Stop twisting - 2. About ways to fix the cable

At the request of the audience, so to speak. Correctly connecting the cable is half the battle, but if it hangs loose, it will not live long — either they touch, tear, or bite off (not necessarily with evil intentions). Or maybe just under his weight to slip out of the connection. But it can not slip out, which is even worse - go and find the place where the contact disappears. So this article will talk about how you can fix the cable so that it does not go anywhere.

Yes, and here such attachments are ugly, inconvenient, and they are given by a non-professional:

What, in essence, is the process of fixing wires? These are actions aimed at connecting (it can be rigid or not, detachable, or one-piece, etc.) a single object (cable) that cannot independently maintain its position in space, to another object (wall, beams, masts and another exotic), which is usually much more solid, and does not require additional props.

The walls are different, it is a fact. But in most cases, their classification can be reduced to three types:

Problems usually do not arise, only a screw and a screwdriver are needed. Well, anyone who will twist, of course. Spins easily, holds tight, hang anything. After twisting leaves a minimum hole.

')

We make a hole with a perforator, a drill (for singles, do not appreciate yourself at least 20 pieces with a percussion drill), a bump stop (for masochists, or the USSR fil), insert a plastic dowel (chopik, as the Tajiks say), or the USSR style: manually carved a piece of wood, and in it we twist the screw. With the right choice of the size of the dowel and the hole - it holds perfectly. After dismantling leaves already a hole more.

And here traditionally there are questions - when you try to twist a screw there, it falls through, it turns uselessly, not wanting to stick. If it is possible to wrap it there, nothing can be harder to hang than a painting - with any tangible load, it will simply bend and burst out of the wall, leaving behind a hole.

For such cases, there are many solutions that are called so - fasteners for hollow structures. Here are the 3 most common types:

It looks like this:

Of the minuses - it is necessary to drill a hole in advance, and not small.

Driva (dowel with DRIVA drill (metal) or TT22 (plastic)), an awesome-looking drill,

It looks like this:

It is inserted into the screwdriver (although you can do with a drill, and even with a screwdriver), and it is twisted into the wall like a normal screw:

It turns out that there is such a bum in which the screw is already twisted:

After that, already on this screw you can fasten everything you need. I showed metal above, and there are also plastic ones:

The meaning is simple. A hole is made in the wall, the dowel is straightened and pushed into the wall. You start to tighten the screw - it clings to the far part of the dowel and pulls it to the wall, squeezing it in such a way that it turns out to be pressed to the wall from the other side.

Disadvantages - he must hold something from “your” side, otherwise the thin bezel will jut out and the dowel together with the screw will disappear into the depths of the wall. You can't hang a picture on a string just like that on a dowel.

All of the above fasteners are used only for hollow structures - walls of gypsum fiber plating, gypsum plasterboard.

As a result of the aforementioned activities, we have a wall ready for screwing in the screws. But it will not be possible to fasten the wire with screws, this only works with the Soviet telephone "noodles". One of the principles of the organization of cables - means of organization should not damage the cable.

Option One: the wires in the pipe.

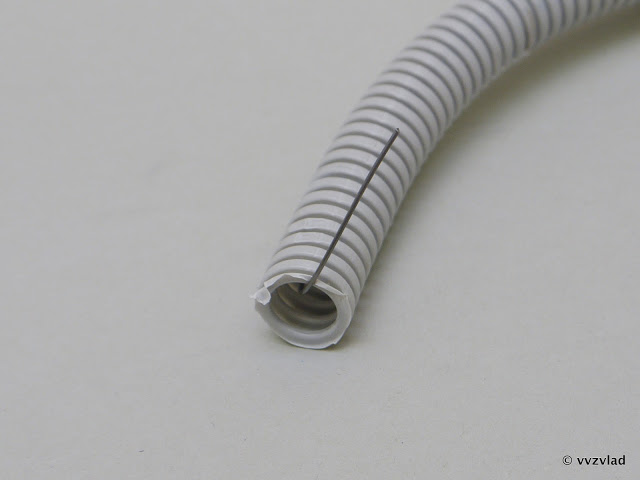

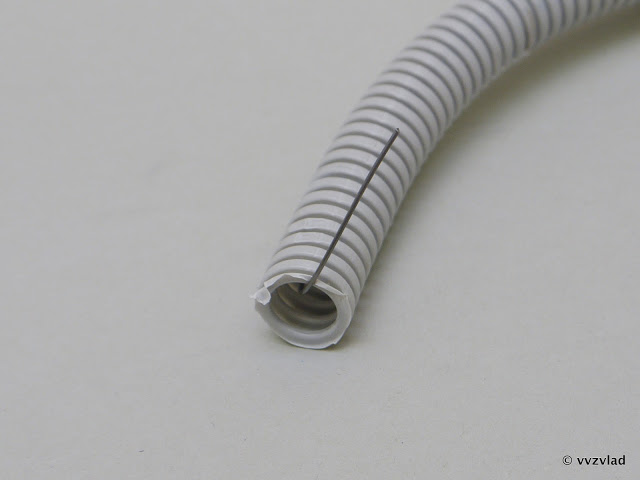

Or rather in the corrugation. Is called " Pipe corrugated PVF with a broach "

Broach is the wire that sticks out from both ends.

