An inside view: the world around us - 2

Unexpectedly, a good selection of material still unpublished on Habré was discovered in the bins of the Motherland. Unfortunately, everything in one post did not fit - it is necessary to observe the limits of decency ?! Therefore, I offer to the attention of the respected Habra users a final couple of articles from the “Inside Look” series.

In the last article devoted to the world around us, it was given - perhaps not entirely successful - an example of photographs of paper, or rather napkins. The main problem turned out to be in charging the sample and, consequently, the poor quality of the photos, so I hasten to correct my mistake.

')

Paper

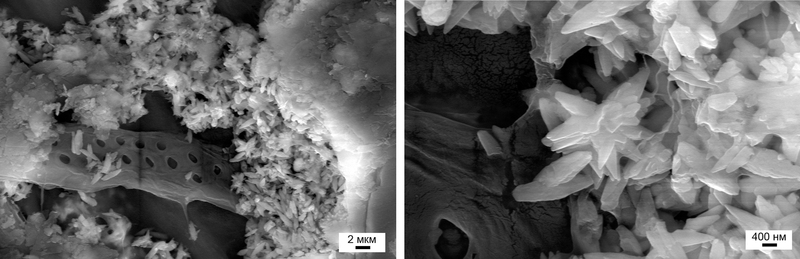

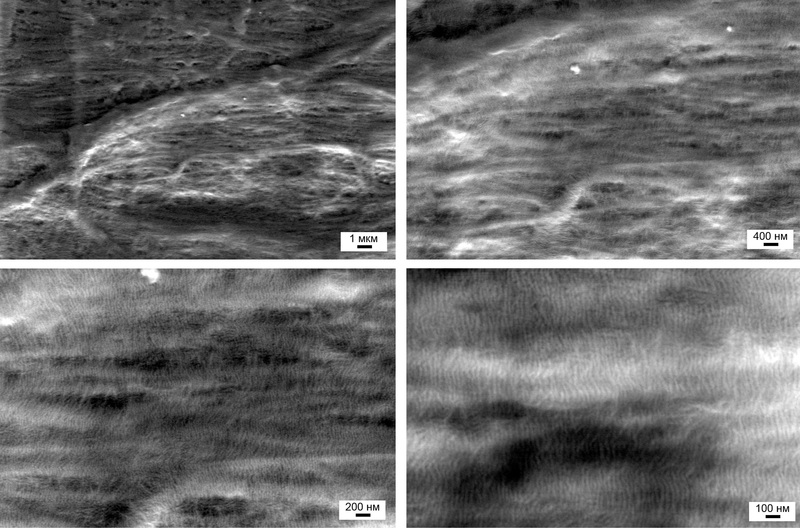

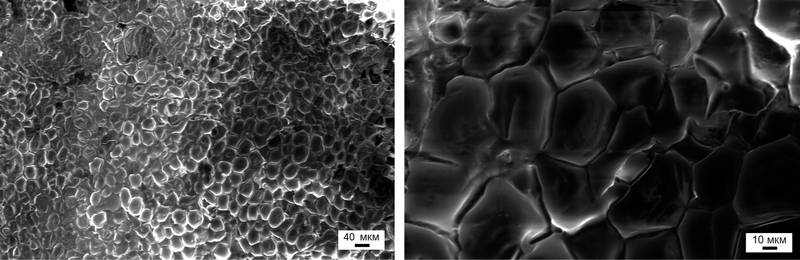

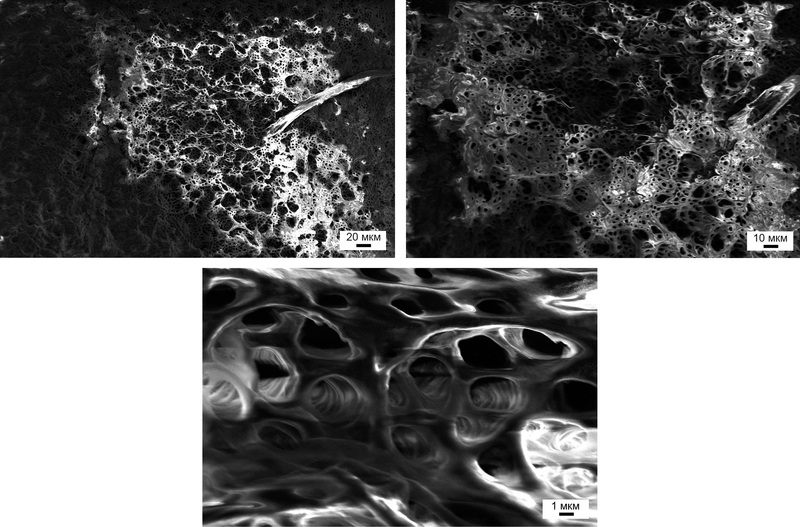

Spraying a 5-10 nm layer of chromium - below, in the bonus part of the article, it will be demonstrated how sputtering and etching with the help of plasma is done - has allowed a significant increase in the quality of the photographs obtained. It seems to me that no one doubts that paper is made from wood, but the only question is whether it is possible to understand a posteriori that it is made from organic matter. It turns out - yes, no problems:

Structures characteristic of wood: cellular structure and respiratory pores

Now we will try to repeat some analogue of the Nobel experiment - we rub with a regular pencil on the surface:

Perhaps it was just such stars who first saw Novoselov and Geim before tearing the graphene monolayer from the surface of the pencil with the help of an adhesive tape.

