Phosphors. A bit of theory and practice

As promised, the continuation of the theme "glowing in the dark."

As promised, the continuation of the theme "glowing in the dark."About six months ago we were looking for an additional business with elements of entertainment. We stopped at glowing in the dark colors and objects. The real wow effect was when we painted the letters from foam with our own hands. I wrote about it in July.

Our company currently has a very extensive experience working with suppliers and an assortment of what we ourselves have tested as high-quality.

')

First you need to say that the varieties of phosphors is quite enough:

- Photoluminophors

- Electroluminescent materials

- Cathodoluminophores

- X-ray phosphors

- Radioluminophores

I am studying photoluminophores. I give a link to the only producer of phosphors in Russia that I know of, if anyone is interested in “seeing everyone”.

Some theory

The phosphor itself is a powder with a particle size of 15 - 50 microns. The brightness of the glow depends on the size of the particles. But large particles cannot be used everywhere. For example, if we are talking about the application in silk screening or painting with an airbrush, then the particle size here should be placed at the right intervals so as not to clog the mesh or nozzles of the paint equipment.

The most common colors of the glow - yellow-green and turquoise. These are phosphors with a long afterglow (up to 12 hours).

It is based on strontium aluminate (SrAl2O4): Eu, Dy, Y. It has excellent resistance to water and various radiation, so its shelf life is practically unlimited. Another advantage is that it is safe for the health of people and animals. I even came across formulations for application to the skin - hypoallergenic. In addition, the phosphor that we are engaged in is “charged” also in UV rays, which expands its field of application.

In daylight, the color of the powder is close to white (slightly greenish). To change the color, special fluorescent pigments are used (they glow with UV radiation). Add in proportions of 3% -5% by weight of the phosphor. The colors that I saw - blue, white, yellow, green, red. The color of the pigments is quite “poisonous”. If you go too far with them, you can completely kill the afterglow effect.

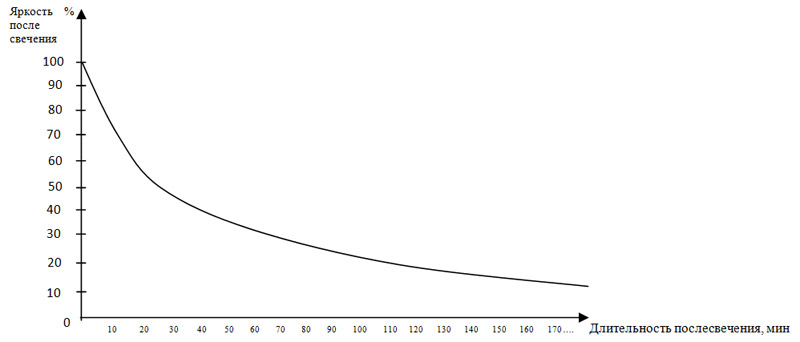

By the way, the painted surface will glow really brightly for the first 60-80 minutes, after which the glow will fade away unevenly:

The most common pictures on the technology of applying phosphor look like this:

In this picture, it is necessary to explain only the meaning of the base, the reflector, the finishing layer.

- The phosphor does not dissolve and it is kneaded into a varnish (base), depending on the type of the painted surface. It is important that there are no UV filters in the lacquer, otherwise the afterglow will not occur.

- Ideally, the substrate on which the finished composition is applied should be white. It is white that serves as the best reflector, with the result that the afterglow effect will be the best.

- After painting with phosphor varnish, the surface will be “rough”, as the phosphor particles are still large. Therefore, for a glossy and even surface, an additional transparent coating will be needed.

For those who are eager to learn more about the technology of use and painting, laid out the archive I found in the public domain.

Some money

I received a few questions in my account about setting up my own small business on phosphors.

Beg a couple of paragraphs about this.

The situation is ambiguous. I wrote off with about 40 companies that are suppliers or representatives of large wholesalers. Everything is very different depending on the chosen niche and a particular city. One comrade, for example, wrote that his sales had fallen when the white nights came.

Everyone is vying to write that it is easy to grow a business. Nifiga like. Phosphor - a thing incomprehensible to many. Everyone still remembers phosphorus, which for 15 years has already been banned for free use and undoubtedly unhealthy.

You can really make money either on services related to the use of phosphor (interior design, car tuning), or with the sale of large quantities of paint / powder. At the resale of finished products is difficult to earn. They are well kept in the office as examples of applications so that you can “touch”.

This is due to the fact that on most sites suppliers of photos such that you had to order everything to see how it actually looks.

Some pictures

In general, look for a niche and ask questions. I will answer all.

Source: https://habr.com/ru/post/166125/

All Articles