Industrial networks in the context of the fourth industrial revolution

First, a small historical digression about what the fourth industrial revolution, announced last year.

- The emergence of industry. The first industrial revolution took place at the beginning of the 19th century and was associated with a massive transition from the use of muscular strength to the energy of a steam engine. Key technologies - steam engine, factory. There was the possibility of mass production, but its products were expensive.

- Mass production. The second revolution happened at the beginning of the 20th century, and marked the beginning of cheap mass production. Key technologies are conveyor and Taylorism . Mass-produced products fell by an order of magnitude.

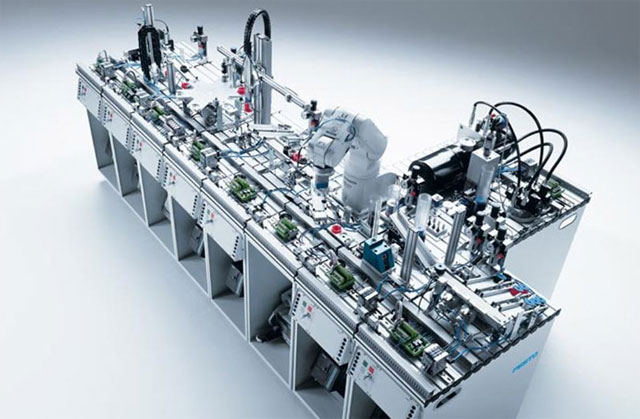

- Automation. The third industrial revolution occurred in the 1980s. CNC machines and robots made modern factories almost deserted. (Outsourcing of manual labor to developing countries has smoothed over this tendency.) Mass-produced products fell by an order of magnitude (it became cheaper to throw out than to repair).

- Decentralization. The four point zero revolution is happening now. The key technology is the convergence of industry and IT, 3D printers. It becomes possible to produce a small series or a unique product at a price approaching the cost of the same in a large series.

It seems to me that in the introduction I wrote too many common phrases and too little technical hardcore. I will correct it under a cat, having described some technical details about industrial networks and the Intel products connected with them (+ one more picture with the robot).

For me personally, the main question of the fourth industrial revolution is

Above, I repeated the mantra - "technologies from IT come to industry, and radically reduce the cost of production." In order not to be unfounded, it would be necessary to list which technologies. I see three main elements.

1. The use of control devices based on general-purpose processors / chipsets, slightly modified to meet industrial requirements (reliability, realtime, temperatures, fanless, etc.). I already wrote about this trend here.

2. Use of IT network infrastructure for communication of sensors, actuators, robots, automatic machines with control elements. About this post today.

3. The two preceding paragraphs automatically signify the need for using industrial IT products for programming, system administration, and information security. The field here is tilled! (By the way, do you need a post on Habré about the features of programming CNC machines and robots, and how programming technologies that we are used to in IT already penetrate into this area?)

')

The economic argument for the use of IT technologies in industry is very simple. Billions of laptop and personal computer users have already paid for R & D and mass production of related technologies. Why not take advantage of it, for example, in the same way as it does at HPC? (Most supercomputer processors are manufactured on a multi-billion-dollar Faba, loaded mainly with notebook processors. The Xeon EP and Core i3 microarchitecture is no different.)

So, more about industrial networks ( Filedbus ). During the third industrial revolution, many Fieldbus standards were created: Profibus, Modbus, Sercos, and so on and so on ... They all use specialized phy , and as a result, vendors had to develop and maintain special hardware (ASIC or FPGA) and special firewood, and users - to pull non-standard cables and use exotic connectors.

In IT, once there was the same zoo of networks (remember Token Ring, Apple Net, ARCNET, Ethernet via coax?). In the end, Ethernet over twisted pair and TCP / IP all won. In industry with the basis of convergence at the phy level, there are no more questions either. Obviously, the future of industrial networks is based on Ethernet-based protocols on a conventional twisted pair: Profinet , Ethercat , Sercos III and EtherNet / IP . In fact, the number of types of industrial networks based on Ethernet is somewhat larger. For example, there is even a Korean national standard. But the above are the most common, and therefore in this review I will limit myself to them.

All of them can use cable and network infrastructure, proven over years of use in the IT industry. You can debug them with Wireshark, not with an oscilloscope, like old fieldbus. Each standard has a big mom (Profinet - Siemens, Ethercat - Beckhoff, Ethernet / IP - Rockwell, Sercos III - Bosch) and a consortium of companies that promote it. However, the equipment of each major manufacturer supports not only its “favorite” standard of the industrial network, but most of the rest. Therefore, the market has a myriad of options for bridges between these networks. Such fragmentation is not very happy, and there is a suspicion that in a few years there will be 1-2 basic standards. You can do anti-scientific fortune telling and jot down a sign comparing the characteristics of the most common protocols.