Indeed, the size of graphite particles is no more than a micron (~ 1/100 of the thickness of a human hair), and if you look at them with a transmission microscope, you can certainly see the layered structure.

What next? Hmm, let's stay in the carbon theme ...

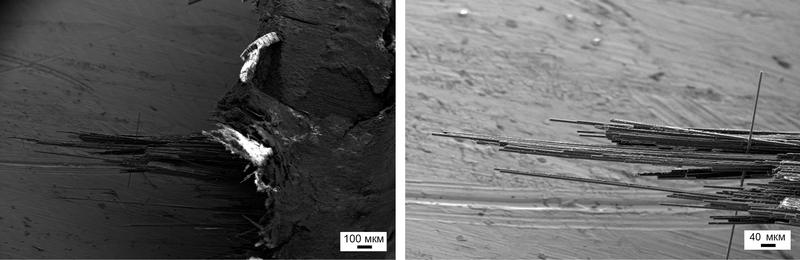

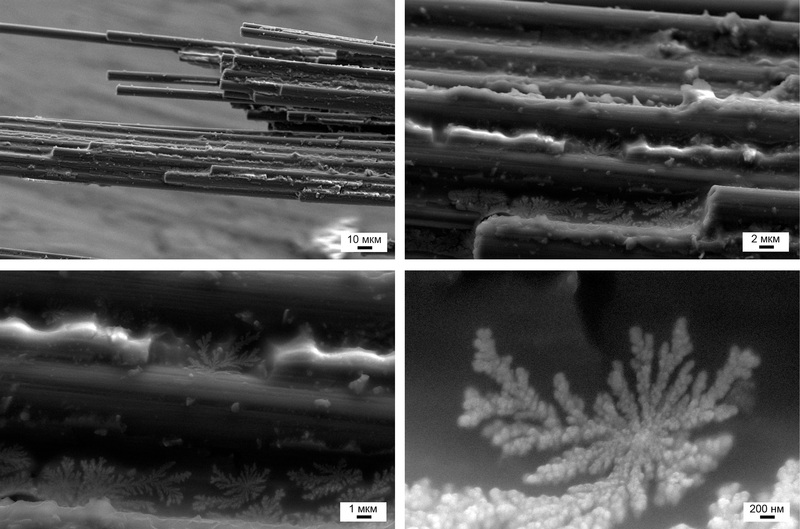

Carbon fiber

NB: At the request of atd, we change the “pre-prep” to a more correct “carbon fiber”.

What is carbon fiber ?! Good question…

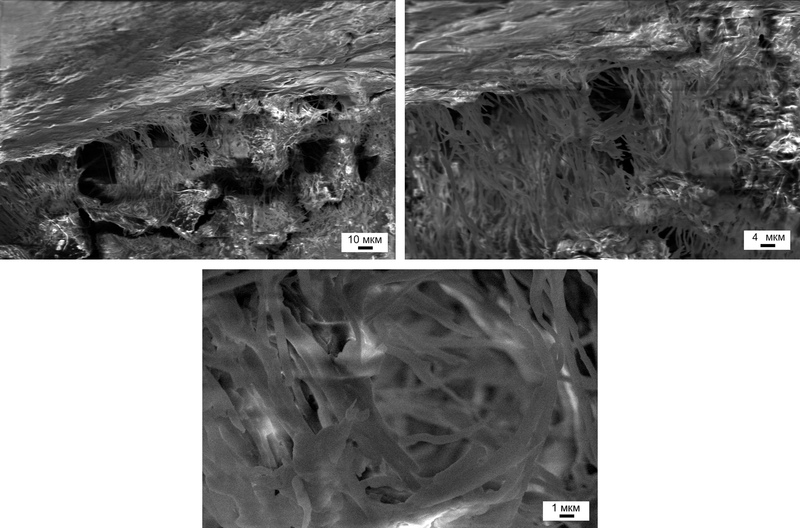

If you do not go far into the details, then imagine that ordinary fabric can be burned, but without air. Remove all volatile substances from the fabric, without subjecting it to oxidation. Typically, this procedure is performed at high temperatures under 1000, and sometimes even more degrees Celsius, in an inert atmosphere or in vacuum. The result is a fabric of the so-called carbon fiber. Individual pieces of fabric can be glued together, getting carbon fiber or one of its varieties - carbon.

