Utilization of liquid crystal and plasma displays

One of the problems of the present time is the problem of utilization and processing of electronic equipment, the number of which is steadily increasing. It is expected that in the future a significant proportion of e-garbage will fall on liquid crystal and plasma displays. After all, it is already now possible to say with complete confidence that the century of liquid crystals and plasma has come, and the cumbersome kinescopes are a thing of the past. However, nothing lasts forever and that sad moment may come when, for one reason or another, the device can no longer perform its functions and is sent to a landfill. In the best case, the equipment should be sent for recycling, and if you are wondering how liquid-crystal and plasma displays are being disposed of now, then I ask for a cat.

In order to minimize the negative impact of e-waste on the environment, a number of developed countries are actively conducting programs for its collection and disposal. For example, the European Union adopted directive 2002/96 / EC, according to which all devices with LCD displays with an area of more than 100 cm 2 and CCFL backlighting are subject to disposal.

How does the process of recycling?

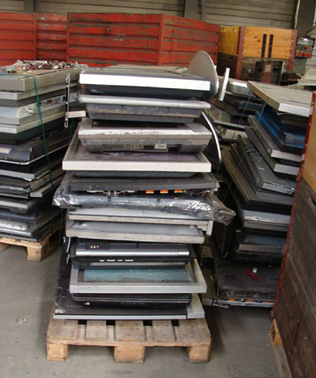

The processing process begins with the manual dismantling of electronic components. Disassembled components are usually sorted into plastic, metal, printed circuit boards, wires, fluorescent lamps, LCD displays for further processing. 3-4 units of equipment take approximately one hour to dismantle.

As can be seen from the pie charts presented, the main mass fraction of electronic equipment is metal and plastic, and LCD displays - from 6 to 18%.

')

Fractional composition of the LCD TV, monitor and laptop

LCD displays with a CCFL (cold cathode fluorescent lamp) backlight are particularly hazardous to the environment. Depending on the characteristics of the fluorescent lamp, it may contain up to 3.5 mg of mercury. For comparison, the energy-saving fluorescent lamp contains about 5-7 mg of mercury.

| LCD diagonal (inches) | Number of lamps | Mercury content (mg) |

|---|---|---|

| 15 | 2 | 7 |

| 17 | four | 14 |

| nineteen | four | 14 |

| 20 | 6 | 21 |

| 26 | 13 | 45.5 |

| 32-37 | sixteen | 56 |

| 42 | 18 | 63 |

Cold Cathode Fluorescent Lamps for LCD Displays

Therefore, the reception, storage and transportation of electronic equipment is carried out in such a way as to avoid damage to fluorescent lamps. However, very often TVs and monitors arrive at the processing site with already broken lamps (up to 20% of broken lamps in TVs and up to 5% in monitors). In this regard, on the site, constant monitoring and measures are taken to prevent mercury concentrations in the air above the maximum allowable concentration. Disassembled lamps are usually disposed of using the same technology as conventional energy-saving fluorescent lamps. It should be noted that LCD displays with LED or OLED backlights are considered safe for the environment because they do not contain toxic substances in any significant quantities. Already there is a tendency to switch to LCD displays with LED, and in the future with OLED backlights.

Between the backlight and the LCD display, there is a package of various polymer optical films. It is a brightness magnifier, a light-scattering film, a prismatic film, a light guide and a reflective film. As a rule, these films are sent to an incinerator due to their diverse composition and low cost.

And now we turn our attention to the LCDs themselves. First of all, let's see what LCD displays are made of to figure out what to dispose of and how.

Simplified schematic representation of the structure of the LCD

Consider all the layers of the LCD display in order:

A polarizing filter is a multilayer composition of polymers of organic and inorganic origin. It is considered environmentally safe, but at low temperatures, combustion can release harmful substances.

The glass substrate has a thickness of 0.4-1.1 mm and is made of sodium or more expensive borosilicate and aluminosilicate glasses. It is environmentally friendly.

Electrodes are a transparent coating of In 2 O 3 -SnO 2 (ITO). The layer thickness can be up to 125 nm, which is approximately 234 mg / m 2 . Due to high indium oxide prices, this coating is of potential interest for processing. For example, there are already technologies for extracting indium oxide from LCD displays by the hydrometallurgical method. However, the economic efficiency of this method is still questionable due to the low concentration of indium oxide in the raw materials.