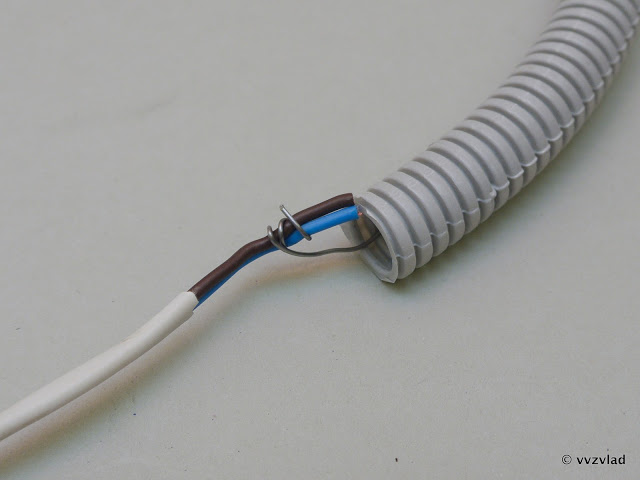

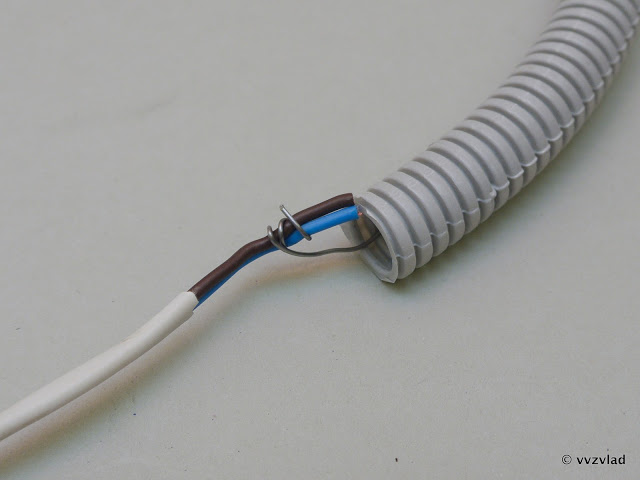

One end is fixed on the wire:

And for the second you need to gently pull, and the cable will be in the corrugation.

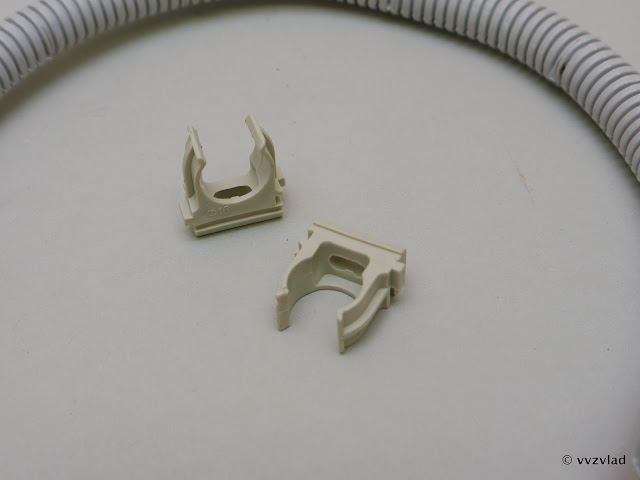

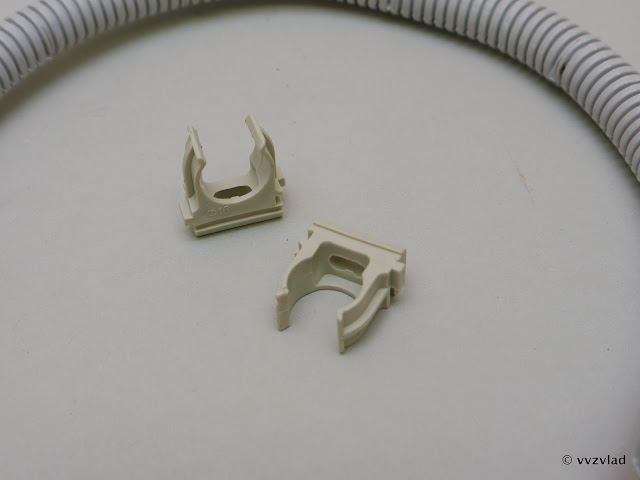

Pieces in the middle - mounting.

They are screwed to the wall with screws:

And in them the corrugation snaps:

It turns out like this:

For greater convenience, the fasteners can snap into each other, for smooth installation of several corrugations at once.

The main advantage of the corrugations - it is sealed. Therefore, it can be used on the street:

True, it must be borne in mind that in this case there should not be cuts and holes on it, and if there is, they should be from the bottom. In the holes located at the top, a pair of liters of water can easily be poured in and tear the corrugation out of the mountings under its weight. For such cases, there are special fasteners that are additionally snapped on top, but for some reason I haven’t seen them in stores for a long time. Of course, all connections for operation on the street should be sealed whenever possible. At least a simple sealant, if there are no seals.

Another PVC corrugation does not like frequent shoving-taking out of the mount, ideally - secured and everything. Otherwise, it crumples and cracks:

By the way, here the fasteners are snapped into each other.

And it does not support burning, does not allow the wires to catch fire, restricting the flow of air to them, saves the wires from crushing when they are bricked up into expanding mixtures. However, such a sleeve should not be placed where there is a risk of flooding, or nibbling by rodents. In these cases, it is better to use the same corrugation, but metal. A metal hose is called, usually with a long code, in which the size, thickness, shell and so on are encrypted. But I usually buy it, poking into the shop window, "and now this 10 meters." :)

And the corrugation saves the wires from prying eyes, and the sense of beauty from the type of wires. But, let's say, we have a bundle of wires that does not offend our sense of beauty, because it will be laid behind the suspended ceiling or closed with a partition.

For a start, it must be collected to visually distinguish it from other similar beams, and prevent entanglement.