Parallel and perpendicular layers of fabric with the corresponding direction of the fibers

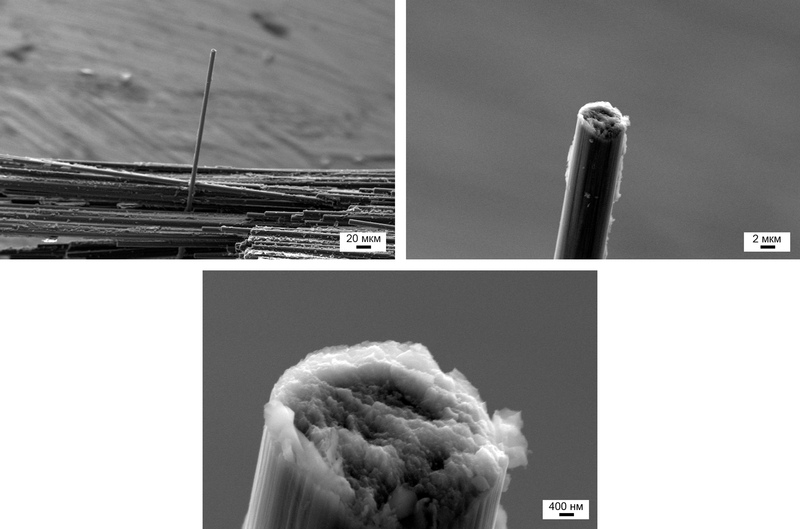

To complete the picture - one single fiber, stuck perpendicularly.

The range of application of such material is huge - from F1 cars to the latest generation aircraft.

Carbon sports cars (up to the intake manifold) are a reality. 83 Geneva Motor Show.

Once, my acquaintance, Sergei Lurie, broke a carbon - coated board in public - it did not work out. The board was stronger (yes, in the video shown was a little trick - the board worked for maximum rigidity).

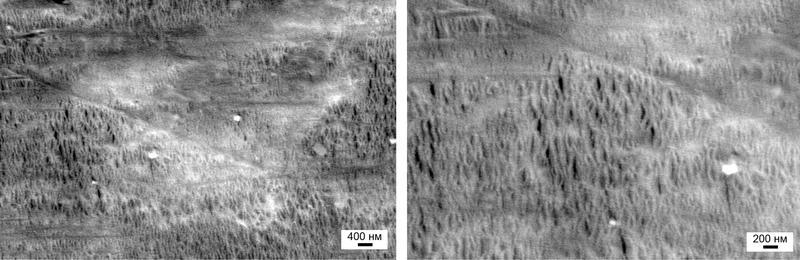

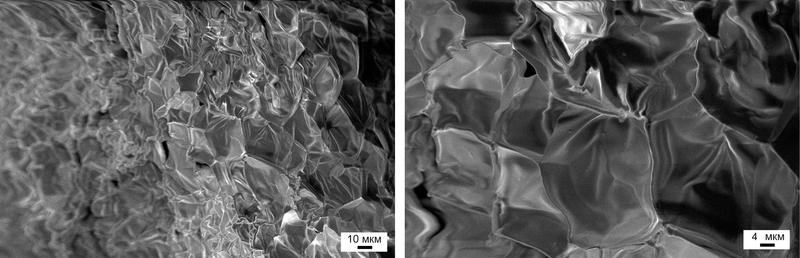

Inside the fiber is amorphous, that is, it has no crystalline structure, but it is so strong that it can withstand a tremendous load. By the way, notice that in the lower left figure to the right, scales are stuck to the fiber - most likely graphene:

Cross section of prepreg fiber

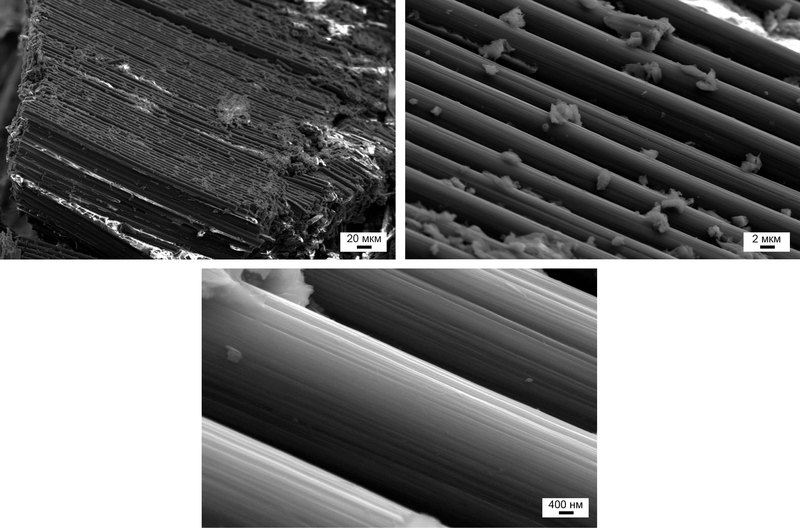

At first glance it seems that the surface of the fiber is smooth. But this is not entirely true, since a smooth surface has a worse adhesion compared to “structured”, as in this case:

"Nano" rough fiber - the best adhesive properties and it is impossible to imagine

Such nano-roughness allows the glue to better hold the fibers together. I must say, to get the scrapping, I spent about 30 minutes picking, breaking and mocking in every possible way a piece of prepreg, which was lighter than a credit card and had a thickness of only ~ 3 mm and a width of no more than 5-6!

