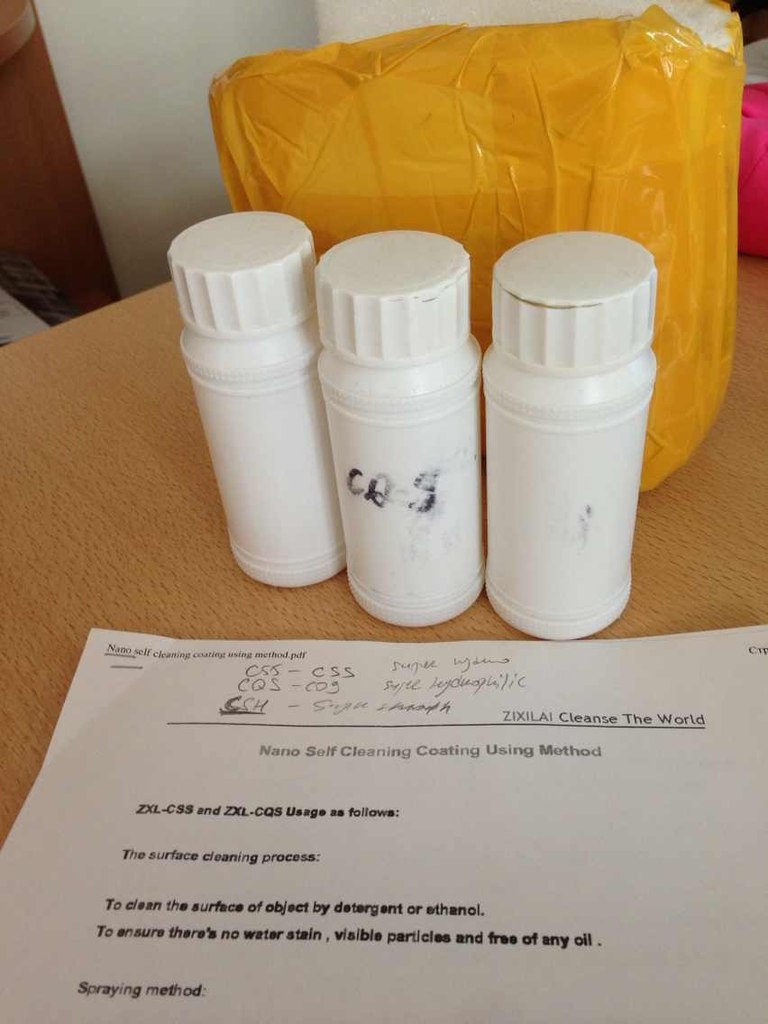

After thinking a bit, I decided to stick myself to where they could produce anything on an industrial scale. There, where the bulk of generally available (and not very) products is produced - China. As a result of a small study of the industrial chemical market in China, a certain Liyang ZiXiLai factory, which produces its own hydrophobic coating, emerged. After the negotiations, three samples of their products and instructions were sent.

Also, the Chinese provided information on the toxicity of the NeverWet coating, and that this is not a thin, but rather thick coating of a milky color, which significantly limits the applicability.

Anyway, in the banks were three different liquids: Superhydrophobic, Superhydrophilic and some kind of Supersmooth coating.

All fluids were tested, and the result was far from what was stated. According to the documentation, the solvent - the basis turned out to be ethyl alcohol, and the particles ... Titanium dioxide. It's funny how the manufacturer boldly curled the 140 ◦ wetting angle and the durability of the coating. After processing, a slightly sticky surface remains, resembling a fatty layer on kitchen hoods. wettability is the same.

Photos are not the most indicative, but nonetheless. these are surface properties a day after processing

For the sake of fairness, it must be said that a certain effect was nevertheless achieved, but far from what was expected. I don’t put a photo of the tests — at best, the water-repellent ability turned out to be about the same as the means for coating car windows — nothing but a fountain.

It would seem, that's all - if the Chinese market does not have adequate quality super-hydrophobic coatings, then you can not search for them anytime soon. However, a NeverWet clone called Ultra Ever Dry ( UltraEverDrystore.com ) was discovered, as well as a WaterBeader (waterbeader.com) spreading a similar mixture. With direct contact via the Ultra Ever Dry post, it turned out that the office is small, and there is a Russian manager (keep silence), who agreed to send a cover kit to Russia (the minimum packing size is 1 qt-0.9 liters). The cost of sending the same composition was around $ 600. I could not decide on such a step, therefore I cannot give an assessment to the composition. Recently, also, it was reported that the product is not sent to individuals. If the translation would have been completed, I doubt that further communication with the office would be continued. It remains only to note that this composition is also toxic, and is intended only for production conditions.

As a result, I continue to search for solutions for everyday “home” use, although such “toxic” options will also suit me - there are respirators in the end - ends.

I hope this article will give a general idea of the issue at the moment for those interested.

Today's brief review is devoted to formulations that make it possible to achieve super-hydrophobicity of the treated objects at home.

