Energy center with trigeneration: just what is needed in the Russian reality

Electricity in Russia is such a thing that can suddenly turn off, which can rise in price or become worse in quality. If you have a data center, hospital, shopping center or other important object, it is logical to attend to your power source: starting with a certain amount of energy consumed, it’s beneficial not to be powered by the city, but to build your own energy center.

Photos of the power center in Naberezhnye Chelny

Considering that for all these facilities (especially for the data center) not only electricity but also heat and cold will be needed, large customers rely on their energy centers - and we design, build and deploy them, and use a very interesting scheme trigeneration, which allows to get immediately heat, cold and electricity without unnecessary transformations.

')

Under the cut - photos of the power center, a short story about its device and trigeneration in general.

Electricity costs money. In many cases, it is cheaper to build an energy center than to build infrastructure and regularly pay the city for food. The question “how much electricity, heat, water and cold will cost after the facility is commissioned” is no longer a minor issue today.

Often, even the choice of site occurs not only on the basis of a convenient location for future customers, but also in terms of the possibility and cost of providing the necessary energy resources. It is difficult to plan something when the planned tariffs for electricity after commissioning of the object increase 1.5-2 times with the wording “the newly introduced object was not included in the balance of the generating supplier”.

One of the ways out in this situation may be the construction of own generating capacities (own energy center) based on gas piston or gas turbine plants with heat recovery using absorption chillers (ABCM). The trick is that all the “surplus” of heat or cold is not “dumped” somewhere in the process of generating electricity, and are used for the relevant consumers of the facility.

The principle is as follows: when operating a gas piston or gas turbine plant, we can get from 1 to 2 kW of heat energy as hot water from 1 kW of generated electricity. In the filled and working data centers, the electrical load is fairly uniform throughout the year, and the need for cold is comparable to the active electrical IT-power. From hot water using ABHM we get cold with an average coefficient of 0.75. Thus, depending on the type of power plants, from their heat one can get from 50% to 100% of the necessary cold. The result is an extremely energy efficient system. The lack of heat, as well as the reserve, is ensured by ordinary water-heating boilers, the efficiency of which is close to 99%.

From outside, only low-pressure natural gas is consumed, electricity, heat for heating and cold for conditioning are produced at the outlet. At the same time reliability exceeds standard suppliers, and the cost of resources is much lower. The cost of electricity consumed is up to 2 rubles / kWh and below, which corresponds to external tariffs for voltages of 110 kV and above.

The combined production of electricity, heat and cold can not only achieve a reduction in energy costs by 2 or more times, but also reduce the amount of electricity consumption for ventilation and air conditioning. This is achieved by fully or partially replacing the compressors of the cooling system with ABCM, which practically does not consume electricity. The experience of the projects implemented by us shows that the recoupment of our own energy center with the right technical solution is only 2-3 years, after which the decision begins to bring additional income to the owner.

The energy center is an independent, fully automated engineering structure operating in an autonomous mode, which consists of power plants based on a gas engine and an attached electric generator.

During the construction of a high availability data center, the main source of electricity should be independent of the power system input, traditionally implemented on the basis of diesel generator sets (the “city” at levels above TIER III according to TIA 942 and TIER III according to Uptime cannot be the main one).

The average cost of 1 kWh for diesel fuel varies from 7-10 rubles. For these reasons, the “main” input remains so only on paper, and the electricity in normal mode is obtained according to classical schemes from the power grid, that is, from an additional source according to the standard. A small data center with a total capacity of 1 to 2 MW will be connected to the power grid at a voltage of 6 or 10 kV, and will buy electricity at the appropriate tariff group (from 3 to 4 rubles / kWh). With this approach, the cold in the data center cooling system is produced by vapor compression chillers (PCCM), which consume networked electricity.

The cooling capacity of the PCHM cycle is related to power consumption through the ε - coefficient of performance.

