Once again about inventory management

The other day I had talks with two different companies. The main topic of both negotiations is inventory management. In both cases, they tried to convince me that the methods of Goldratt's Theory of Constraints do not suit them.

And it happened every time from the banal ignorance of how these methods work.

First in the meeting room one person from the company. Directly the one who invited us.

Excerpts from the dialogue:

“I understand correctly that the key topic of the negotiations is stocks?” I ask.

- Yes. We have been dealing with this issue for a long time and are looking for a solution. We heard about the decision of company X (I will not name it in this post), the peaks are very nicely smoothed out there, everything is planned. They have been using this system for a year now. Very good, effective system.

- How have the stocks of this company changed over the last year?

- uh, I don't know. What for do you need it?

“Why then do you say the system is effective?” It seems to me that the effectiveness of any inventory management system should be assessed not by how it smoothes out the peaks, but by how the stocks have changed. If they have fallen by an amount that exceeds the investment in this system, and the volume of sales and demand satisfaction have not been affected, then yes, the system is effective. Everything else is a game of numbers and beautiful graphs.

- HM interesting. Now people will come to our meeting room, you don’t tell them that a decrease in stocks is the main criterion of the work of such a system. Low stocks are not always good.

- Not understood. And what, any other criteria of efficiency? And what about low stocks in more detail?

- Well, if, for example, your reserves grow, then banks will give you loans with great pleasure.

I sigh. It says, not some student on the Internet forum, but a person from business. Thank God that IT-director. Uffff, I sigh with relief that this is not a logistics director.

Then three more people enter the meeting room. One of which is the person who is directly responsible for the stocks and we continue the dialogue.

- I watched your site, I know about the methods of the Theory of Constraints, but they do not suit us. We have our own way.

- Why?

- Because we regularly have strong jumps in shipments.

- So. And why the Theory of Constraints does not suit you?

- Because "buffers" will not solve this problem.

- This problem should not be solved by buffers. What kind of horse racing can you tell us in more detail?

- Yes, these are wine promotions that take place regularly.

- Are the dates of these shares known? The nomenclature and the required quantity is known?

- Yes of course.

- Then you simply enter this action into the system, indicate what you need and when, and send it to the purchase. The system builds in your need for priorities and logistics will take your share when needed. Buffers are responsible for other things.

I specify. Constraint Theory is not just buffer management. These are deliveries “under the order”, “under the plan”, name it as you please.

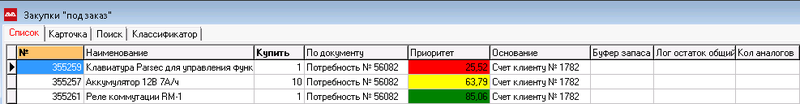

In the picture I showed how it looks in reality. Items where something is indicated in the "Base" column are target deliveries by a certain date. Where nothing is indicated in the base - these are deliveries under the “buffer”.

')

What is surprising, this company has already turned to us about a year and a half ago. Then at the talks, I said that in such a company, implementing such a system in less than a year would be almost impossible. The company has 1,000 people. 80% of the time the project - it will delay the company itself, its bureaucracy and mess. I said as it is. However, the people involved in the implementation of 1c, who promised that they would implement in three months, also participated in the negotiations. They were chosen. Moreover, they said that everything is ready for them and it is necessary to “finish” quite a bit.

Apparently "a little bit" was delayed ... And so much so that now another person from this company turned to us, tired of expecting "a little bit".

However, we still called the one who applied a year and a half ago and asked for comment.

Well, the conversation turned to inventory management. What actually fight and a half years, those who remained "to finish a little bit." True, it is not clear that they are left to finish. Because, as far as I know, in the basic configuration 1c there is generally no inventory management system . But I can be wrong.

- The Theory of Constraints does not suit us. We will work on sales plans.

- Why do you think that TOC does not suit you?

- Because we have a very long delivery cycle, goods can be delivered for four months each. And we'd better incur losses from the fact that there is a lot of unsold stock, than to get a situation when a client comes in and we don’t have what he needs. Therefore, we make sales plans and buy them.

- But after all plans immediately cease to be respected. What are you doing about it?

- These are our risks. Unfortunately, this is so.

Further content of the dialogue is no longer important. Another thing is important. People have some completely incomprehensible stereotypes, and they believe that they have some special way, and they think that they will come up with a stock management system for their particular way. You have to be Goldratt to come up with such a system. But Goldratt was already there, and there is no need to reinvent the wheel. And his system is already used by thousands of enterprises around the world, and even Toyota, which developed the kanban, recognizes that Goldratt methods work more correctly.

For example, in the case of intermittent, intermittent demand, where kanban works much worse.

So, consider a long supply cycle. If you can carry goods to order and your customers agree to this, then there are no questions at all. This is done as I described above and as shown in this video .

If you want to protect yourself from the situation when the client comes, but there is no product, then the only solution is the stock buffer. The question is only in its size. I also told about this in the video. And do not be afraid that the system will immediately begin to fill the buffer, and you will get surplus (however, even with a full buffer, this is not surplus). It will not happen. Because Goldratt is a management genius. He developed a self-regulating system. Here you set the buffer equal to 100pcs. When your reserves drop to 90pcs, the system will actually create a request for the replenishment of 10 pcs. And by this the Goldratov method theoretically differs little from the traditional one. Differences further. In the traditional scheme, this application will fall into the procurement and logistics will begin to deal with it. And if you apply the Theory of Constraints, then, most likely, this application will not be a priority, because the buffer state is quite a nothing. Therefore, no one rushes urgently to provide this application. This is the key difference between Goldratt’s methods and classical methods. And therefore stocks will always be in perfect order.

