ABS vs PLA. What to choose for 3D printing?

Introduction

Let's start with the fact that I have long been interested in the topic of 3D printing. And if I have already figured out the device of the printers, the software component, then the question remains: "What is better? ABS or PLA?"

I think that many will be interested in this topic, since the choice of material for printing is a kind of analogue for the choice of material when designing a particular device. I will try in the manner of an engineer to sort through all the advantages and disadvantages of each material.

Let's get started

Theory

ABS

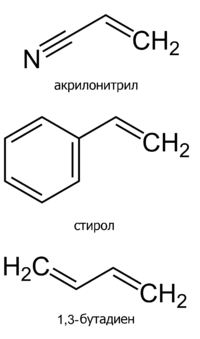

Acrylonitrile butadiene styrene , or just ABS. “Impact-resistant technical thermoplastic resin based on copolymer [1] of acrylonitrile with butadiene and styrene (the name of the plastic is formed from the initial letters of the names of monomers)”.

For greater clarity, we demonstrate:

Properties:

1. Opaque (Painted in various colors).

2. Increased impact resistance and elasticity

3. Non-toxicity

4. Durability

5. Resistance to alkalis and detergents

6. Moisture resistance

7. Oil resistance

8. Acid resistance

9. Heat resistance 103 ° C (up to 113 ° C for modified brands)

10. Wide operating temperature range (from −40 ° C to +90 ° C)

It is recommended to use for the manufacture of: large car parts (instrument panels, hand controls, radiator grilles), large household appliances, radio and television equipment, electrical lighting and electronic devices, vacuum cleaners, coffee makers, control panels, telephones, fax machines, computers, monitors, printers, calculators, other household and office equipment, sports equipment, parts of weapons, furniture, plumbing products, medical equipment parts,

Advantages:

1. Relative cheapness

2. Solubility in acetone (you can smooth the "steps" of the seal).

3. Easy to paint

4. “Finishing” operations are possible (grinding, painting)

5. Can work in a large range of temperatures.

6. Maintains significant shock loads.

disadvantages

1. It is impossible to make color.

Required temperatures:

Working temperature - 210-270 degrees.

The desktop is about 110 degrees.

PLA

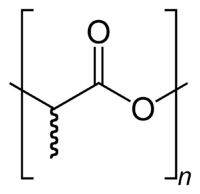

Polylactic (PLA) is a biodegradable, biocompatible, thermoplastic, aliphatic [2] polyether, the monomer of which is lactic acid.

where, a zigzag line shows a section with CH3

It is used for: the production of environmentally friendly biodegradable packaging, disposable tableware, personal care products, for the production of surgical yarns and pins, as well as in drug delivery systems.

Advantages:

1. Have a low coefficient of friction (which makes it almost indispensable in the production of sliding bearings).

2. Non-toxic

3. Low glass transition temperature [3]

4. There is no need for a sufficiently smooth surface for the desktop.

5. No table heating required.

6. Cleaner production from renewable sources

Disadvantages:

1. More expensive ABS

2. Degradability property

3. Does not respond to acetone (impossibility of smoothing the contours)

Required temperatures:

The working temperature is about 185 degrees.

')

Conclusion

From the foregoing it is clear that the materials are in many ways similar. The choice of one or another depends only on the purpose of the product being manufactured. Definitely determine the favorite did not work. Both have strong arguments, but because of the specifics of my work, I prefer ABS to plastics. Although you should not forget about the biodegradability of PLA plastic.

Notes

1. Copolymers - a kind of polymers, the chains of molecules of which consist of two or more different structural units.

2. Aliphatic compounds - compounds that do not contain "rings" similar to benzene.

3. Vitrification (vitrification) - transition from a liquid to a glassy state with decreasing temperature.

Source: https://habr.com/ru/post/179601/

All Articles