For central Russia, ε is approximately 3.0. This means that to generate 1.0 kW of cold, an electrical output of 0.33 kW is required.

At the same time, it is more than realistic to install your own gas energy center (where there is a trigeneration system). As a result, the required amount of cold can be obtained using ABCM without using traditional (and expensive) compressors. Experience in designing and backing up systems has been accumulated sufficiently large, so even for TIER III and TIER IV there is no fundamental problem in the construction and certification of such an object.

One of the examples is the energy center of the ESSEN shopping center in Naberezhnye Chelny, built by KROK in 2007. The project paid for itself in just over 2 years, even with an incomplete load. Currently we have several more such projects in our work.

Here is his card:

And here are his photos:

Type of cogeneration gas piston installation (KSU) inside, expansion tanks:

Container with backup diesel generator

Gas distribution point (PIU) of the energy center:

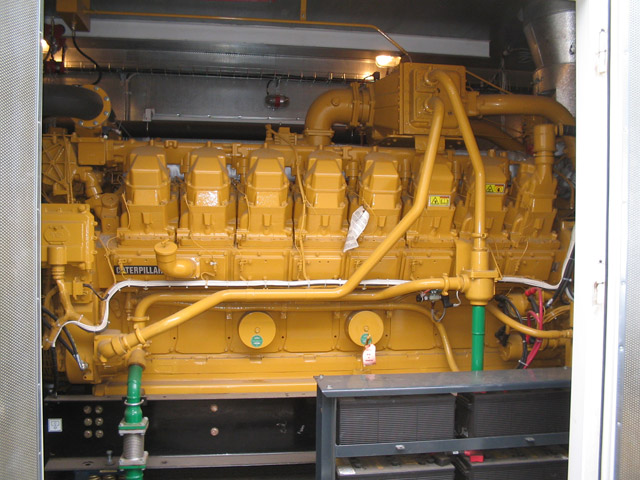

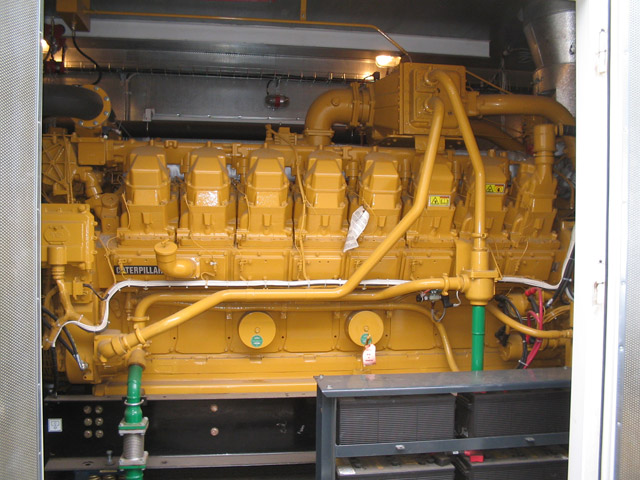

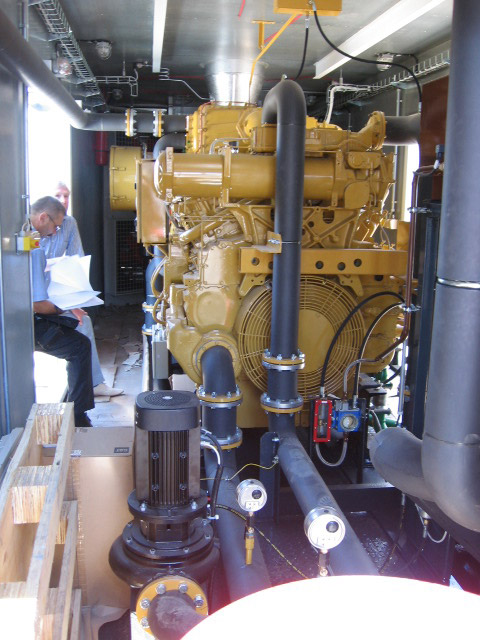

Gas engine piston (GPU) CATERPILLAR:

