How is LED technology better than laser technology? (and worse)

Terminology

Laser printing is the common name for a printing method using the principle of dry electrostatic transfer. The essence of the principle is that the dye (toner) due to electrostatics "sticks" to the photosensitive drum in those places where it was exposed to a light source. Next, the toner is dragged onto the paper by electrostatics, as a result of which an image is formed on the paper, which is fixed in the printer's kiln under the influence of temperature and pressure.

Traditionally, a single laser diode is used as a light source, the beam from which, passing through the scanning system, hits the photosensitive drum. But the laser diode is not the only light source used in modern printers. A worthy and in many ways interesting alternative to laser are light-emitting diodes (LED from Light Emmitting Diode) assembled in a line and called the LED Line. Both light sources make prints absolutely identical in terms of consumer properties. However, each of the technologies has its own characteristics.

')

Consider LED printing in more detail.

Main advantages:

compactness and lack of moving parts

no ozone emission

high image accuracy

Information Security

high speed

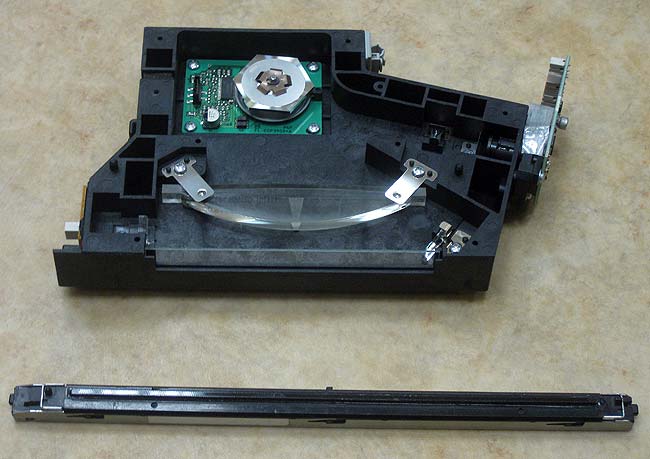

Laser (top, cover removed) and LED (bottom) light sources for electrographic printers

LED ruler design: top to bottom - cover with focusing lenses, textolite board with LEDs and contact group, dielectric and metal case

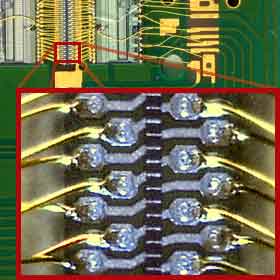

Separate LEDs at high magnification (600dpi LED bar)

Compact and no moving parts

The light source in the LED printer consists of thousands (from 2,500 to 10,000 pieces) of individual LEDs mounted on a textolite board in the same way that conventional electronic components of modern devices are mounted. The textolite board itself is placed in a metal case, which prevents its damage.

Due to the miniature size of the LEDs, they can be placed in a very small device - an LED line (also called a print head). The size of this head is so small that still OKI LED page printers are the most compact black and white printing devices in the world!

In a laser printer, however, a rather complex optical-mechanical system is used, in which there are precision mirrors in adjustment and a rotating multifaceted prism (it is she who emits a light whistle when the laser printer is in operation). Traditionally it is believed that a system that includes moving parts is less reliable than a system without such parts. This postulate is tested by time and in relation to OKI LED heads. Since 1999, they are given a lifetime warranty of the manufacturer!

No ozone emission

Ozone - triatomic oxygen, which is a highly active chemical element (oxidizing agent). In small quantities, ozone is useful for the human body, but in large quantities it is very harmful, as it is a conditionally potent poison.

One of the most common sources of ozone in everyday life is copying equipment. In the construction of such a technique, there used to be an element, called a coronator, and a thin wire, through which a high voltage current flows. The oxygen of the air in contact with this wire is ionized and ozone is produced from it.

In modern devices, the coronator was abandoned, replacing it with a special roller, which actually prevents the release of ozone. But in laser printers there is one more source of ozone - the laser beam itself. If you look at the scheme of the laser printing system, you can see that the laser beam makes a rather long journey through the system of mirrors and lenses before it reaches the surface of the photodrum. On this way he electrifies the air, which is also accompanied by the release of ozone. Of course, not in the quantities in which his coronator produced it, but the characteristic smell of ozone is still felt when operating a laser printer.