For a long time there is a lot of talk about the potential of nanotechnology, in particular, about nanotubes, graphene, fullerenes and their applications, which are able to solve all our problems. In short, another technological breakthrough is about to come. However, there are years and special accessible "revolutionary" movements are not observed. In this connection, I decided to conduct a small study of the western market in order to distribute new materials, thanks to which it will be possible to simplify my life. But first things first.

')

The task was set simply: to find a means for coating the surface to achieve maximum hydrophobicity, i.e. maximum reduction of the wettability of the treated medium with water (in my case, the coloring fluid, based on water). The simplest, and, from the point of view of production, profitable, are powdery emulsion systems and compositions that, upon drying, create and / or leave a surface of scanty roughness (due to filling cracks and dimples in the material with nanometer-sized particles) and with low-intensity properties of molecular interaction of substances surface (deposited) phase and liquid medium.

Thus, the task is technically to ensure that the specific free surface energy at the interface between the media is extremely small.

At the moment there are a lot of products of this kind, ranging from car waxes and Umbrella-type coatings to shoe care products (water-repellent coatings), but none of the tools I used have had a satisfactory effect.

In this regard, I remembered the long-standing project (www.neverwet.com ) of an American metallurgical company Ross Technologies and its subsidiary Ross Nanotechnologies, which won the Grand Prix Award at the prestigious American exhibition INPEX 2011 (The Invention & New Product Exposition).

This small company from Philadelphia produces all kinds of steel products. The crisis gave everyone a light, and the management needed to urgently resolve the issue of the safety of overproduced products, as a result of which Ross Nanotechnology was created.

The essence of the material is that it creates a layer of superhydrophobic material on the surface of the treated object. An AF is declared up to 175◦ wetting angle, which is, in general, incredibly cool.

You can see the results of such low wettability on the attached videos.

The most complete video:

and additionally from the manufacturer’s website:

As a result, we obtain not only a surface that is resistant to wetting with water, which can cover not only clothing and electronics, but also an anti-icing, anti-bacterial, anti-corrosion self-cleaning surface. Just imagine: to treat the inner surface of the pipes, the hull of the ship, to cover shoes for maximum tightness and preserve the appearance, to cover electronic boards, to cover the surface of the aircraft fuselage, avoiding costly "washing" before each flight ... Do not find ideas for using the material.

And everything would be fine, but this product, as it turned out, is impossible to obtain. Calls were made, attractive letters were written in various content. The answer is one - “Leave a request on the site, we will consider it. There are no retail sales yet. ” Dates of retail sales were constantly postponed on the site, which could not help but raise doubts, at least, about the environmental friendliness and toxicity of the product. With the understanding that in reality you can find it on the wound, I went to foreign forums, sales sites, with the hope that someone has probes or is “cast in a jar home,” but everyone is looking for and no one offers.

After thinking a bit, I decided to stick myself to where they could produce anything on an industrial scale. There, where the bulk of generally available (and not very) products is produced - China. As a result of a small study of the industrial chemical market in China, a certain Liyang ZiXiLai factory, which produces its own hydrophobic coating, emerged. After the negotiations, three samples of their products and instructions were sent.

Also, the Chinese provided information on the toxicity of the NeverWet coating, and that this is not a thin, but rather thick coating of a milky color, which significantly limits the applicability.

Anyway, in the banks were three different liquids: Superhydrophobic, Superhydrophilic and some kind of Supersmooth coating.

All fluids were tested, and the result was far from what was stated. According to the documentation, the solvent - the basis turned out to be ethyl alcohol, and the particles ... Titanium dioxide. It's funny how the manufacturer boldly curled the 140 ◦ wetting angle and the durability of the coating. After processing, a slightly sticky surface remains, resembling a fatty layer on kitchen hoods. wettability is the same.

Photos are not the most indicative, but nonetheless. these are surface properties a day after processing

For the sake of fairness, it must be said that a certain effect was nevertheless achieved, but far from what was expected. I don’t put a photo of the tests — at best, the water-repellent ability turned out to be about the same as the means for coating car windows — nothing but a fountain.

It would seem, that's all - if the Chinese market does not have adequate quality super-hydrophobic coatings, then you can not search for them anytime soon. However, a NeverWet clone called Ultra Ever Dry ( UltraEverDrystore.com ) was discovered, as well as a WaterBeader (waterbeader.com) spreading a similar mixture. With direct contact via the Ultra Ever Dry post, it turned out that the office is small, and there is a Russian manager (keep silence), who agreed to send a cover kit to Russia (the minimum packing size is 1 qt-0.9 liters). The cost of sending the same composition was around $ 600. I could not decide on such a step, therefore I cannot give an assessment to the composition. Recently, also, it was reported that the product is not sent to individuals. If the translation would have been completed, I doubt that further communication with the office would be continued. It remains only to note that this composition is also toxic, and is intended only for production conditions.

As a result, I continue to search for solutions for everyday “home” use, although such “toxic” options will also suit me - there are respirators in the end - ends.

I hope this article will give a general idea of the issue at the moment for those interested.

Source: https://habr.com/ru/post/183342/

All Articles