Organization of power and low-current wiring in office premises

Quite often, when moving to a new office, one has to face the need to build an electricity supply network and SCS for employees' workplaces. This applies not only to premises in new buildings, but also to offices that have already been leased and require redecoration with full replacement or radical modernization of engineering networks.

As a rule, for the organization of power and low-current wiring, you have to choose between the following options:

- Hidden wiring in brick / concrete walls;

- Hidden wiring in plasterboard partitions;

- Hidden wiring under the raised floor;

- Open electrical wiring in plastic mini-channels;

- Open wiring in plastic wiring ducts.

')

Consider each of these options in more detail.

Concealed wiring in brick / concrete walls

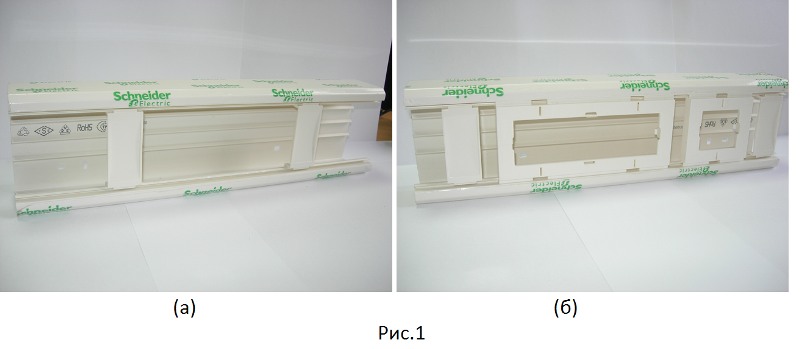

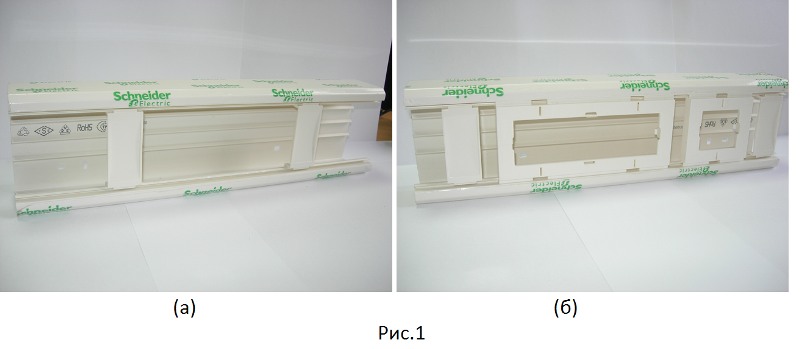

The organization of the strobe and holes for the installation boxes (podozetnikov) - the process is time-consuming and very expensive, requiring the use of specialized tools (Fig. 1). In addition, it is tied to the phasing of the finishing and general construction works - this increases the total cost. In many cases, in order to save power cables and cables, the SCS should be bundled into one penalty, which can not but affect the quality of the signal transmitted over a twisted pair.

This way of organizing the wiring makes its modernization or relocation virtually impossible, which is unacceptable for a modern office. The weak link is also maintainability and protection of wiring from damage: for example, if someone decides to screw the screw for the picture. The process of installing power outlets, which requires considerable experience and skill, is also very lengthy.

The only advantages of this approach are the long service life of the electrical accessories (due to the rigid fixation of the installation boxes) and the aesthetic look. It should be noted that the last factor is relevant only in the management offices.

Hidden wiring in plasterboard partitions

This is the most common wiring arrangement solution, relatively inexpensive and quick to implement (Figure 2). However, it is also imperfect, since it is tied to different stages of general construction. Upgrading and moving sockets is also not always possible, because sometimes pulling a cable through vertical and horizontal profiles is very difficult. In this case, you have to cut holes in the wall, putty them and repaint the whole wall again. In addition, drywall - not the best material for fixing installation boxes (podozetnikov). Over time, it will crumble and the socket block will begin to play, and in some cases it may just fall out of the wall. In addition, after a few years of operation it will be difficult to guarantee an aesthetic appearance.

Hidden wiring under the raised floor

Raised floor is most often used in open space offices and is extremely rare when using desk space organization. And in the first case, laying cables under the raised floor and installing sockets in the floor "hatches" or columns is often the only possible way to organize workplaces. If the raised floor has not yet been mounted, or there is a possibility of dismantling individual plates, the cost of installing cable routes is minimal. The bulk of the time is spent on installing floor hatches.

