Micron - the heart of Russian microelectronics

From recent articles about microelectronics ( 1 , 2 , 3 ) you could learn that the most modern microcircuits in Russia (90nm) are made at the Micron plant, in Zelenograd. Recently, I just managed to visit it, look at the production, ask questions.

From recent articles about microelectronics ( 1 , 2 , 3 ) you could learn that the most modern microcircuits in Russia (90nm) are made at the Micron plant, in Zelenograd. Recently, I just managed to visit it, look at the production, ask questions.Photos from clean rooms, answers to tricky questions about subway tickets, civilian electronics in Russia and the future of Micron - under the cut.

We first look at the production:

On the first two floors - the actual equipment for processing plates. "Leaky" raised floor - in order not to disrupt the laminar air flow between the ceiling and the floor. Operators - in usual suits, but not in space suits and without robotic conveyors. As it turned out, air purity requirements are significantly weakened by SMIF containers (standing on the shelf to the right) - they don’t carry bare plates around the room, and the SMIF container is airtight and does not let dust pass through. Inside each plate processing apparatus - the container opens inside the apparatus and dust cannot enter there. As a result, there are more dust problems in the old production at micron norms than in the new one.

')

Heat treatment furnaces:

SMIF containers can only be carried with two hands. For violators are monitored :-)

Control plates on an optical microscope. There are also electron microscopes on Micron itself - but we didn’t get them.

On the 3rd floor - the technical infrastructure that provides clean room operation - water and gas purification, distribution of reagents.

The end result of the work is a 200mm plate with chips, in this case for transport cards. It remains only to test, cut, and roll into plastic.

Well, now let's move on to the questions that have been asked:

What is imported, and what is yours?

On the spot - get clean water, gases - air separation products. Everything else — practically all chemistry, “clean” plates, and other materials — have to be imported, whether in Russia there is no production of the necessary materials, or they are of insufficient quality for microelectronics. To create the production of materials for such small volumes of production is certainly not profitable. Small-scale production of photo masks under 90-180nm is, but photo masks for critical layers (with the smallest details) have to be made abroad.The supplier of the base technology 180 and 90 nm is the French company STMicroelectronics. Further modifications of the technology are already done on Micron (for example, SiGe, silicon-on-insulator, etc.). The equipment is also imported.

On the climate of Russia

Someone may have read the book by Parshev A.P. “Why Russia is not America”, where it was argued that the climate in Russia makes any production here more costly. So, in the case of microelectronics - everything turned out quite the opposite.Microelectronic production requires a fixed temperature and humidity in a clean zone - and in the countries of Southeast Asia, the air must first be cooled to condense excess moisture and then heated to produce the required temperature and humidity (If cooled immediately to the desired temperature, without heating - humidity will be 100%).

For this whole process, the energy costs in Russia with our continental climate are just less. But of course, at a fraction of total costs, this is a very small part.