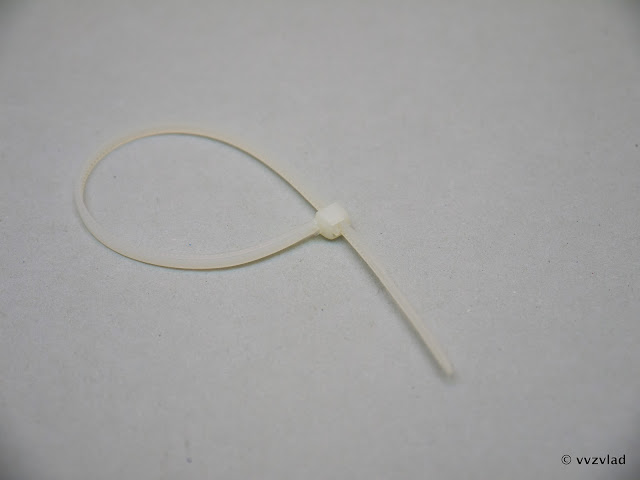

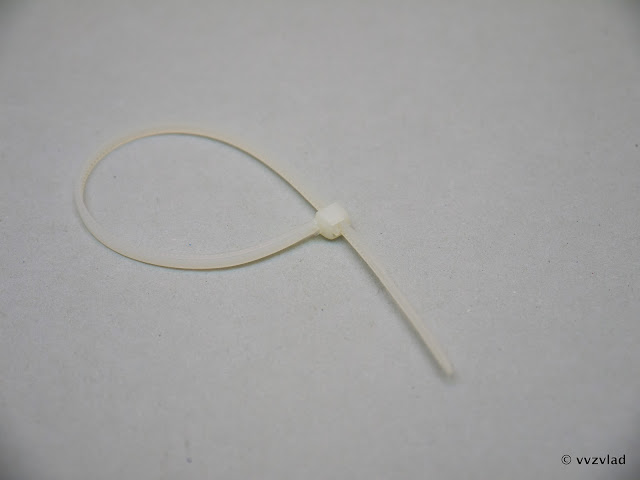

I think, to explain what a nylon tie is , nobody needs it here? Everyone has seen her at least once.

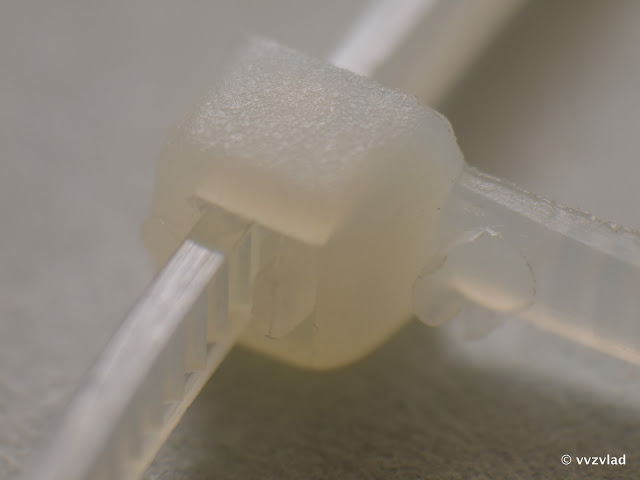

At one of the tips there is a head with a ratchet latch:

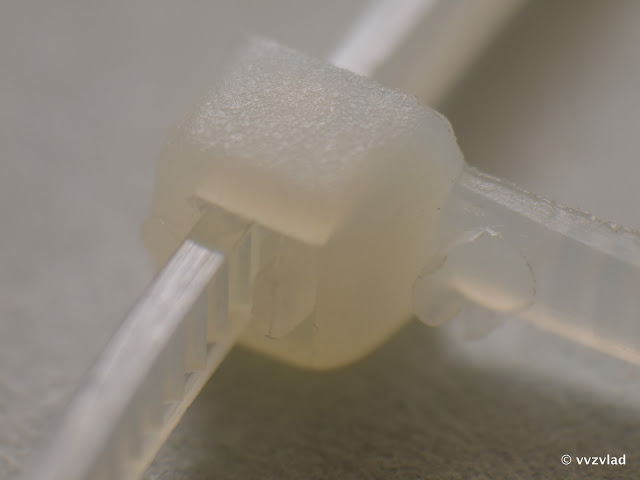

And throughout the rest of the screed - inclined corrugated surface. Latch misses only in one direction, and in the other - is locked.