If the office has a mixed layout of "open-space + cabinets", it makes sense to install outlets in partitions or wiring boxes. This is due to the fact that the use of hatches has several disadvantages. The main ones are:

- The high cost of hatches and short service life with active mechanical action;

- The inconvenience of operation when it is necessary to connect / disconnect power cords and patch cords;

- Hard binding to the location of the tables. In addition, when the table is even shifted by 20-40 cm, there is a risk of simply locking the flap (Fig.3).

Problems may arise when adding new jobs. Plates of raised flooring are often plastered with carpet tiles, while the dimensions and grid of laying the plates differ. As a result, the main advantage of the raised floor is lost - the ability to access the networks laid under it. In such cases, you can use holes for already mounted hatches in slabs for cable pulling, which does not always lead to the expected result. The problem can be solved by moving the flap by 2-3 meters, which usually does not cause much difficulty.

In general, cable laying under the raised floor and the use of hatches and columns for the organization of jobs is a very convenient and flexible solution. The only reason that may force it to be abandoned is the high cost of the raised floor itself.

Open electrical wiring in plastic mini-channels

This is the easiest, relatively fast and inexpensive option for wiring for a small office. True, the installation of a new workplace will take less time than moving the old one. Just as with the penalties, the problem arises of the joint laying of power and information cables. From the point of view of appearance, such a solution seems to be budget and rather forced, therefore, it is not very advisable to use it for networking from scratch.

Open wiring in plastic wiring ducts

This option can be called the best solution to date, both in terms of cost and time of implementation. It can be said, for the sake of its coverage, this article was conceived. Therefore, we will focus on this method in more detail.

The attitude to plastic cable channels in the domestic market is, to put it mildly, skeptical. The majority of ordinary citizens associate it with a forced measure that is disfiguring the premises. And this is despite the fact that the tiled suspended ceiling, which has already become an indispensable element of the office, can hardly be called a beautiful solution. But engineering networks are laid behind the suspended ceiling, with its help it is possible to hide beams and the ceiling levels drops, to place lamps in it. This is a simple and inexpensive solution that provides ample opportunity.

The situation with wiring channels is approximately the same. They provide:

- Quick installation in one, maximum two stages;

- Ability to move jobs;

- Quick and easy organization of new jobs;

- Reliable fixation of power and information outlets;

- Reliable cable protection against accidental damage;

- Ability to separate power and low current wiring;

- The ability to quickly and without damage to dismantle both the cable channel and cable lines;

- Long service life.

Installation of boxes made on the finished wall, often already painted. This avoids dependence on the construction work and splitting the installation process into several stages. Two experienced installers, if necessary, can install from 60 to 100 meters of the box per day, including laying the cable. Moving the workplace (for this purpose, a cable reserve of 1.5-2 m is left in the box) will take no more than 15-20 minutes. Adding a new one will be connected only with the dismantling / mounting of the box cover, cable laying and mounting of sockets. You can safely drill the walls for paintings, shelves, etc. The box is always in sight and you will have no fear of breaking the cable.

To ensure long-term operation of the wiring and decent appearance of the office, it is necessary to carefully select the manufacturer. At the end of 2012, Schneider Electric, one of the world leaders in electric power management equipment, entered the domestic cable channel market. The company introduced the Ultra system, which includes solutions based on wiring ducts and mini-channels.

The main advantages of Schneider Electric are the cost, high quality of components and the availability of its own frames and sockets of 45x45 mm format, which ensures compatibility with sockets of most manufacturers of SCS (TE Connectivity, Panduit, Systimax, Molex, R & M, Brand-Rex, etc.).

Schneider Electric cable channels are made of self-extinguishing PVC, free of unhealthy lead and cadmium additives. Products are certified and fully comply with Ukrainian standards of fire safety.

Now we will take a closer look at the system components and installation steps.

Figure 5 (a) shows the cable box 101x50, without a cover with mounted cable holders. They are installed every 1.5 m on straight sections of the box and on each internal, external or flat turn, ensuring fixation of the cable.

In Fig. 5 (b), you can see mounted calipers for mechanisms of 45x45mm format. As is the case with cable holders, installation is done by simply “snapping” into special grooves.