Until now, this fact remains a mystery to me. This structure is observed on many heterogeneous samples of organic origin - and so is the same on the prepreg:

Insanely beautiful pattern, more like a fractal than anything else.

Next on the materials - polymers on the example of polyethylene and polypropylene.

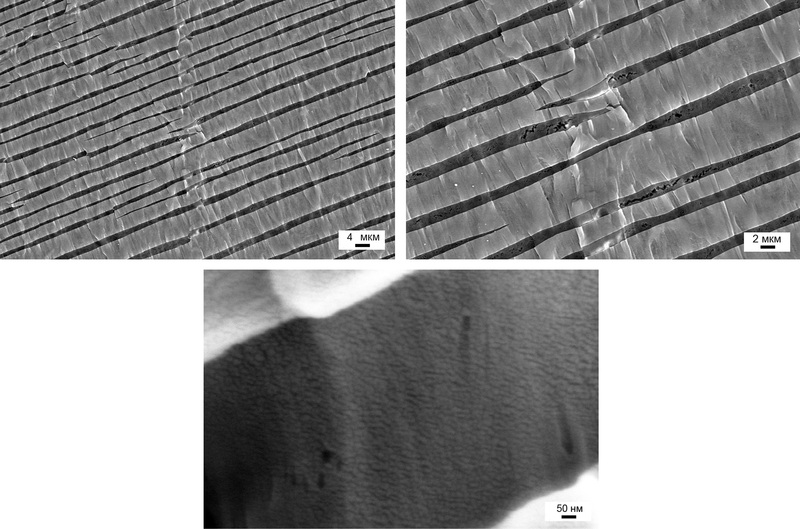

Polymers

Even though I know the details of the receipt of certain materials, but in order not to violate any know-how and secrets, I deliberately did not disclose them and did not disclose them. So it will be with our next guest - polyethylene.

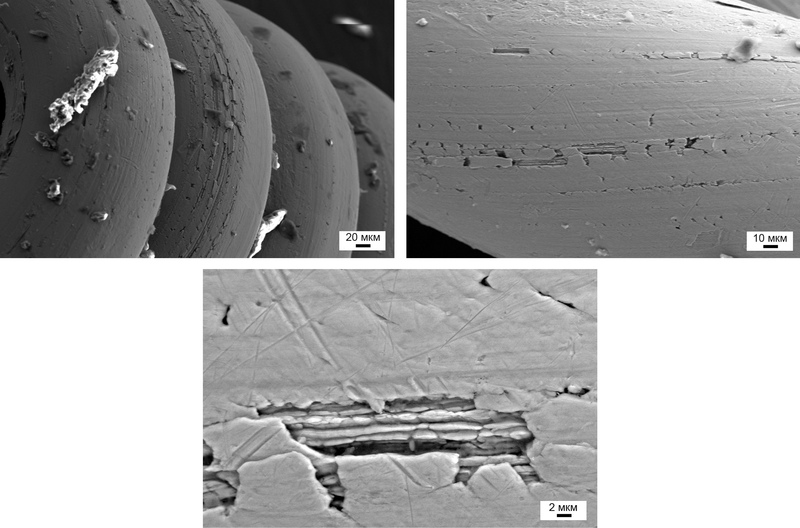

Let's start with simple - polyethylene (PE). Initially, a layer of metal was applied to a thin film of polymer to improve conductivity, and then deformed - stretched.

PE - dense polymer film

Yes, in the lower photo you can distinguish individual domains - this is amazing, their size hardly falls short of a couple of tens of nanometers. According to the generally accepted theory, polymers such as PE are composed of “crystalline” (quoted, since these are not exactly crystals, in the usual sense of the word for physicists) and amorphous regions between them.

If in some place the deformation for some reason turns out to be a little more than that, then you can see the following picture:

The same sample of polyethylene, only the deformation was slightly more than the

For comparison. There is a huge class of so-called hard-elasctic polymers, that is, such polymers that have high elasticity. For example, specially prepared polypropylene (PP), which is used in chemistry as a replacement for glass and can withstand loads up to 20,000 g.

An example of PP, which is stretched to form necks with a diameter of several tens of nanometers

Further, PVP or polyvinyl propididone , the range of application of which is extremely wide: from the component of adhesives to the buffer for the extraction of DNA. These photos show a cross section of the polymer:

Cross section pvp

By the way, a good example for fans of various holivars, especially on the subject of Russian and Western production.

So, there is polyethylene, which with the help of a special machine is pulled out of a certain volume. The machine is called an extruder, and the process itself is extrusion . The extrusion axis on all photos is horizontal. Machines in factories around the world are more or less the same - they are supplied, as in a recent post about Applied Materials , several firms.