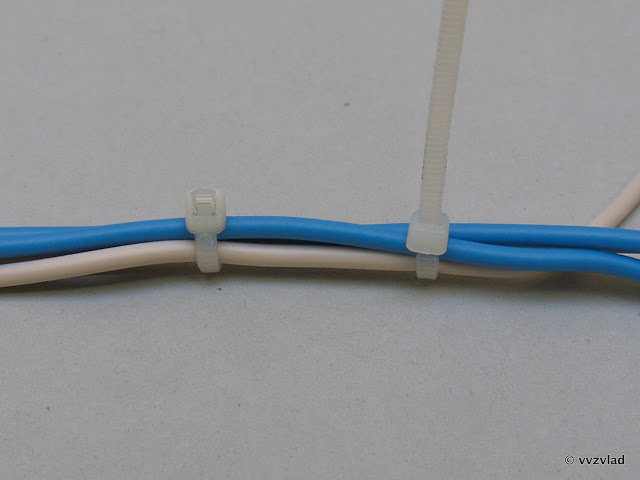

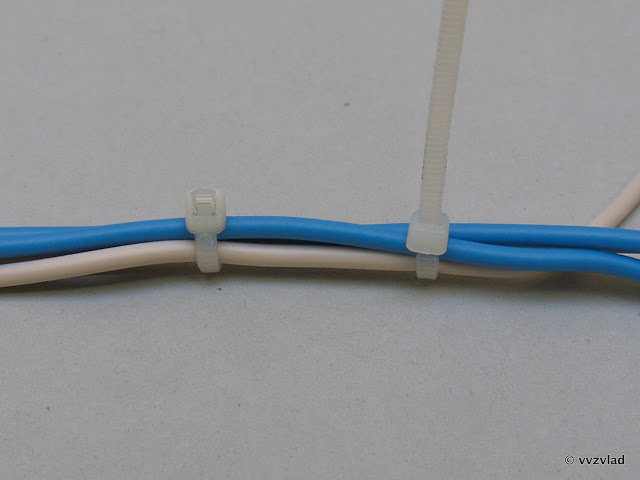

We wrap the wires, snap into place, tighten to the limit. At will - we trim the tip.

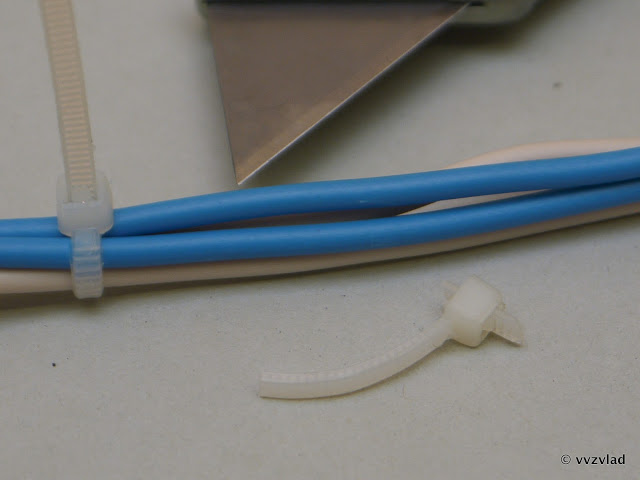

By itself, disposable. Something needs to be pulled out or added - we cut, and snap the new one.

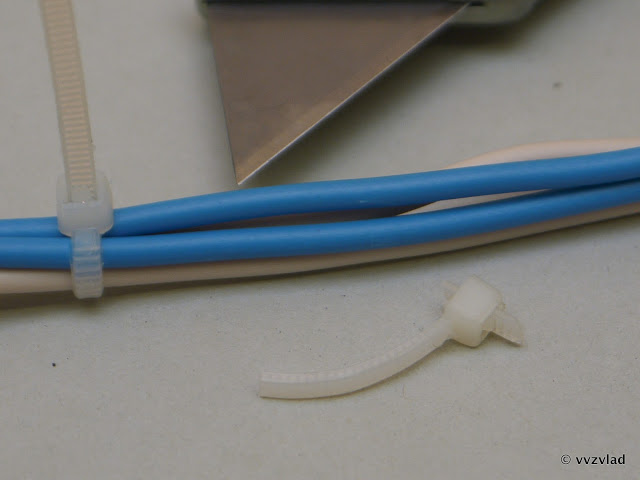

Not suitable for negative temperatures and bright sun - in the cold it becomes brittle, after which the first gust of wind effectively breaks the screed along the entire length of the cable. Dispersed after exposure to the sun (from a month to a year or two, depending on the manufacturer). They do not like excessive tension and loads - they are torn. In short, the lot of polyethylene screed - the organization of lightweight cables, fastening them to the panels. Do not hang the cable on the ties, at least completely. Secure for more.

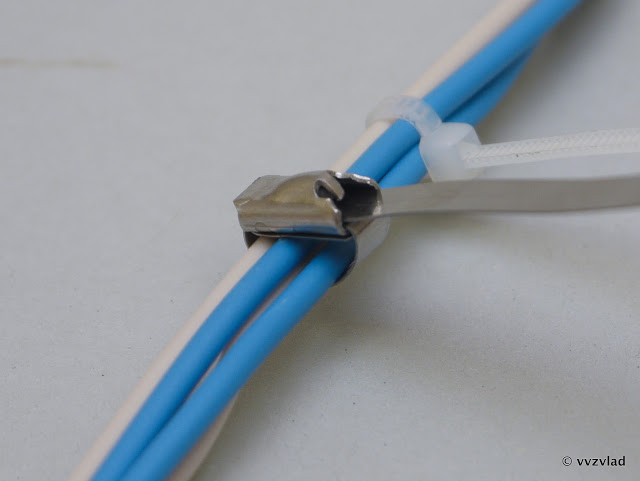

For example, on a metal tie:

So called - stainless steel screed .

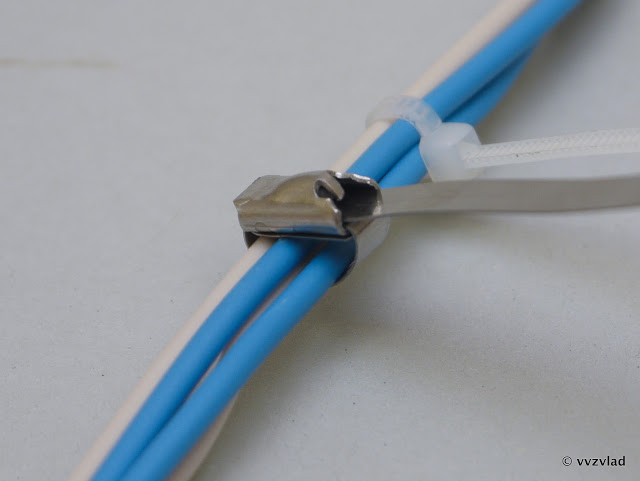

The principle is clear, refuel and tighten. Very strong, holds, emnip up to 30kg one minimum. It bites only with pliers, do not try to “unscrew” the joint with pliers - it cuts the cable jacket easily, but it does not break.

