How we built a fail-safe data center level TIER-III

In 2009, there was a warehouse of unique compressors that had not been used for a long time (in particular, for the Energia-Buran system), where the train once stopped by for unloading.

We immediately liked the building . We bought it for building our own data center of increased responsibility. A few years later, a modern data center appeared on the site of the shop, which became the third in Russia certified by the Tier III Uptime Institute level as an object.

')

Recently I found quite a few photos from the construction. I think you will be interested to see how it all looks in the process, usually such things do not show.

And this is 2012, the machine room is just starting to fill up.

Carefully, under the cut a lot of photos

This was already the third of our own data center and not the first or even the twentieth of those that we built or helped build across the country for various customers. Accordingly, by this time we already had an excellent team of engineers and proven suppliers.

Basic parameters of the data center "Compressor"

We started the construction of "Compressor" in 2009 . I wanted to do everything according to my mind, since the specificity of some of our clients is such that data centers should work no matter what. The TIER-III level was chosen as the most appropriate for the tasks (such data centers continue to work stably without changes when any system node fails and have an availability indicator of 99.98%). We have been certified by the Uptime Institute for the project and for the facility - there were only two data centers of this level in Russia before us.

So, at the beginning of the work we had a building. In general, it was in good condition. We added the overlap between the first and second floor, plus increased the third floor for household needs (for example, there is now a dining room).

At first we took everything we found in the workshop:

This is how the place looked in 2010, view from above. This installation of floor slabs of the second floor:

Same moment, view from inside the building. Here is the installation of the supporting supports of the second floor:

2011, the installation of the second floor ceilings is completed, we install internal partitions:

Here you can see the height of the raised floor, this is January 2011:

In the same January 2011, the technological premises were already ready for finishing:

And in February and March we mounted a double floor in the room of uninterruptible power supply units:

Double floor indoor battery:

Here is visible fire protection of bearing metal structures, also February:

Photos of March 2011, the construction of the route between the distribution substation of diesel generator sets and the data center building:

And here you can clearly see the openings, where the air is supplied under the raised floor. The height is about 1.2 meters, this is due to the high power.

April 2011, we are building pipelines. In the photo - chilled water supply pipelines to the fan coils. The main pipes have a diameter of 400 millimeters, and the valves had a ton, which created a number of installation difficulties.

Completion of the cooling circuit of the engine rooms

Installation of pipelines for tying chillers and cooling towers, May 2011:

