Future productivity growth: long-term perspectives

Long-term plans to increase the performance of microprocessors and the development of the semiconductor industry, according to ITRS (International Roadmap for Semiconductors), are directly related to the development of technologies and materials that can replace traditional CMOS electronics and silicon. The complexity of this task is difficult to overestimate, since the search for such alternatives is akin to trying to find a water substitute for our daily needs ...

The H2O we are used to is an incredibly interesting liquid. It is a universal solvent, transparent to the visible part of the light spectrum and able to move against the force of gravity under the influence of capillary effects. Water is highly efficient for cooling and requires a large amount of energy to convert to steam. It becomes less dense and expands when it freezes, and also easily mixes with many other liquids. It has a high refractive index, a neutral pH, it is easy to clean, and it is found in abundance almost everywhere. The list goes on and on, but the point is this: there are quite a few liquids that are superior to water in one area, but none of them is an adequate substitute if all characteristics are taken into account.

To give up silicon in electronics today is almost as difficult as giving up water in everyday life.

')

In the same way, there are a number of technologies that can improve some particular aspects of the current production technology, and there are a number of materials that can replace silicon. But such a replacement will require many changes at almost all stages of production. Local changes can not do.

ITRS reports consider almost all currently known alternatives: the use of carbon nanotubes, graphene, nanowires, spintronics, germanium, etc. Not mentioned except molybdenum. The description of what each of these technologies is is easy to pull on an independent post, so instead, we will focus on the question "when?"

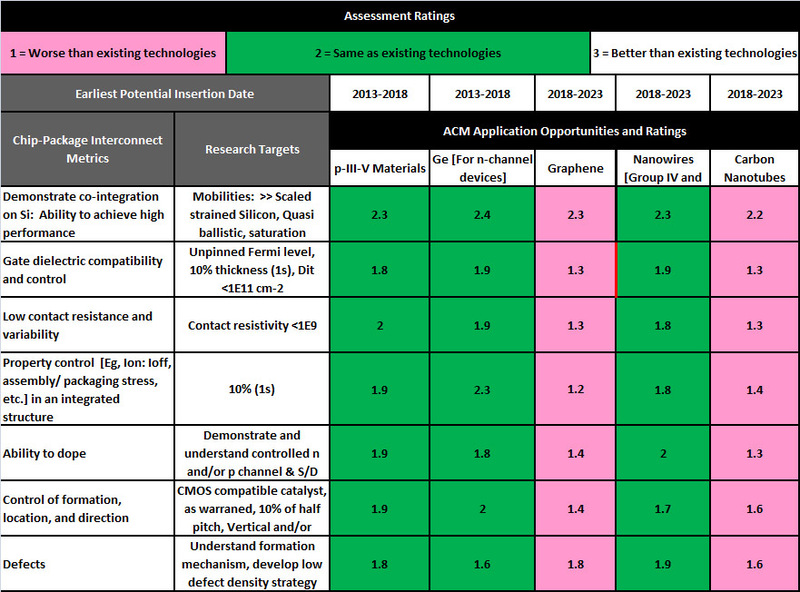

The reports are not overly dark, but indicate the seriousness of the problems. The table below shows the different stages of the production process and when the appropriate technology could theoretically be ready for implementation.

You may notice that in the near future, a number of new technologies in the field of device packaging are expected. That is why this area is now attracting so much attention. In the next 3-5 years, CPU manufacturers can rely on innovations in this area. Progress in almost all other areas requires the overcoming of various technological obstacles. Probably, the use of graphene or carbon nanotubes will turn out to be the following technology, ready for use in creating elements of memory and logic, but the “official” point of view says that these technologies will reach the level of commercial applicability no earlier than in 10-15 years.

And the following table shows the expected performance indicators from the use of new technologies in comparison with the technologies used now. Values less than 2 indicate deterioration, and more than two - improvement compared with current indicators.

Each of these technologies has a greater potential than silicon, but their use requires making many compromises. In many cases, the solution to the problems that arise is not even known approximately. And the implementation dates specified in the ITRS are just speculation that a solution will be found during this time.

Best of all, the scale of the problems is seen on the example of carbon nano tubes. In order to consider them as material for the electronics of the future, it is necessary to learn how to grow them with a negligible amount of impurities. Over the past 1-2 years, almost nothing has changed in this direction: the purity achievable now is 99% or even 99.8%, while it is necessary to achieve more than 99.999999999999% purity. Coming back to analogies with water, this is one drop of impurities per dozen of Olympic water pools. If a technology appeared now that is less demanding of cleanliness and precision of operations than CMOS, it would have become the main candidate for the speedy implementation. But alas ...

The volume of water in the Olympic pool ~ 2500 m 3

The total number of considered “technologies of the future” indicates that no one now really knows which of them will be the most useful. Sometimes there are harsh statements, but there is no agreement on what will be a likely replacement for current technology.

Be that as it may, in the medium term, transistors will continue to decrease. The transition of production to silicon wafers with a diameter of 450mm should reduce production costs (although recent ASML statements cast doubt on this, as well as whether there will be 450mm wafers at all). In general, the trend will be aimed at improving energy efficiency, rather than productivity. And the use of approaches like More-than-Moore means that although the productivity growth in the usual places will remain extremely modest, it is possible that productivity will increase where it has not been expected.

One thing is clear for sure: even if it is possible to further improve the technical process (14nm, 10nm, 6nm ...), then the practical benefit from this (and without that is now small) with each next step almost disappears. And the only way out is to search for alternative technologies.

On the other hand, this has its advantages. This situation forces all companies, from Intel and AMD, to Google and Nvidia, to revise the basic principles of how data is processed. Over the past 30 years, progress has been the same, the easiest way, but there are others. Perhaps such a rethinking of the basic principles will give a much greater gain than the improvement of production technology and an increase in clock frequency.

Source: https://habr.com/ru/post/176387/

All Articles