Liquid crystals have a complex composition and are a mixture of 10-25 different components based on aromatic polymers. The amount of liquid crystals per square centimeter is approximately 0.6 mg. The main manufacturer of liquid crystals is the German company Merck, which performed a number of toxicological and ecotoxicological studies. According to the results obtained, liquid crystals are not acutely toxic, carcinogenic, mutagenic, not harmful to aquatic organisms and have a low potential for bioaccumulation.

The color filter , TFT layer , and orientation film do not need to be disposed of, since they do not contain any toxic substances.

LCD displays

Thus, it can be concluded that the materials used in LCD displays are not dangerous for the environment. This means that LCDs can be disposed of by landfill or incineration at an incinerator. However, such methods of disposal are ineffective. Other available technologies for the disposal of LCD displays are mainly aimed at the extraction and reuse of the main constituent component - glass. The quality of recycled glass is often very low and its chips are usually used as an additive in asphalt, concrete and other building materials. Better glass can be obtained by removing the polarization filter, but this greatly complicates and increases the cost of technology.

The aforementioned company Merck proposed several other ways to dispose of LCD displays. For example, LCD glass can be used to protect the lining of incineration rotary kilns from aggressive substances or to partially replace the sand in the blend for the metallurgical process for the extraction of precious metals. In both cases, the burning of the polarization film occurs at temperatures of 1200-1300 o C, which allows you to burn dioxins, even if they were formed.

Recycling Plasma TVs

Televisions with plasma displays (PD) make up a relatively small part of the other types of TVs, which can be explained by their low sales volumes. The process of recycling televisions with PD also begins with the dismantling and sorting of its various components for further processing. Unlike technology with an LCD display, a significant mass fraction of the TV, besides metal and electronics, is glass.

Fractional composition of the plasma TV

Speaking of plasma displays in the light of this topic, it should be mentioned that they are mainly AC and DC types. Because of their design, DC-type plasma displays contain mercury, the amount of which can be up to 30 mg per display. The reason for the introduction of mercury in the gas discharge cells PD is to increase the service life of the display by preventing the cathode material from entering the anode. However, now almost all manufactured PD are AS-type, therefore, we will consider them in more detail.

Simplified schematic of the plasma display

| Element PD | Material |

|---|---|

| Front and rear window | Soda glass |

| Dielectric and ribs | PdO-B 2 O 3 -SiO 2 , BaO-ZnO-B 2 O 3 -SiO 2 , ZnO-Bi 2 O 3 -B 2 O 3 -SiO 2 Systems Systems |

| Transparent electrode | In 2 O 3 -SnO 2 |

| Power and address electrodes | Ag, Al, Cr / Cu / Cr |

| Protective layer | MgO |

| Phosphor | Red: Y 0.65 Gd 0.35 BO 3 : Eu 3+ Green: Zn 2 SiO 4 : Mn 2+ Blue: BaMgAl 10 O 17 : Eu 2+ |

It can be seen from the above table that PD does not contain polymeric materials, and its main part is made of glass. Lead oxide glass (40-63 wt.% PbO), from which the dielectric and the partition are made, belong to toxic materials. Its relative mass fraction in relation to the other constituent elements of PD is rather small and amounts to about 1.5%. Again, if you refer to the European Directive on the restriction of harmful substances, the use of lead glass in the PD is currently allowed. However, some manufacturers have already begun to use alternative glass based on ZnO or BaO, which are not dangerous to the environment.

The extraction of indium oxide and valuable metals from PD still has only potential interest.

Today, due to the lack of more efficient processing technologies, plasma displays are utilized by grinding them on crushers. The resulting glass chips are usually used in building materials.

findings

In the near future, today's LCD displays with CCFL backlighting will account for a significant proportion of e-junk. The main environmental hazard is mercury contained in the CCFL backlight, while the LCDs themselves are safe. Plasma displays contain lead oxide, which is part of the glass and is toxic. However, now there is a tendency to replace lead glass with alternative glass. Existing technologies for the utilization of LCD and plasma displays make it possible to obtain low-quality recyclable materials without significant capital expenditures. At the same time, new technologies for more complete processing of displays are still only in their infancy.

Source: https://habr.com/ru/post/167883/

All Articles