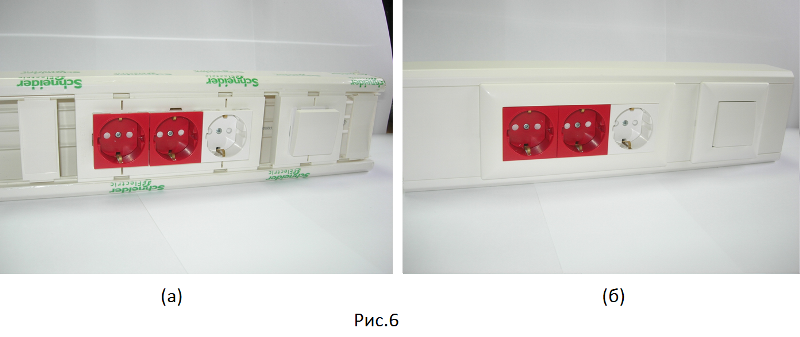

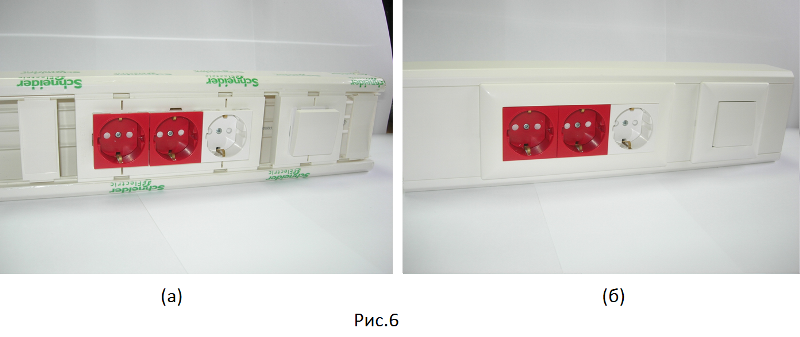

Figure 6 (a) shows mounted power outlets and a switch. Figure 6 (b) shows the ready-for-use panel with the mounted box cover, frames and protective film removed.

Figure 7 (a), (b) shows a special podrozetnik, included in the nomenclature of the Ultra system. It is used in cases where it is necessary to mount a third-party power outlet or switch. Figure 7 (b) shows the mounted frame for the keysone type SCS modules, having dimensions of 80x80 mm manufactured by Brand-Rex.

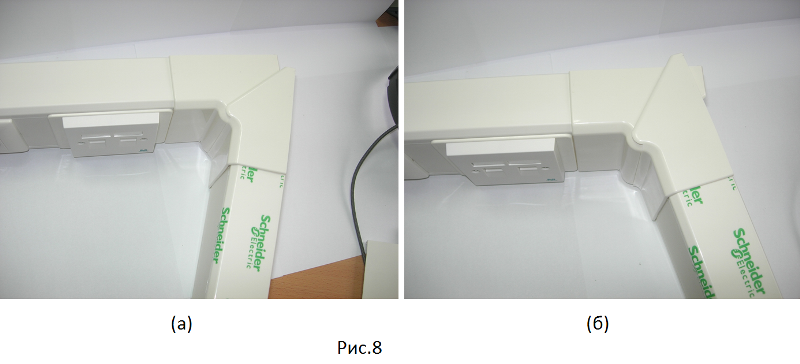

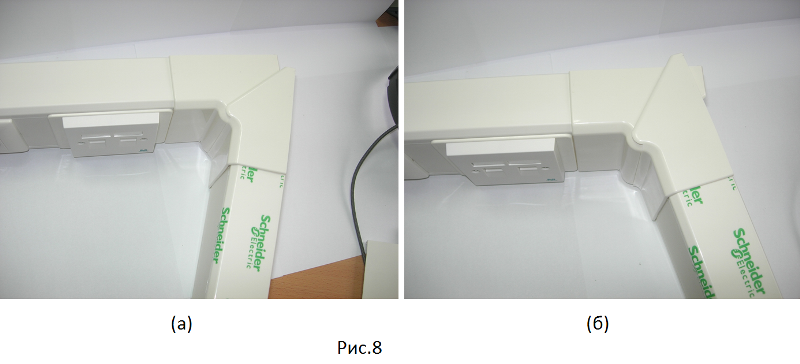

Adjustable inner and outer corners - this feature is very relevant when installing ducts in old buildings (Fig. 8).