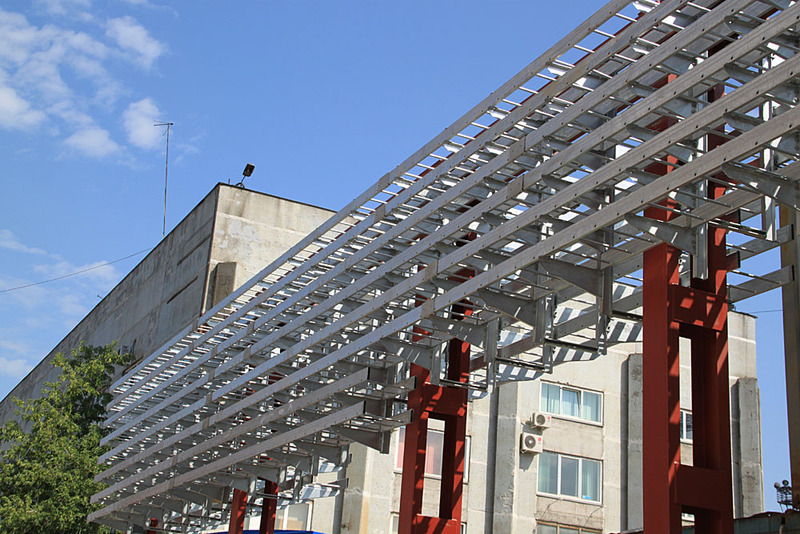

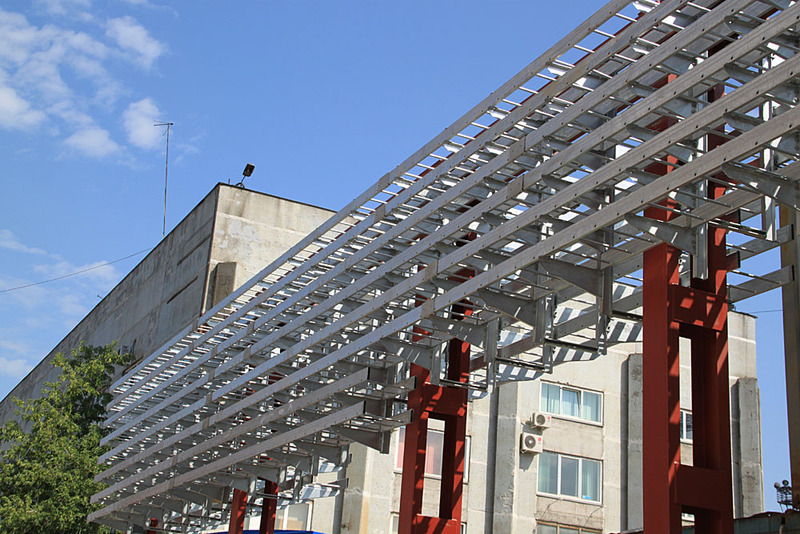

June 2011, we install the cooling system, this is the installation of chillers and drycoolers on a special structure on top of the building.

Their use was due to the fact that it was necessary to fit into the existing dimensions of the building, so the chillers were put on the roof.

But the installation of the pumping station in July 2011 has already been completed:

Busbars also appeared in July 2011:

And here are the switchboards:

July 2011, installation of suspended ceilings and trays in machine rooms is in full swing

In August 2011, internal air conditioning units were installed:

So they look like this:

Installation of a transformer substation cooling system:

Distribution substation for a diesel generator set at the cable connection site:

In August 2011 we also began to mount the facade of the building. Here the insulation is almost mounted, install the entrance gate:

The same facade on the other side:

This installation of cable trays diesel power plant. Here will be several tons of cable (photo - also August):

The refueling site in August was already fully prepared:

Final painting of pipelines in the first floor refrigeration center:

So in August, the distributive substation of DES looked like, inside view

August 2011, very soon the Compressor will be launched, but CROC employees cannot wait to look at it (on the roof with chillers):

Here diesel generator sets, during installation. A total of 7 of them were installed. The beginning of the installation of the cable system. Picture taken in September 2011:

And these are gas fire extinguishing cylinders of machine halls, also September photo:

By September 2011, the installation of the ventilated facade of the building was almost completed:

The last thing they did was to finish the rooms and reserve non-critical equipment like microwaves.

That's all. After the façade of the building was fully lined, we still tidied up the area, set up a fence for security and planted a lawn.

Here there is a photo tour of this data center, here - more details , and here - about the features of certification .

PS If it is interesting, I will write a post about the equipment, engineering systems and suppliers (by the way, some domestic suppliers have very well recommended themselves).

We immediately liked the building . We bought it for building our own data center of increased responsibility. A few years later, a modern data center appeared on the site of the shop, which became the third in Russia certified by the Tier III Uptime Institute level as an object.

')

Recently I found quite a few photos from the construction. I think you will be interested to see how it all looks in the process, usually such things do not show.

And this is 2012, the machine room is just starting to fill up.

Carefully, under the cut a lot of photos

Introductory

This was already the third of our own data center and not the first or even the twentieth of those that we built or helped build across the country for various customers. Accordingly, by this time we already had an excellent team of engineers and proven suppliers.