Principle of operation:

Inside - a rough ball inside a narrowing cavity. When you push the tape in the “right” direction - it rolls out to the wide side (a small metal tongue doesn't allow it to fall out completely, you can see it in the photo), and when you try to pull it back - the ball rolls back, gets into a narrow slot, and presses against the tape the stronger, the harder you pull.

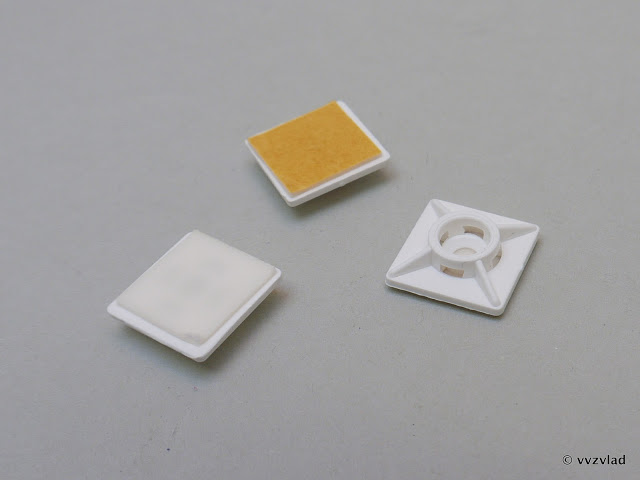

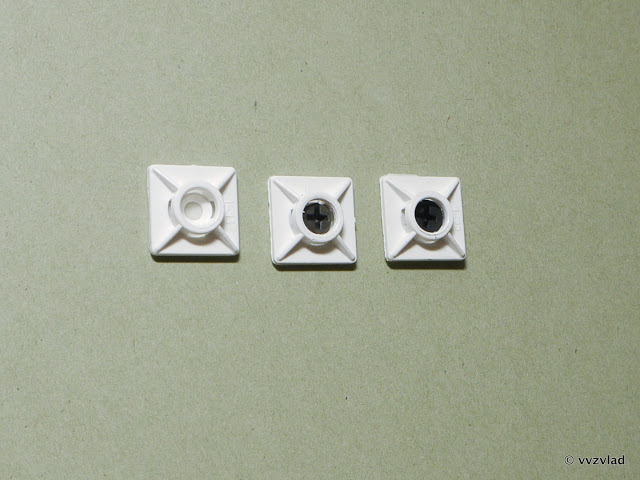

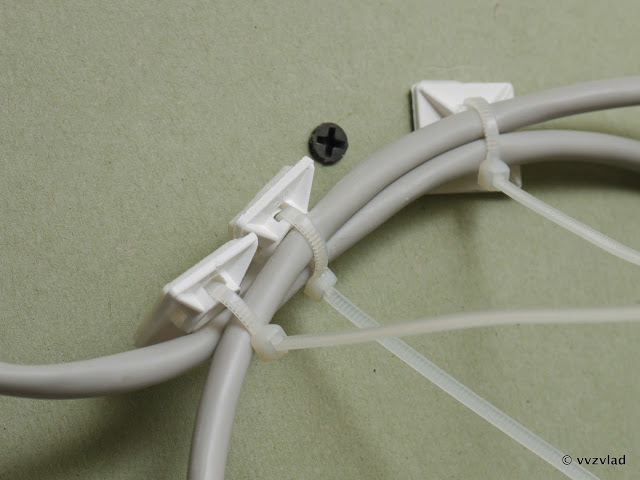

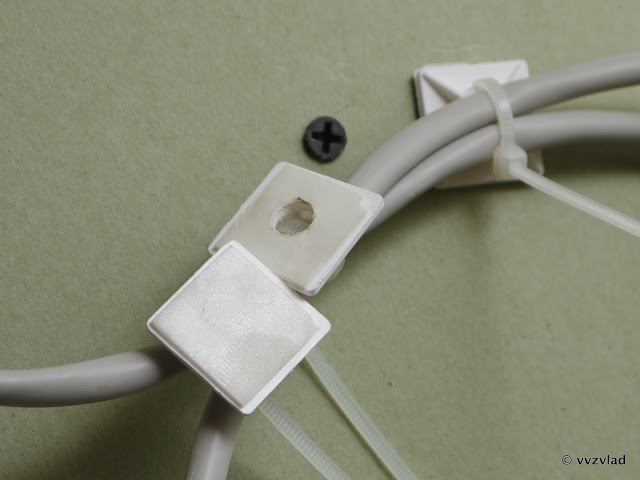

But fasteners to the screws attach uncomfortable. To eliminate this drawback, there are sites for cable clamps.