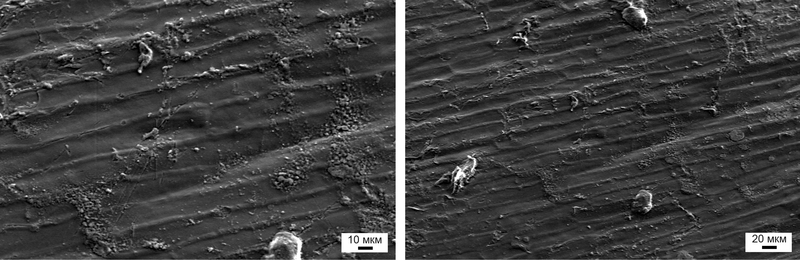

Here is an example of western production:

PE western production

Lamellae neatly packed, "holes" is practically not observed. Just an ideal film for packaging, in particular, in the food industry.

The same film produced in Russia:

PE Russian production

The naked eye can see that the process needs to be adjusted: reduce the pressure or increase the temperature of the polymer, and maybe it is in raw materials?

For a minute from the matter of non-living, we turn to the favorite delicacy of all moviegoers - popcorn.

Popcorn

What can be said about pop root? These are dried corn kernels that have been heated in oil, and they, in the truest sense of the word, exploded. For example:

The surface of one grain of popcorn looks discreet:

Corn grain surface

Whereas inside the cells are hidden in a "cubic style." Most likely, they had some more or less spherical or elongated shape before the moment of drying, but only cubes remained after it:

Hidden inside the cubic world of dried cells

Of course, the insides of the cell can not just take and evaporate in a matter of fractions of a second, even if they are heated to a high temperature, such as in boiling oil:

Cells of cooked popcorn are more like spherical

However, there are areas where only thin walls of cells remain:

We are almost memory of cells by rising ...

So ... so that you can still show from the diversity that surrounds us?

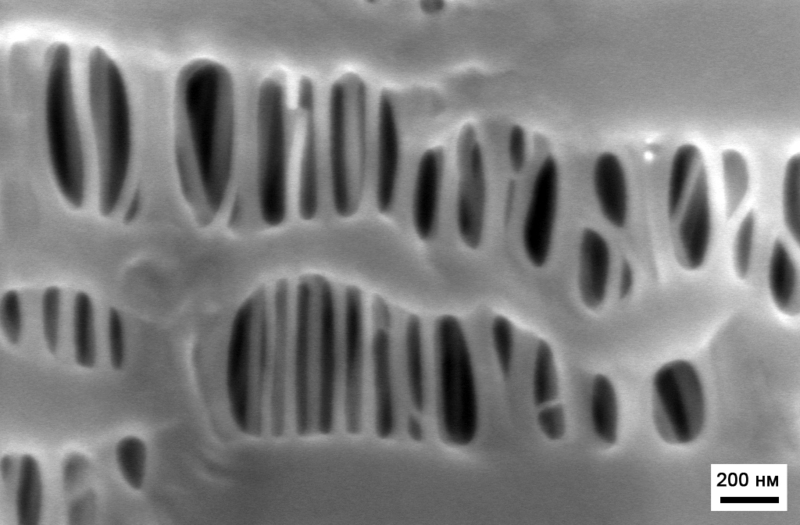

Teeth

Yes, many children in the Soviet Union probably still have a pair of milk teeth, so I think it would be interesting to look inside the tooth.

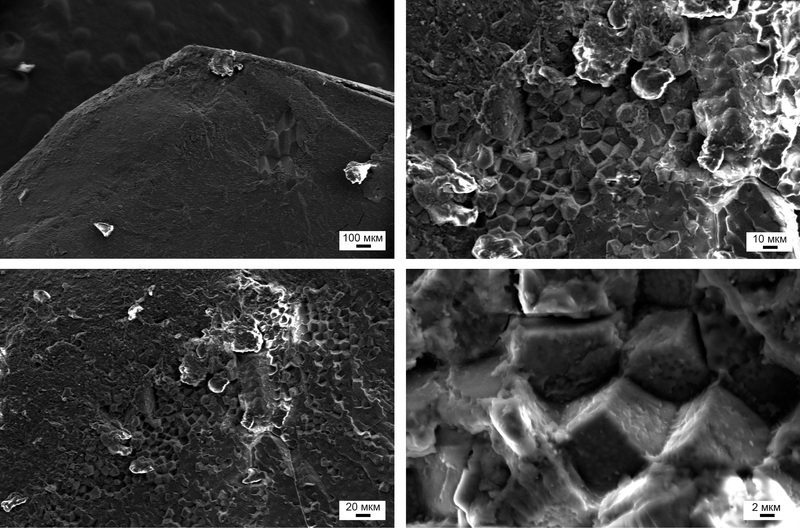

So, what do we know about the structure of teeth? In short, everything is simple. The main dental tissue is dentin, which is protected from aggressive environment by enamel, and is fed through a special cavity called pulp.