The list of components of the system includes power sockets 220v 16A in white and red (Fig.9 (a)), as well as single- and dual-key switches. To separate low-current and power wiring, a special cable separator is used, which is mounted inside the box (Fig.9 (b)).

Summing up, in our brief review, we can confidently assert that the system of electrical installation cable channels for an office with a cabinet system is the most functional and justified solution in terms of the deployment of the power supply network and SCS.

The rationale for this, although subjective, but dictated by years of experience, can be seen in Table 1. In her rating form, the conformity of the technical solutions discussed above with the requirements set by the customer is assessed.

MUK-Service - all types of IT repair: warranty, non-warranty repair, sale of spare parts, contract service

As a rule, for the organization of power and low-current wiring, you have to choose between the following options:

- Hidden wiring in brick / concrete walls;

- Hidden wiring in plasterboard partitions;

- Hidden wiring under the raised floor;

- Open electrical wiring in plastic mini-channels;

- Open wiring in plastic wiring ducts.

')

Consider each of these options in more detail.

Concealed wiring in brick / concrete walls

The organization of the strobe and holes for the installation boxes (podozetnikov) - the process is time-consuming and very expensive, requiring the use of specialized tools (Fig. 1). In addition, it is tied to the phasing of the finishing and general construction works - this increases the total cost. In many cases, in order to save power cables and cables, the SCS should be bundled into one penalty, which can not but affect the quality of the signal transmitted over a twisted pair.

This way of organizing the wiring makes its modernization or relocation virtually impossible, which is unacceptable for a modern office. The weak link is also maintainability and protection of wiring from damage: for example, if someone decides to screw the screw for the picture. The process of installing power outlets, which requires considerable experience and skill, is also very lengthy.

The only advantages of this approach are the long service life of the electrical accessories (due to the rigid fixation of the installation boxes) and the aesthetic look. It should be noted that the last factor is relevant only in the management offices.

Hidden wiring in plasterboard partitions

This is the most common wiring arrangement solution, relatively inexpensive and quick to implement (Figure 2). However, it is also imperfect, since it is tied to different stages of general construction. Upgrading and moving sockets is also not always possible, because sometimes pulling a cable through vertical and horizontal profiles is very difficult. In this case, you have to cut holes in the wall, putty them and repaint the whole wall again. In addition, drywall - not the best material for fixing installation boxes (podozetnikov). Over time, it will crumble and the socket block will begin to play, and in some cases it may just fall out of the wall. In addition, after a few years of operation it will be difficult to guarantee an aesthetic appearance.

Hidden wiring under the raised floor

Raised floor is most often used in open space offices and is extremely rare when using desk space organization. And in the first case, laying cables under the raised floor and installing sockets in the floor "hatches" or columns is often the only possible way to organize workplaces. If the raised floor has not yet been mounted, or there is a possibility of dismantling individual plates, the cost of installing cable routes is minimal. The bulk of the time is spent on installing floor hatches.

If the office has a mixed layout of "open-space + cabinets", it makes sense to install outlets in partitions or wiring boxes. This is due to the fact that the use of hatches has several disadvantages. The main ones are:

- The high cost of hatches and short service life with active mechanical action;

- The inconvenience of operation when it is necessary to connect / disconnect power cords and patch cords;

- Hard binding to the location of the tables. In addition, when the table is even shifted by 20-40 cm, there is a risk of simply locking the flap (Fig.3).

Problems may arise when adding new jobs. Plates of raised flooring are often plastered with carpet tiles, while the dimensions and grid of laying the plates differ. As a result, the main advantage of the raised floor is lost - the ability to access the networks laid under it. In such cases, you can use holes for already mounted hatches in slabs for cable pulling, which does not always lead to the expected result. The problem can be solved by moving the flap by 2-3 meters, which usually does not cause much difficulty.

In general, cable laying under the raised floor and the use of hatches and columns for the organization of jobs is a very convenient and flexible solution. The only reason that may force it to be abandoned is the high cost of the raised floor itself.

Open electrical wiring in plastic mini-channels

This is the easiest, relatively fast and inexpensive option for wiring for a small office. True, the installation of a new workplace will take less time than moving the old one. Just as with the penalties, the problem arises of the joint laying of power and information cables. From the point of view of appearance, such a solution seems to be budget and rather forced, therefore, it is not very advisable to use it for networking from scratch.