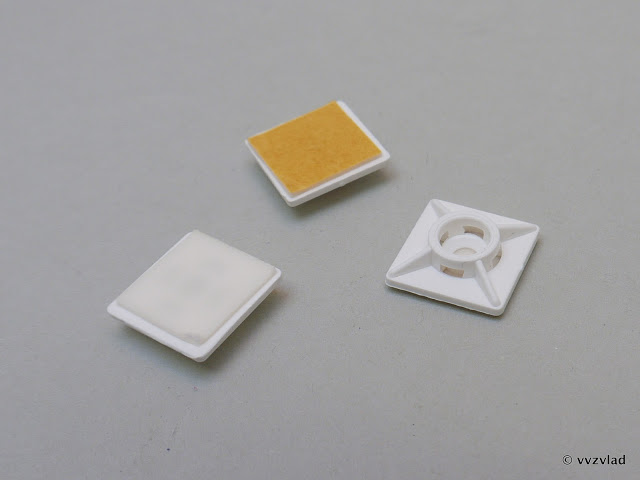

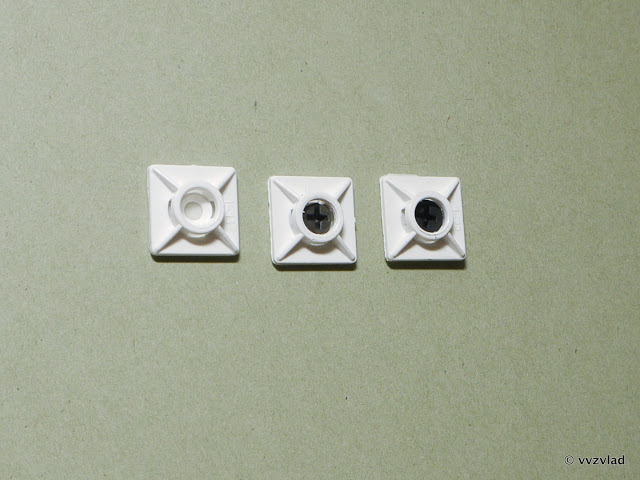

There are species with or without glue pad. Of course, you can only rely on the glue pad when laying telephone wiring laid on the floor in a very quiet place where no one walks. IMHO, the only application of the site is to glue it right into the right place, before screwing it in with a screw (there is a special hole in the center for this).

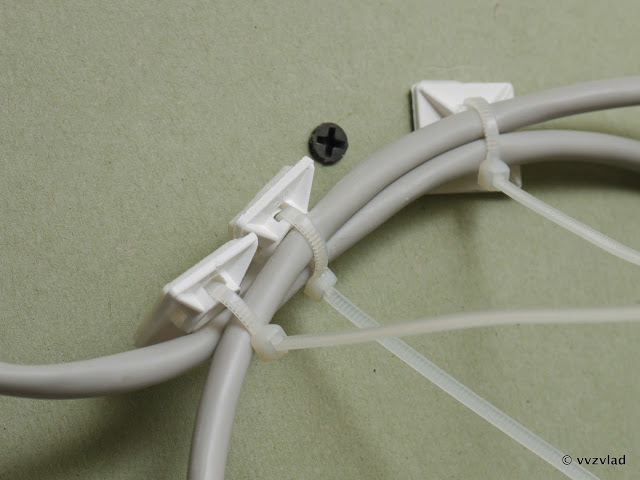

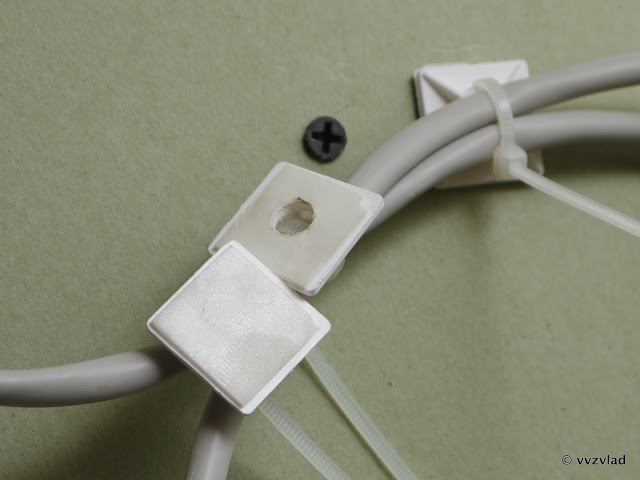

After that we pass through the tie in the narrow holes and fix it on the cable

By the way, here are three types - on glue, on a screw, and on a screw in a metal dowel.

We pull:

Only a normal screw with a wide head, twisted into a DRIVA-dowel, holds tightly.

One of my favorite things is the dowel-clamp .

Great solution. I think that everyone has already guessed what to do with it, but I will nevertheless explain. Drill a hole:

Wrap the cable clamp:

And shove it in the hole!

Everything. The cable is securely fastened. The clamp is much thicker than the tie, and with the right hole it easily carries the weight of even a bundle of power cables.

Hit of all times and peoples, favorite fasteners installers provider. Plastic mounting bracket.

Cheap, sold in all stores. This is where her merits end. I do not know, maybe there is some trick, but for more than 10 years I have not been able to learn how to score it the first time and without swearing. Carnation is small, uncomfortable to keep. It keeps well only in wooden surfaces, which, together with the installers, loving it, fasten it to the GVL, it ensures the separation of the cable in a week. And sometimes they are trying to drive into the plastic baseboards and plaster of concrete walls. Or in the mortar between bricks, yes. In general, it is not necessary to do this, for such installers in hell are burning, above the smoky fire from cable insulation.