| Protocol | EFFECTS IN ONE SEGMENT | Minimum cycle | Internet compatibility | Topology |

| Ethercat | 65536 | 12.5us | Not really | arbitrary but logical rings |

| Profinet | dofig | 31.25us | the good | arbitrary |

| Sercos III | 511 | 31.25us | the good | ring line |

| Ethernet / IP | dofig | ~ 1ms | the best | arbitrary |

I evaluated the level of Internet compatibility by the degree of support for the TCP / IP network protocols. The packets of each of the Ethercat, Profinet and Sercos III networks are transmitted in Ethernet frames and have their own Ethertype (as IP or ARP). Ethernet / IP, by contrast, uses IP, except for the case of ring topology, then it also uses its ethertype. Thus, Ethernet / IP is the most IT-oriented of many industrial Ethernet standards. This is its main feature, but this is also the main drawback - it is difficult to ensure real time with fast cycles. Then come Profinet and Sercos III, in which by design Internet traffic runs along the same wires, while they are not busy transmitting critical data. For example, in the profinet network, you can use IP, UDP, TCP, distribute addresses via DHCP (or use his younger brother - DCP ).

The most distant from IT is Ethercat, but it is also potentially the fastest. Ethercat, Profinet and Sercos III networks are distinguished by the fact that they have two classes of devices — master and slave (controller and device). Master can be implemented on a regular network card, and the slave card works a bit more cunning. It should read the incoming packet on the fly, insert its data into it and send it further (or back, if it is at the end of the Ethercat line). It turns out that it implements a MAC resembling a token ring.

I simplified a bit by describing how industrial networks can use network infrastructure. Of course, cables and connectors will work, as well as some switches (however, with them nuances are possible). But ordinary network cards and most importantly their drivers with deterministic cycles of tens of microseconds do not work. What are the usual requirements in numbers? You must be able to connect multiple devices in one network segment, exchanging small data packets (from units to hundreds of bytes) with a frequency of tens of kilohertz, and with guaranteed data delivery on time every cycle. The maximum frequency of 30 kilohertz means that the minimum cycle is 33 microseconds. Hence, in Profinet IRT and SERCOS III standards, the minimum cycle is defined as 31.25 microseconds. Transferring hundreds of bytes each cycle is up to 25 megabits per second per device. Industrial networks still live well on 100BASE-TX. The transition to 1 gigabit is just beginning, and mainly for reasons of reduced latency (the width of the "pipe", as I showed enough on a hundred megabits).

All vendors have a special card with a regular Ethernet phy transceiver, and a special adapter for implementing the higher layers of the corresponding network stack. There are also varying degrees of paid firmware with the implementation of these networks for FPGA Xilinx and Altera. Everyone knows that in addition to processors and chipsets, Intel produces network cards. The I210 (Springville) card was recently released, which features several features that allow you to implement a fast cycle fieldbus adapter on its basis.

What makes the Intel I210 particularly suitable for the implementation of industrial networks based on Ethernet phy? It has its own RT timer, available for reading and writing, and allowing to generate interrupts. This allowed to realize in the gland

IEEE 1588 / 802.1AS synchronization, which is included in the Profinet and Sercos III protocols. It also makes it possible to transmit frames by timer, which is useful for implementing any fieldbus protocol. 4 independent transfer queues and 4 per reception can be used to separate realtime and non-realtime traffic or to run multiple virtual machines (with VMDq).

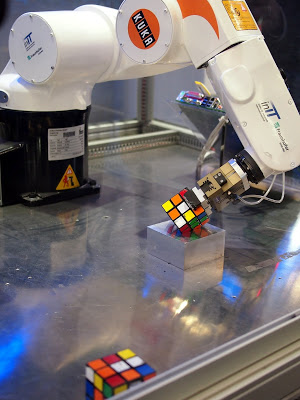

This iron companion, collecting Rubik's cubes, I photographed at the Intel exposition at Embedded World 2013 two months ago. It is controlled from the motherboard in the background, through the Profinet network, the Intel I210 network adapter and the Profinet IRT stack from KW-Software.

This iron companion, collecting Rubik's cubes, I photographed at the Intel exposition at Embedded World 2013 two months ago. It is controlled from the motherboard in the background, through the Profinet network, the Intel I210 network adapter and the Profinet IRT stack from KW-Software.I hope I gave the tax to technical details to the readers, and now I will be allowed to complete the post with a couple of common phrases. We in the IT industry are accustomed to hype - the annual emergence of a new technology that should turn the world around (cloud, web 2.0, etc.) There is also an industry hype - the Internet of things, M2M, etc. But I think that the fourth industrial revolution has a specific technical and economic basis. And you can participate in it. In the 70s-2010s there was such a common parental curse - you will learn poorly, go to vocational school, and then to the factory. But now, it seems, the work in the factory can again become sexy! (True, the factories will be completely wrong)

In addition to direct working experience (unfortunately, Ethernet / IP is not very common in Europe, so I never came across it and took data from Wikipedia), the post used data from two academic articles:

1. "Minimum Cycle Time Analysis of Ethernet Based Real-Time Protocols"

2. "The Final War: History or Short Break Between Battles?"

Source: https://habr.com/ru/post/176313/

All Articles