The structure of the human tooth ( Source )

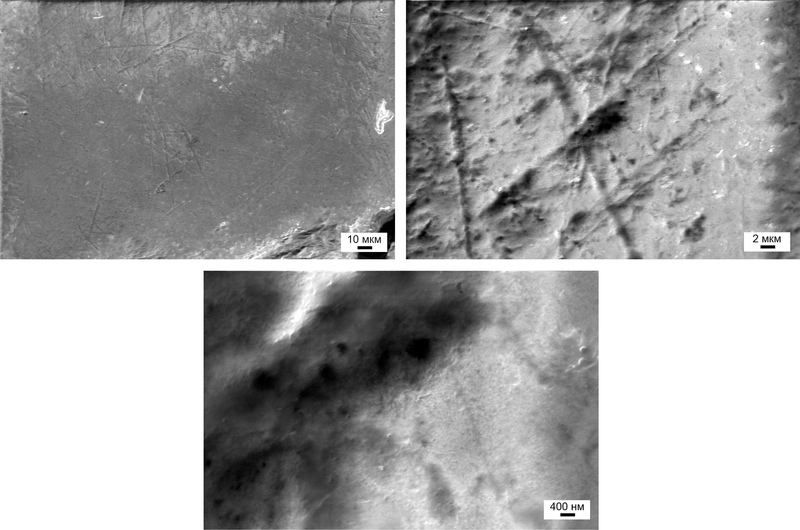

Not sure exactly whose tooth it was - maybe even mine, but using it to its fullest - this is definitely. Why are only enamel furrowed furrows:

Tooth surface

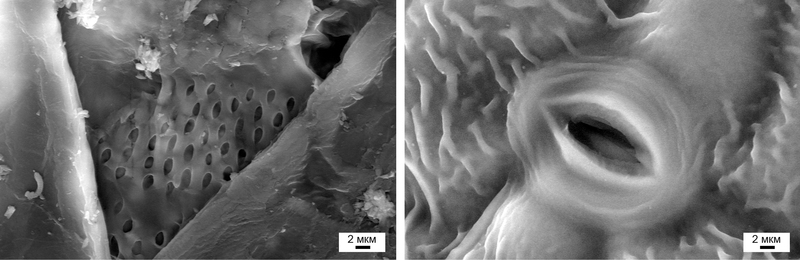

If you look at the tooth from the inside, you can see that dentin is strikingly different from dense enamel. This is a honeycomb structure that consists of two types of pores and that will fill almost the entire space inside the tooth itself, leaving only a small channel for the blood capillaries and the nerve.

Dentin micrographs

2 types of porosity in dentin: pores of tens of microns in size and very small pores of several micrometers

It is worth noting that similar channels, only larger ones can be easily distinguished at the cut of almost any flower - a truly unique invention of Nature. In the plant, they are used for the transport of nutrients, in the human tooth - similarly, but few people think that they are guilty of excessive sensitivity to heat, cold, and acidic substances. Imagine if the enamel in some place "swept" (whether it is caries or any other, more serious disease / damage), then through the channels, acidic products are in direct contact with the pulp and nerve. And it already causes discomfort.

By the way, let's talk about the unpleasant - about caries. Everyone knows that caries is a microorganism that feeds on the remains of food and lives on the surface of our teeth; however, few people have met face to face with this enemy of modern man. Please love and favor - caries:

The area of the tooth where caries lived and worked on ...

It is possible that in those 10–15 years that the teeth lay on the shelf, the microorganisms themselves disappeared one way or another, but the consequences of their work on the tooth surface remained, especially noticeable with an electron microscope - even the most insignificant areas.

And the strings will beat up at today's celebration of life ...

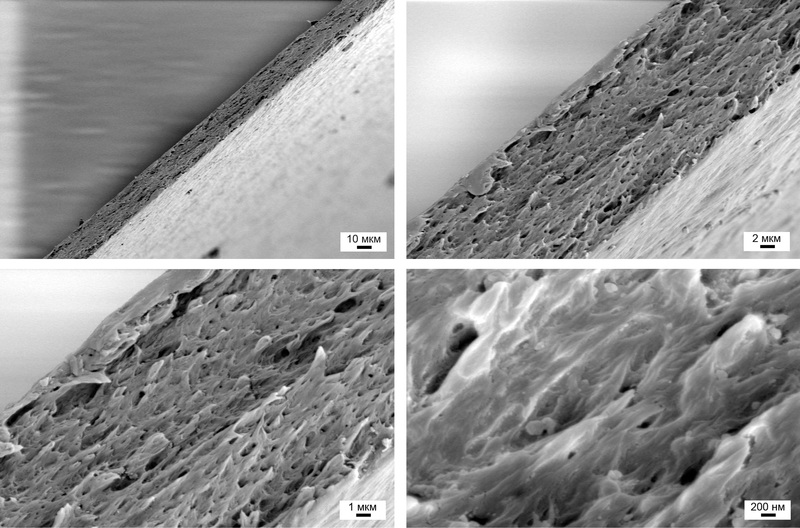

String theory

About a year ago, GreyCat , responding to my call for new ideas and patterns for cutting, issued a whole package of the most diverse strings to the mountain - up to the thickest bass.