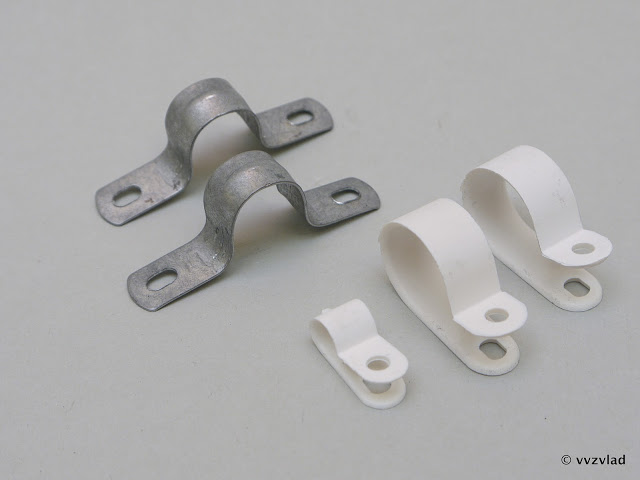

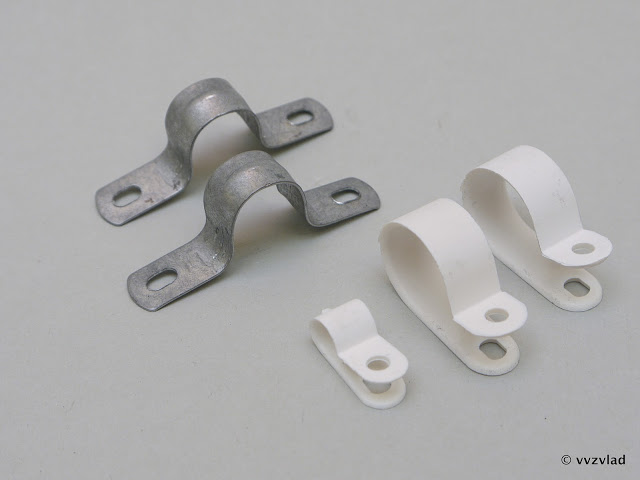

Plastic cable earrings (yes, they are called so) and metal cable clips (I have nothing against them, unlike their plastic namesake).

The first ones are good because they are fastened with just one screw, but unlike the dowel-clamps, it can be used several times - unscrew the screw, add-remove cable, and tighten it again. And metal brackets perfectly hold any heavy cable, and have an excellent tensile strength, successfully coping with the attacks of cleaners, legs and hands of visitors and fans to attach their cable to someone else.

Surely, like last time I forgot about some obvious ways, but they will certainly be remembered in the comments.

And if you do not want to skip the discussion, check the box .

.

And if you do not want to miss another useful article, then you can subscribe to my profile (button "subscribe")

Yes, and here such attachments are ugly, inconvenient, and they are given by a non-professional:

What, in essence, is the process of fixing wires? These are actions aimed at connecting (it can be rigid or not, detachable, or one-piece, etc.) a single object (cable) that cannot independently maintain its position in space, to another object (wall, beams, masts and another exotic), which is usually much more solid, and does not require additional props.

The walls are different, it is a fact. But in most cases, their classification can be reduced to three types:

Dense

Timber, sleepers, earthenware, chipboard, wood, plaster and soft mortars, including gypsum. In general, where you can tighten the screw without any problems.Problems usually do not arise, only a screw and a screwdriver are needed. Well, anyone who will twist, of course. Spins easily, holds tight, hang anything. After twisting leaves a minimum hole.

')

Solid

Solid solutions, concretes, bricks, cements, screeds. That where the screw does not turn.We make a hole with a perforator, a drill (for singles, do not appreciate yourself at least 20 pieces with a percussion drill), a bump stop (for masochists, or the USSR fil), insert a plastic dowel (chopik, as the Tajiks say), or the USSR style: manually carved a piece of wood, and in it we twist the screw. With the right choice of the size of the dowel and the hole - it holds perfectly. After dismantling leaves already a hole more.

Thin

Plastic, drywall, GVL, and other thin materials, followed by - emptiness. Accordingly, it is better not to twist the screw there - most of it will just hang in the air.And here traditionally there are questions - when you try to twist a screw there, it falls through, it turns uselessly, not wanting to stick. If it is possible to wrap it there, nothing can be harder to hang than a painting - with any tangible load, it will simply bend and burst out of the wall, leaving behind a hole.

For such cases, there are many solutions that are called so - fasteners for hollow structures. Here are the 3 most common types:

Molly (MOLLY, "umbrella"), a special case of anchor bolts.

Serious metal construction, which is revealed (sometimes even with a special tool) on the other side of the wall, and does not go anywhere. And you can do anything with it - even if you hang a chandelier (some models already come with a hook and a fixing strip for lamps), even with hanging equipment.It looks like this:

Of the minuses - it is necessary to drill a hole in advance, and not small.

Driva (dowel with DRIVA drill (metal) or TT22 (plastic)), an awesome-looking drill, as if specially made for a lobotomy

It looks like this:

It is inserted into the screwdriver (although you can do with a drill, and even with a screwdriver), and it is twisted into the wall like a normal screw:

It turns out that there is such a bum in which the screw is already twisted:

After that, already on this screw you can fasten everything you need. I showed metal above, and there are also plastic ones:

Butterflies (butterfly anchor, TNF, TNF-W)

The meaning is simple. A hole is made in the wall, the dowel is straightened and pushed into the wall. You start to tighten the screw - it clings to the far part of the dowel and pulls it to the wall, squeezing it in such a way that it turns out to be pressed to the wall from the other side.

Disadvantages - he must hold something from “your” side, otherwise the thin bezel will jut out and the dowel together with the screw will disappear into the depths of the wall. You can't hang a picture on a string just like that on a dowel.

All of the above fasteners are used only for hollow structures - walls of gypsum fiber plating, gypsum plasterboard.

As a result of the aforementioned activities, we have a wall ready for screwing in the screws. But it will not be possible to fasten the wire with screws, this only works with the Soviet telephone "noodles". One of the principles of the organization of cables - means of organization should not damage the cable.

Option One: the wires in the pipe.