Absorption chiller (ABHM) inside:

Heat exchangers of a boiler station heat point:

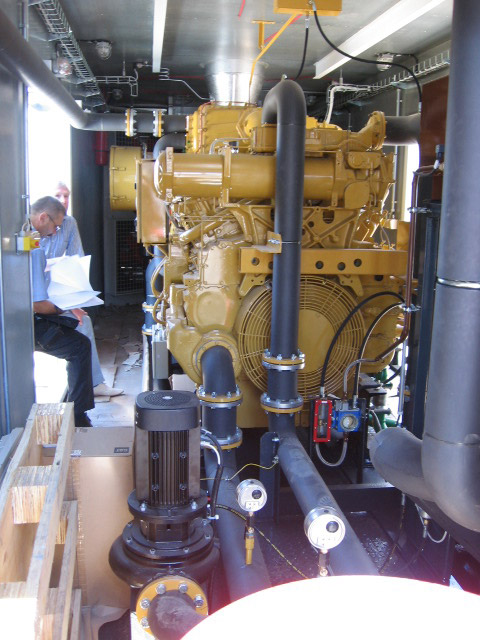

GPU inside - adjustment:

Exhaust gas utilizer:

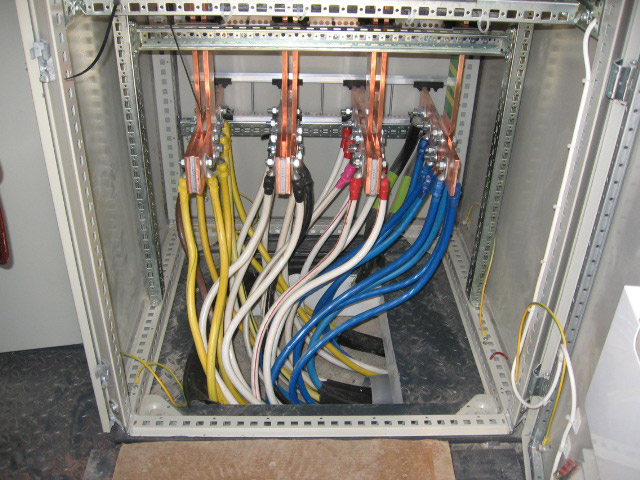

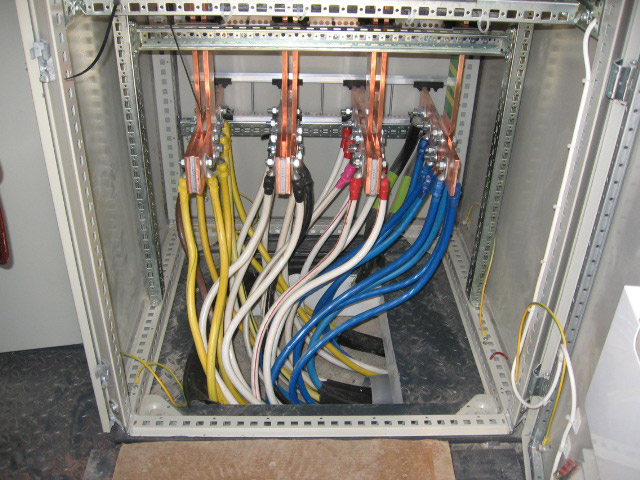

Connection to the tires of the power shield of the GPU:

Cogeneration gas piston units (KSU):

Dry cooler (draykuler) KSU:

He is:

KSU - chimneys, draykuler, exhaust gas utilizer:

UPD. A lot of questions on payback and the economic part. In general, it all depends on the specific project. General approaches are as follows (the numbers in the calculations are approximate, may differ in different situations and regions):

Detailed calculation on a specific situation is ready to be provided on request by e-mail DMarkin@croc.ru.