About Metro tickets

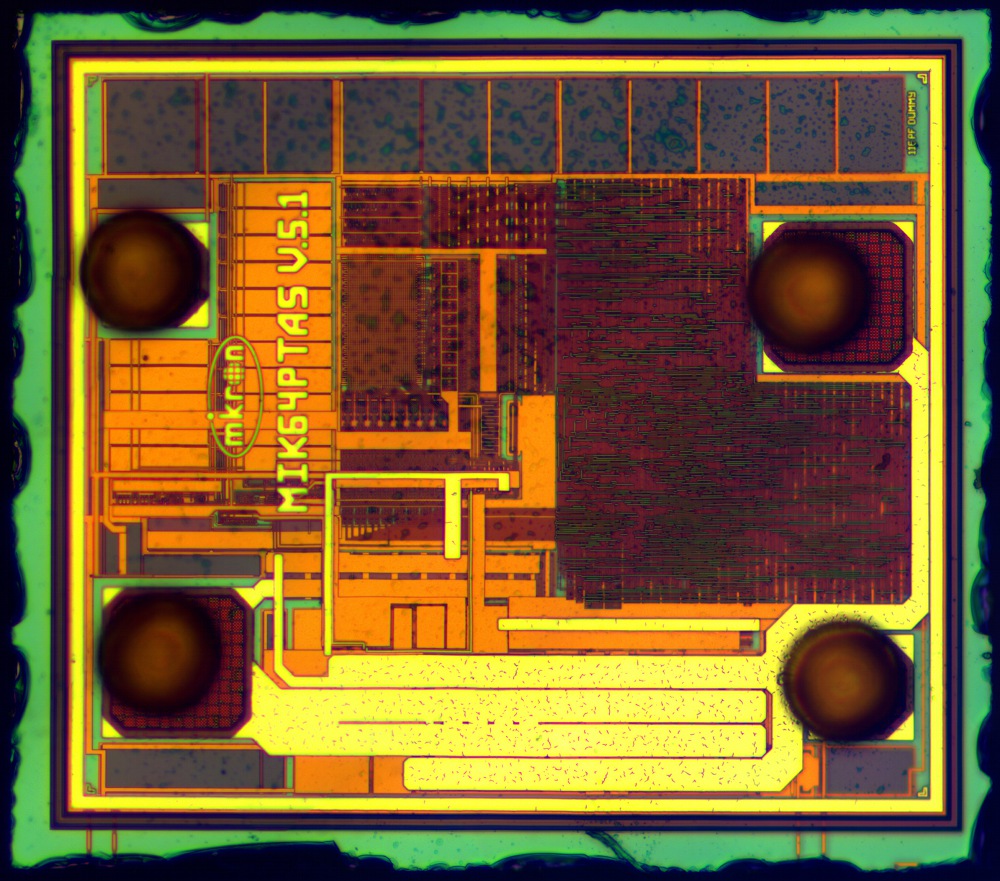

If you haven’t yet seen, the new RFID chip for Metro tickets, designed and manufactured in micron, looks like this:

The first revisions were the same area as the imported ones - because Micron partially used imported chips, simultaneously increasing the yield, improving the technology and design of his chip. In 2012, the Micron version was already 20% less than the import equivalent , and now it’s him that is put on the subway tickets.

How was the issue with patents resolved, because the MIFARE technology is closed? By a happy coincidence, these patents did not apply to Russia - so Micron patented his decision in Russia, and can produce it legally.

By the way, remember the story of fake subway tickets? As it turned out, even chips with a programmer and anyone can buy - to make a subway ticket so simply will not work. Each ticket has a unique number, and it must be entered into the base of the metro. Accordingly, in that story there were no accomplices who had access to the database.

About Micron products and civil electronics in Russia

The main commercial direction of Micron is various RFID tags, chips for sim-cards, documents - in general, everything that can be sold in Russia. Micron also produces a lot of products on the orders of Russian design centers, but in most cases information about specific products is not disclosed. Among the well-known examples are the Quark processors developed by KM211 . Also now, the MCST finishes the Elbrus under the production at Micron.In general, 20-25% of products are exported (LF and HF RFID chips), the rest - on the orders of domestic design centers, and to the domestic market. Microcircuits for consumer electronics are not yet produced as much. the volume of consumer electronic products in Russia is also not large, and what is produced is collected almost entirely from imported components.

This problem has 2 possible solutions: to motivate producers to use domestic chips (for example, using unique national standards for digital television broadcasting - even though we don’t like it all

Micron cannot even get tax benefits, which are the first way to support microelectronic production worldwide (this is about unsuccessful attempts to join Micron to the special economic zone "Zelenograd").

By the way, referring to the issue of money: for some reason, many people believe that Micron exists on the “budget money” from Rosnano. This is not the case: Rosnano provides financing on commercial terms - the money will have to be returned with interest, there is no freebie here.

On the future development of technologies on Micron

Initially, Micron wanted to build a new plant on the 45-65nm technology with 300mm plates, since on the 200mm wafers, no one works with 65nm technology. But for such production volumes - in Russia there are no markets yet. Therefore, it was decided to continue the development of small-scale production - to the existing 90nm line, additional equipment will be purchased, so that the opportunity to produce microcircuits using 65nm technology will be “low blood”.Then, when there are orders for a full load of available capacity at 65 nm - you can already begin to build a new plant. Also, with 65 nm, Micron will retain the technological leadership in Russia in the coming years. Despite the fact that 65nm is far from the front edge of microelectronics, for the overwhelming majority of microcircuits this is quite enough.

But processors for mobile phones and desktop computers - while you have to use imported ones.

Update: The unconfirmed phrase that “non-standard standards” are adopted in the west to support their manufacturers has been removed from the article.

Source: https://habr.com/ru/post/181119/

All Articles