And it happened every time from the banal ignorance of how these methods work.

Negotiations №1. Vintorgovaya company.

First in the meeting room one person from the company. Directly the one who invited us.

Excerpts from the dialogue:

“I understand correctly that the key topic of the negotiations is stocks?” I ask.

- Yes. We have been dealing with this issue for a long time and are looking for a solution. We heard about the decision of company X (I will not name it in this post), the peaks are very nicely smoothed out there, everything is planned. They have been using this system for a year now. Very good, effective system.

- How have the stocks of this company changed over the last year?

- uh, I don't know. What for do you need it?

“Why then do you say the system is effective?” It seems to me that the effectiveness of any inventory management system should be assessed not by how it smoothes out the peaks, but by how the stocks have changed. If they have fallen by an amount that exceeds the investment in this system, and the volume of sales and demand satisfaction have not been affected, then yes, the system is effective. Everything else is a game of numbers and beautiful graphs.

- HM interesting. Now people will come to our meeting room, you don’t tell them that a decrease in stocks is the main criterion of the work of such a system. Low stocks are not always good.

- Not understood. And what, any other criteria of efficiency? And what about low stocks in more detail?

- Well, if, for example, your reserves grow, then banks will give you loans with great pleasure.

I sigh. It says, not some student on the Internet forum, but a person from business. Thank God that IT-director. Uffff, I sigh with relief that this is not a logistics director.

Then three more people enter the meeting room. One of which is the person who is directly responsible for the stocks and we continue the dialogue.

- I watched your site, I know about the methods of the Theory of Constraints, but they do not suit us. We have our own way.

- Why?

- Because we regularly have strong jumps in shipments.

- So. And why the Theory of Constraints does not suit you?

- Because "buffers" will not solve this problem.

- This problem should not be solved by buffers. What kind of horse racing can you tell us in more detail?

- Yes, these are wine promotions that take place regularly.

- Are the dates of these shares known? The nomenclature and the required quantity is known?

- Yes of course.

- Then you simply enter this action into the system, indicate what you need and when, and send it to the purchase. The system builds in your need for priorities and logistics will take your share when needed. Buffers are responsible for other things.

I specify. Constraint Theory is not just buffer management. These are deliveries “under the order”, “under the plan”, name it as you please.

In the picture I showed how it looks in reality. Items where something is indicated in the "Base" column are target deliveries by a certain date. Where nothing is indicated in the base - these are deliveries under the “buffer”.

')

Negotiations №2. Production and distribution.

What is surprising, this company has already turned to us about a year and a half ago. Then at the talks, I said that in such a company, implementing such a system in less than a year would be almost impossible. The company has 1,000 people. 80% of the time the project - it will delay the company itself, its bureaucracy and mess. I said as it is. However, the people involved in the implementation of 1c, who promised that they would implement in three months, also participated in the negotiations. They were chosen. Moreover, they said that everything is ready for them and it is necessary to “finish” quite a bit.

Apparently "a little bit" was delayed ... And so much so that now another person from this company turned to us, tired of expecting "a little bit".

However, we still called the one who applied a year and a half ago and asked for comment.

Well, the conversation turned to inventory management. What actually fight and a half years, those who remained "to finish a little bit." True, it is not clear that they are left to finish. Because, as far as I know, in the basic configuration 1c there is generally no inventory management system . But I can be wrong.

- The Theory of Constraints does not suit us. We will work on sales plans.

- Why do you think that TOC does not suit you?

- Because we have a very long delivery cycle, goods can be delivered for four months each. And we'd better incur losses from the fact that there is a lot of unsold stock, than to get a situation when a client comes in and we don’t have what he needs. Therefore, we make sales plans and buy them.

- But after all plans immediately cease to be respected. What are you doing about it?

- These are our risks. Unfortunately, this is so.

Further content of the dialogue is no longer important. Another thing is important. People have some completely incomprehensible stereotypes, and they believe that they have some special way, and they think that they will come up with a stock management system for their particular way. You have to be Goldratt to come up with such a system. But Goldratt was already there, and there is no need to reinvent the wheel. And his system is already used by thousands of enterprises around the world, and even Toyota, which developed the kanban, recognizes that Goldratt methods work more correctly.

For example, in the case of intermittent, intermittent demand, where kanban works much worse.

So, consider a long supply cycle. If you can carry goods to order and your customers agree to this, then there are no questions at all. This is done as I described above and as shown in this video .

If you want to protect yourself from the situation when the client comes, but there is no product, then the only solution is the stock buffer. The question is only in its size. I also told about this in the video. And do not be afraid that the system will immediately begin to fill the buffer, and you will get surplus (however, even with a full buffer, this is not surplus). It will not happen. Because Goldratt is a management genius. He developed a self-regulating system. Here you set the buffer equal to 100pcs. When your reserves drop to 90pcs, the system will actually create a request for the replenishment of 10 pcs. And by this the Goldratov method theoretically differs little from the traditional one. Differences further. In the traditional scheme, this application will fall into the procurement and logistics will begin to deal with it. And if you apply the Theory of Constraints, then, most likely, this application will not be a priority, because the buffer state is quite a nothing. Therefore, no one rushes urgently to provide this application. This is the key difference between Goldratt’s methods and classical methods. And therefore stocks will always be in perfect order.

Source: https://habr.com/ru/post/172899/

All Articles