Or rather in the corrugation. Is called " Pipe corrugated PVF with a broach "

Broach is the wire that sticks out from both ends.

One end is fixed on the wire:

And for the second you need to gently pull, and the cable will be in the corrugation.

Pieces in the middle - mounting.

They are screwed to the wall with screws:

And in them the corrugation snaps:

It turns out like this:

For greater convenience, the fasteners can snap into each other, for smooth installation of several corrugations at once.

The main advantage of the corrugations - it is sealed. Therefore, it can be used on the street:

True, it must be borne in mind that in this case there should not be cuts and holes on it, and if there is, they should be from the bottom. In the holes located at the top, a pair of liters of water can easily be poured in and tear the corrugation out of the mountings under its weight. For such cases, there are special fasteners that are additionally snapped on top, but for some reason I haven’t seen them in stores for a long time. Of course, all connections for operation on the street should be sealed whenever possible. At least a simple sealant, if there are no seals.

Another PVC corrugation does not like frequent shoving-taking out of the mount, ideally - secured and everything. Otherwise, it crumples and cracks:

By the way, here the fasteners are snapped into each other.

And it does not support burning, does not allow the wires to catch fire, restricting the flow of air to them, saves the wires from crushing when they are bricked up into expanding mixtures. However, such a sleeve should not be placed where there is a risk of flooding, or nibbling by rodents. In these cases, it is better to use the same corrugation, but metal. A metal hose is called, usually with a long code, in which the size, thickness, shell and so on are encrypted. But I usually buy it, poking into the shop window, "and now this 10 meters." :)

And the corrugation saves the wires from prying eyes, and the sense of beauty from the type of wires. But, let's say, we have a bundle of wires that does not offend our sense of beauty, because it will be laid behind the suspended ceiling or closed with a partition.

For a start, it must be collected to visually distinguish it from other similar beams, and prevent entanglement.

I think, to explain what a nylon tie is , nobody needs it here? Everyone has seen her at least once.

At one of the tips there is a head with a ratchet latch:

And throughout the rest of the screed - inclined corrugated surface. Latch misses only in one direction, and in the other - is locked.

We wrap the wires, snap into place, tighten to the limit. At will - we trim the tip.

By itself, disposable. Something needs to be pulled out or added - we cut, and snap the new one.

Not suitable for negative temperatures and bright sun - in the cold it becomes brittle, after which the first gust of wind effectively breaks the screed along the entire length of the cable. Dispersed after exposure to the sun (from a month to a year or two, depending on the manufacturer). They do not like excessive tension and loads - they are torn. In short, the lot of polyethylene screed - the organization of lightweight cables, fastening them to the panels. Do not hang the cable on the ties, at least completely. Secure for more.

For example, on a metal tie:

So called - stainless steel screed .

The principle is clear, refuel and tighten. Very strong, holds, emnip up to 30kg one minimum. It bites only with pliers, do not try to “unscrew” the joint with pliers - it cuts the cable jacket easily, but it does not break.

Principle of operation:

Inside - a rough ball inside a narrowing cavity. When you push the tape in the “right” direction - it rolls out to the wide side (a small metal tongue doesn't allow it to fall out completely, you can see it in the photo), and when you try to pull it back - the ball rolls back, gets into a narrow slot, and presses against the tape the stronger, the harder you pull.

But fasteners to the screws attach uncomfortable. To eliminate this drawback, there are sites for cable clamps.

There are species with or without glue pad. Of course, you can only rely on the glue pad when laying telephone wiring laid on the floor in a very quiet place where no one walks. IMHO, the only application of the site is to glue it right into the right place, before screwing it in with a screw (there is a special hole in the center for this).

After that we pass through the tie in the narrow holes and fix it on the cable

By the way, here are three types - on glue, on a screw, and on a screw in a metal dowel.

We pull:

Only a normal screw with a wide head, twisted into a DRIVA-dowel, holds tightly.

One of my favorite things is the dowel-clamp .

Great solution. I think that everyone has already guessed what to do with it, but I will nevertheless explain. Drill a hole:

Wrap the cable clamp:

And shove it in the hole!

Everything. The cable is securely fastened. The clamp is much thicker than the tie, and with the right hole it easily carries the weight of even a bundle of power cables.

Hit of all times and peoples, favorite fasteners installers provider. Plastic mounting bracket.

Cheap, sold in all stores. This is where her merits end. I do not know, maybe there is some trick, but for more than 10 years I have not been able to learn how to score it the first time and without swearing. Carnation is small, uncomfortable to keep. It keeps well only in wooden surfaces, which, together with the installers, loving it, fasten it to the GVL, it ensures the separation of the cable in a week. And sometimes they are trying to drive into the plastic baseboards and plaster of concrete walls. Or in the mortar between bricks, yes. In general, it is not necessary to do this, for such installers in hell are burning, above the smoky fire from cable insulation.

Plastic cable earrings (yes, they are called so) and metal cable clips (I have nothing against them, unlike their plastic namesake).

The first ones are good because they are fastened with just one screw, but unlike the dowel-clamps, it can be used several times - unscrew the screw, add-remove cable, and tighten it again. And metal brackets perfectly hold any heavy cable, and have an excellent tensile strength, successfully coping with the attacks of cleaners, legs and hands of visitors and fans to attach their cable to someone else.

Surely, like last time I forgot about some obvious ways, but they will certainly be remembered in the comments.

And if you do not want to skip the discussion, check the box

.

.And if you do not want to miss another useful article, then you can subscribe to my profile (button "subscribe")

Source: https://habr.com/ru/post/161067/

All Articles