This disadvantage is completely devoid of LED printers. The distance from the LEDs of the printing ruler to the surface of the photodrum is so small that there is practically nothing to ionize in this gap, and the characteristics of the light emitted by the LED rulers are such that they cannot decompose oxygen with the release of ozone. That is why LED printers are the most environmentally friendly devices for modern toner printing.

High image accuracy

When a laser printer is in operation, each line of the future image is formed by “scanning” the surface of the photosensitive drum (photodrum) with a laser beam. The prism deflecting the beam rotates by means of a stepper motor. At each step, the prism rotates at the same angle. However, due to the fact that in order to reach the surface of the drum, the beam needs to pass a different distance in the center of the drum and along its edges, the distance between adjacent points will be different. In addition, due to the fact that the beam falls on the edge of the drum at an angle to its surface, the very shape of the point that will be formed on the drum is not round, but oval.

In the LED printing system over each point of the photodrum has its own LED. The distances between the diodes in the line are the same, and the shape of the point does not change along the length of the photodrum. It is these properties that provide equally high image accuracy both in the middle of the sheet and at its edges. And that is why professional printing systems do not use a laser scanning system, but work according to principles similar to those used in LED printing devices.

The differences in image accuracy described above can be seen with a strong increase in small text. For example, below are two pieces of text in 1.5pt size, made by laser and LED printers and scanned with the same parameters:

The imprint made by a laser printer with a resolution of 1200x1200dpi. Pay attention to the quality of drawing small elements of letters - all the "circles" are filled with toner.

The imprint made by the LED printer with a resolution of 1200x600dpi. Even despite the initially lower physical resolution, the LED printer is much better at handling fine details of text.

Information Security.

A laser diode operating as a light source in a laser printer emits a series of consecutive light pulses that, reaching the surface of the photodrum, create an electrostatic image on it, which is subsequently translated into an imprint. However, like any other electronic device, a laser diode emits not only in its operating range (laser beam), but also in the radio band, being, in fact, a radio transmitter. Each point, which is placed on paper, and from which the printed image is obtained, corresponds to one pulse in the radio. Using modern technology, these pulses can be received on a radio antenna, sent to a computer and restored using an image printed by the printer.

Light-emitting diodes in an LED printer also create electromagnetic oscillations that can be picked up by the receiver, but due to the fact that there are a lot of LEDs in the printing line, and they all flash simultaneously, “white noise” gets on the air (it is impossible to decipher “Flashed”, and which one did not, respectively, where the dot was put on paper and where not), that is, you cannot restore the image that is printed on the LED printer. Such security of documents printed on LED printers can be claimed in any important places when printing sensitive and confidential information, as well as where personal data about clients is printed. Indeed, according to the law on the protection of personal data, it does not matter how the leakage of this data occurred, the responsibility under the law is always the same. Therefore, if you intend to print personal data on a laser printer, be prepared to become guilty of violating this law. So it is better to use LED printers for printing such data right away!

High speed

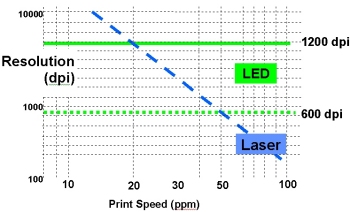

Due to the fact that all the LEDs in the line are placed in one row and flash at the same time, the printing speed of LED printers is practically unlimited. In contrast, laser printers, which are forced to draw each line of the image sequentially, have physical limitations on the maximum print speed, depending on the horizontal resolution used, which does not cause geometrical distortion of the printed lines. The graph on the right clearly shows that with a physical resolution of 1200dpi, the maximum printing speed of a laser printer is about 20 pages per minute. At a higher print speed, linear distortions of the lines of the print will occur: the lines will not be strictly horizontal, but slightly tilted. An alternative to distortion would be a reduction in physical resolution. For example, when printing with a resolution of 600dpi, the maximum speed of laser printers can reach 50 ppm. If it is necessary to achieve high speed at high resolution, designers are forced to install two or more laser mechanisms into laser printers, each of which will work only with a part of the image. This significantly increases the cost of construction and increases its dimensions, besides it creates obvious problems with the configuration of such printers. All these problems are fundamentally absent in LED printers, for which the limitations on printing speed lie far beyond the limits of the actually demanded print speeds.