Photos of the power center in Naberezhnye Chelny

Considering that for all these facilities (especially for the data center) not only electricity but also heat and cold will be needed, large customers rely on their energy centers - and we design, build and deploy them, and use a very interesting scheme trigeneration, which allows to get immediately heat, cold and electricity without unnecessary transformations.

')

Under the cut - photos of the power center, a short story about its device and trigeneration in general.

Why do we need power centers?

Electricity costs money. In many cases, it is cheaper to build an energy center than to build infrastructure and regularly pay the city for food. The question “how much electricity, heat, water and cold will cost after the facility is commissioned” is no longer a minor issue today.

Often, even the choice of site occurs not only on the basis of a convenient location for future customers, but also in terms of the possibility and cost of providing the necessary energy resources. It is difficult to plan something when the planned tariffs for electricity after commissioning of the object increase 1.5-2 times with the wording “the newly introduced object was not included in the balance of the generating supplier”.

Decision

One of the ways out in this situation may be the construction of own generating capacities (own energy center) based on gas piston or gas turbine plants with heat recovery using absorption chillers (ABCM). The trick is that all the “surplus” of heat or cold is not “dumped” somewhere in the process of generating electricity, and are used for the relevant consumers of the facility.

The principle is as follows: when operating a gas piston or gas turbine plant, we can get from 1 to 2 kW of heat energy as hot water from 1 kW of generated electricity. In the filled and working data centers, the electrical load is fairly uniform throughout the year, and the need for cold is comparable to the active electrical IT-power. From hot water using ABHM we get cold with an average coefficient of 0.75. Thus, depending on the type of power plants, from their heat one can get from 50% to 100% of the necessary cold. The result is an extremely energy efficient system. The lack of heat, as well as the reserve, is ensured by ordinary water-heating boilers, the efficiency of which is close to 99%.

From outside, only low-pressure natural gas is consumed, electricity, heat for heating and cold for conditioning are produced at the outlet. At the same time reliability exceeds standard suppliers, and the cost of resources is much lower. The cost of electricity consumed is up to 2 rubles / kWh and below, which corresponds to external tariffs for voltages of 110 kV and above.

The combined production of electricity, heat and cold can not only achieve a reduction in energy costs by 2 or more times, but also reduce the amount of electricity consumption for ventilation and air conditioning. This is achieved by fully or partially replacing the compressors of the cooling system with ABCM, which practically does not consume electricity. The experience of the projects implemented by us shows that the recoupment of our own energy center with the right technical solution is only 2-3 years, after which the decision begins to bring additional income to the owner.

The energy center is an independent, fully automated engineering structure operating in an autonomous mode, which consists of power plants based on a gas engine and an attached electric generator.

What are the benefits?

During the construction of a high availability data center, the main source of electricity should be independent of the power system input, traditionally implemented on the basis of diesel generator sets (the “city” at levels above TIER III according to TIA 942 and TIER III according to Uptime cannot be the main one).

The average cost of 1 kWh for diesel fuel varies from 7-10 rubles. For these reasons, the “main” input remains so only on paper, and the electricity in normal mode is obtained according to classical schemes from the power grid, that is, from an additional source according to the standard. A small data center with a total capacity of 1 to 2 MW will be connected to the power grid at a voltage of 6 or 10 kV, and will buy electricity at the appropriate tariff group (from 3 to 4 rubles / kWh). With this approach, the cold in the data center cooling system is produced by vapor compression chillers (PCCM), which consume networked electricity.

The cooling capacity of the PCHM cycle is related to power consumption through the ε - coefficient of performance.

ε = Q/PFor central Russia, ε is approximately 3.0. This means that to generate 1.0 kW of cold, an electrical output of 0.33 kW is required.