At first I wanted to write a separate post about the strings, suggesting that I could find something interesting in them, as was the case with other objects, samples. However, something went wrong from all the accumulated material I will describe only a few characteristic and instructive examples.

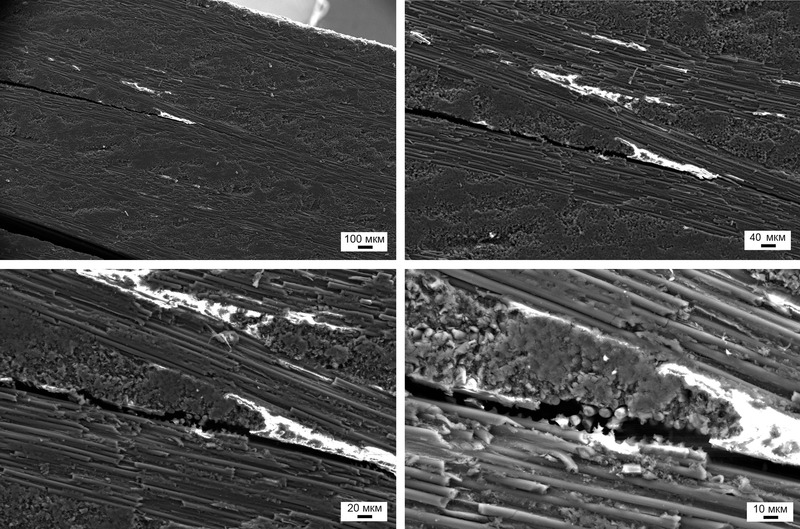

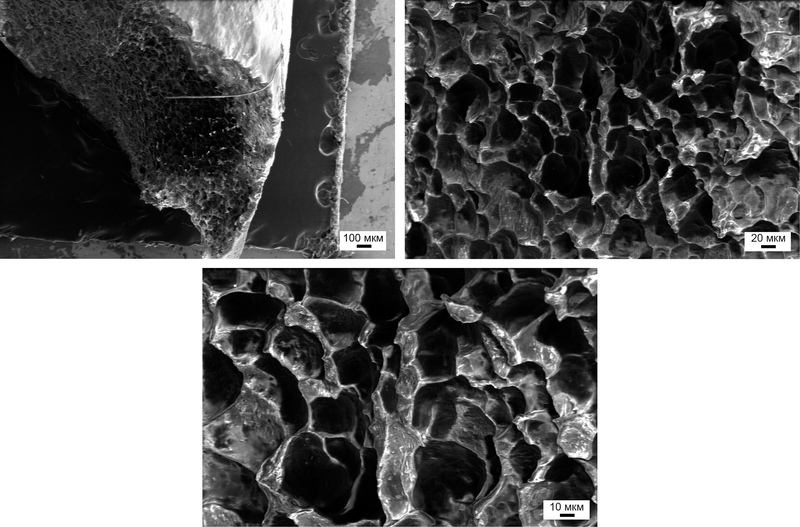

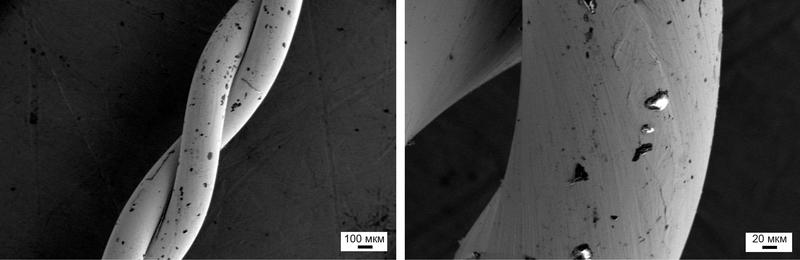

Along its entire length, the string looks relatively smooth, without any significant defects:

Plain string with a diameter of 2-3 human hairs

The first thing that catches your eye is the deformation of the strings and their surfaces at the ends, where they are twisted in one way or another to be fixed on the neck or deck, for example. As a result, you can easily detect the lines caused by such a twisting of the metal:

Deformation of the smooth surface of the strings when twisting

If the deformations are large, then the internal structure of the strings will open:

Slightly more force, a bit steeper than the angle and deformation of the string already leads to completely different consequences.

The main question, of course, is such a layered structure the result of a deformation or a feature of the technological process of production ?! Unfortunately, I do not have an answer to this question.

The cut also looks very, very funny and partly resembles the layers in the photograph of the deformed string above:

String cut - flowing lava music

And the last shot is elegance itself. Kai had to put not the word eternity, but twist the strings:

Eternity...

On this, perhaps, everything - all the strings look the same, apparently made by the same manufacturer and from the same material.

Bonus number one

A great variety of materials is used as heating elements. For micro furnaces (for example, in scientific devices), an alloy of platinum and rhodium (10–15%) is used, the wire from which is sufficiently flexible — unlike the fragile platinum. However, the constant heating of the cooling, especially in the presence of phosphates leads to the recrystallization of the alloy and in the end result in a short circuit.