Often highlighted shortcomings:

The resolution is no more than 600 dpi, and the images created by LED printers are often obtained with blurred and fuzzy edges, the thin halftone lines had gaps, the combination of colors on color images was inaccurate. Print quality, especially in terms of resolution and stability, is the weak side of LED printers.

Firstly, a big misconception about the resolution of “no more than 600dpi”. Already in 2000, OKI released two older models of color printers - C7400 and C9400, A4 and A3 formats, respectively, the resolution of which LED lines was 1200dpi. Then there were models C7500 (A4) and C9500 (A3), then C9800 (A3) and, finally, today's A98 C9850. All of them had 1200 individual LEDs each on one inch of the LED line, thereby achieving a physical resolution of 1200x1200dpi.

“Blurry and fuzzy edges” is a figment of imagination and conjecture. A very long time ago in LED printers, vector-based anti-aliasing technology has been used, based on the ability of LED bars to create dots of various sizes. Even the most inexpensive and, frankly, not the best representatives of the OKIPAGE family of black-and-white printers gave more than sufficient smoothness of text and vector images already at the basic resolution of 300dpi! What can we say about today's printers, working with a resolution of 600 and 1200 dpi and using the same technology to the full!

But not enough stable image - lack of truth. But ... 10 years ago. Indeed, even 10 years ago, the LEDs in the rulers differed slightly in intensity of illumination from each other, which gave a slight banding along the movement of the sheet. But with the advent of the C7000 and C9000 series of printers in 2000, a new line of light was seen, the glow of each LED in which was automatically monitored and normalized to one level. Since then, issues of image stability due to the difference in LED emission have no longer been raised.

findings

compactness and lack of moving parts

Provides the small sizes of the mechanism and long trouble-free operation of the device. The most crucial element - the LED line - is given a lifetime warranty from the manufacturer!

no ozone emission

Printers working on LED technology are the most environmentally-friendly of modern toner printing devices, preventing the harmful effects of ozone such as dizziness and drowsiness.

high image accuracy

Created documents are characterized by high accuracy and linearity of the image, technologically unattainable on classic laser printers.

Information Security

LED printers can be used in such applications that require increased confidentiality of workflow.

high speed

In LED printers, you don’t have to sacrifice work speed or print quality, since the illumination parallel across the entire width of the sheet makes it possible to print without speed limits with any optical resolution, which is unavailable for laser printers.

What does not apply to LED technology, but is attributed

Very often, considering LED printers, people wonder - what will happen if one LED burns out, how does a pixel burn out on the monitor screen? However, this rather funny question can in no way be attributed to LED technology. The association should be sought in another field of computer technology and wondering - what will happen if one transistor burns out on a processor? After all, they are there by orders of magnitude more than LEDs in the line, and the manufacture of those and others, by and large, is done using similar technological processes. And in both cases, the weak link is rejected at the production stage and the percentage of processors with burned-out transistors is extremely small, and the LED bars with burned-out diodes almost do not get into the printer. If something happens to the LED bar, it is the failure of the control board, which is responsible for the whole LED section. Separate LEDs during operation fail so rarely that they do not even fall into the statistics of failures, that is, they are outside 0.01% of the total number of failures of LED printers. And in any case, whatever happens to the LED ruler, we can always be sure that it will be replaced as part of a lifetime warranty! By the way: LEDs operate with an intensity of at least 5000 times lower than the laser. Therefore, do not fail. Therefore, such a guarantee.

OKI has been developing and improving the LED technology created by it since 1987. Today, OKI is one of the few companies that continues to conduct basic technological research and independent development in the field of black and white and color printing, investing in them significant funds. In this article, I only indirectly outlined the direction of development to improve LED technology, however, as you can see, in recent years, the technology has got rid of almost all of its shortcomings.

Sergey Lebedev, OKI Marketing Director

Source: https://habr.com/ru/post/162207/

All Articles