At the same time, it is more than realistic to install your own gas energy center (where there is a trigeneration system). As a result, the required amount of cold can be obtained using ABCM without using traditional (and expensive) compressors. Experience in designing and backing up systems has been accumulated sufficiently large, so even for TIER III and TIER IV there is no fundamental problem in the construction and certification of such an object.

Specific example

One of the examples is the energy center of the ESSEN shopping center in Naberezhnye Chelny, built by KROK in 2007. The project paid for itself in just over 2 years, even with an incomplete load. Currently we have several more such projects in our work.

Here is his card:

- Type of construction - new construction

- Location of the construction site - Naberezhnye Chelny, Republic of Tatarstan

- Staged construction - turn 1

- Purpose - electricity, heat and cooling of its own shopping and entertainment center.

- The reason is the lack of technical ability to connect to electrical networks.

- Rated capacity - electric power 2 MW - actual consumption 70%, thermal energy 4 Gcal - actual power consumption 3.7 Gcal, cold consumption - 1.2 MW, actual consumption 1 MW

- Execution of CHP - container

- Equipment - KSU - Caterpillar (USA), boilers - Buderus (Germany), ABKHM - Carrier (China)

And here are his photos:

Type of cogeneration gas piston installation (KSU) inside, expansion tanks:

Container with backup diesel generator

Gas distribution point (PIU) of the energy center:

Gas engine piston (GPU) CATERPILLAR:

Absorption chiller (ABHM) inside:

Heat exchangers of a boiler station heat point:

GPU inside - adjustment:

Exhaust gas utilizer:

Connection to the tires of the power shield of the GPU:

Cogeneration gas piston units (KSU):

Dry cooler (draykuler) KSU:

He is:

KSU - chimneys, draykuler, exhaust gas utilizer:

Summary

- The construction of our own energy center using the turnkey trigeneration technology will cost approximately 2,000 euros / kWe. This is quite comparable with the price of connecting to external networks.

- Own power center for the data center does not lead to an increase in investment, but significantly reduces the energy consumption of the data center and its OPEX as a whole.

- Reliability and efficiency of the data center increases.

- The choice of site can be approached more freely: the non-volatility of the object from the local infrastructure is achieved, which can be an important advantage.

- The construction of the power center is carried out in parallel with the construction of the main facility and in terms of time is 1.5-2 years.

- CROC has experience in the construction of such facilities, so if interested, contact DMarkin@croc.ru and discuss specific issues. Ready to answer general questions in the comments.

UPD. A lot of questions on payback and the economic part. In general, it all depends on the specific project. General approaches are as follows (the numbers in the calculations are approximate, may differ in different situations and regions):

- It is important to provide for the fullest and most stable marketing of all resources produced. If the consumption is uneven (day / night, seasonality) - you can “cut out” the energy center only the stable part, and bursts to get out of the network. In the sense that it is not necessary to take the energy center under the peak, it is economically justified with a stable load above, for example, 60%.

- The cost is more than half the cost - the price of fuel. 270 cubic meters for 1 MW * h, for example, let it be 4 rubles per cubic meter and 8,200 hours per year (taking into account regulations and downtime) is about 9 million rubles. Let the service, staff, taxes, oil and so on be the same, although less experience. We get OPEX 18 million rubles or 2.19 rubles \ kW * h. A plug with an external tariff of 4 rubles \ kW * h will be about 15 million rubles for electricity and at least 2 million rubles for heat. At large stations, the effect is even greater.

- The cost of the power center depends on many parameters. Cogeneration of 1 MW (electricity and heat), in a container with one machine, even with connection to networks costs less than 1 million euros "turnkey". More difficult decision, including trigeneration is more expensive. For example, 1.5 million euros / annual savings of 17 million rubles = 3.5 years. The use of cold improves the situation twice. And if you take into account the cost of connecting to electric networks - the project can pay off at the start.

Detailed calculation on a specific situation is ready to be provided on request by e-mail DMarkin@croc.ru.

Source: https://habr.com/ru/post/160325/

All Articles