Open wiring in plastic wiring ducts

This option can be called the best solution to date, both in terms of cost and time of implementation. It can be said, for the sake of its coverage, this article was conceived. Therefore, we will focus on this method in more detail.

The attitude to plastic cable channels in the domestic market is, to put it mildly, skeptical. The majority of ordinary citizens associate it with a forced measure that is disfiguring the premises. And this is despite the fact that the tiled suspended ceiling, which has already become an indispensable element of the office, can hardly be called a beautiful solution. But engineering networks are laid behind the suspended ceiling, with its help it is possible to hide beams and the ceiling levels drops, to place lamps in it. This is a simple and inexpensive solution that provides ample opportunity.

The situation with wiring channels is approximately the same. They provide:

- Quick installation in one, maximum two stages;

- Ability to move jobs;

- Quick and easy organization of new jobs;

- Reliable fixation of power and information outlets;

- Reliable cable protection against accidental damage;

- Ability to separate power and low current wiring;

- The ability to quickly and without damage to dismantle both the cable channel and cable lines;

- Long service life.

Installation of boxes made on the finished wall, often already painted. This avoids dependence on the construction work and splitting the installation process into several stages. Two experienced installers, if necessary, can install from 60 to 100 meters of the box per day, including laying the cable. Moving the workplace (for this purpose, a cable reserve of 1.5-2 m is left in the box) will take no more than 15-20 minutes. Adding a new one will be connected only with the dismantling / mounting of the box cover, cable laying and mounting of sockets. You can safely drill the walls for paintings, shelves, etc. The box is always in sight and you will have no fear of breaking the cable.

To ensure long-term operation of the wiring and decent appearance of the office, it is necessary to carefully select the manufacturer. At the end of 2012, Schneider Electric, one of the world leaders in electric power management equipment, entered the domestic cable channel market. The company introduced the Ultra system, which includes solutions based on wiring ducts and mini-channels.

The main advantages of Schneider Electric are the cost, high quality of components and the availability of its own frames and sockets of 45x45 mm format, which ensures compatibility with sockets of most manufacturers of SCS (TE Connectivity, Panduit, Systimax, Molex, R & M, Brand-Rex, etc.).

Schneider Electric cable channels are made of self-extinguishing PVC, free of unhealthy lead and cadmium additives. Products are certified and fully comply with Ukrainian standards of fire safety.

Now we will take a closer look at the system components and installation steps.

Figure 5 (a) shows the cable box 101x50, without a cover with mounted cable holders. They are installed every 1.5 m on straight sections of the box and on each internal, external or flat turn, ensuring fixation of the cable.

In Fig. 5 (b), you can see mounted calipers for mechanisms of 45x45mm format. As is the case with cable holders, installation is done by simply “snapping” into special grooves.

Figure 6 (a) shows mounted power outlets and a switch. Figure 6 (b) shows the ready-for-use panel with the mounted box cover, frames and protective film removed.

Figure 7 (a), (b) shows a special podrozetnik, included in the nomenclature of the Ultra system. It is used in cases where it is necessary to mount a third-party power outlet or switch. Figure 7 (b) shows the mounted frame for the keysone type SCS modules, having dimensions of 80x80 mm manufactured by Brand-Rex.

Adjustable inner and outer corners - this feature is very relevant when installing ducts in old buildings (Fig. 8).

The list of components of the system includes power sockets 220v 16A in white and red (Fig.9 (a)), as well as single- and dual-key switches. To separate low-current and power wiring, a special cable separator is used, which is mounted inside the box (Fig.9 (b)).

Summing up, in our brief review, we can confidently assert that the system of electrical installation cable channels for an office with a cabinet system is the most functional and justified solution in terms of the deployment of the power supply network and SCS.

The rationale for this, although subjective, but dictated by years of experience, can be seen in Table 1. In her rating form, the conformity of the technical solutions discussed above with the requirements set by the customer is assessed.

Supplement: video review Plastic cable channels

Contacts if you need to write somewhere

product questions in the review: Aleksandr.Dzuba@muk.ua

MUK-Service - all types of IT repair: warranty, non-warranty repair, sale of spare parts, contract service

Source: https://habr.com/ru/post/168279/

All Articles