And once this day has come:

Recrystallized platinum wire

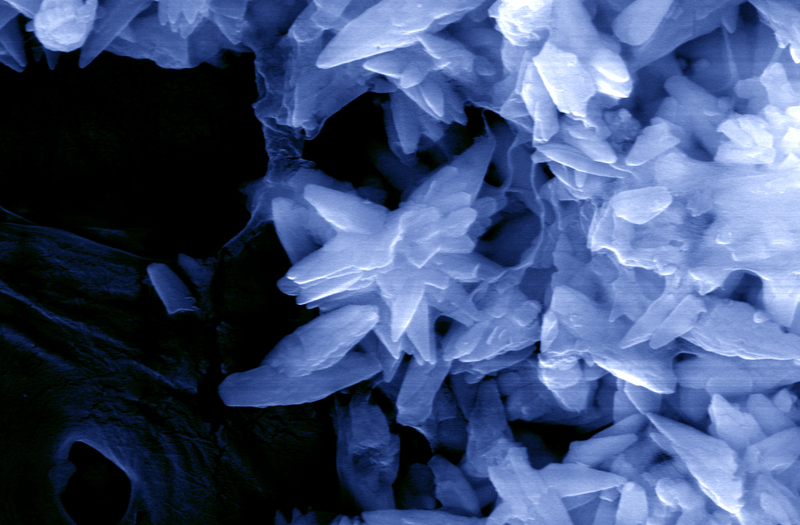

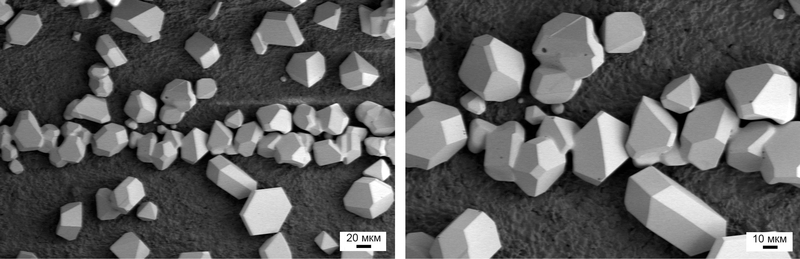

Some of the crystals have such a regular shape - apparently formed long ago that sometimes it is impossible to imagine that it was once a wire:

Platinum microcrystallites on the surface of a ceramic part

Bonus number two

What is plasma etching ?! Very simple. We take the cathode, the anode, put them in the chamber from which we pump out the air, and add gas to taste (argon, oxygen, etc.). Then, between the cathode and the anode, we pass a high-frequency current, which actually creates the plasma.

Many probably have such a toy at home, working on the principles of Tesla's transformer :

Example of peaceful use of plasma ( Source )

Since the particles formed in the plasma have a high reactivity, they effectively clean almost any surface from “nano” impurities.

Magnetron sputtering is a bit more complicated. It is necessary to add a magnetic field to the electric field to keep the plasma at the cathode. This is done so that the plasma attacks the target with gold, chromium, nickel or some other metal or not metal, pulling individual atoms out of the target and creating a cloud of low-energy particles flying to the cathode.

The principle of operation of the installation for magnetron sputtering of coatings ( Source )

And now the promised video, how it all looks and works on living examples (due to poor color rendition, the oxygen plasma turned out to be blue, although in fact purple):

NB! I want to thank Clevik for the cool selection of old processors. I think that I will find them a worthy use and someday I will write a review about them.

First , the full list of published articles on Habré:

Opening the Nvidia 8600M GT chip , a more detailed article is given here: Modern chips - a view from the inside

An inside look: CD and HDD

An inside look: LED bulbs

An inside look: the LED industry in Russia

An inside look: Flash and RAM

An inside view: the world around us

Inside View: LCD and E-Ink Displays

An inside look: matrix digital cameras

An inside look: Plastic Logic

An inside look: RFID and other tags

An inside look: postgraduate study at EPFL. Part 1

An inside look: postgraduate study at EPFL. Part 2

An inside view: the world around us - 2

An inside view: the world around us - 3

View from the inside: the world around us - 4

An inside look: 13 LED lamps and a bottle of rum. Part 1

An inside look: 13 LED lamps and a bottle of rum. Part 2

An inside look: 13 LED lamps and a bottle of rum. Part 3

An inside look: IKEA LED strikes back

An inside view: are Filament lamps good for you?

and 3DNews:

Microview: a comparison of modern smartphones displays

Secondly , in addition to the blog on HabraHabr , articles and videos can be read and viewed on Nanometer.ru , YouTube , and Dirty .

Thirdly , if you, dear reader, liked the article or you want to stimulate the writing of new ones, then act according to the following maxim: “pay what you want”

Yandex.Money 41001234893231

WebMoney (R296920395341 or Z333281944680)

Sometimes briefly, and sometimes not so much about the news of science and technology, you can read on my Telegram channel - welcome;)

Source: https://habr.com/ru/post/174239/

All Articles