Basic parameters of the data center "Compressor"

- Fault tolerance: Tier III, confirmed by the Uptime Institute,

- Cooling: N + 1, an average of 6 kW / rack (there are 30 kW racks, they are placed next to the less powerful ones in the machine room),

- Power supply: 2N, UPS - 15 minutes, diesel generator set - 24 hours without refueling,

- Capacity - 800 racks,

- The premises of the warehouse and the staff of the customer,

- Guarded territory

- Building owned

- Connected by a fiber-optic ring to the CROC data center network,

- 6000 kW total cooling capacity, of which 1500 kW reserve,

- Through reservation of the cooling system N + 1 (3 + 1),

- The average annual PUE is not worse than 1.45,

- Cold margin of 15 minutes when power is disconnected,

- The temperature range is -36 ... + 37 degrees (this is the absolute minimum and maximum for the last 10 years in Moscow).

We started the construction of "Compressor" in 2009 . I wanted to do everything according to my mind, since the specificity of some of our clients is such that data centers should work no matter what. The TIER-III level was chosen as the most appropriate for the tasks (such data centers continue to work stably without changes when any system node fails and have an availability indicator of 99.98%). We have been certified by the Uptime Institute for the project and for the facility - there were only two data centers of this level in Russia before us.

So, at the beginning of the work we had a building. In general, it was in good condition. We added the overlap between the first and second floor, plus increased the third floor for household needs (for example, there is now a dining room).

At first we took everything we found in the workshop:

This is how the place looked in 2010, view from above. This installation of floor slabs of the second floor:

Same moment, view from inside the building. Here is the installation of the supporting supports of the second floor:

2011, the installation of the second floor ceilings is completed, we install internal partitions:

Here you can see the height of the raised floor, this is January 2011:

In the same January 2011, the technological premises were already ready for finishing:

And in February and March we mounted a double floor in the room of uninterruptible power supply units:

Double floor indoor battery:

Here is visible fire protection of bearing metal structures, also February:

Photos of March 2011, the construction of the route between the distribution substation of diesel generator sets and the data center building:

And here you can clearly see the openings, where the air is supplied under the raised floor. The height is about 1.2 meters, this is due to the high power.

April 2011, we are building pipelines. In the photo - chilled water supply pipelines to the fan coils. The main pipes have a diameter of 400 millimeters, and the valves had a ton, which created a number of installation difficulties.

Completion of the cooling circuit of the engine rooms

Installation of pipelines for tying chillers and cooling towers, May 2011:

June 2011, we install the cooling system, this is the installation of chillers and drycoolers on a special structure on top of the building.

Their use was due to the fact that it was necessary to fit into the existing dimensions of the building, so the chillers were put on the roof.

But the installation of the pumping station in July 2011 has already been completed:

Busbars also appeared in July 2011:

And here are the switchboards:

July 2011, installation of suspended ceilings and trays in machine rooms is in full swing

In August 2011, internal air conditioning units were installed:

So they look like this:

Installation of a transformer substation cooling system:

Distribution substation for a diesel generator set at the cable connection site:

In August 2011 we also began to mount the facade of the building. Here the insulation is almost mounted, install the entrance gate:

The same facade on the other side:

This installation of cable trays diesel power plant. Here will be several tons of cable (photo - also August):

The refueling site in August was already fully prepared:

Final painting of pipelines in the first floor refrigeration center:

So in August, the distributive substation of DES looked like, inside view

August 2011, very soon the Compressor will be launched, but CROC employees cannot wait to look at it (on the roof with chillers):

Here diesel generator sets, during installation. A total of 7 of them were installed. The beginning of the installation of the cable system. Picture taken in September 2011:

And these are gas fire extinguishing cylinders of machine halls, also September photo:

By September 2011, the installation of the ventilated facade of the building was almost completed:

The last thing they did was to finish the rooms and reserve non-critical equipment like microwaves.

That's all. After the façade of the building was fully lined, we still tidied up the area, set up a fence for security and planted a lawn.

Links

Here there is a photo tour of this data center, here - more details , and here - about the features of certification .

PS If it is interesting, I will write a post about the equipment, engineering systems and suppliers (by the way, some domestic suppliers have very well recommended themselves).

Source: https://habr.com/ru/post/182938/

All Articles